One-step buckling and molding type cable connector

A cable connector and type technology, which is applied in the field of one-time crimping and forming cable connectors, can solve the problems that the overall cable cannot be placed and twisted freely, the processing is cumbersome, and the cable connector cannot be adjusted for plugging and unplugging angles, etc., to achieve good dustproof and waterproof Impact performance, ensuring safety performance, and improving the effect of pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

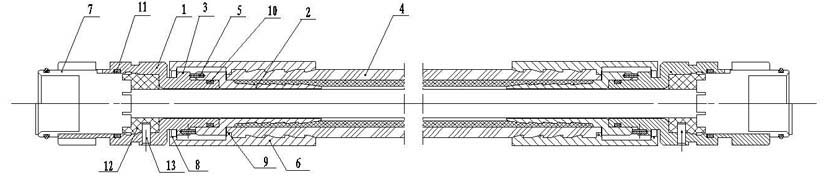

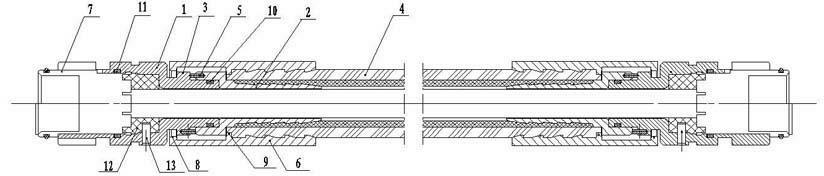

[0014] As shown in the figure, the one-time crimping type cable connector of the present invention includes connectors arranged at the sheaths at the left and right ends of the cable, and the connectors are steps that are sequentially sleeved on the ends of the cables from outside to inside. Sleeve 1 and stepped core 2, the outer peripheral surface of the small-diameter tube of described stepped casing 1 is provided with annular boss 3, and groove is formed between described annular boss 3 and the stepped platform of stepped casing; The small-diameter tube of the core 2 extends into the cable sheath 4, and the large-diameter tube of the stepped core 2 is set on the small-diameter tube of the stepped sleeve 1; at the end of the stepped core 2 and the annular boss 3 of the stepped sleeve Pin holes are respectively opened in the axial direction on the joint surface of the part, and a pin shaft 5 is arranged in it; a protective jacket 6 is extended from the groove of the small-diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com