Patents

Literature

34results about How to "Evenly across" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

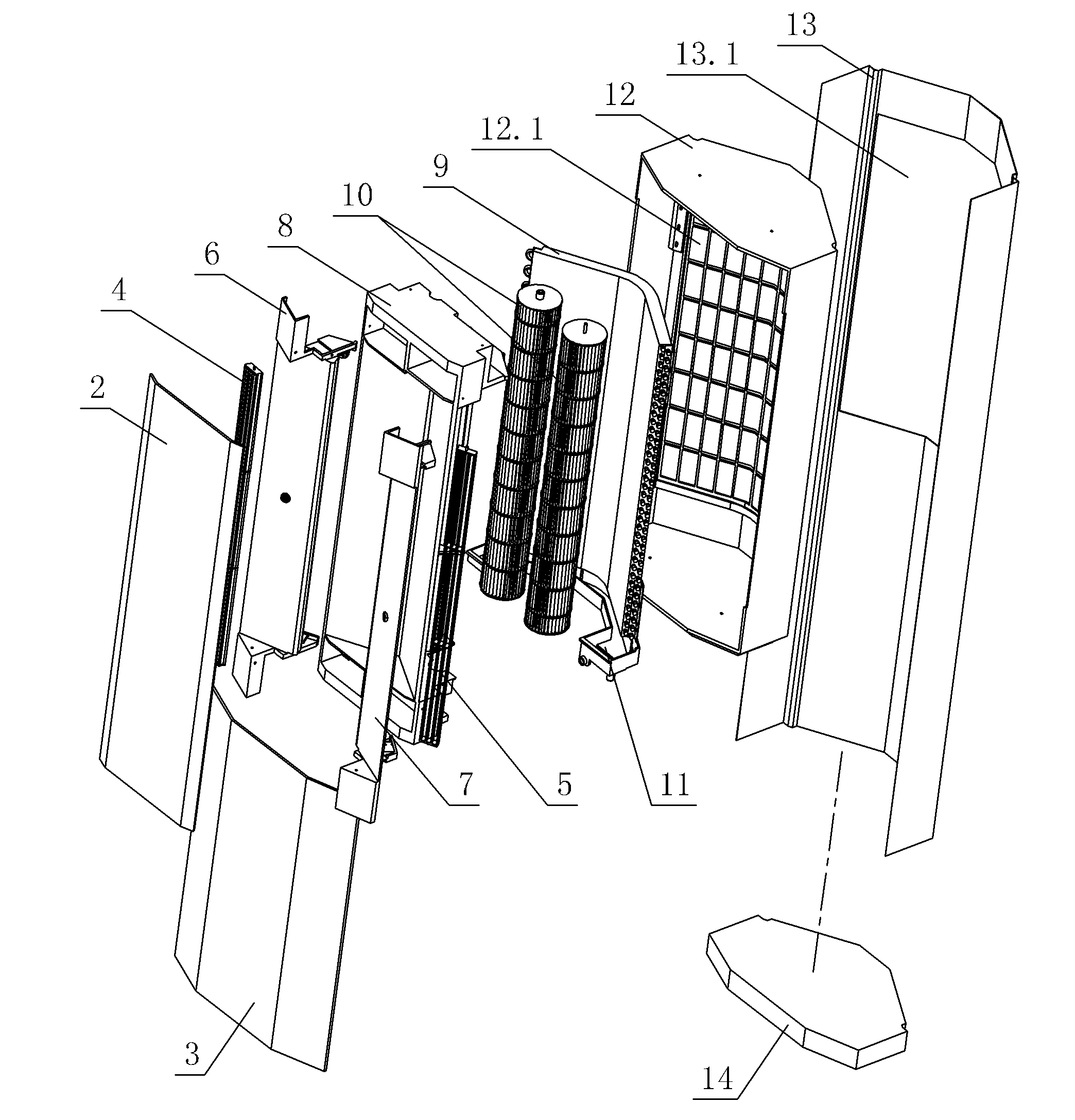

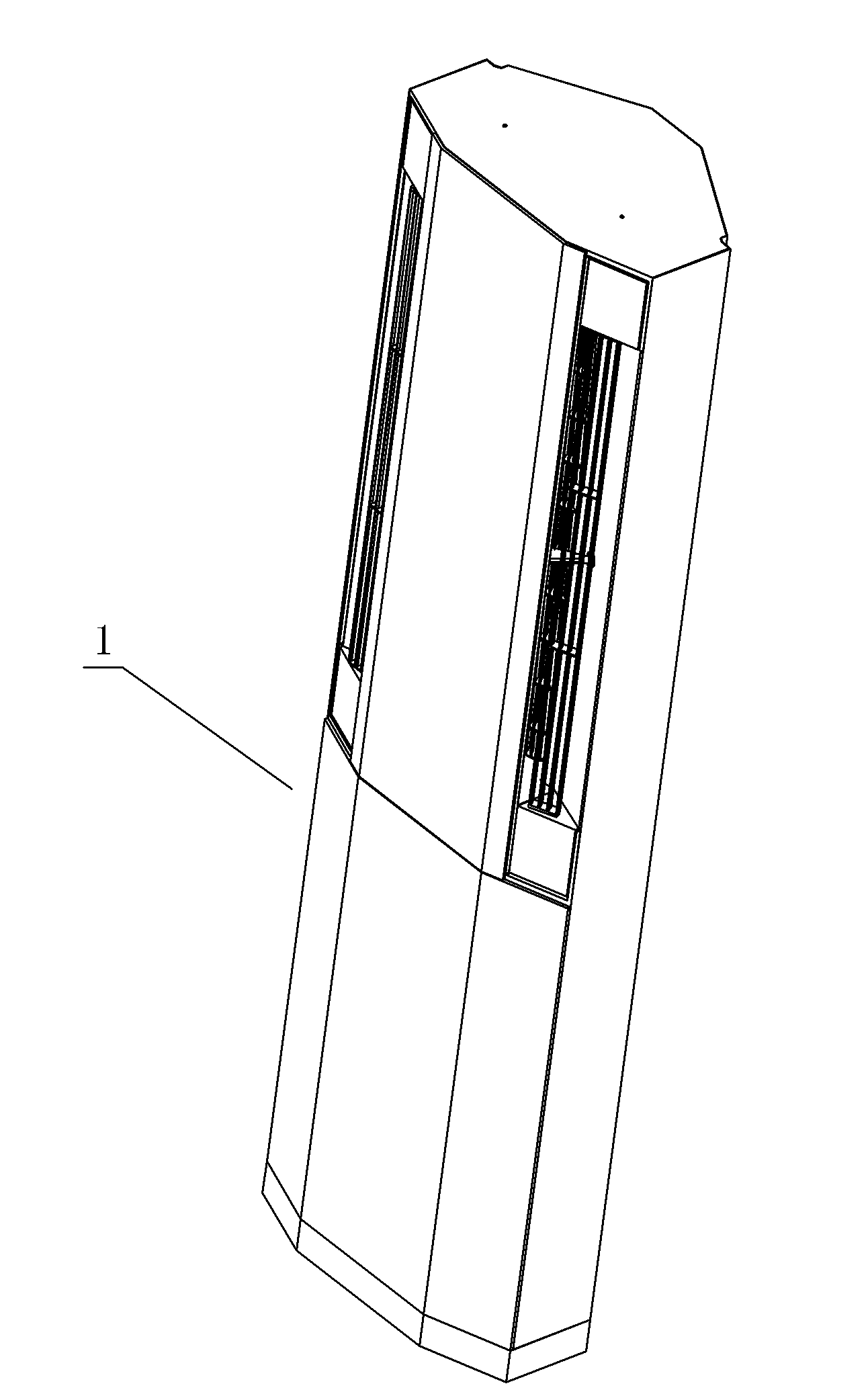

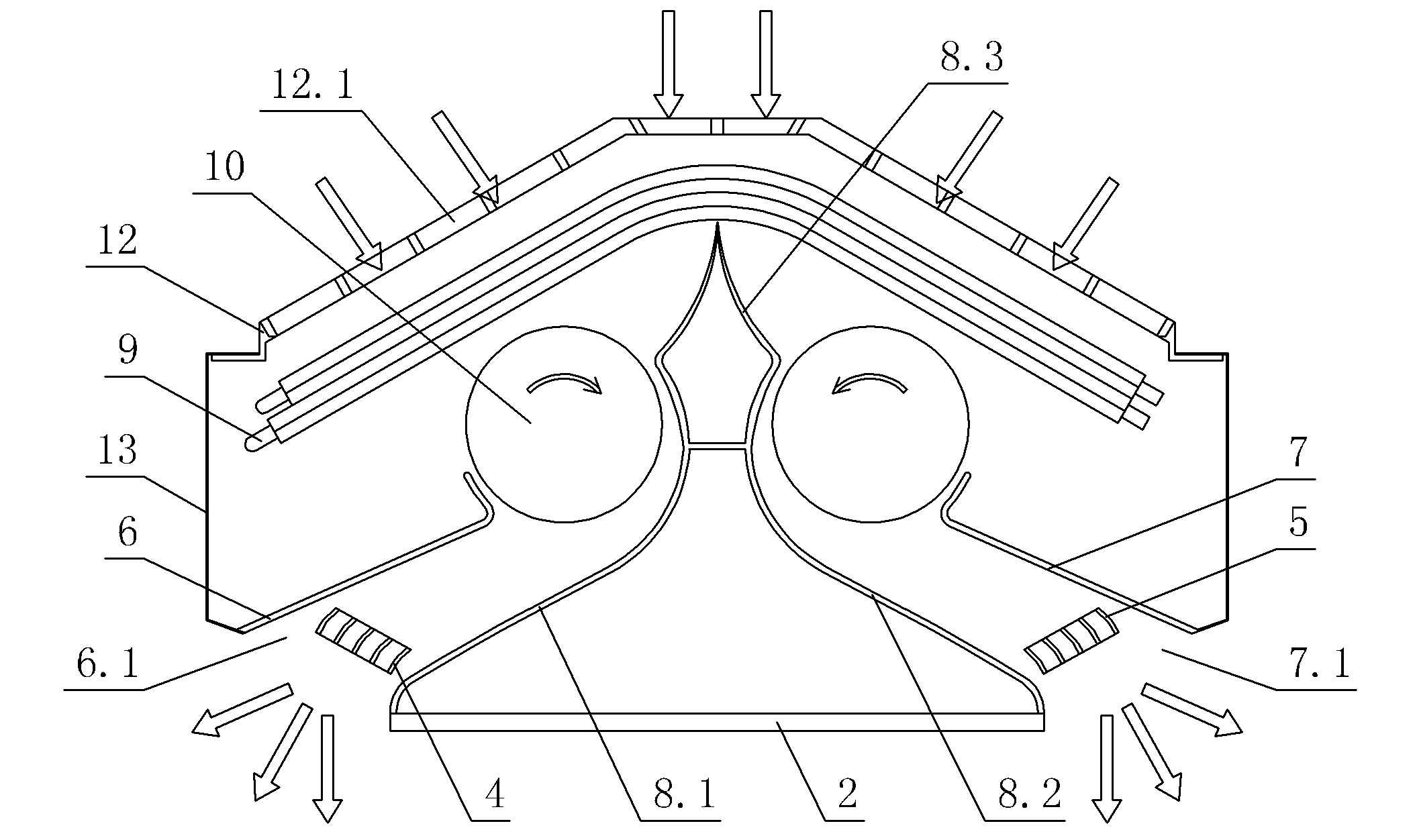

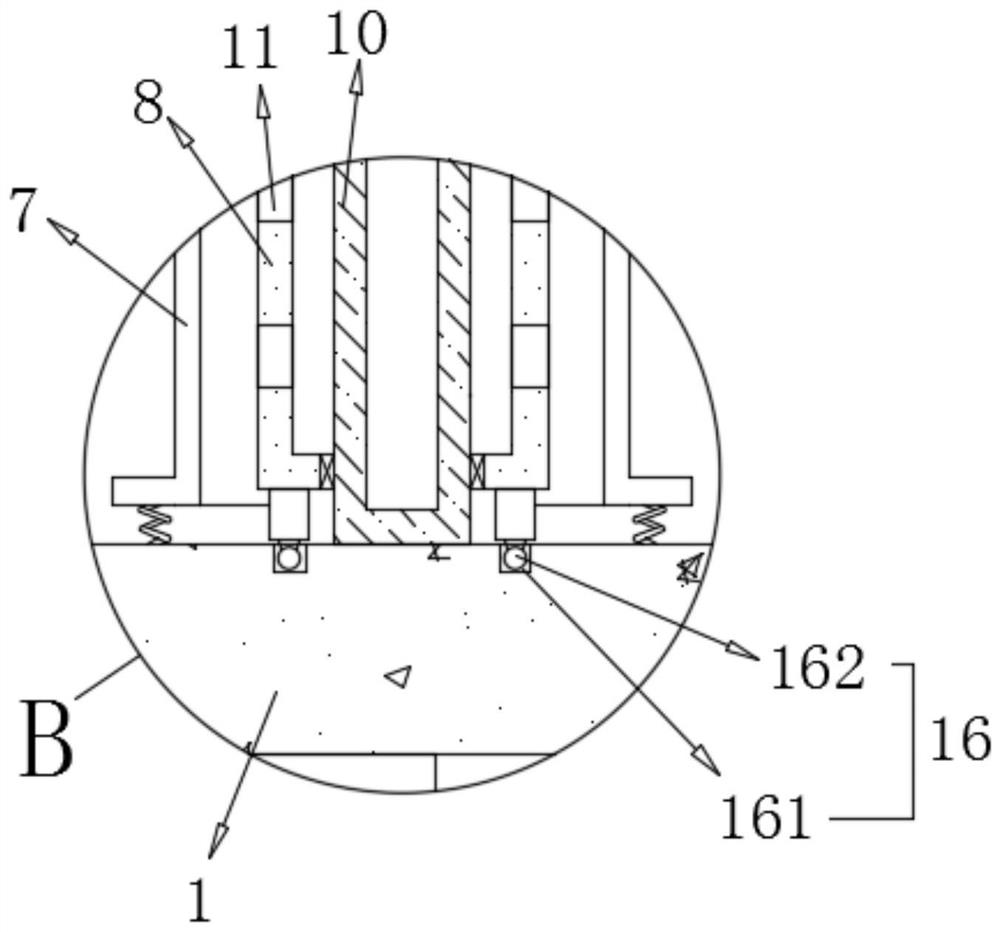

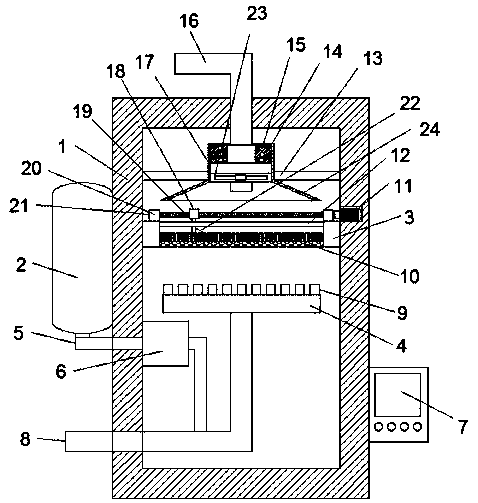

Indoor machine of two-tubular air conditioner

InactiveCN102147130AIncrease the effective heat transfer areaReduce wind resistancePump componentsLighting and heating apparatusEngineeringMicro heat exchanger

The invention discloses an indoor machine of a two-tubular air conditioner, which comprises a housing, a left and a right tubular fan wheels, a heat exchanger, an air inlet and an air outlet, wherein the housing consists of a front panel assembly and a shell; the left and the right tubular fan wheels are vertically arranged in the housing; the heat exchanger is arranged in the housing and positioned at the rear side of the tubular fan wheels; the air inlet is arranged behind the housing and the air outlet is arranged in front of the housing; the shell is connected to the rear side of the front panel assembly, the inner side of the shell is provided with a box body corresponding to the heat exchanger; back parts of the box body and the shell protrude outwards, the protruding part of the box body is provided with the air inlet, and the protruding part of the shell is provided with an air inlet window corresponding to the air inlet; the heat exchanger is bent towards the protruding direction of the back of the box body and arranged at a position close to the air inlet; and the housing is also internally provided with a volute assembly positioned between the two tubular fan wheels, the volute assembly comprises a left volute, a right volute, and a connecting bulge for connecting the left volute and the right volute together, and the connecting bulge extends to the position close to the heat exchanger. The invention has the advantages of larger air inlet area, compact assembly, low cost, small noise and high heat exchange efficiency.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

