Torque extraction device

A technology of housing and input shaft, which is applied in the field of power take-off devices, can solve the problems that hydraulic automatic transmissions cannot realize power interruption, etc., and achieve the effects of high-efficiency coaxial gearless transmission, small transmission device size, and high transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

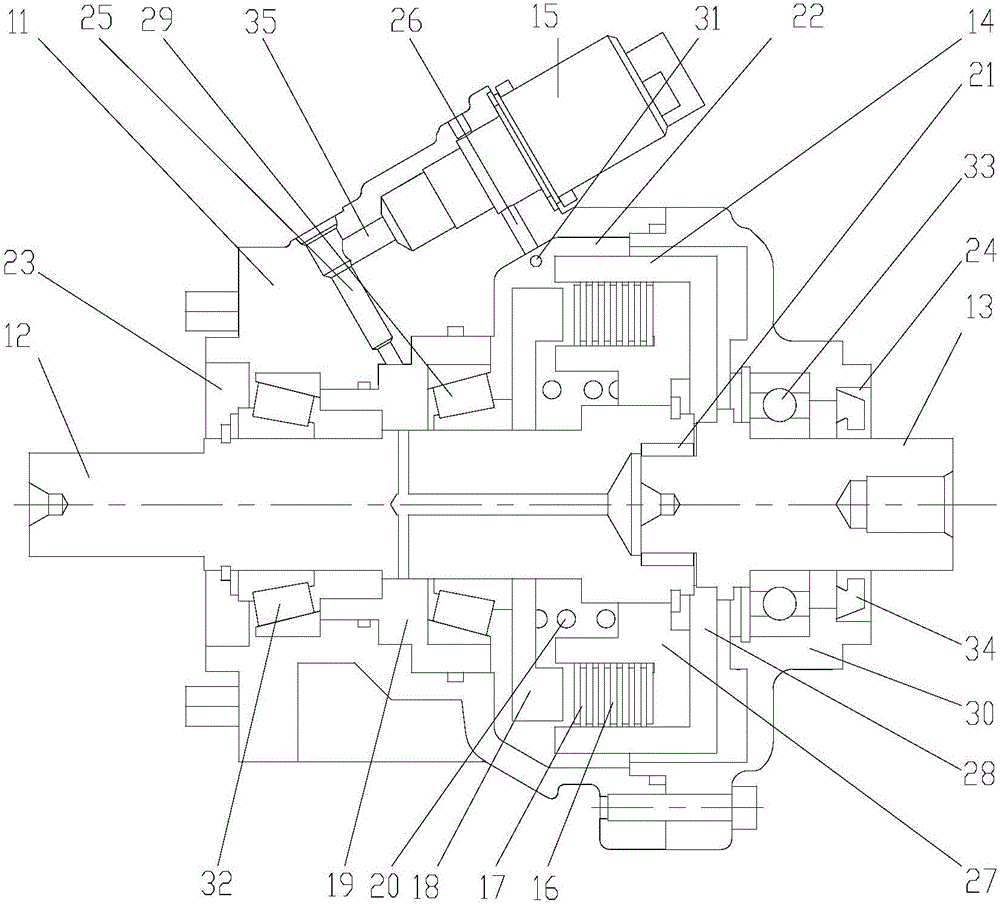

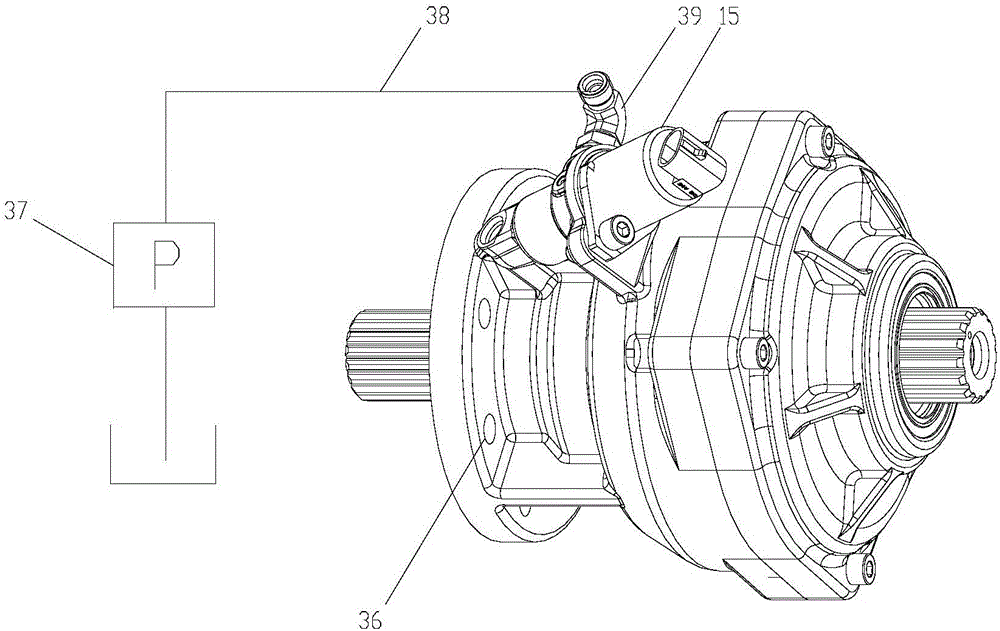

[0026] like figure 1 and 2 As shown, the present invention discloses a power take-off device, which includes a housing 11 , an input shaft 12 , an output shaft 13 , a clutch 14 , a solenoid valve 15 and a bearing cover 30 . The oil pump 37 provides a source of hydraulic oil, and the generated high-pressure oil provides control pressure for the combination and separation of the power take-off device, and at the same time provides oil for lubrication and cooling for the power take-off device. The oil pump 37 is generally installed on the transmission and driven by a power source such as an engine.

[0027] The housing has an inner surface and an outer surface. The inner surface forms a cavity 22, and a first opening 23 and a third opening 35 are formed between the inner and outer surfaces. The first opening 23 and the cavity 22 provide parts to be placed in the housing. Three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com