Dust recovery device

A technology of dust recovery and tower body, which is applied in the directions of separation device, use of liquid separation agent, cleaning method and utensils, etc., can solve the problems of low cleaning efficiency and difficult cleaning of dust, and achieves improved effect, simple and practical operation, and increased number of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

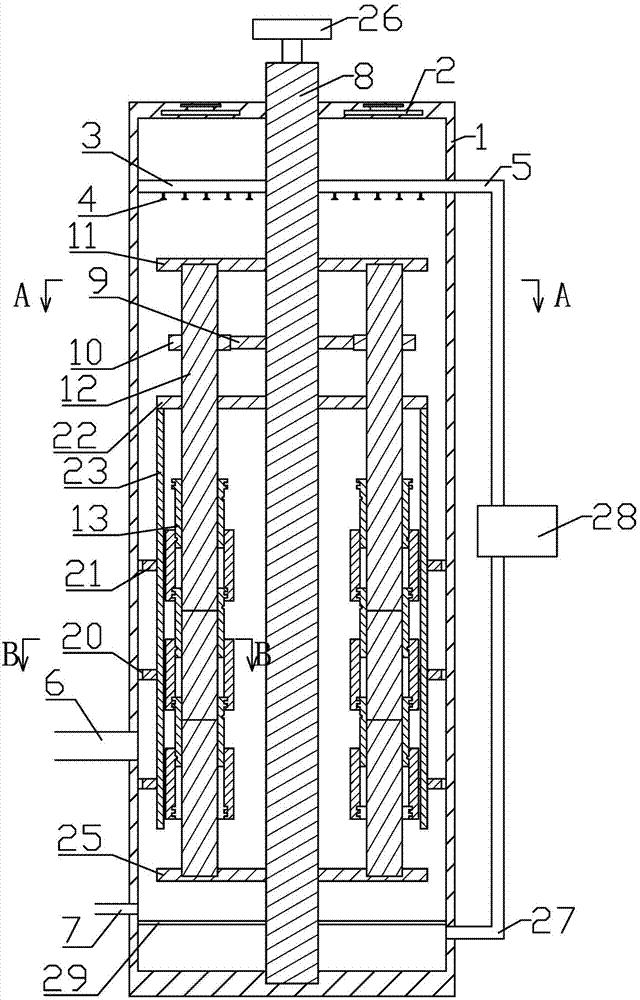

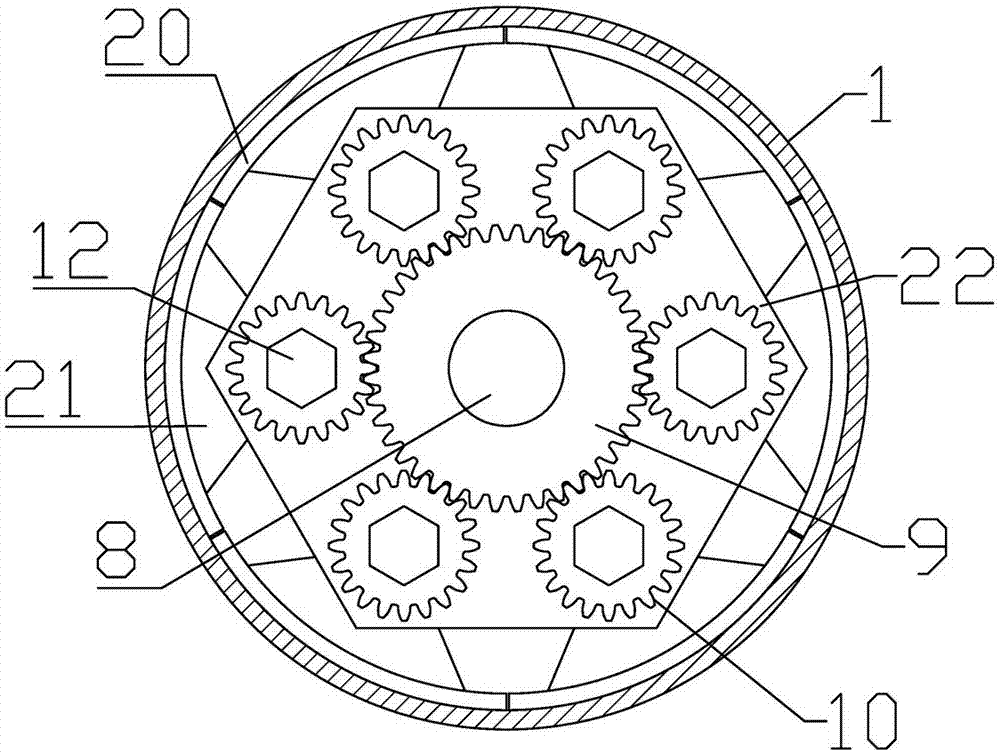

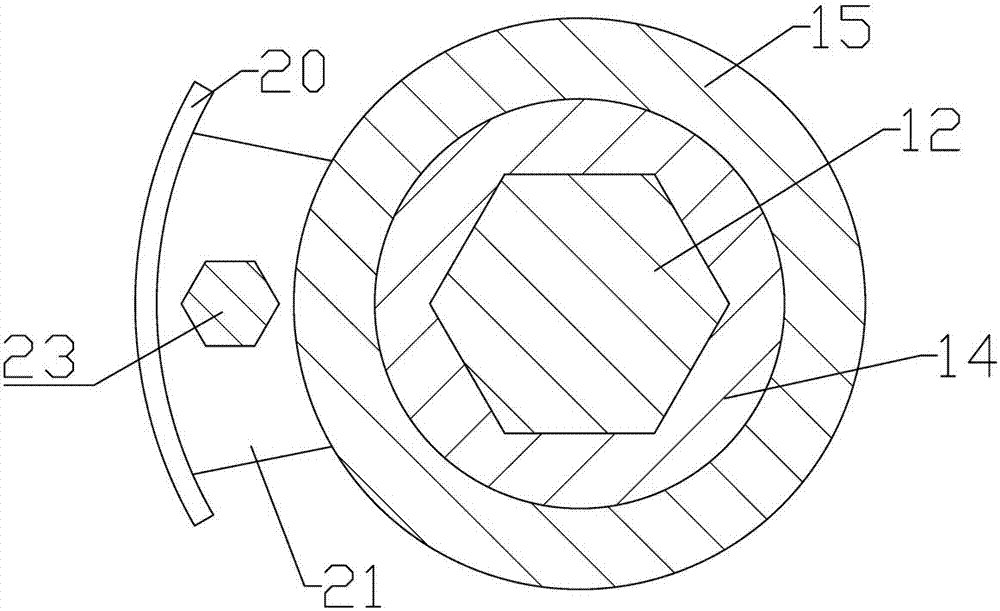

[0017] The following is attached Figure 1-7 The specific implementation manner of the present invention will be described in further detail.

[0018] Depend on Figure 1-7 Given, the present invention comprises tower body 1, and tower body 1 top is provided with suction blower 2, and the bottom of suction blower 2 is provided with water spray plate 3, and water spray plate 3 lower end is connected with a plurality of water spray nozzles 4, and water spray nozzle 4 Water is supplied through the water inlet pipe 5 at the right end of the tower body 1, and the left side of the tower body 1 involves an air inlet 6, and a dust discharge outlet 7 is provided below the air inlet 6, and a rotating shaft 8 is arranged inside the tower body 1, and the rotating shaft 8 is equipped with There is a sun gear 9, and a plurality of planetary gears 10 are meshed on the outer side of the sun gear 9. A first planetary carrier 11 is arranged above the planetary gears 10. The first planetary car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com