Motorcycle bottom fork

A technology for motorcycles and flat forks, applied in bicycle accessories, axle suspension devices, transportation and packaging, etc., can solve the problems of poor driving comfort, high requirements on coaxiality, and insignificant adjustment effects, so as to improve the Driving comfort, improved comfort and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

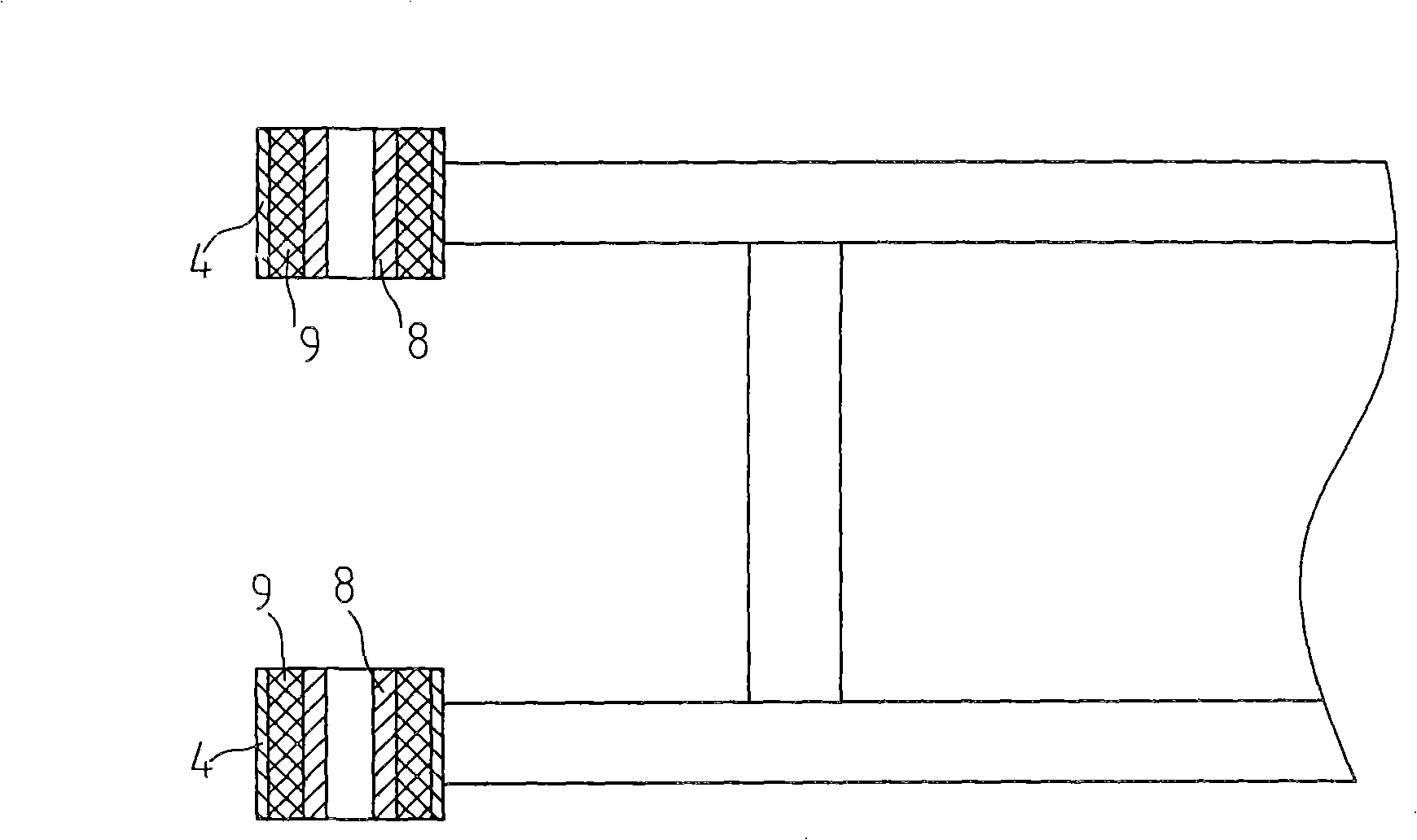

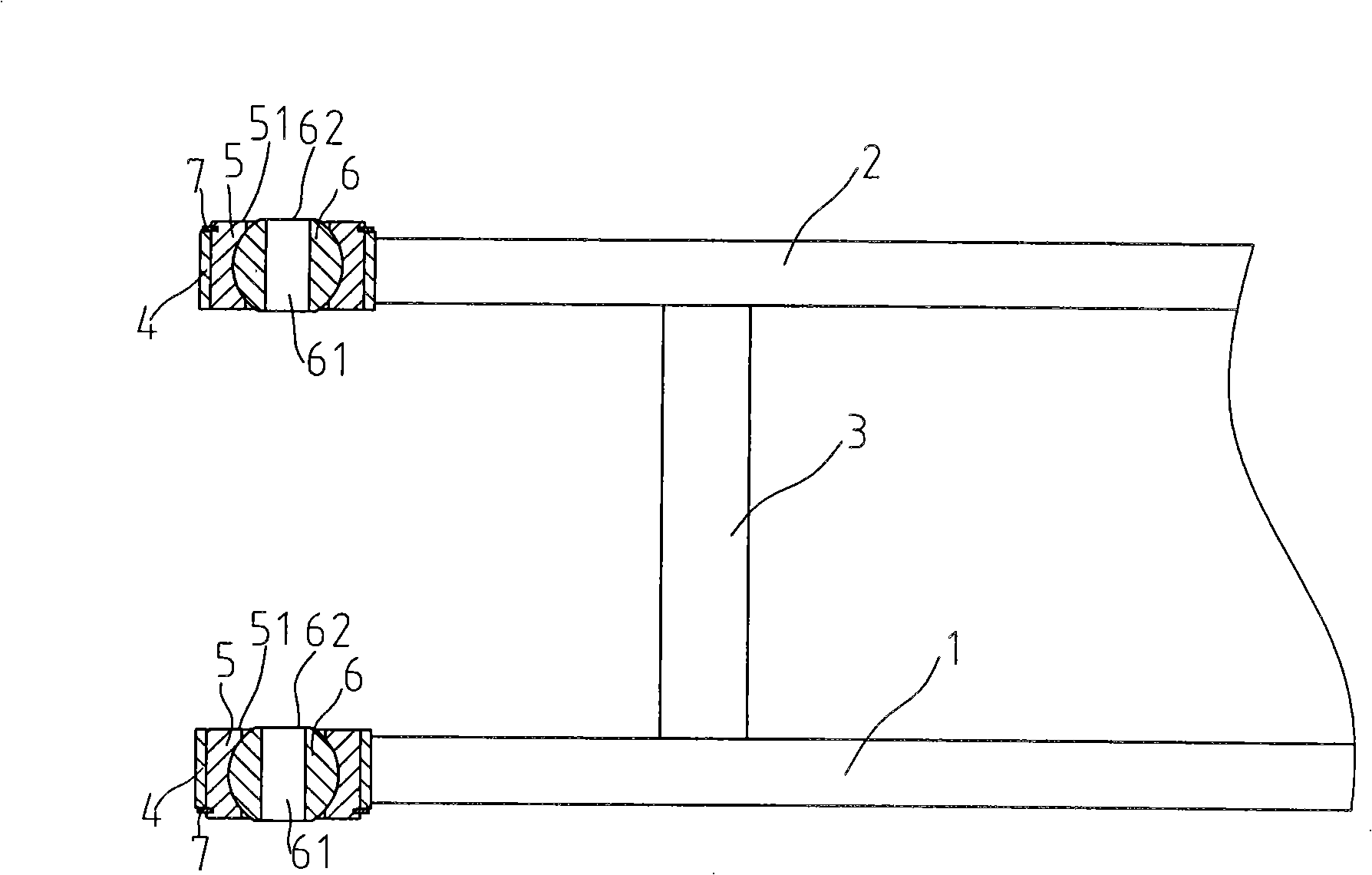

[0012] Such as figure 2 The flat fork of the motorcycle shown has a left frame bar 1, a right frame bar 2 and a connecting rod 3, and the connecting rod 3 is connected between the left frame bar 1 and the right frame bar 2 to form an H shape, and the left and right frame bars 1 and The front end of 2 is provided with a bushing 4 used to realize shaft connection with the large frame of the car. A spherical bearing is installed in the bushing 4. The spherical bearing is composed of a ball sleeve 5 and a steel ball 6 limited in the ball sleeve. , The steel ball 6 has a central shaft hole 61 .

[0013] When assembling, the spherical bearing is axially pressed into the sleeve 4, and the connecting shaft between the flat fork and the large frame passes through the central shaft hole of the steel ball 6, and the connecting shaft and the steel ball 6 are relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com