Method for compensating inertial installation error of cabin assembly

A technology of installation error and compensation method, which is applied in the inertial field, can solve the problems of poor accuracy of navigation system and control system, installation accuracy that cannot meet the requirements, and difficulty in ensuring installation accuracy, etc., achieves small code changes, reduces processing difficulty, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

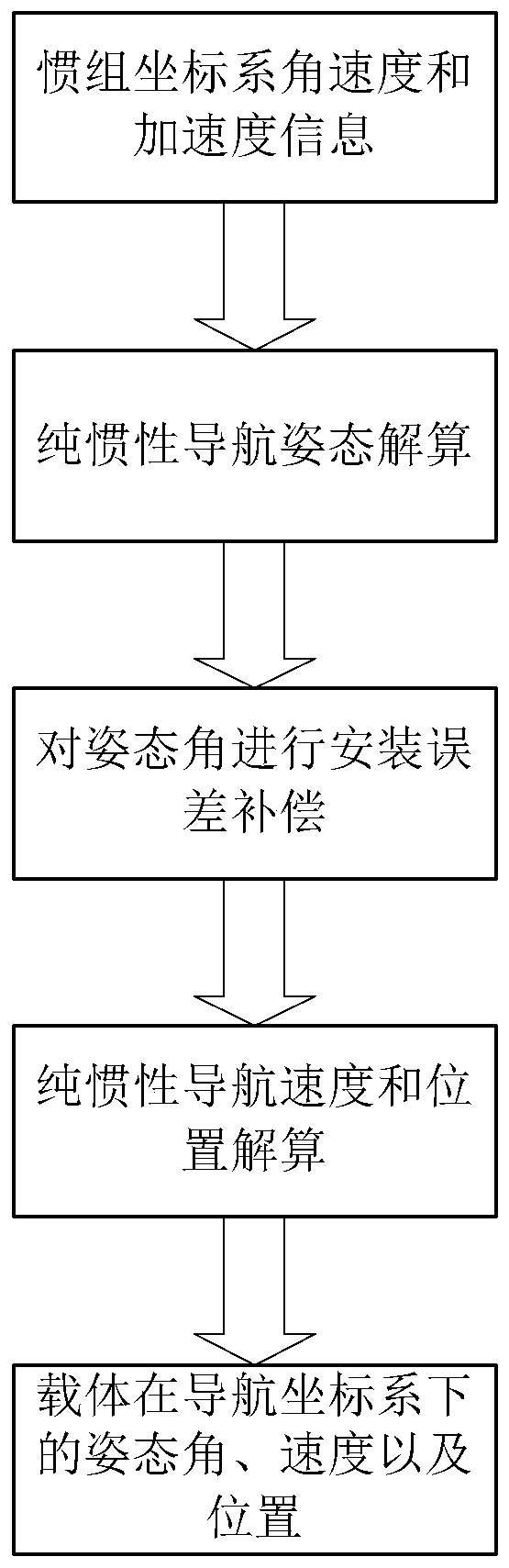

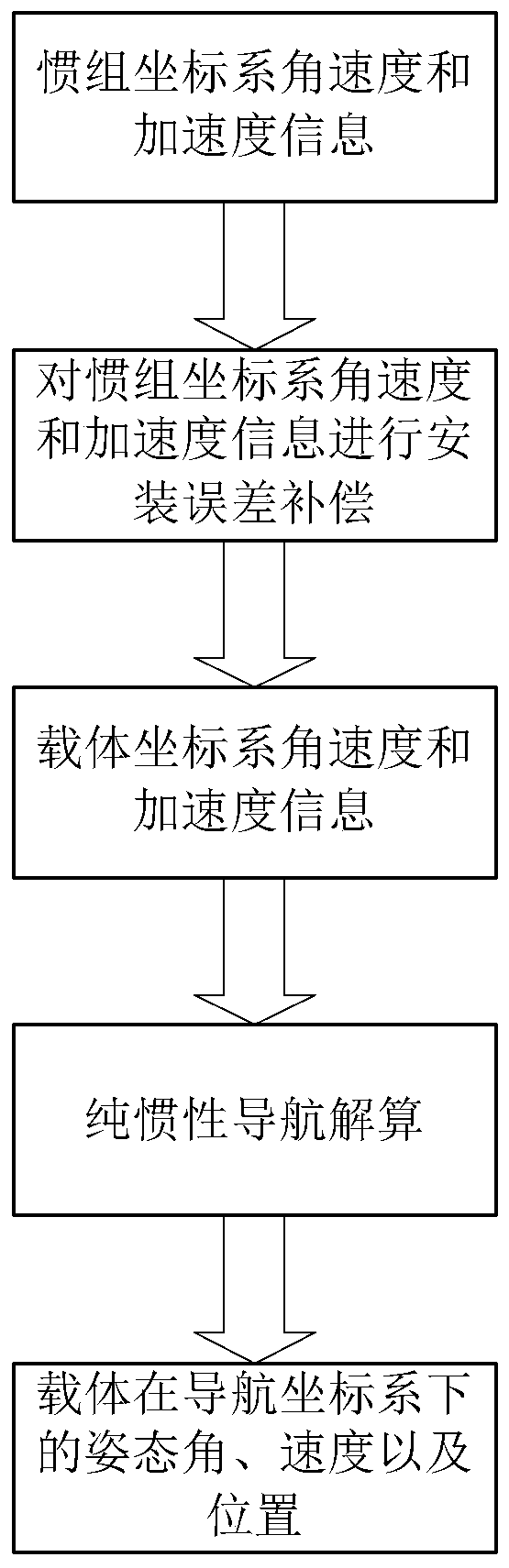

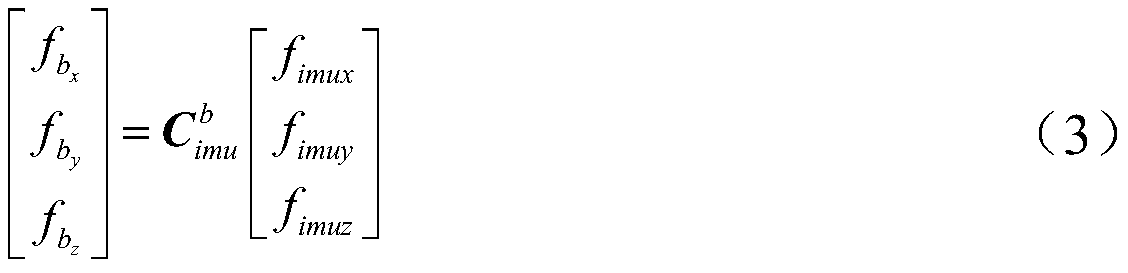

[0041] Due to the large weight and volume of cabin-level products, it is impossible to perform calibration compensation on the turntable, and the multi-stage installation between the inertial group and the cabin will bring installation errors of different sizes and directions. In order to reduce the The installation error between the inertial group and the inertial group improves the accuracy of the control system. The present invention proposes a compensation method for the inertial group installation error based on cabin assembly. This method is a software compensation method and does not rely on redundant hardware equipment and structural parts. It can effectively reduce the impact of installation errors on the control system; at the same time, this method does not need to consider the erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com