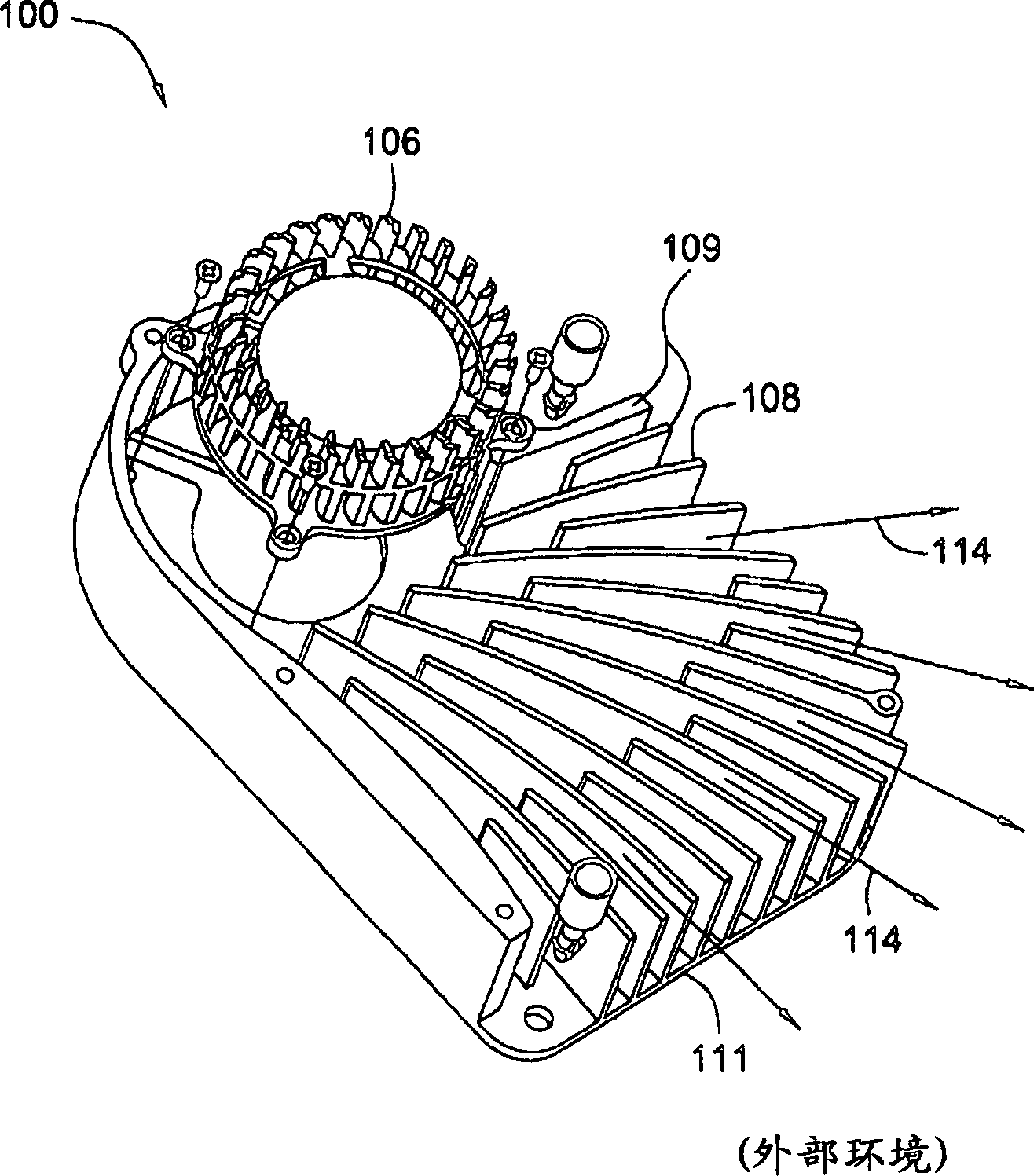

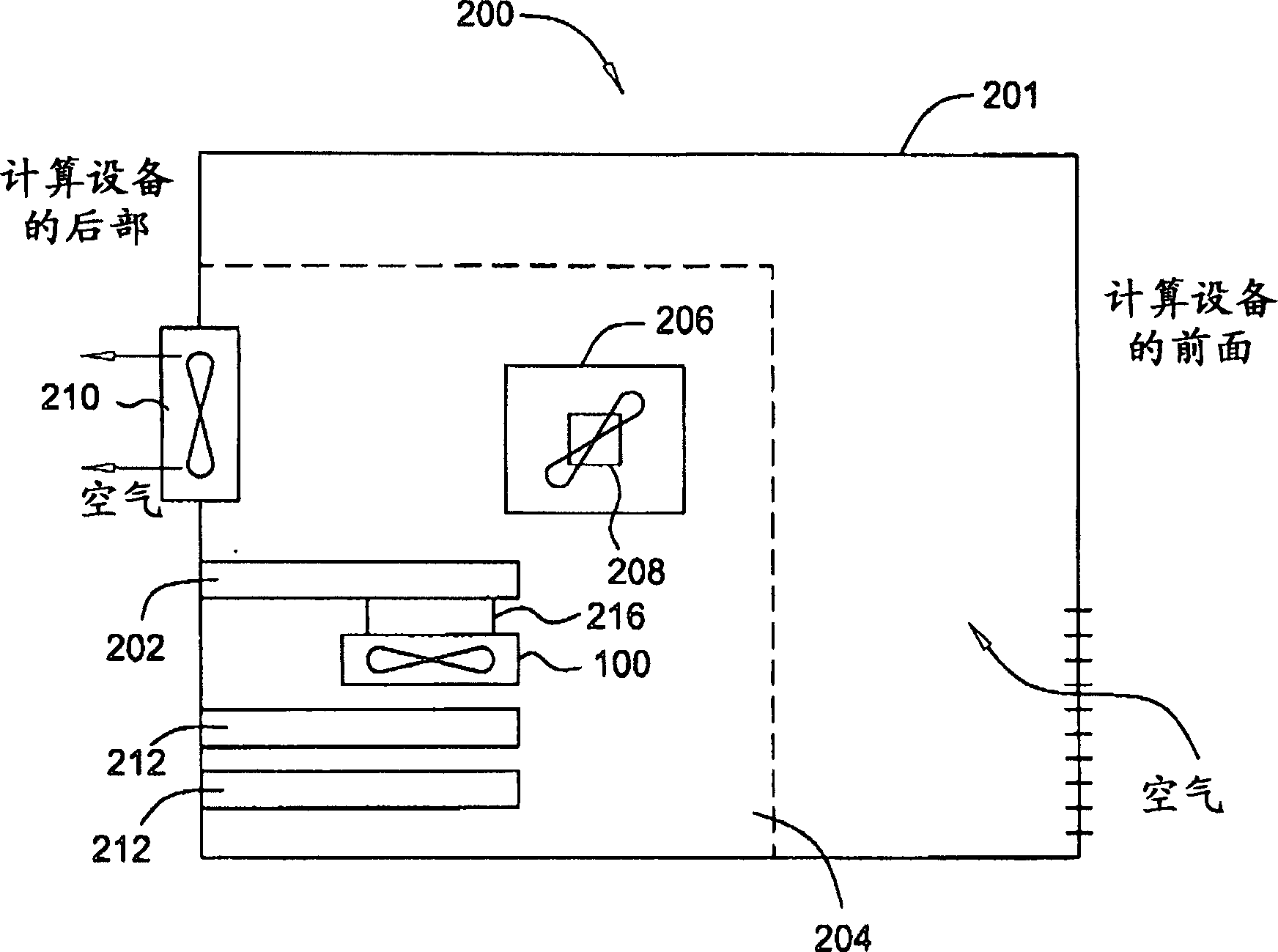

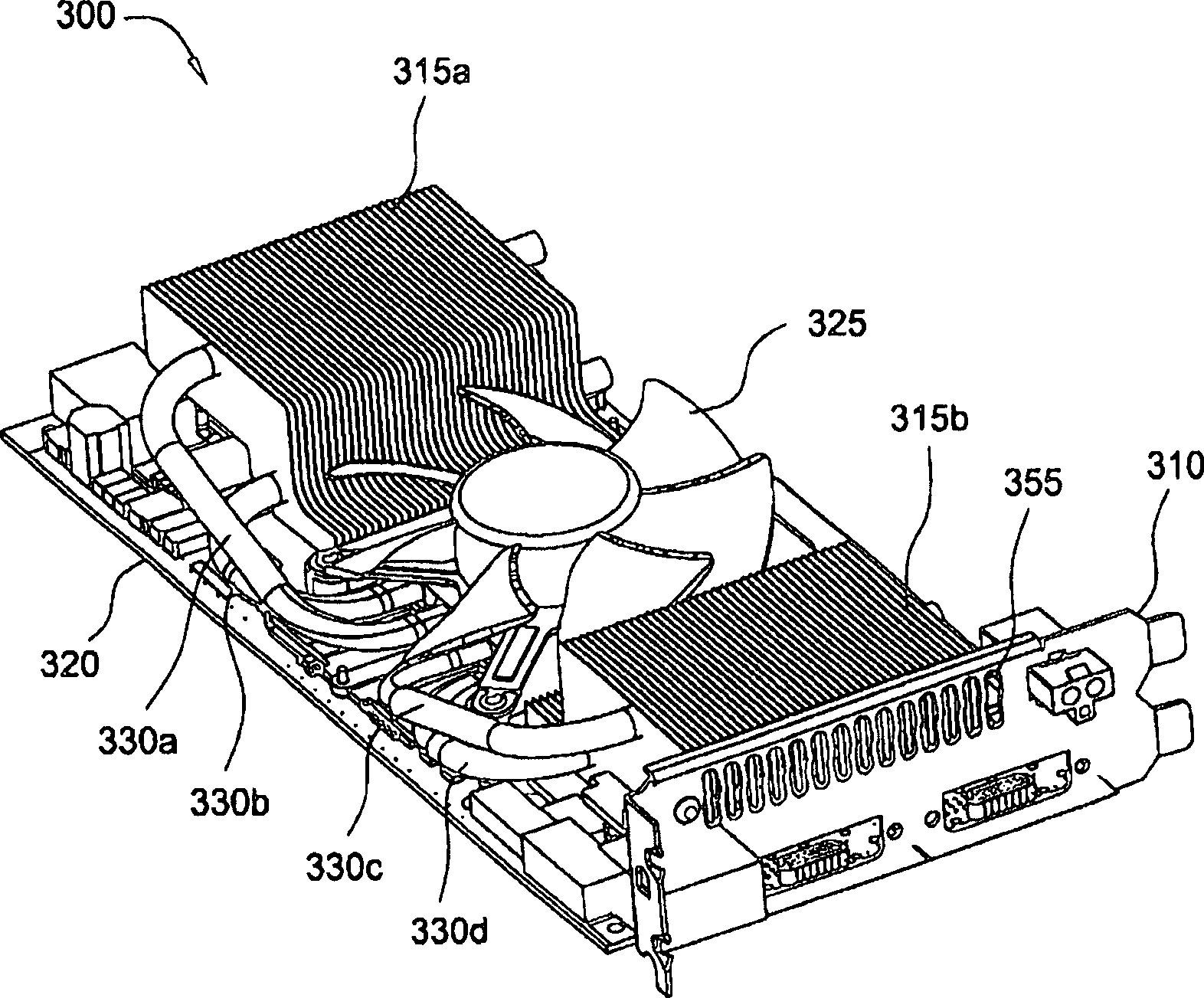

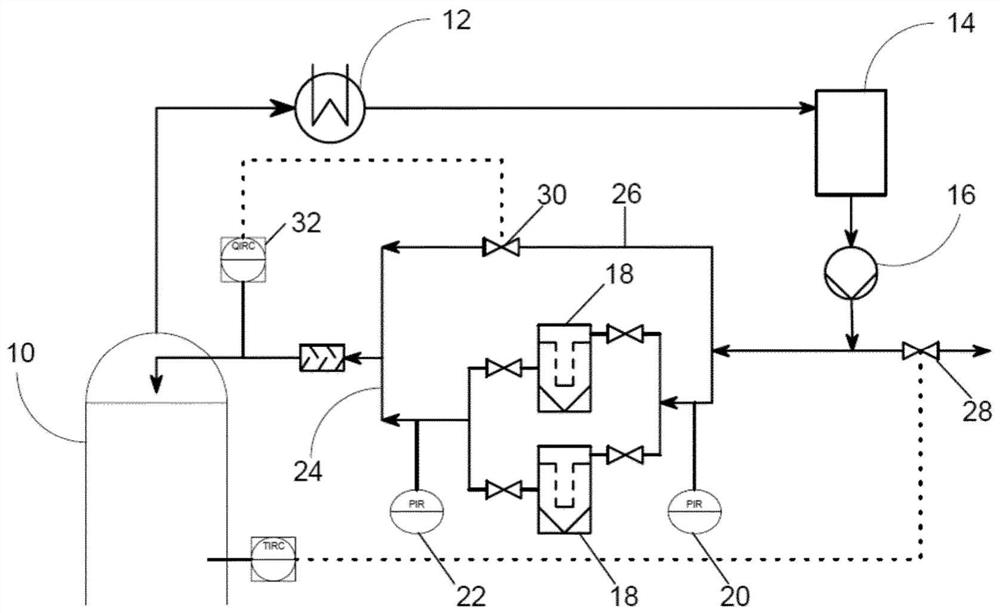

Cooling system for computer hardware

ActiveCN1818827AEvenly acrossIncrease the effective surface areaDigital data processing detailsSemiconductor/solid-state device detailsEngineeringForced-air

The present invention represents a significant advancement in the field of cooling systems for computer hardware. In one embodiment, a system for cooling a heat-generating electronic device is provided. The system is mountable to a first side of a circuit board. The system includes a first set of fins, a fan operable to force air through the first set of fins, and a first heat pipe to conduct heat from the heat-generating electronic device to the first set of fins. One advantage of the disclosed cooling system is that it more equally distributes heat across the fins and more equally distributes airflow across surfaces of the fins. Thus, the design increases the effective area of the fin surfaces used in for transferring heat from the heat-generating electronic device to the air, resulting in a more efficient cooling system.

Owner:NVIDIA CORP

Storing and processing method of rice

InactiveCN103053685AImprove freshnessIncrease elasticitySeed preservation by freezing/coolingRice dishesAgricultural engineering

The invention relates to a storing and processing method of rice and belongs to the technical field of crop processing. The process disclosed by the invention comprises the following steps: feeding into a warehouse: feeding wet rice into the warehouse; removing water: controlling the water content of the rice to 15-16% in a manner of warehouse ventilation; storing at low temperature: reducing the temperature of the warehouse to 18-25 DEG C to carry out low-temperature storage; and carrying out low-temperature and high-humidity processing. According to the process disclosed by the invention, the water content and the temperature of processing and storing the rice are controlled and the low-temperature and high-humidity processing is carried out at the water content and the temperature, so that the oxidation degree of fatty acid is low and the water absorbing speed in a process of immersing the rice to make rice is low; and the rice has the characteristics of small cracks in the water, good elasticity, good appearance and high freshness, and the rice has good edible quality, good mouth feel and good taste.

