Isolating valve sealed by structural ceramic valve clack and metal elastic valve seat

A technology of elastic valve seat and ceramic valve, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems of affecting the sealing effect and service life, adhesive wear of sealing surface, large fluid resistance, etc., and achieves small operating torque and super Strong corrosion resistance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

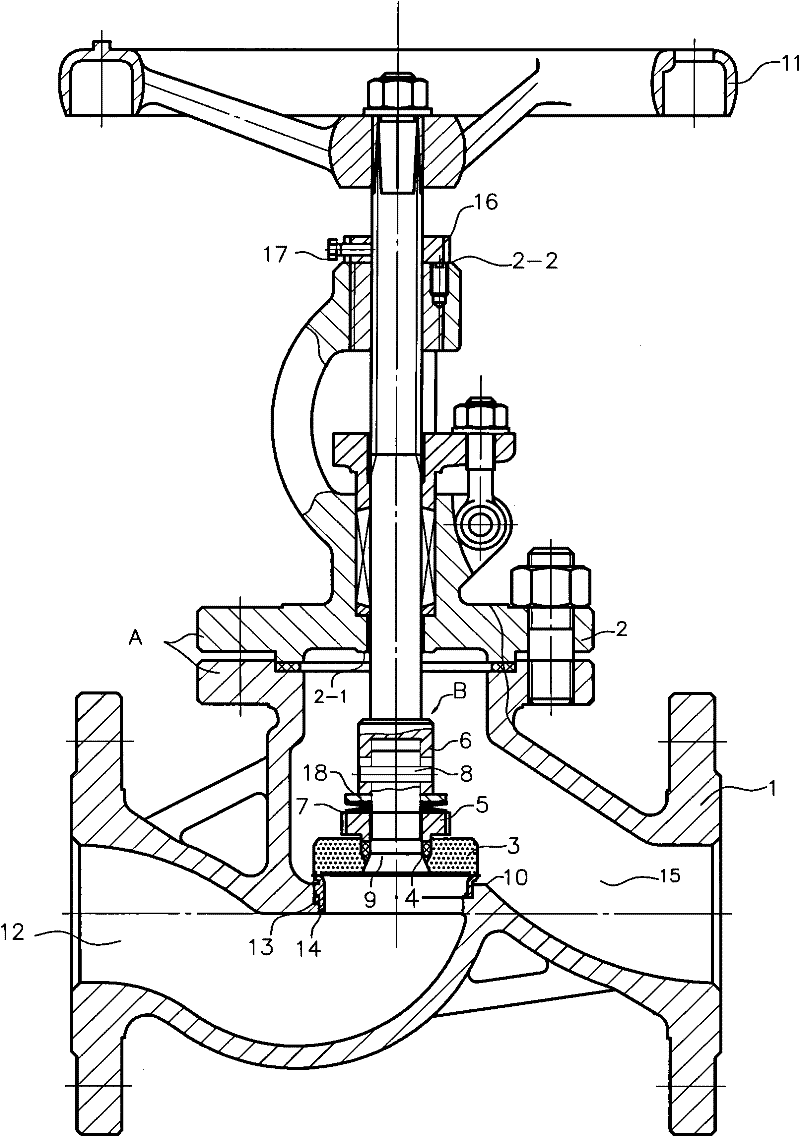

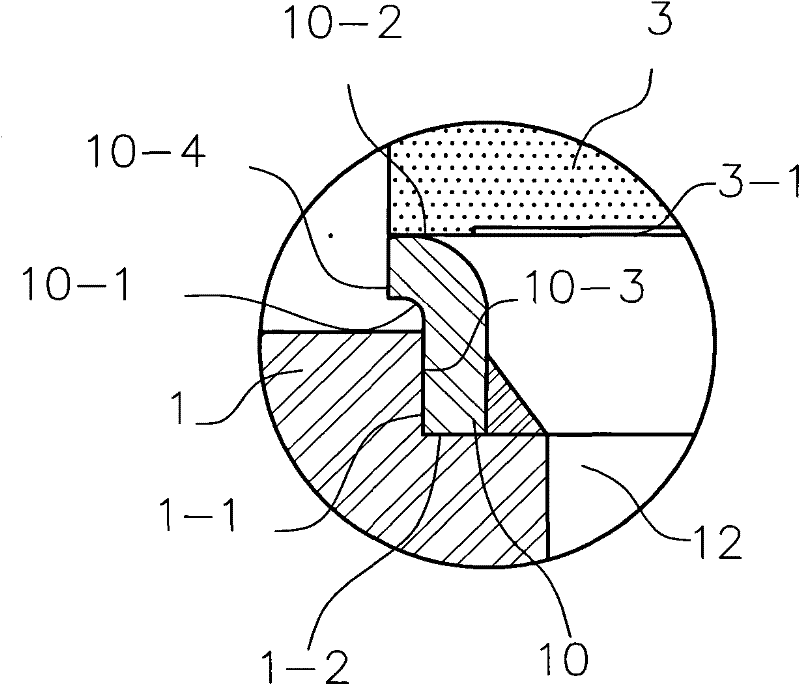

[0045] The above-mentioned shut-off valve of the present invention, as figure 1 , composed of the first part A connecting the valve body 1 and the valve cover 2 and the second part B connecting the ceramic valve seat 3 and the valve stem 6, an upward inlet 15 arranged centered on