Screening equipment and method for screening out solid waste long materials

A technology for screening equipment and long materials, which is applied in chemical instruments and methods, sieving, solid separation, etc. It can solve the problems of low screening efficiency, uniform batching, influence of pneumatic conveying feeder, waste cannot be sieved, etc., to achieve High work efficiency, high screening efficiency, easy to slide down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

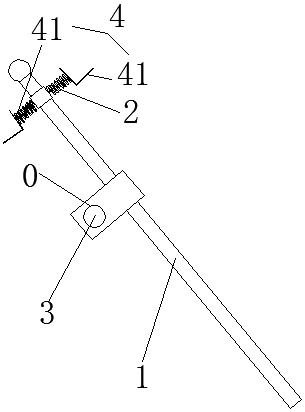

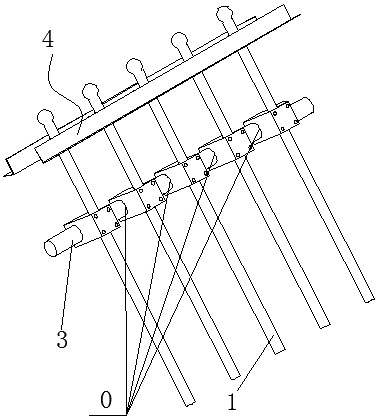

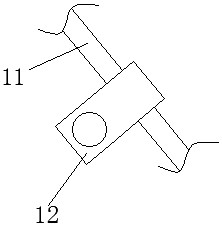

[0034] Embodiment 1: as Figure 1-2 As shown, the screening equipment for screening out solid waste long materials includes at least two sliding bars 1 that can rotate around their corresponding fulcrums 0. (that is, the rod part of the sliding rod 1 below the fulcrum 0) rotates downward around the fulcrum 0, and is always in a tilted state. A sieve drop channel is formed between adjacent sliding rods 1. 1 is always in an inclined state, so that the waste can slide down the slide bar 1 without jamming, and the short material can be sieved from between the slide bar 1, and the long material in the shape of filament and thread can slide down from the tail end of the slide bar 1 , which realizes the effective separation of long-filament and thread-shaped materials from other qualified short materials. At the same time, it does not require users to clean out long-filament and thread-shaped materials on the screening equipment, which improves the screening efficiency of long-filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com