Indoor machine of two-tubular air conditioner

An indoor unit and double cross-flow technology for air conditioners, applied in air conditioning systems, machines/engines, mechanical equipment, etc., can solve the problems of low heat exchange efficiency, small heat exchange area, and small air intake area of air conditioners, and achieve structural Simple and reasonable, large heat exchange area and large air inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

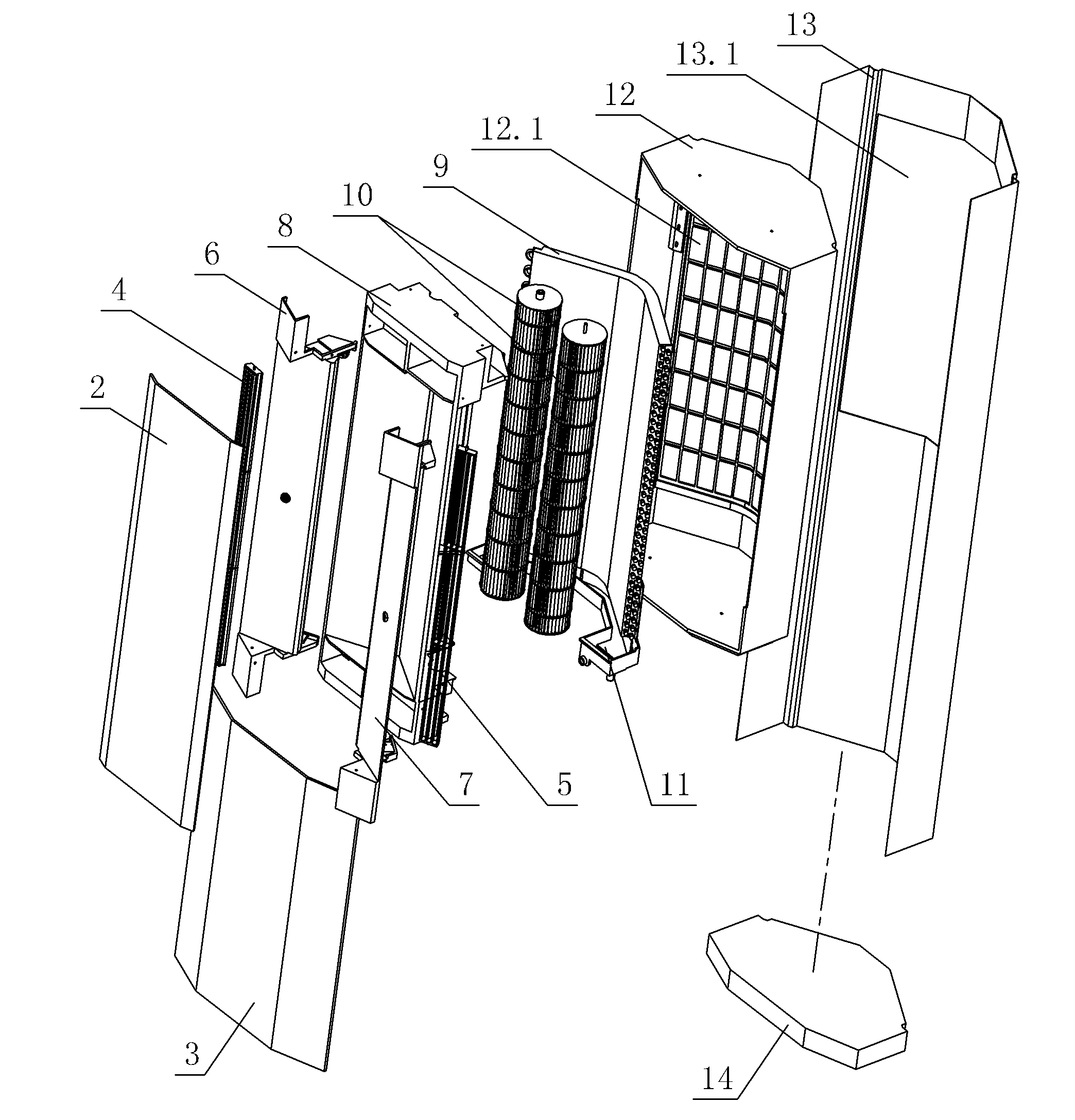

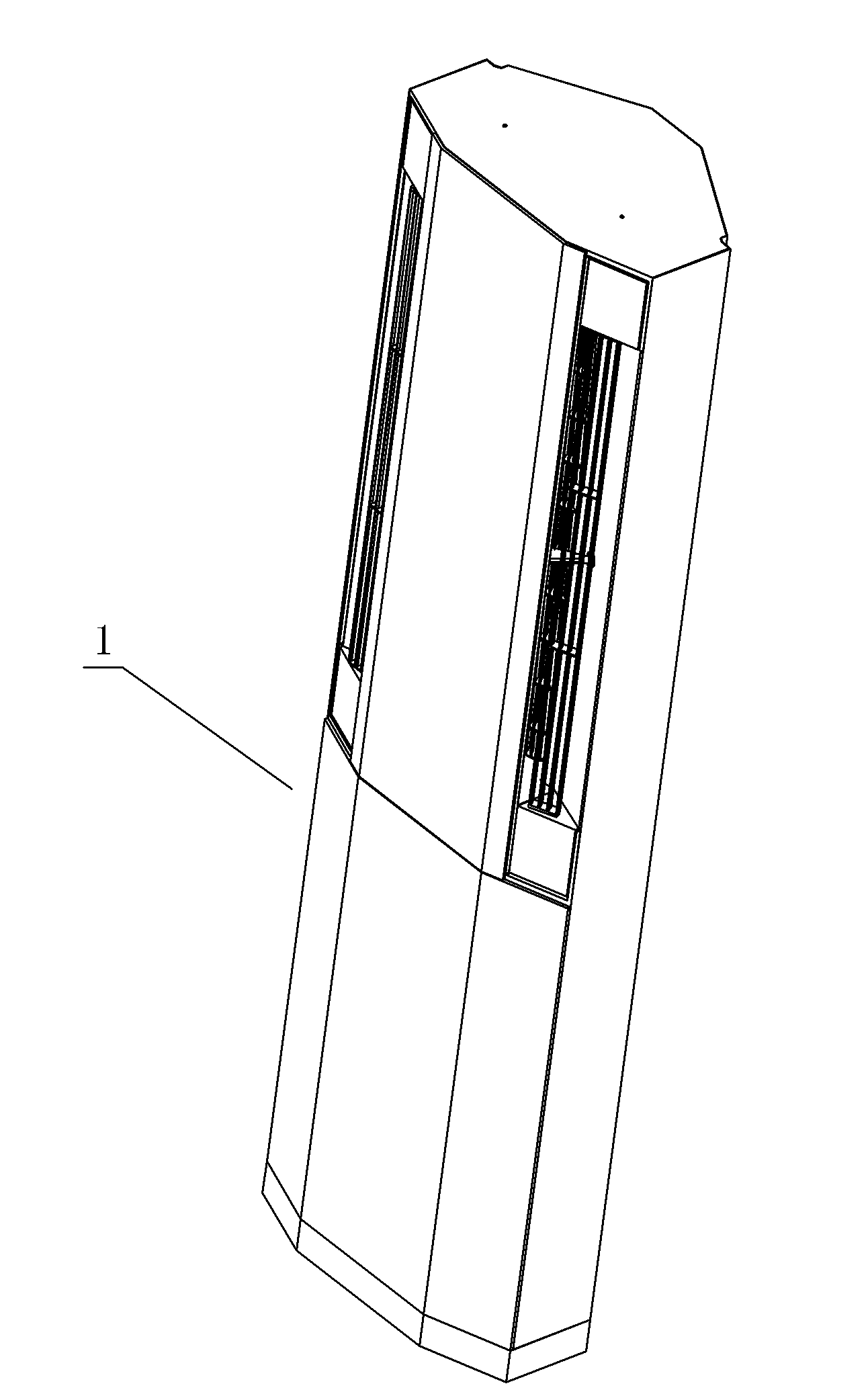

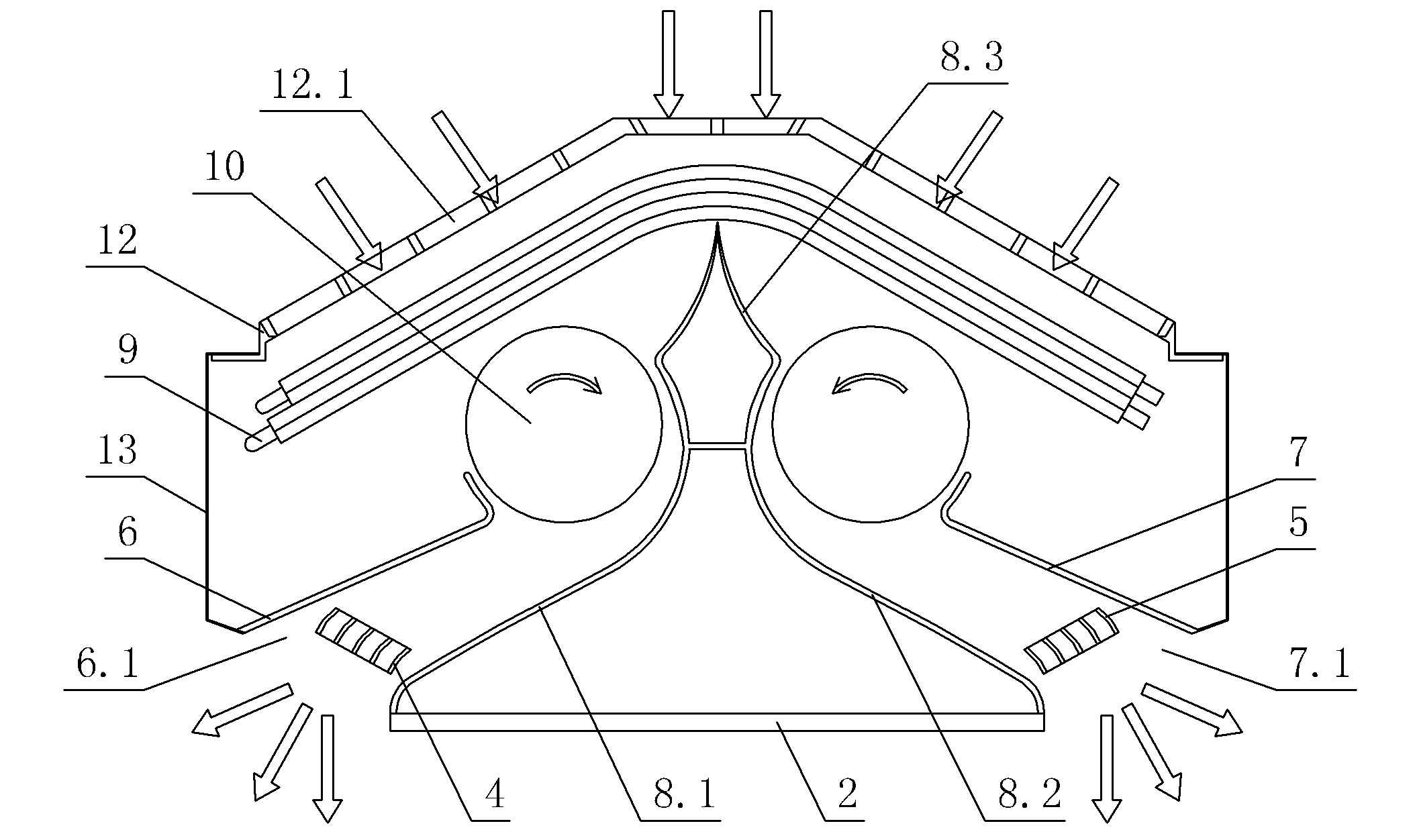

[0021] see Figure 1-Figure 3 , the indoor unit of the double cross-flow air conditioner includes a casing composed of a front panel assembly and a casing 13, two left and right cross-flow wind wheels 10 vertically arranged in the casing, and a cross-flow wind wheel 10 arranged in the casing and located on the rear side of the cross-flow wind wheel 10. The heat exchanger 9, the air inlet 12.1 arranged at the back of the casing and the air outlet arranged in front of the casing; the casing 13 is connected to the rear side of the front panel assembly, and the inside of the casing 13 is provided with a box 12 corresponding to the heat exchanger 9; its characteristics The back of the box body 12 and the casing 13 protrude outward, the protruding part of the box body 12 is provided with the air inlet 12.1, and the protruding part of the casing 13 is provided with an air inlet window 13.1 corresponding to the air inlet 12.1; the heat exchanger 9 is bent toward the protruding directi...

no. 2 example

[0027] see Figure 4 In this embodiment, the distance between the heat exchanger 9 and the air inlet 12.1 is 95mm, and a filter screen 15 is arranged between the air inlet and the heat exchanger, which ensures that the air blown out by the air conditioner is relatively clean. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0029] see Figure 5 , the connection protrusion 28.3 is olive-shaped. Other unmentioned parts are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com