Indirectly driven food processor

A food processing machine, an indirect technology, applied in the field of food processing, can solve the problems of shaft hole and cutter shaft wear, unfavorable container cleaning, high parts processing requirements, etc., achieve vibration and noise mitigation, improve magnetic transmission efficiency, and low processing accuracy requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

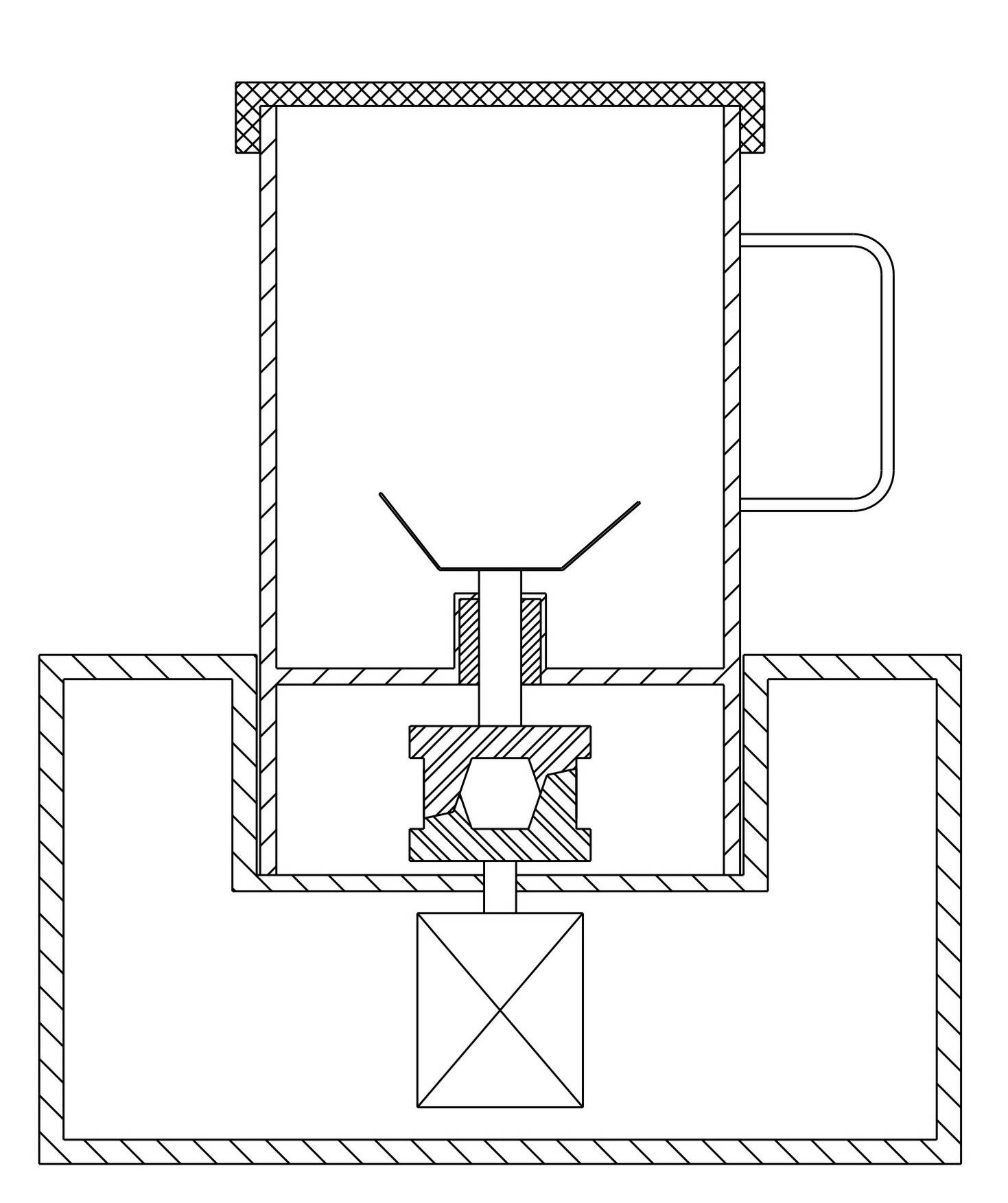

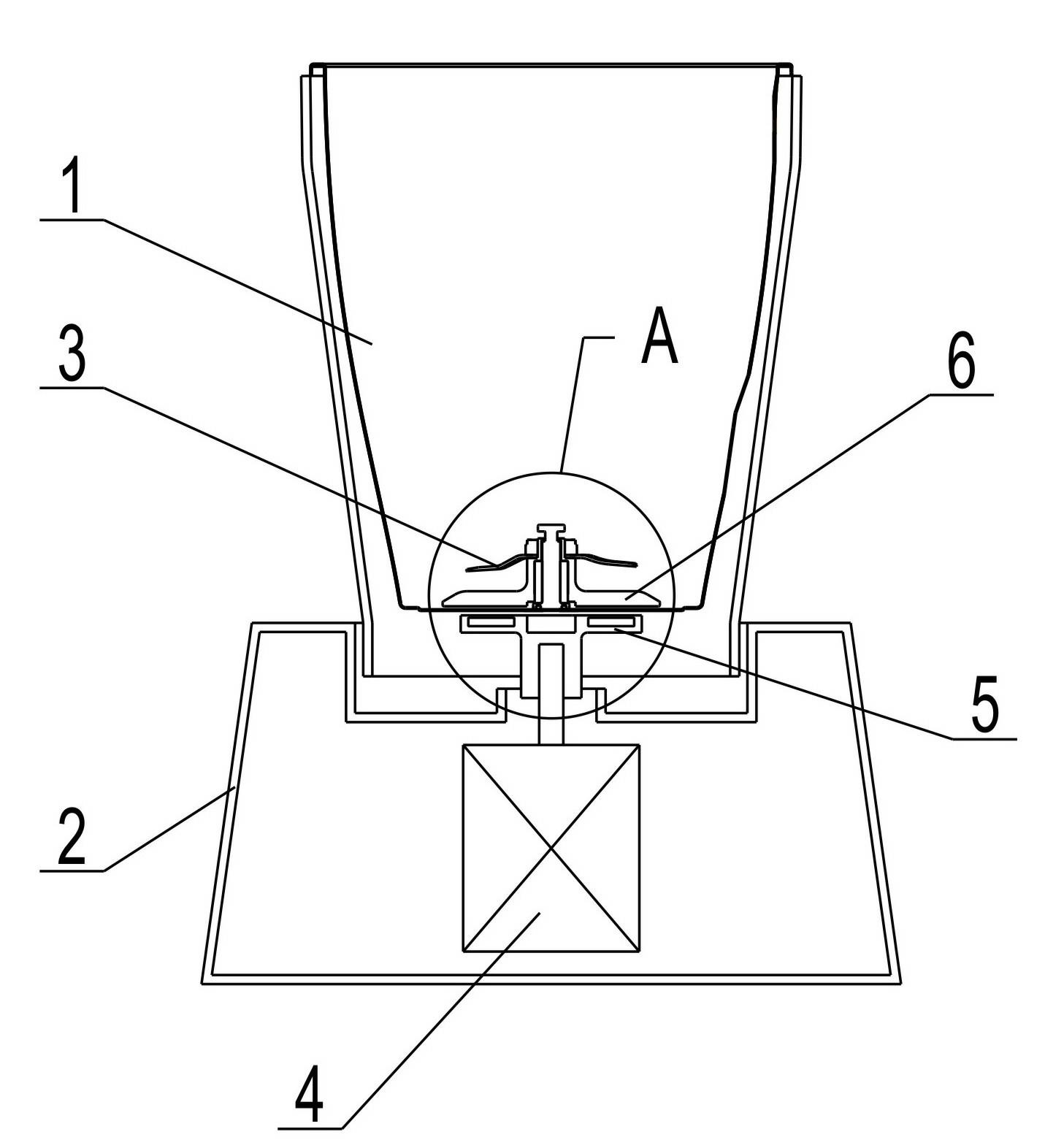

[0048] As the first embodiment of the food processing machine of the present invention, as figure 2 As shown, the food processing machine includes a container 1 , a machine base 2 , a crushing tool 3 , a motor 4 , a driving coupling 5 and a driven coupling 6 . The container 1 is arranged on the base 2, the crushing tool 3 is connected with the driven coupling 6, the motor 4 is vertically arranged in the base 2, and the power output of the motor 4 is A shaft protrudes from the upper end surface of the base 2, and the active coupling 5 is connected with the power output shaft of the motor 4.