Owner:银尧明

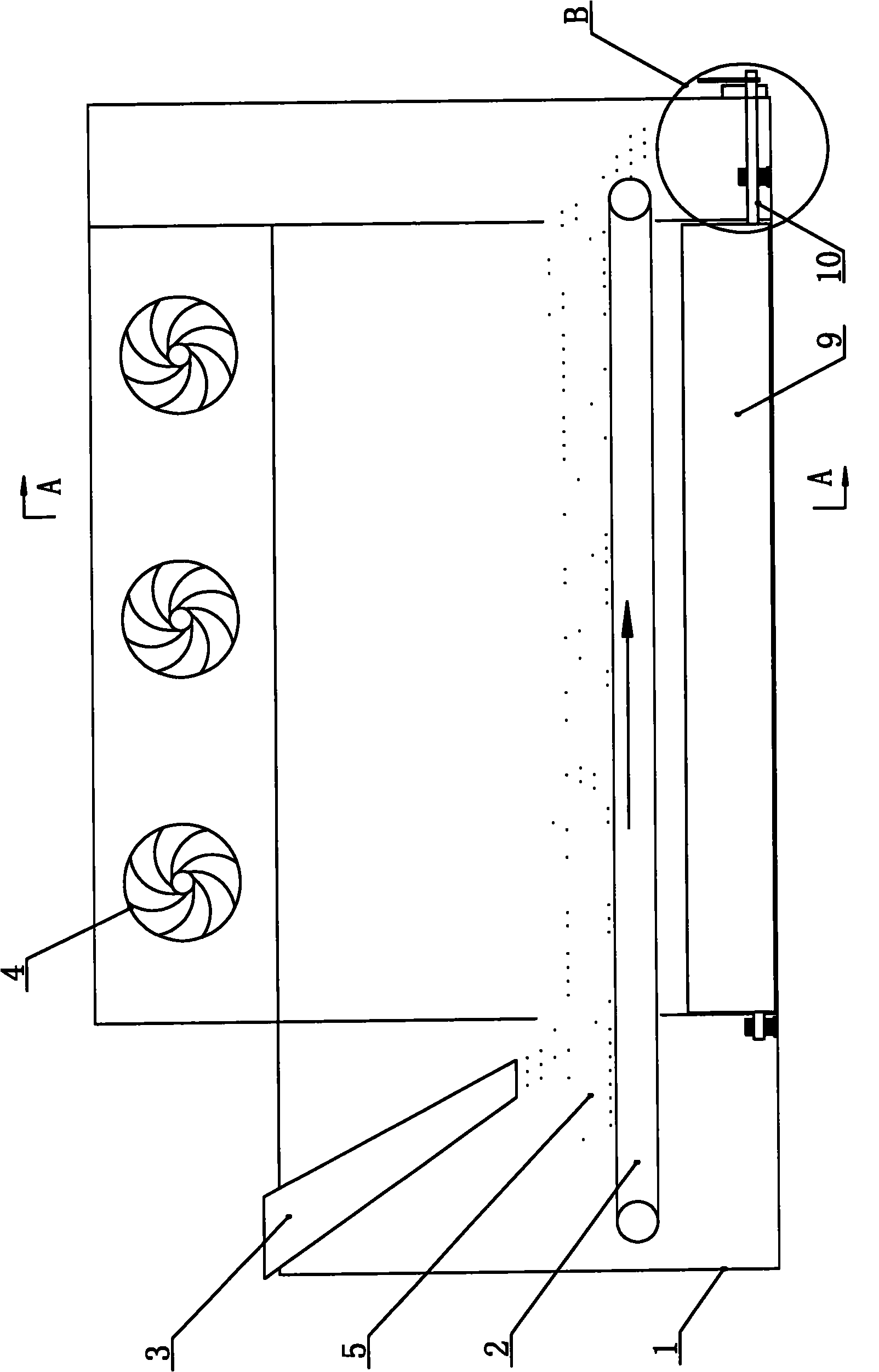

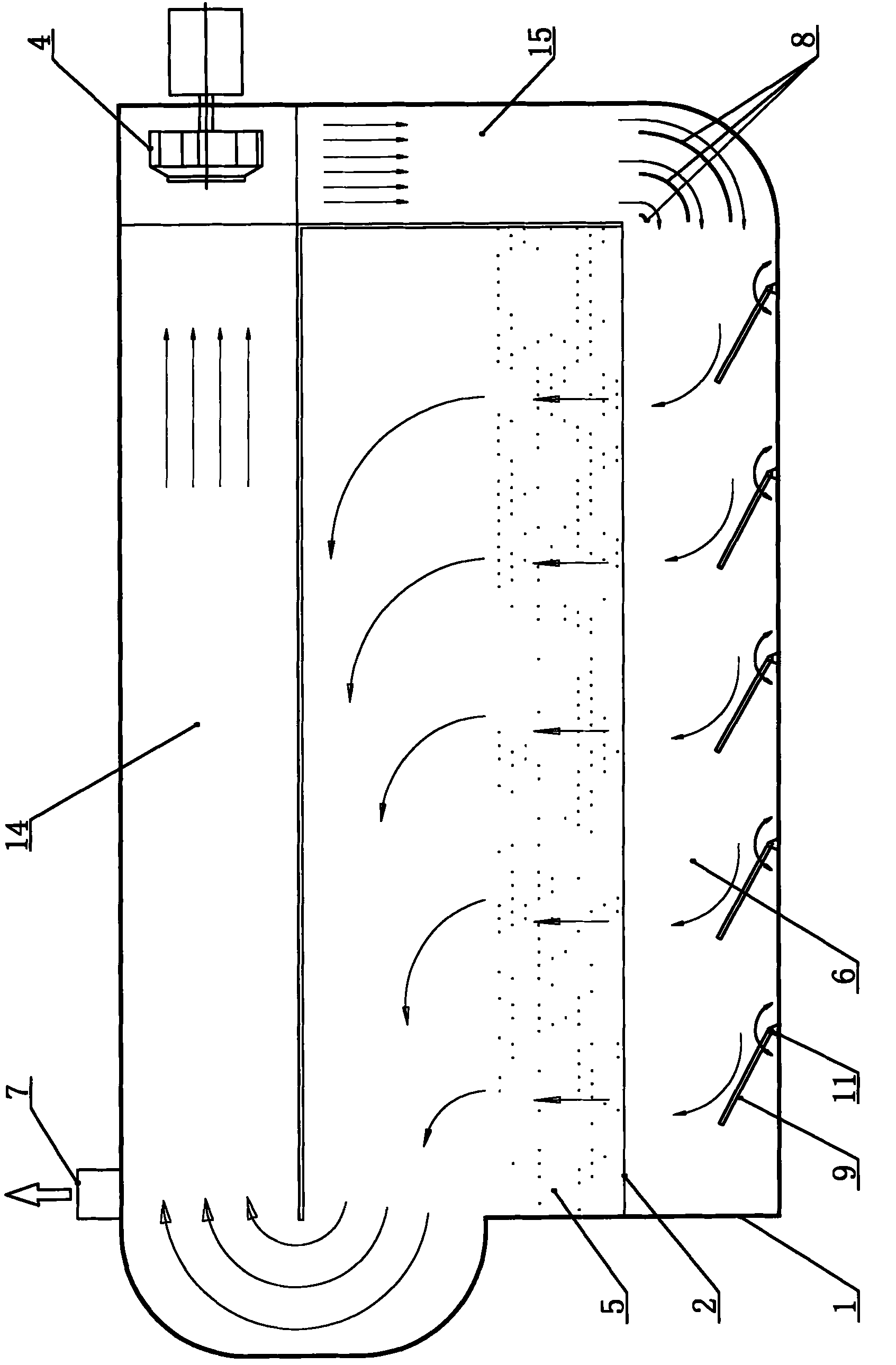

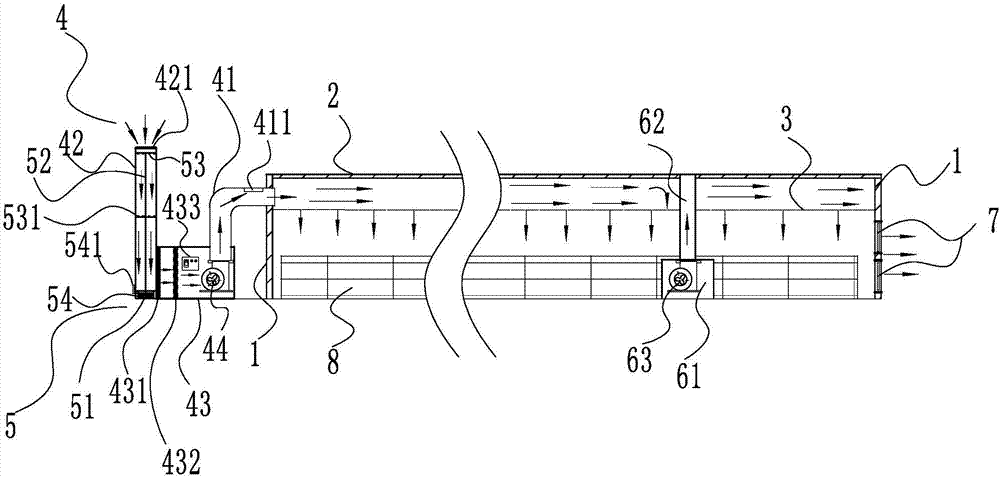

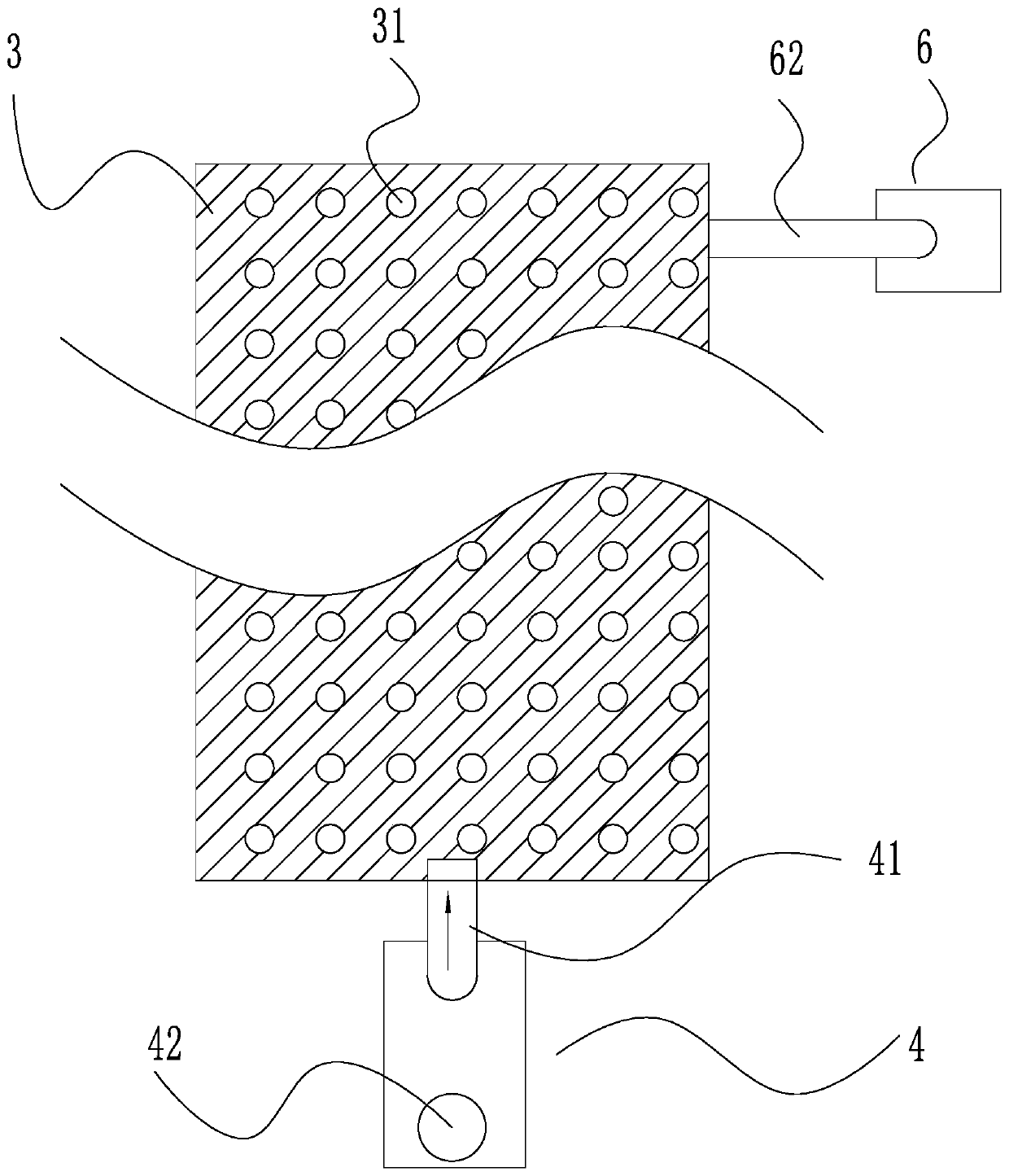

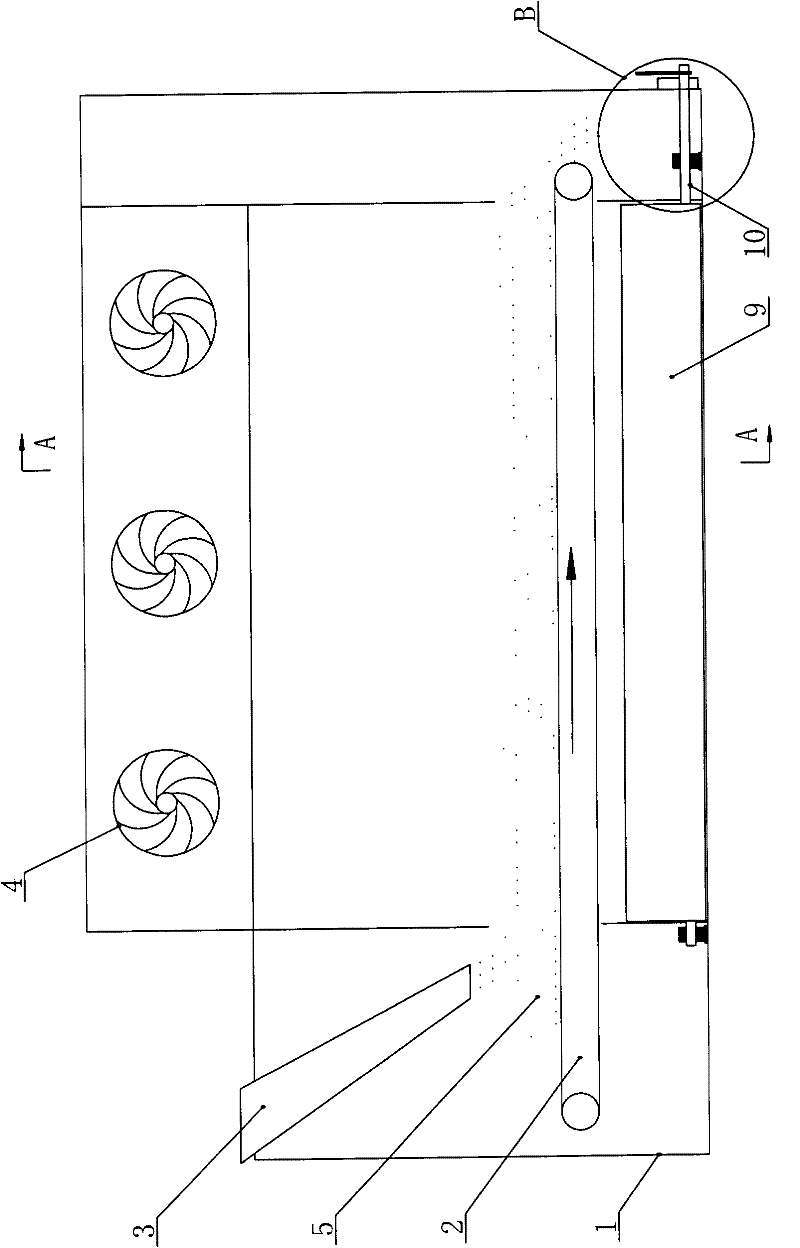

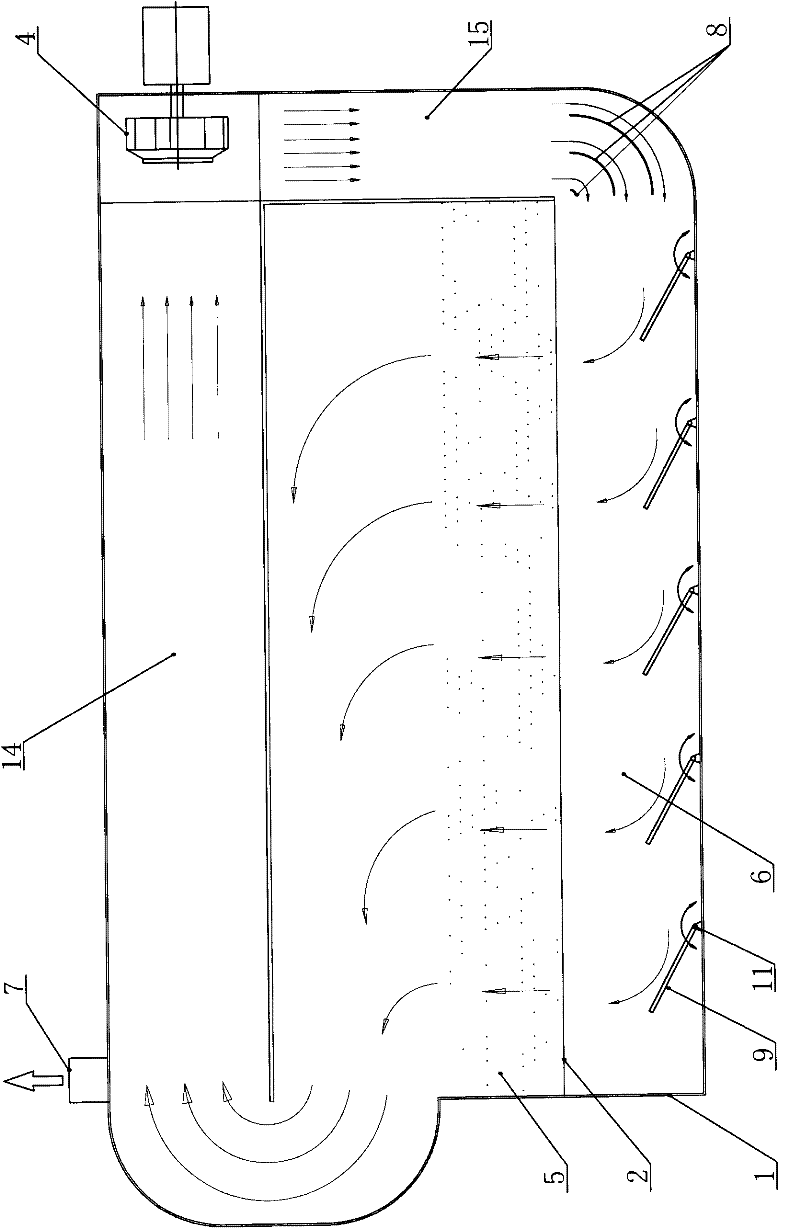

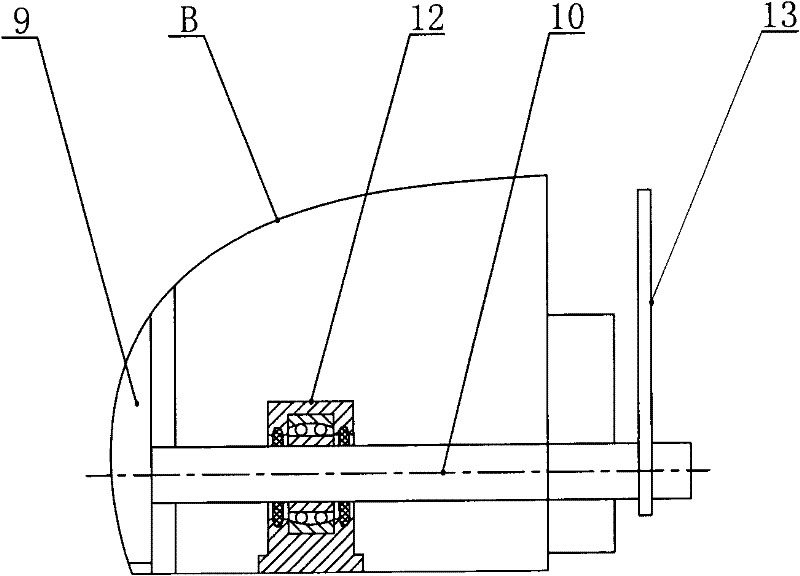

Belt type circulating dryer

InactiveCN102121783AImprove uniformityReduce angleDrying solid materials with heatDrying gas arrangementsAirflowEngineering

The invention discloses a belt type circulating dryer, which belongs to the technical field of feed processing machinery. A material layer is laid on a conveyor belt of the belt type circulating dryer. An air distribution chamber is formed below the conveyor belt. A hot air inlet of the air distribution chamber is positioned at one end of the width direction of the conveyor belt. An outlet air duct of a circulating fan is vertically downwards communicated with the hot air inlet of the air distribution chamber, and a suction mouth air duct of the circulating fan is communicated with an air duct above the material layer. A group of deflectors is arranged at a turning. The group of deflectors is arranged in the air distribution chamber, each deflector is extended along the length direction of the conveyor belt, and the deflectors are uniformly distributed along the width direction of the conveyor belt. Rotating shafts are arranged on each deflector respectively, and each rotating shaft is hinged to own rotating shaft pedestal respectively. Each rotating shaft pedestal is arranged on a bottom plate of the air distribution chamber. One end of the rotating shaft is extended out of a machine body, and an extended end is provided with an adjusting handle for adjusting an angle of the corresponding deflector. The belt type circulating dryer makes uniform a gas flow in a material, and ensures low gas flowing resistance and low energy consumption.

