Fabricated bridge-cutoff keel double-cavity energy-saving wall

A prefabricated and keel technology, applied to walls, passive houses, building components, etc., can solve problems such as unsatisfactory thermal insulation and sound insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

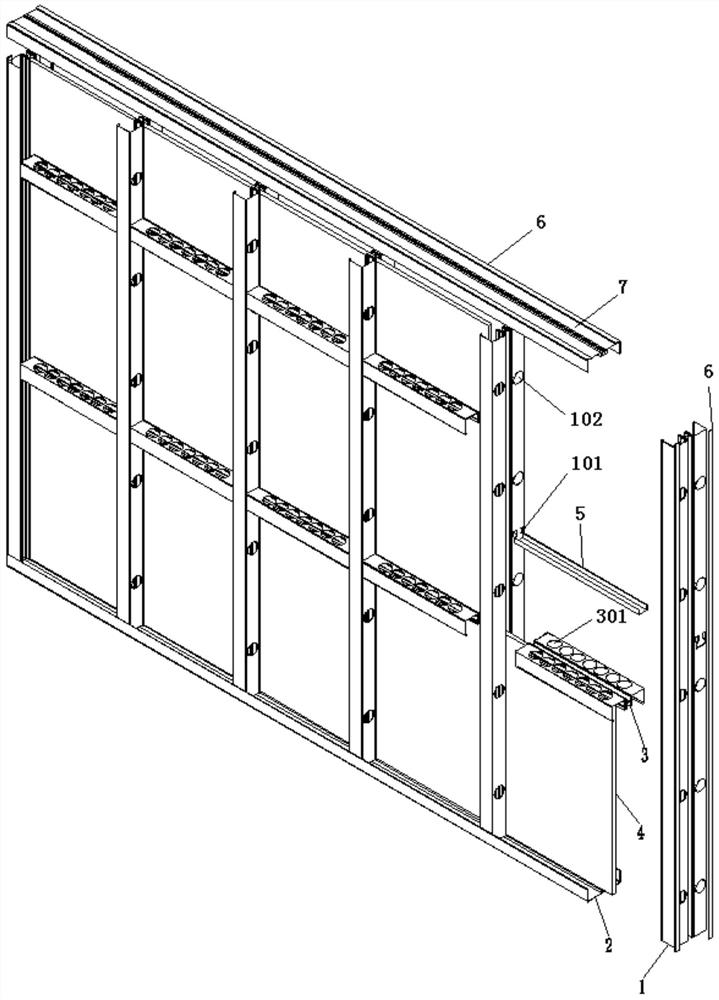

[0038] Such as Figure 4 , Figure 5 As shown, the overall structure installation steps of the technical solution are:

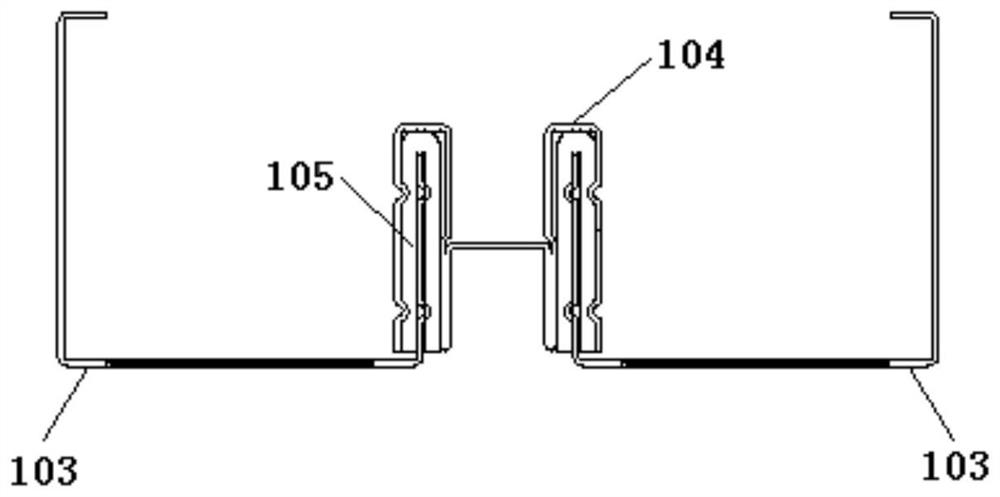

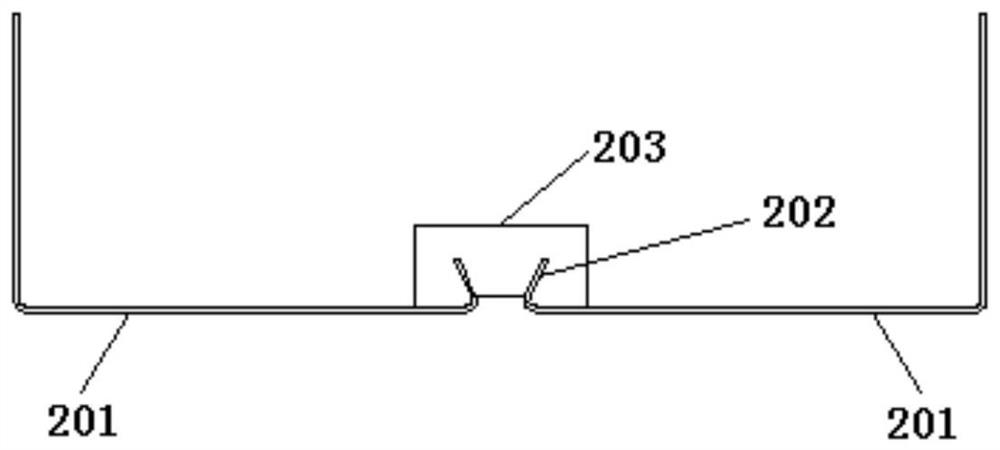

[0039] The vertical keel 1, the lower horizontal keel 2 and the upper horizontal keel 7 are all double-layer keel structures. It is in the shape of a long strip, and the soundproof adhesive strip 6 is pre-pasted to the back of the vertical keel 1, the lower horizontal keel 2 and the upper horizontal keel 7 for later use.

[0040] Step 1: Fix the upper horizontal keel 7 and the lower horizontal keel 2 respectively on the roof and the ground, and the upper horizontal keel 7 and the lower horizontal keel 2 correspond to each other;

[0041] Step 2: Insert the vertical joist 1 into the grooves of the lower horizontal joist 2 and the upper horizontal joist 7 in sequence on one side vertically, the vertical joist 1 is located at one end of the upper horizontal joist 7 and the lower horizontal joist 2, forming a frame structure with one side open;

[0042] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com