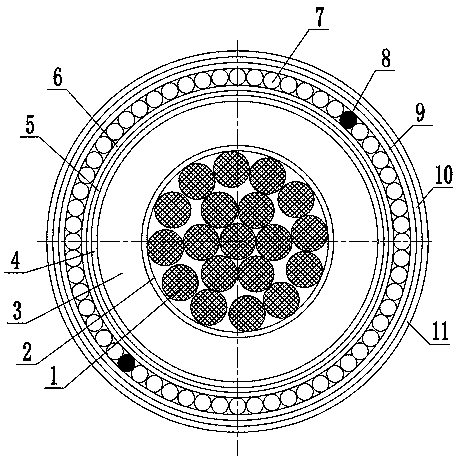

Distributed optical fiber temperature measurement power cable

A distributed optical fiber and power cable technology, which is applied to power cables, power cables including optical transmission elements, and power cables with shielding/conducting layers, etc. , increase the weight and cost of cables, etc., to achieve the effects of automatic measurement and online temperature monitoring, enhanced vibration reduction, and good low-frequency shielding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

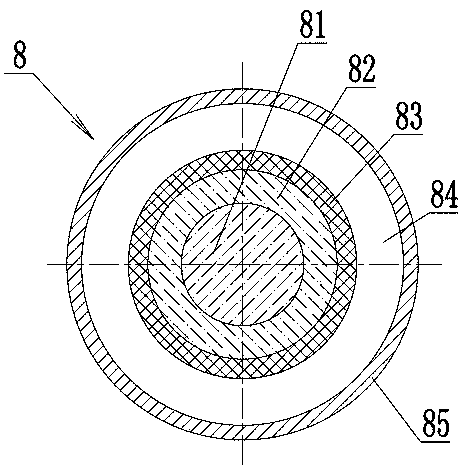

[0024] Example 1: The weight percentage components of the thermal conductive filling paste 84 are: 72% thermal oil, 20% gelling agent, 4% oil separation inhibitor, 1.5% antioxidant, 0.0018% defoamer, and the rest is water absorbent. The heat transfer oil mentioned above is synthetic heat transfer oil, the gelling agent is fumed silica, the antioxidant is alkylphenol antioxidant, the oil separation inhibitor is ethylene propylene rubber or ethylene propylene rubber, the water absorbent is silica gel, and the defoamer is emulsified silicone oil.

Embodiment 2

[0025] Example 2: The weight percentage components of the thermally conductive filling paste 84 are: 72.5% of thermal oil, 18% of gelling agent, 5% of oil separation inhibitor, 2% of antioxidant, 0.002% of defoamer, and the rest are water absorbing agents. The heat-conducting oil is synthetic heat-conducting oil, the gelling agent is fumed silica, the antioxidant is alkylphenol antioxidant, the oil separation inhibitor is diblock polymer, the water-absorbing agent is silica gel, and the defoaming agent is emulsified silicone oil.

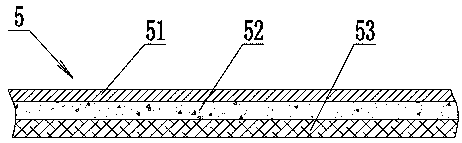

[0026] Such as image 3 As shown, the thermally conductive shielding tape wrapped into the shielding layer 5 adopts a multi-layer composite structure, and its substrate layer adopts a graphite base layer 52, and the graphite base layer 52 adopts a synthetic graphite film with a thickness of 45 μm or a natural stone with a thickness of 100 μm. Ink film, or a mixed film of synthetic graphite and natural graphite. One side of the graphite base layer 52 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com