the horizontal line of the valve body 1 and a cross The center of the downwardly curved outlet channel 12 is equipped with an elastic valve seat 10, 14 at the center of the step hole at the intersection, and an elastic valve seat 1-4 processed directly on the valve body by the stainless steel valve, in which the round One side of 10-2, 14-1, 1-4 is in contact with the end plane 3-1 of the ceramic disc 3 and is tightly fitted to form a sealing pair of the shut-off valve.

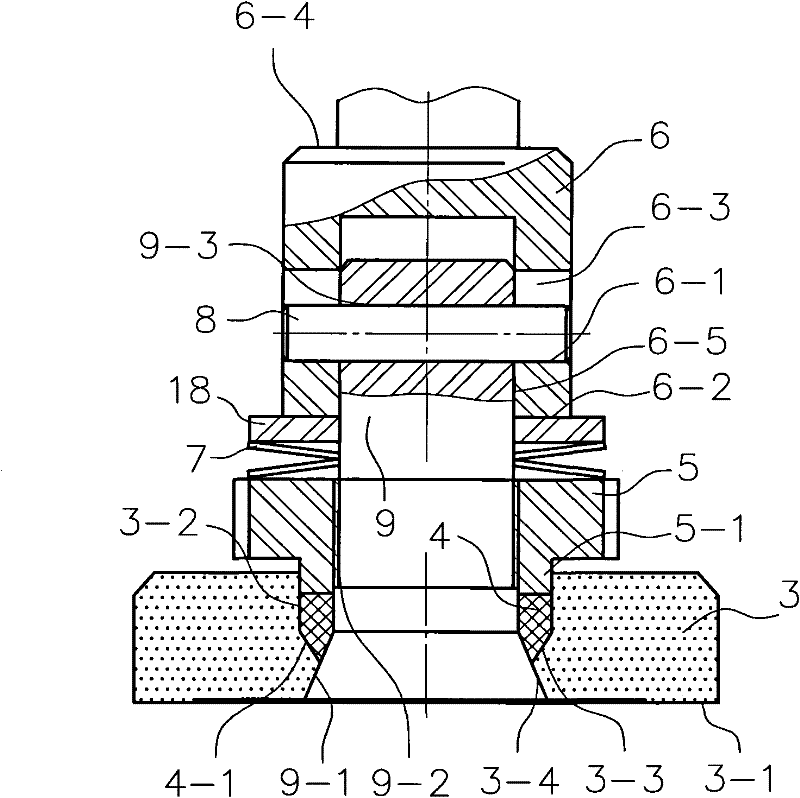

[0046] Please see figure 2 , connected to the ceramic disc 3 is a mandrel 9 with a taper 9-1 at the bottom, the upper part of the mandrel 9 is placed in the hole 6-5 at the end of the valve stem 6, and there is a cylindrical pin t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com