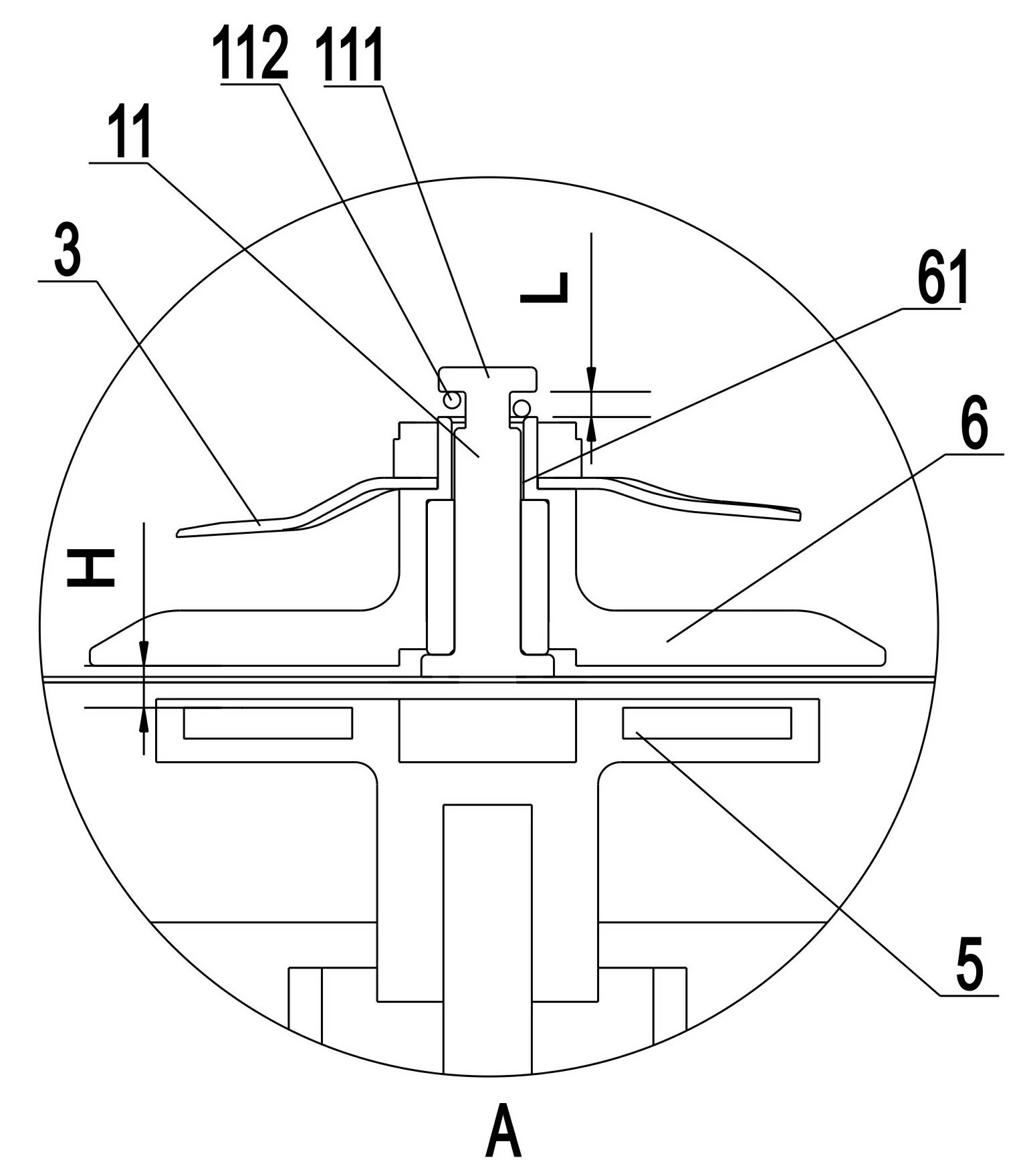

[0049] Such as image 3 As shown, the driven coupling 6 and the crushing tool 3 are integrally arranged in the container 1, the container 1 is provided with a positioning shaft 11, and the driven coupling 6 is provided with a shaft hole 61 , the positioning shaft 11 passes through the shaft hole 61, so that the driven coupling 6 and the crushing tool 3 rotate around the shaft hole 61, a...

Embodiment 2

[0058] As the second embodiment of the food processor of the present invention, as Figure 6 As shown, the difference from the first embodiment is that the container 1 does not include the positioning shaft 11 . The bottom end of the container 1 protrudes inward to form a protrusion 12, and the driven coupling 6 is provided with a recess 64 formed inward, and the protrusion 12 is inserted into the recess 64, so that the driven coupling 6 rotates around said protrusion 12.

[0059] The depression 64 is also provided with a locking groove 641, and the protrusion 12 is also provided with a buckle 121, and the buckle 121 is snapped into the locking groove 641, so that the driven coupling 6 is on the shaft. In addition, the locking groove 641 and the buckle 121 have a floating space, so that the driven coupling 6 is floating in the axial direction. Optionally, the buckle 121 may also be a snap spring. The container 1 is also provided with an elastic member 122, the elastic membe...

Embodiment 4

[0064] As the fourth embodiment of the food processing machine of the present invention, as Figure 8 As shown, the difference from the first embodiment is that the driving coupling 5 and the driven coupling 6 are sleeved together.

[0065] Such as Figure 9 As shown, the bottom end of the container 1 protrudes inward to form a protrusion 12 , and the driven coupling 6 is a metal cylinder and sleeved on the protrusion 12 .

[0066] The active coupling 5 includes a permanent magnet 51 and a cylindrical housing 53, the permanent magnet 51 is embedded in the cylindrical housing 53, the number of the permanent magnets 51 is four, and the plurality of permanent magnets 51 have north and south poles Arranged in sequence with the south magnetic pole, so that the active coupling 5 has a radial magnetic field. Preferably, the active coupling 5 is in a bottomless cylindrical shape, and optionally, the active coupling 5 is in a bottomed cylindrical shape.

[0067] The working gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com