Vibration attenuation and vibration isolation type gearbox for input shaft and output shaft

A technology of vibration attenuation and gear box, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., and can solve problems such as time-consuming, labor-intensive, poor vibration-reducing and isolation effects, and poor effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

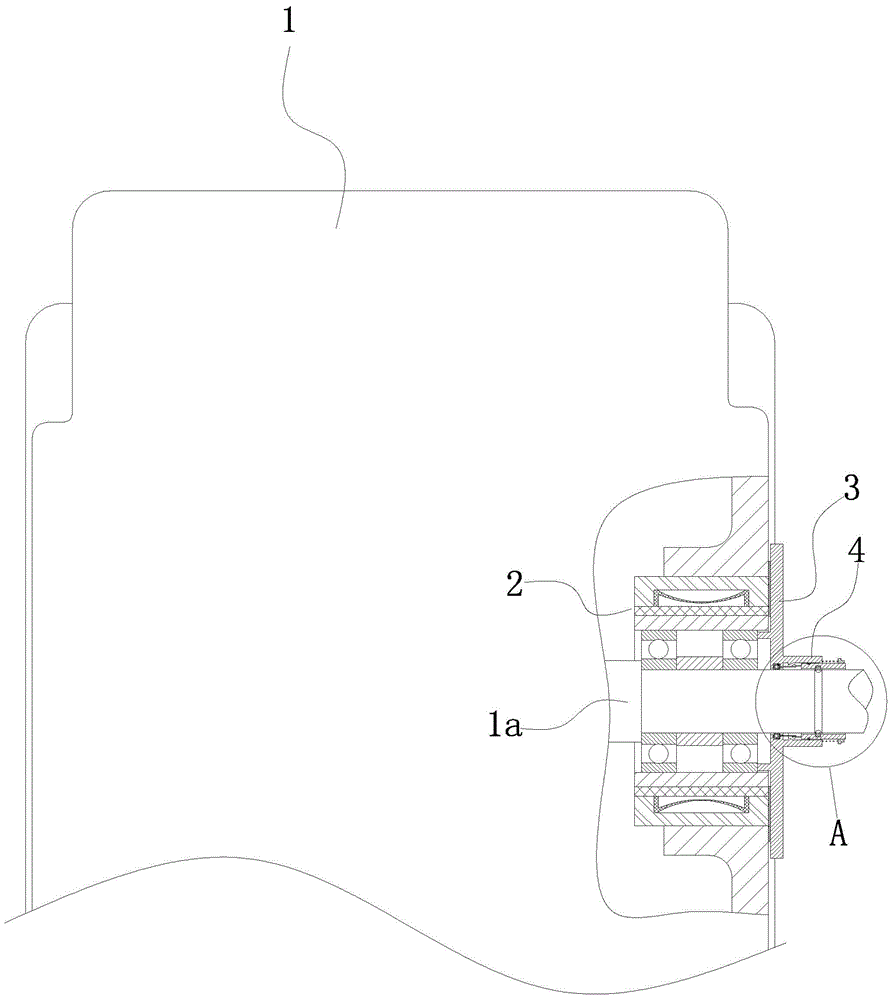

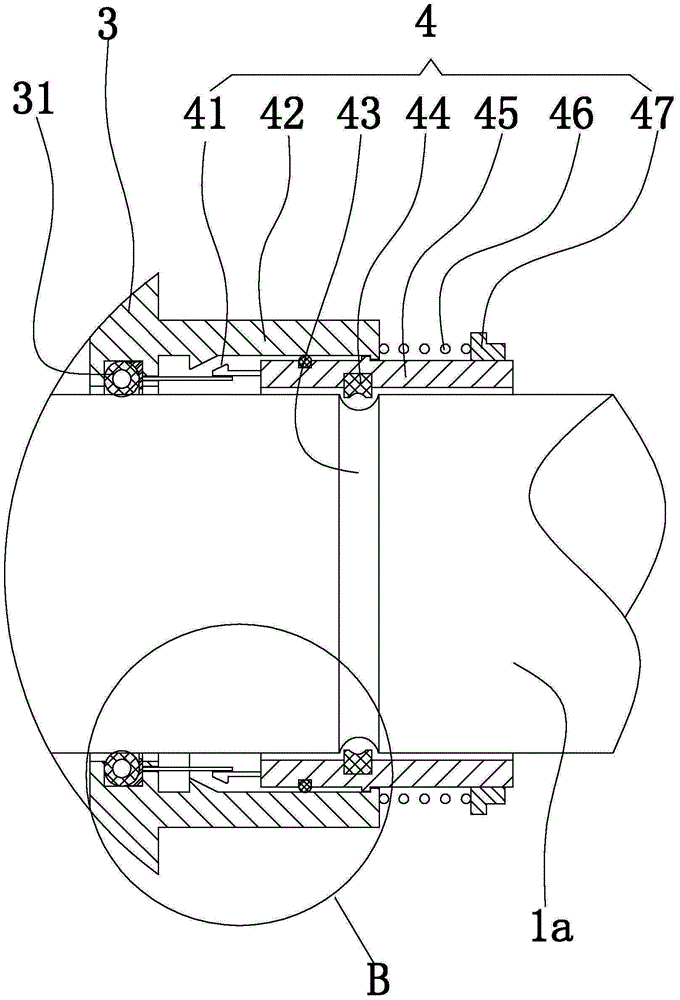

[0053] Embodiment 1: as figure 1 , figure 2 As shown, an input and output shaft vibration attenuation vibration isolation type gearbox includes a gearbox casing 1, an input shaft hole arranged on the gearbox casing, an input shaft 1a, and an input shaft seal end installed on the outer surface of the gearbox casing Cover 3, the output shaft hole arranged on the gear case housing, the output shaft, the output shaft seal end cover installed on the outer surface of the gear case case.

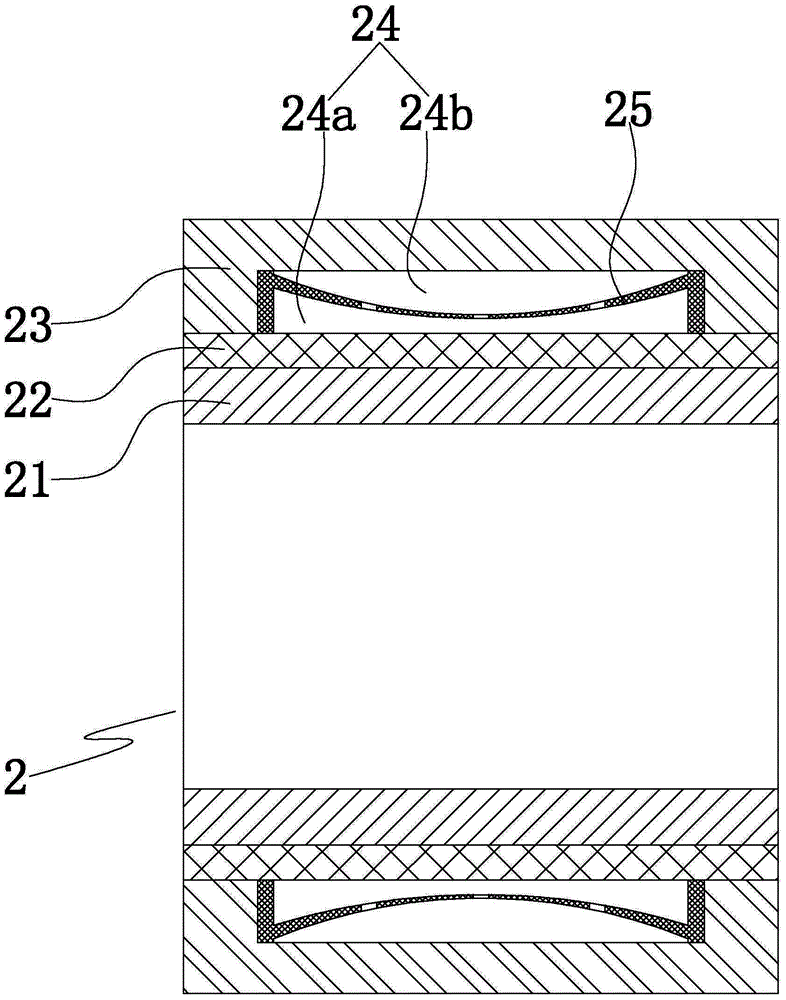

[0054] The input shaft hole and the output shaft hole are respectively provided with vibration-damping sleeves 2 . The vibration-damping sleeve is connected with the gearbox casing by welding. The inner hole of the damping sleeve is a circular hole. The vibration-damping sleeve body includes a support type inner vibration-damping layer 21, a plastic vibration-damping layer 22 and an outer vibration-damping layer 23 from inside to outside. The supporting type inner damping layer and the outer d...

Embodiment 2

[0064] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0065] Such as Image 6 As shown, the bottom of the gearbox housing is also provided with a vibration damping seat 1b. The vibration damping base includes a bottom frame 1b1, a top frame 1b2 for installing the gear box casing, and several hydraulic suspensions arranged on the bottom frame for supporting the top frame. The gearbox casing is connected with the top frame through bolts, and the gearbox casing is located above the top frame.

[0066] Such as Figure 7 As shown, the hydraulic mounts in this embodiment include a left front hydraulic mount 5a, a right front hydraulic mount 5b, a left rear hydraulic mount and a right rear hydraulic mount. The left front, right front, left rear and right rear four hydraulic suspensions are located between the bottom frame and the top frame. The base frame is square. The left front, right front, left rear and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com