Sealing device and application of sealing device for achieving thermal deformation compensation

A sealing device and sealing structure technology, which is applied in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve problems such as sealing and damage, and achieve the effects of reducing stress generation, reducing processing difficulty and cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

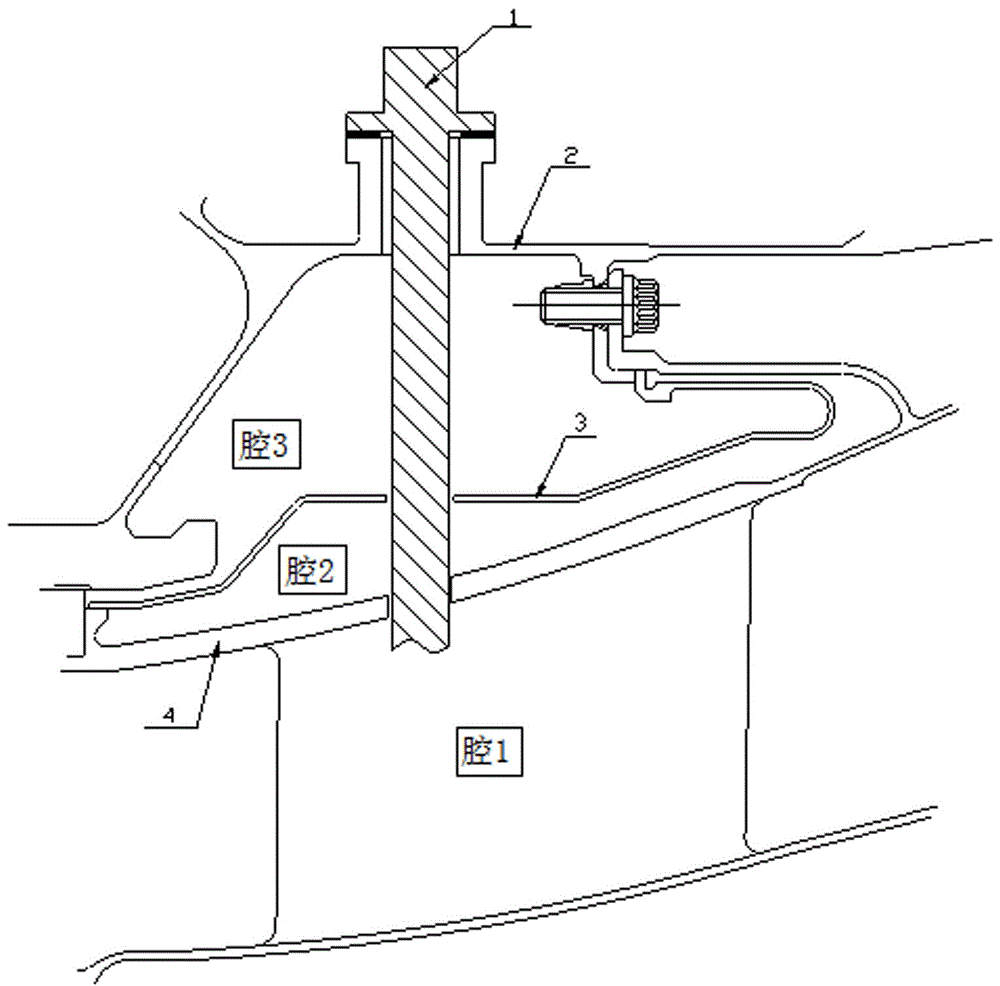

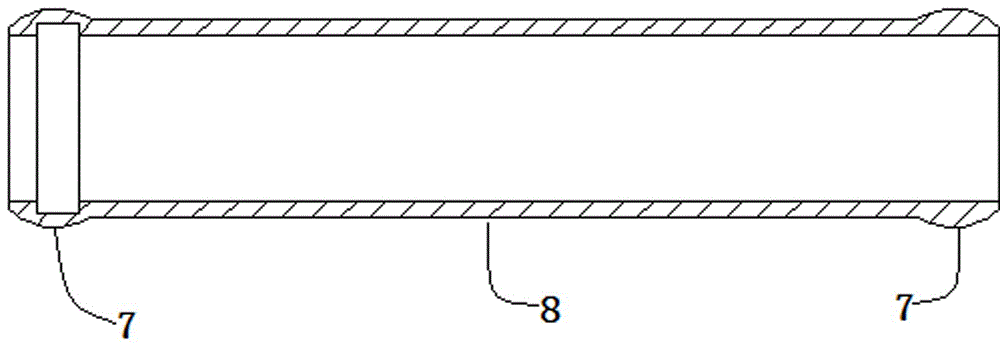

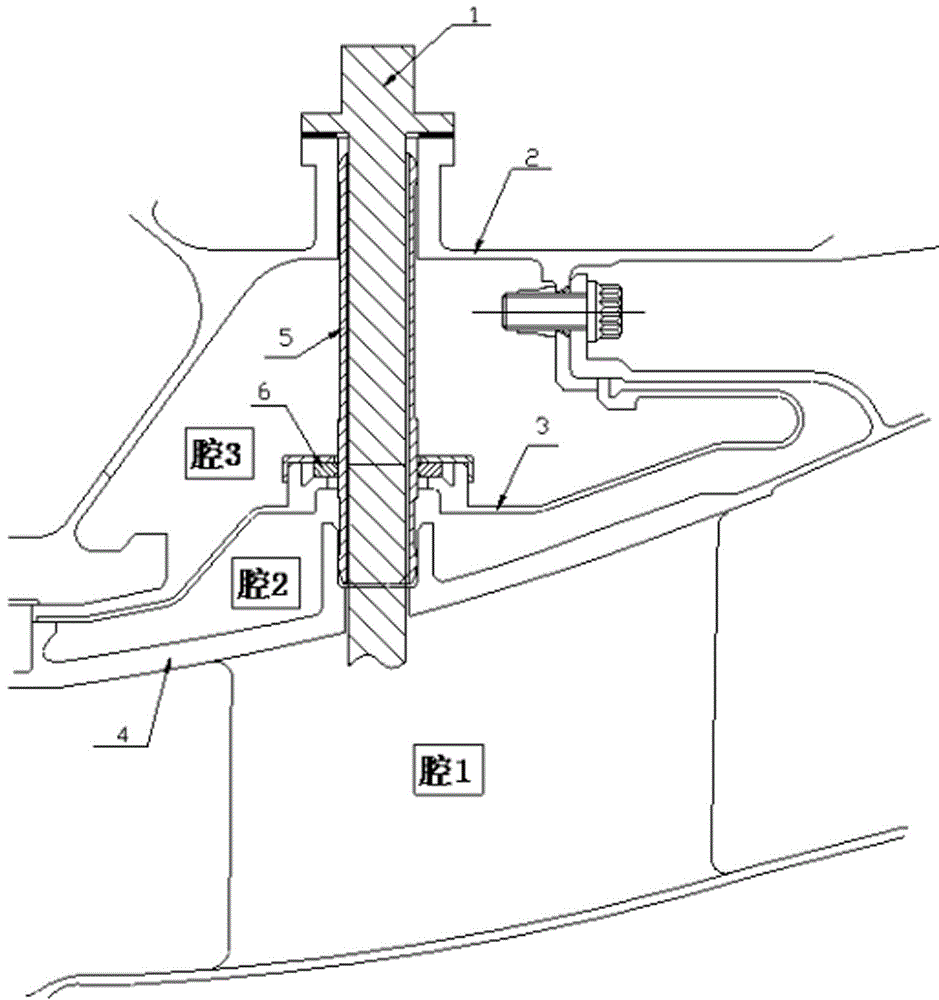

[0031] Such as figure 2 with 3 As shown, the present embodiment provides that the sealing device includes a casing structure and a sealing structure adapted to the casing structure on the casing, the casing structure is installed in the mounting hole of the multi-layer casing, and the casing structure It includes a hollow casing 5 through which the oil pipe or probe 1 passes; both ends of the casing 5 are spherical surfaces 7 , and a cylindrical fitting surface 8 is formed between the two spherical surfaces. The casing is a multi-layer casing, including an inner casing 2, an intermediate casing 3 and an outer casing 4; the outer casing 2, the middle casing 3 and the inner casing 4 are all provided with mounting holes, A cavity 3 is formed between the outer casing 2 and the middle casing 3 , a cavity 2 is formed between the middle casing 3 and the inner casing 4 , and the casing 5 penetrates through the mounting hole of the outer casing 2 and runs through the cavity 3 , pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com