Calender

A technology of calender and frame, which is applied in the direction of textile and papermaking, fabric surface trimming, etc., and can solve the problems of troublesome operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

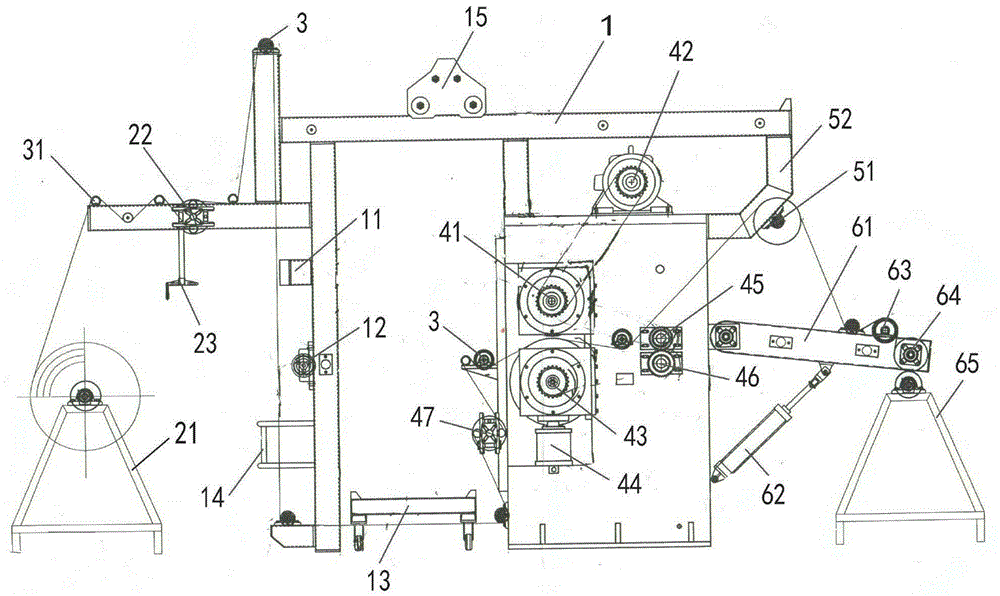

[0017] Such as figure 1 As shown, the calender includes a frame 1, and the frame 1 is provided with a cloth feeding device, a cloth guide roller 3, a cloth pressing device, a cooling device and a cloth discharging device, and the cloth pressing device includes a mirror surface heating roller 41, a driving The cloth pressing end motor 42 that the mirror surface heating roller 41 rotates around its own axis, the hydraulic uniform roller 43 and the cloth pressing end hydraulic cylinder 44 that drives the hydraulic uniform roller 43 to rise and fall, the hydraulic uniform roller 43 is located above the mirror surface heating roller 41, and also includes a transmission mechanism , including a first gear 45 chain-connected with the mirror surface heating roller 41 and a second gear 46 chain-driven with the hydraulic uniform roller 43, the first gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com