Processing method of physical anti-mite down quilt fabric

A processing method and technology for quilt fabrics, applied in the field of down quilt fabrics, can solve the problems of poor anti-mite resistance, good air permeability and hand feeling, and unreasonable processing methods of down quilts, so as to enhance air permeability and anti-drilling properties and reduce costs. The effect of investment and improvement of effective adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

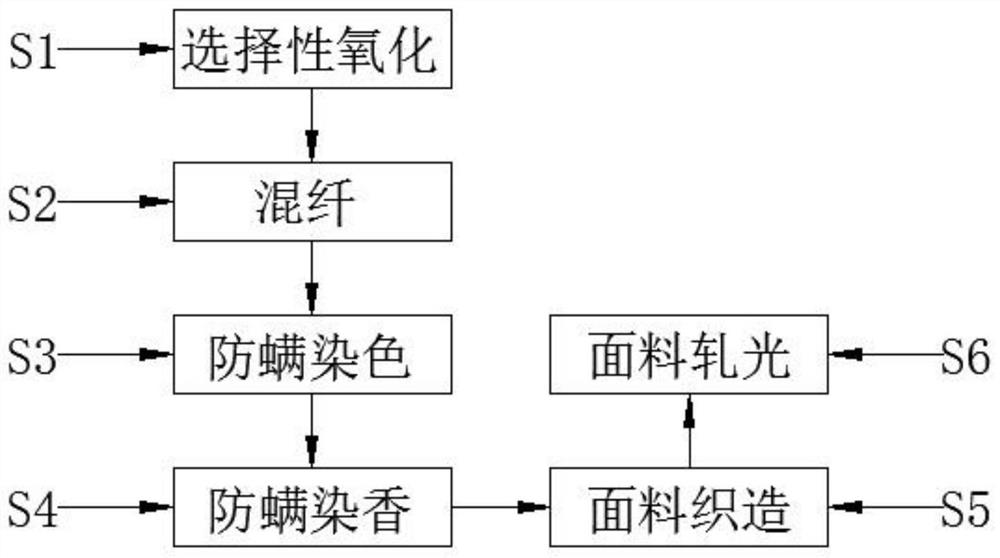

[0026] see figure 1 , a kind of physical anti-mite duvet fabric processing method, comprises the following steps:

[0027] S1. Selective oxidation: Use sodium periodate solution with a concentration of 2.5g / L to selectively oxidize cotton fibers at 30°C for 55 minutes to obtain oxidized cotton fibers, and then place the oxidized cotton fibers in a 0.15mlo / L React in glycerol solution for 20 minutes, then fully wash with distilled water, and finally centrifuge, filter, and dry to obtain aldehyde-based cotton fibers with an aldehyde group content of 0.55-0.60 mmol / g, which are ready for use;

[0028] S2, fiber blending: the prepared aldehyde-based cotton fiber and polyurethane fiber are blended with a mass ratio of 1:1.5, and then processed into a blended yarn through cleaning, carding, drawing, roving, and spinning processes. use;

[0029] S3. Anti-mite dyeing: Dip-dye the blended yarn, and mix an anti-mite agent into the dye solution. The anti-insect and anti-mite agent is m...

Embodiment 2

[0034] see figure 1 , a kind of physical anti-mite duvet fabric processing method, comprises the following steps:

[0035] S1. Selective oxidation: Use sodium periodate solution with a concentration of 2.5g / L to selectively oxidize cotton fibers at 30°C for 55 minutes to obtain oxidized cotton fibers, and then place the oxidized cotton fibers in a 0.15mlo / L React in glycerol solution for 20 minutes, then fully wash with distilled water, and finally centrifuge, filter, and dry to obtain aldehyde-based cotton fibers with an aldehyde group content of 0.55-0.60 mmol / g, which are ready for use;

[0036] S2, fiber blending: the prepared aldehyde-based cotton fiber and polyurethane fiber are blended with a mass ratio of 1:1.5, and then processed into a blended yarn through cleaning, carding, drawing, roving, and spinning processes. use;

[0037] S3, anti-mite dyeing: the blended yarn is dip-dyeed, and an anti-mite agent is mixed into the dye solution, and the anti-insect and anti-m...

Embodiment 3

[0042] see figure 1 , a kind of physical anti-mite duvet fabric processing method, comprises the following steps:

[0043] S1. Selective oxidation: Use sodium periodate solution with a concentration of 2.5g / L to selectively oxidize cotton fibers at 30°C for 55 minutes to obtain oxidized cotton fibers, and then place the oxidized cotton fibers in a 0.15mlo / L React in glycerol solution for 20 minutes, then fully wash with distilled water, and finally centrifuge, filter, and dry to obtain aldehyde-based cotton fibers with an aldehyde group content of 0.55-0.60 mmol / g, which are ready for use;

[0044] S2, fiber blending: the prepared aldehyde-based cotton fiber and polyurethane fiber are blended with a mass ratio of 1:1.5, and then processed into a blended yarn through cleaning, carding, drawing, roving, and spinning processes. use;

[0045] S3, anti-mite dyeing: the blended yarn is dip-dyeed, and an anti-mite agent is mixed into the dye solution, and the anti-insect and anti-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com