Optimization method for mixture ratio of components of working layer of metal plastic composite material

A technology of composite materials and optimization methods, applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve problems such as low efficiency and inaccuracy, achieve vibration reduction and firmness improvement, improve efficiency, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

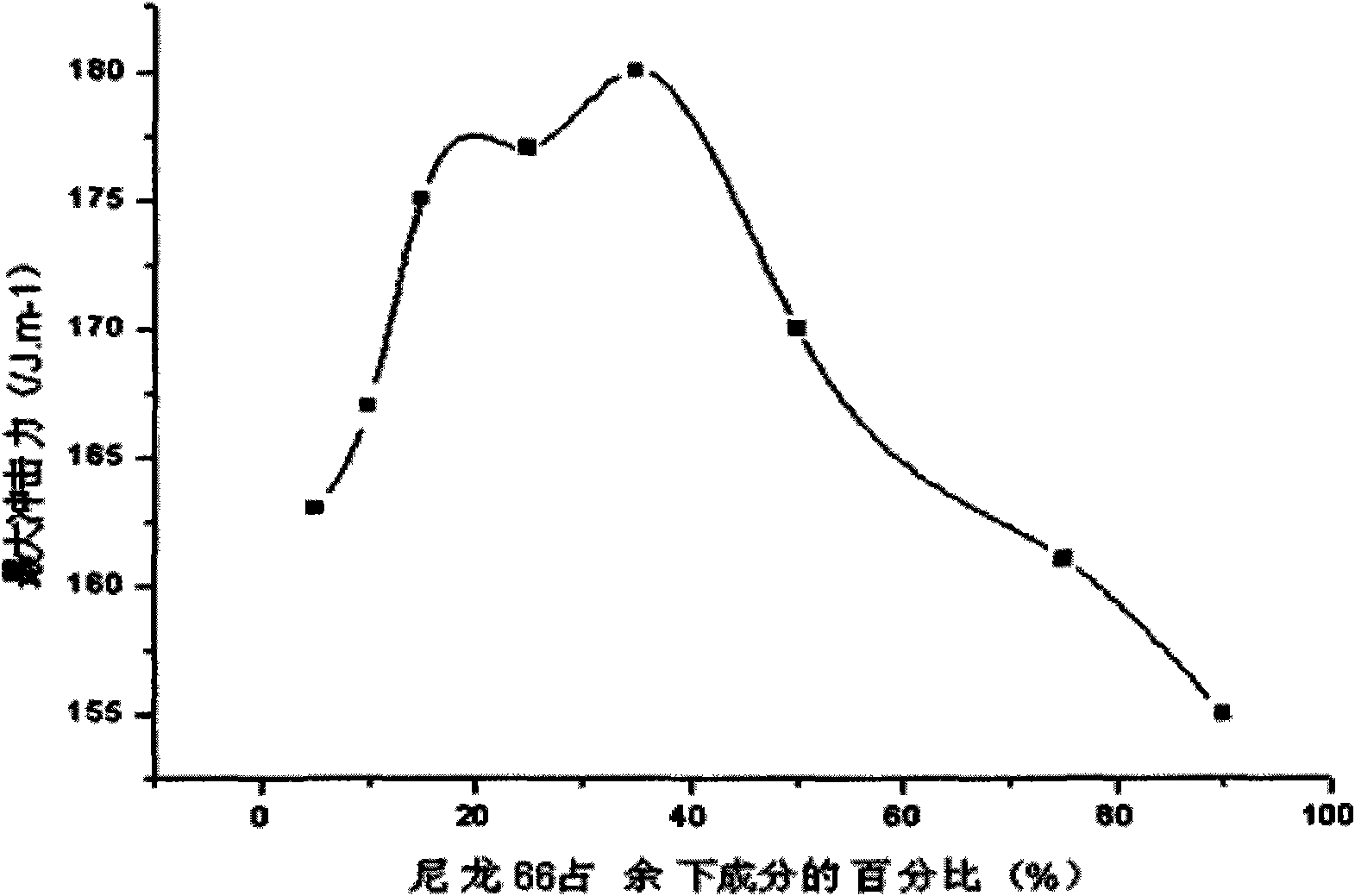

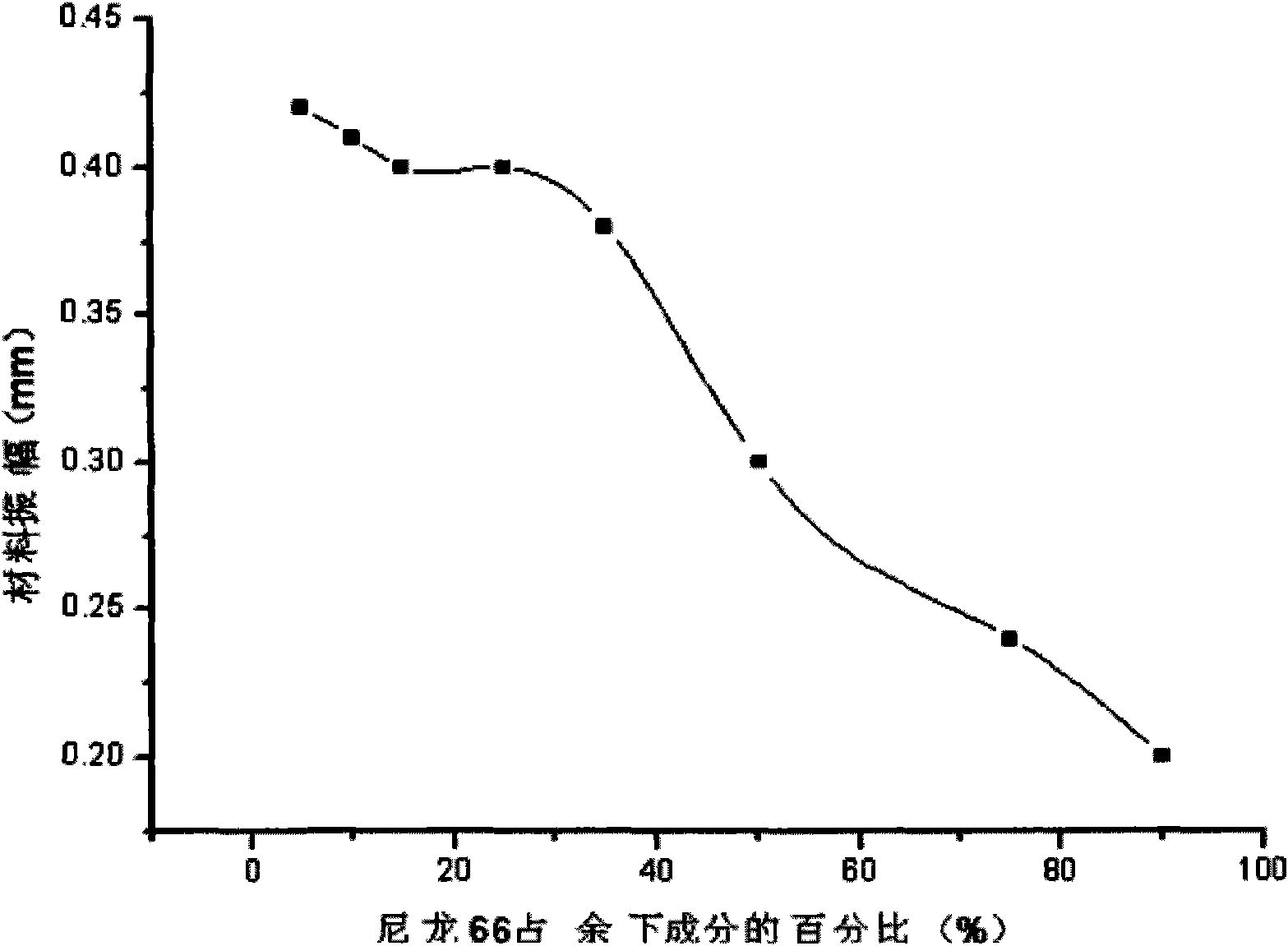

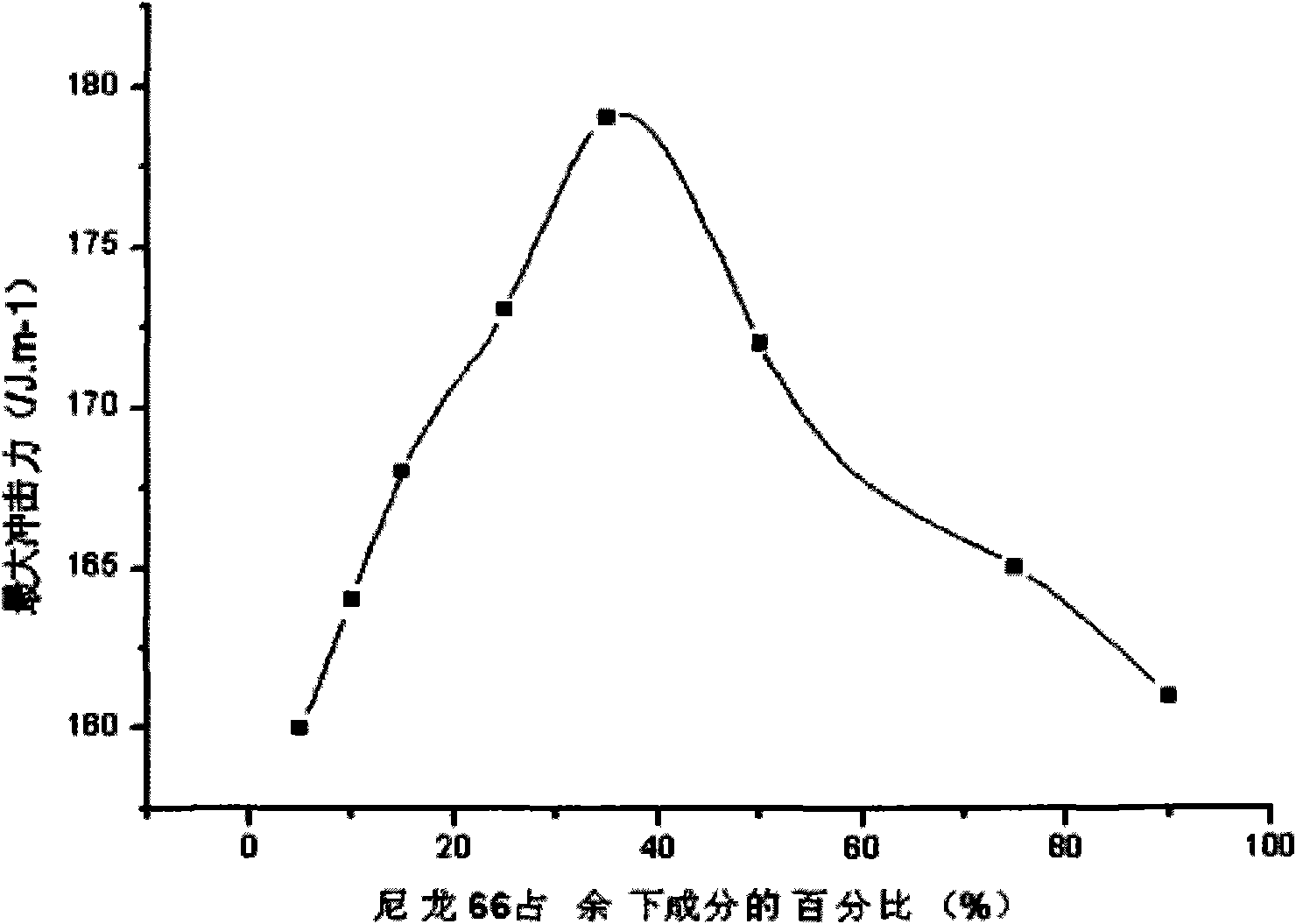

[0019] The metal-plastic composite material working layer is composed of three substances: polyphenylene sulfide, nylon 66 and carbon fiber. Under the condition that the shape and thickness of the metal matrix, intermediate layer and working layer are kept unchanged, the ratio parameters of the working layer of polyphenylene sulfide, nylon 66 and carbon fiber and their relationship are obtained through several sets of orthogonal tests. Corresponding to the material performance parameters of vibration damping and firmness of the composite material, the orthogonal test of the composition ratio of the working layer is arranged according to the principle of high efficiency. The present invention takes the relationship value of composite material firmness and vibration damping property as an example, does a small amount of tests, and draws the composition ratio of several groups of working layers and the relationship value corresponding to the composite material firmness and vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com