Reflux bending pipe auxiliary device and ball screw using same

A technology of return elbow and ball screw, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc. It can solve problems such as poor connection smoothness of return channels, bending deformation of finished products, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] see Figure 1 to Figure 9 Shown are the preferred embodiments of the return elbow auxiliary device and the ball screw applying it according to the present invention, but these embodiments are for illustration only, and are not limited by this structure in the patent application.

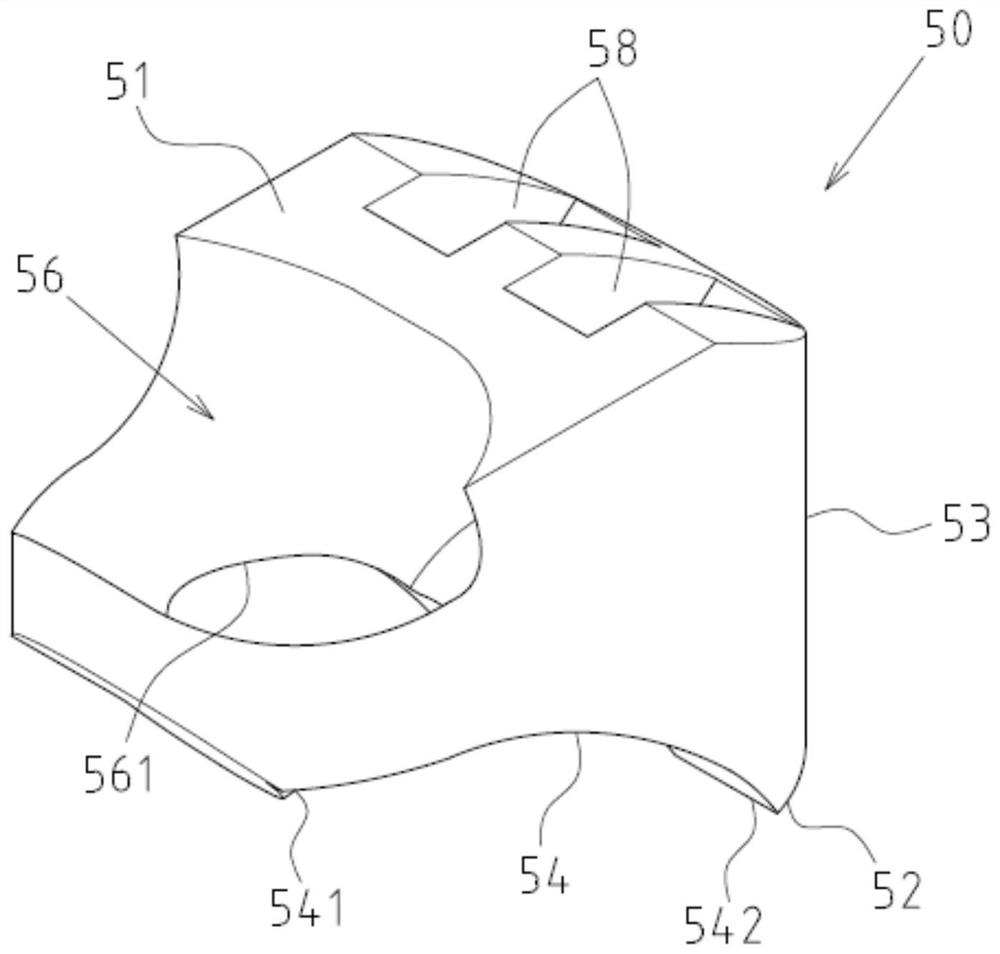

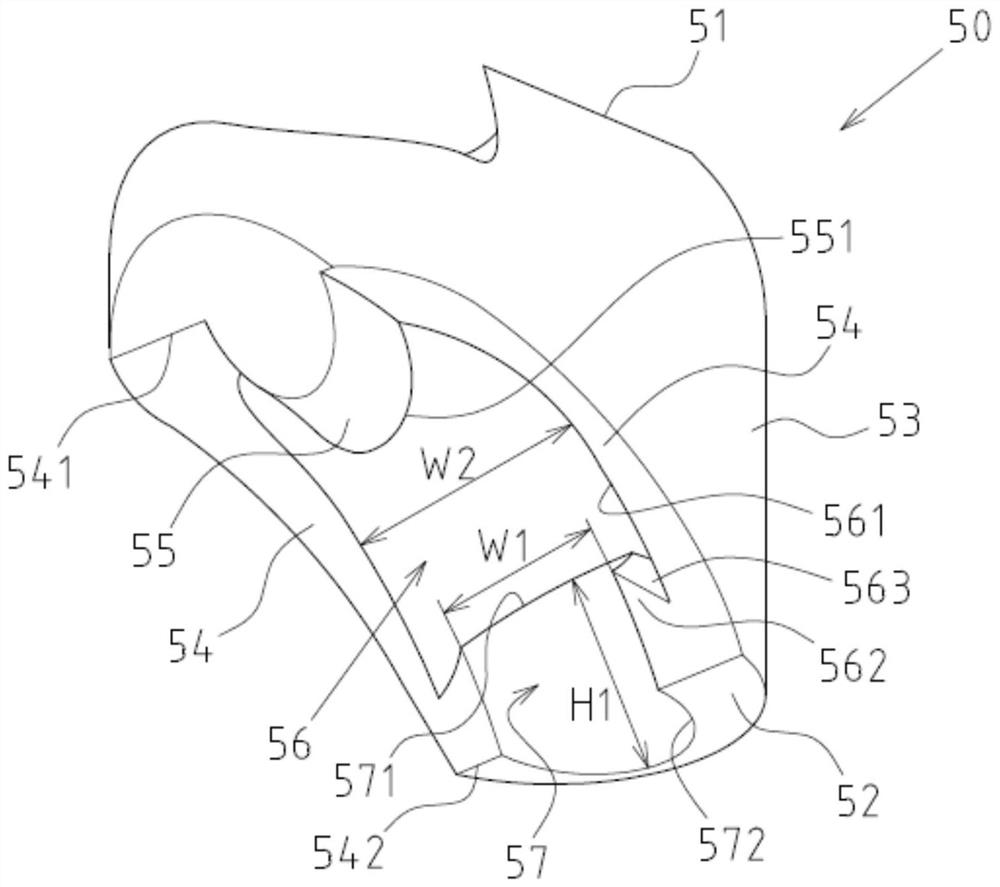

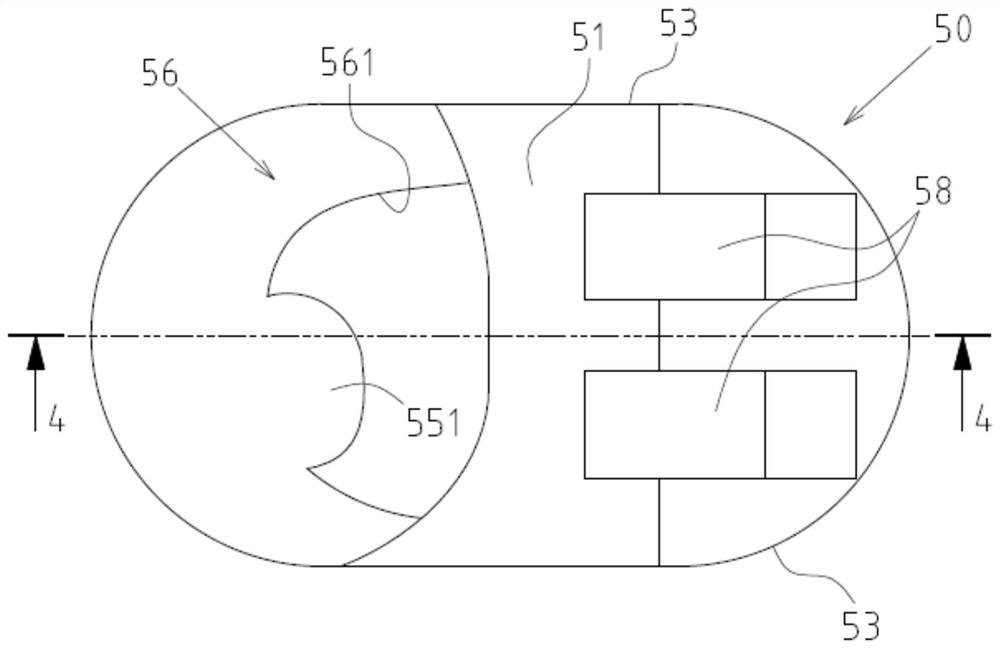

[0028] The return elbow auxiliary device 50 is used to install a groove 24 for installation on the outside of the nut 20 of a ball screw 100, so as to be combined with a return elbow 40 to form a ball return channel; the return elbow The pipe auxiliary device 50 includes a top surface 51, a bottom end 52 and a peripheral wall 53. The peripheral wall 53 is in the shape of a vertical wall relative to a radial base line L2 defined by the nut 20, and an arc is formed on one side of the bottom end 52. Surface 54, the arc surface 54 includes a rising end 541 and a descending end 542, the descending end 542 is connected with the bottom end 52, and the arc surface 54 protrudes downwards adjacent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com