Inner armature type high precision positioning electromagnet

A high-precision, electromagnet technology, used in the field of electromagnets, can solve the problems of large temperature changes in positioning accuracy, low temperature drift, and easy jamming, and achieves the ability to eliminate positioning errors and deformation stress, reduce accuracy requirements, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

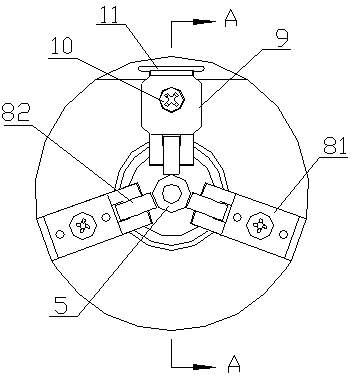

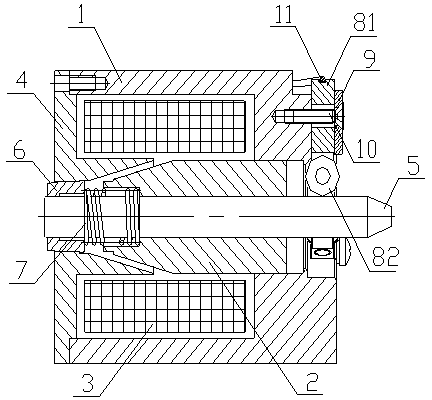

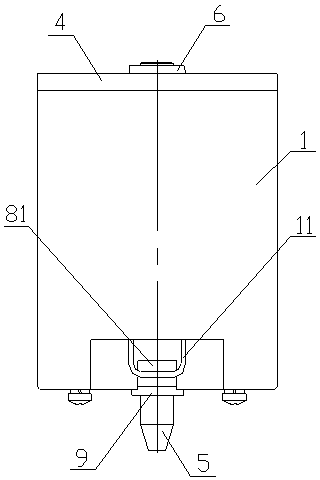

[0027] Example: see figure 1 , figure 2 as well as image 3 , an inner armature type high-precision positioning electromagnet, including a housing 1, an armature 2, a coil 3, an end cover 4, and a positioning shaft 5. The end cap 4 closes one end (rear end) of the housing 1 , and the other end (front end) of the housing 1 has a positioning hole consistent with the outer diameter of the armature 2 . The armature 2 is arranged in the housing 1, and the end of the armature 2 away from the end cover 4 is located in the positioning hole of the housing 1; thereby further improving the coaxiality of the armature 2 and the positioning shaft 5 during movement. The end of the armature 2 close to the end cover 4 is tapered, and the coil 3 is arranged in a cavity surrounded by the housing 1 , the end cover 4 and the armature 2 . The middle part of end cover 4 is provided with a shaft sleeve 6 holes, and a shaft sleeve 6 coaxial with it is fixed in the shaft sleeve 6 holes. During spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com