Owner:JIANGSU MUYANG GRP CO LTD

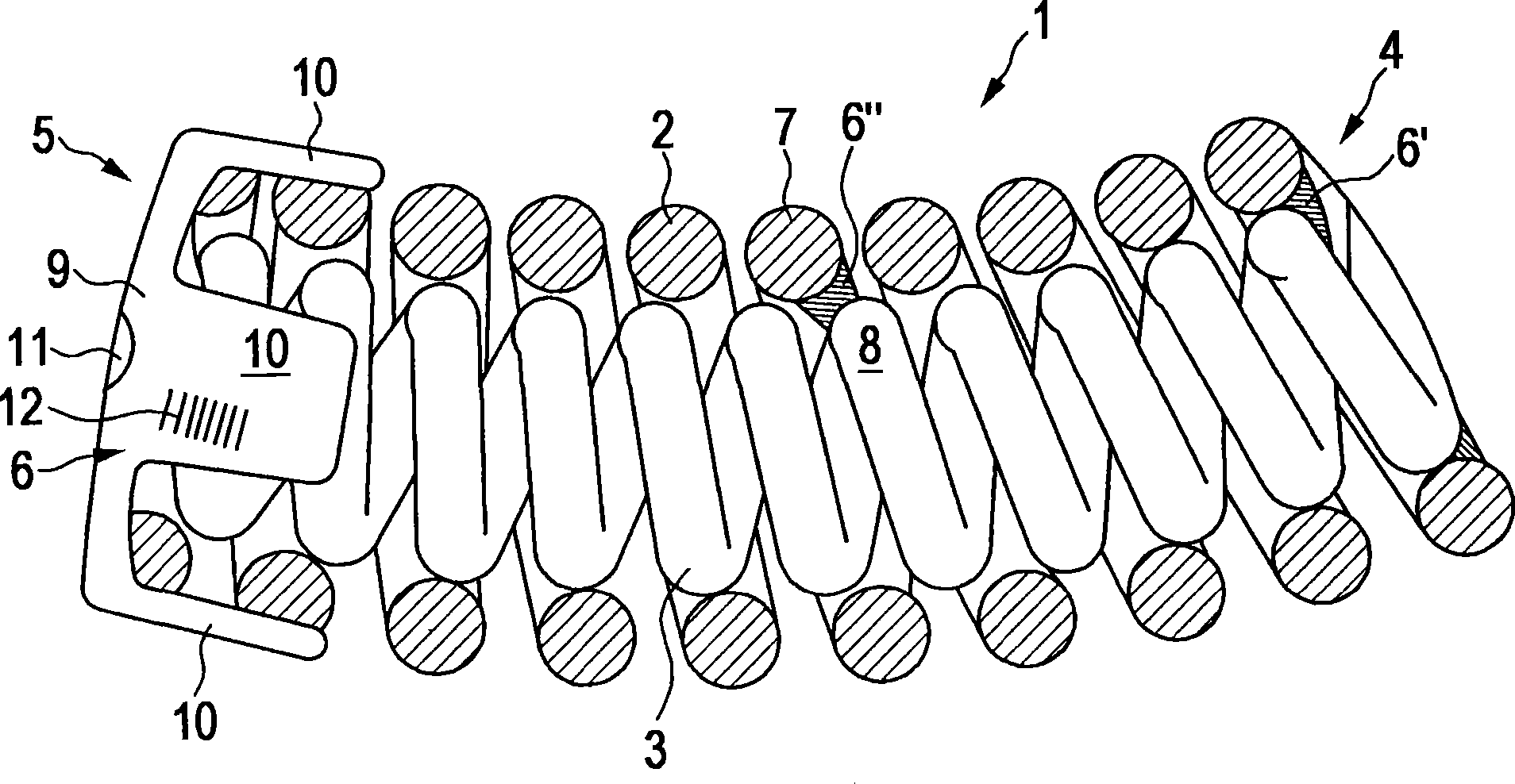

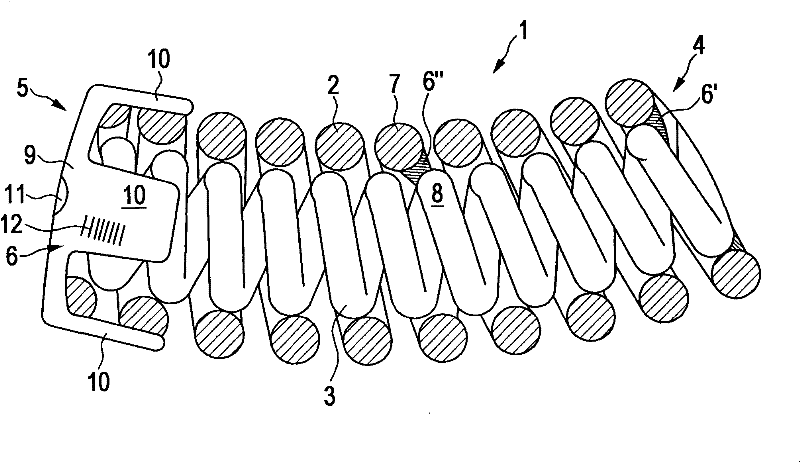

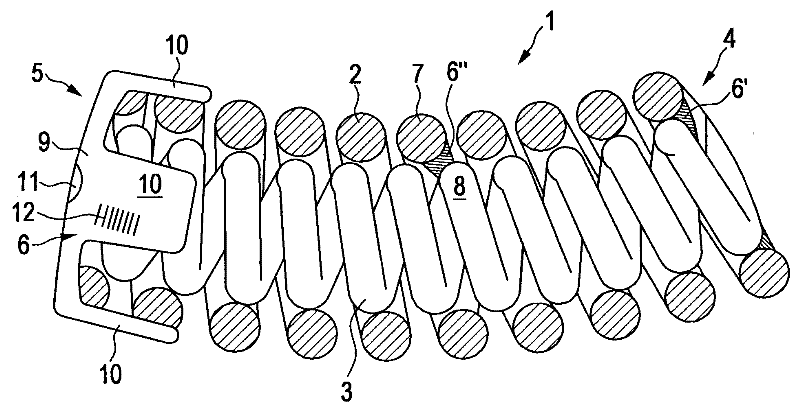

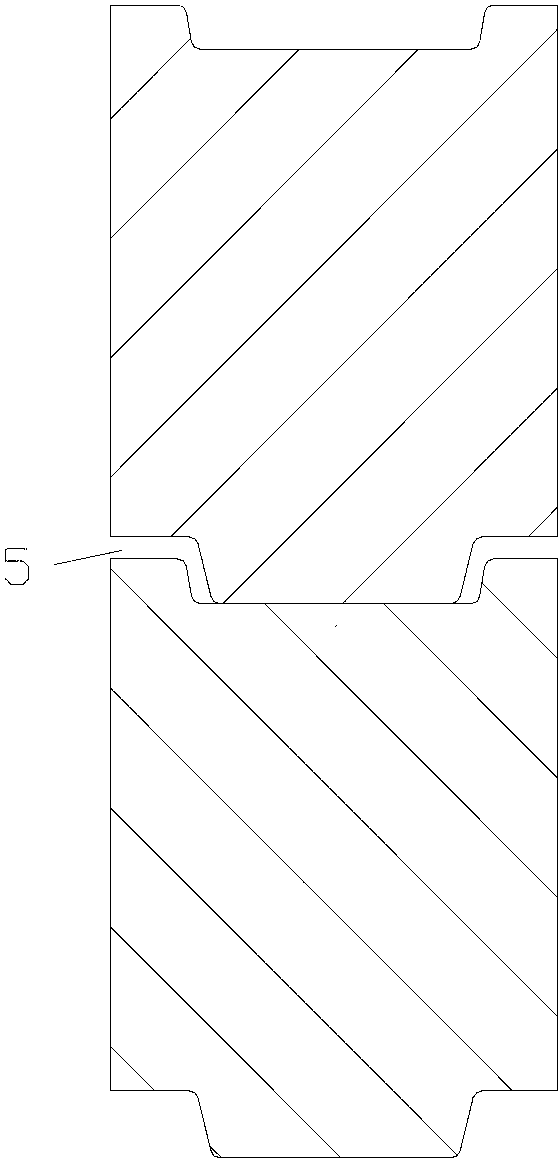

Torsional vibration damper

InactiveCN101463877ADoes not release large particlesPrevent axial displacementSpringsSprings/dampers manufactureCoil springTorsional vibration

The invention relates to a torsional vibration damper having an energy storage acted between an input member and an output member and composed of at least two coil springs nested to each other. The coil springs are secured against each other in a material locking manner, such as by a glued connection in order to prevent lost between the two members before an installation.

Owner:SCHAEFFLER TECH AG & CO KG

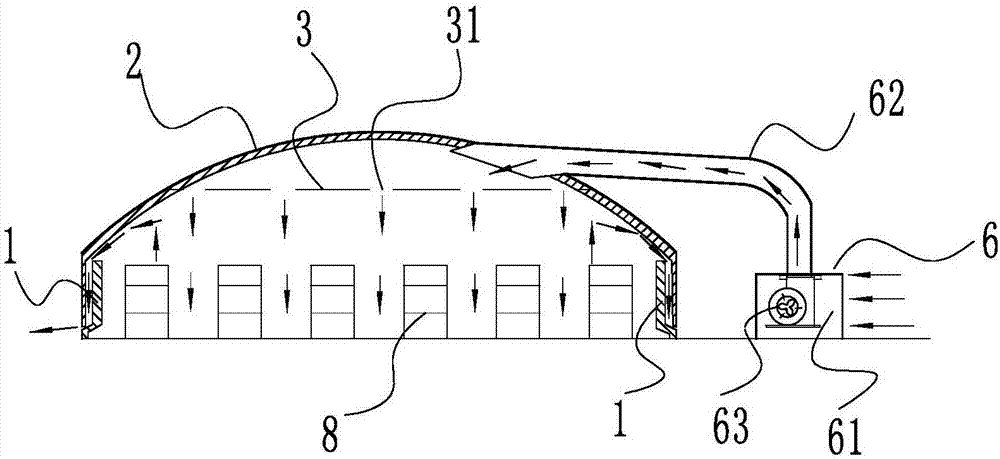

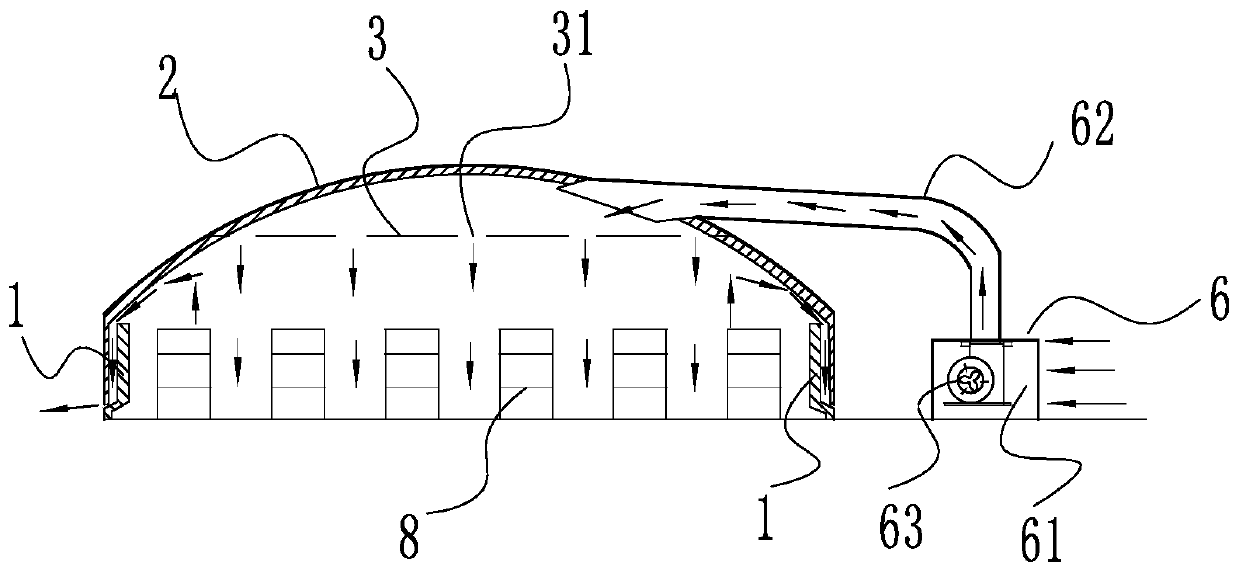

Positive ventilation henhouse

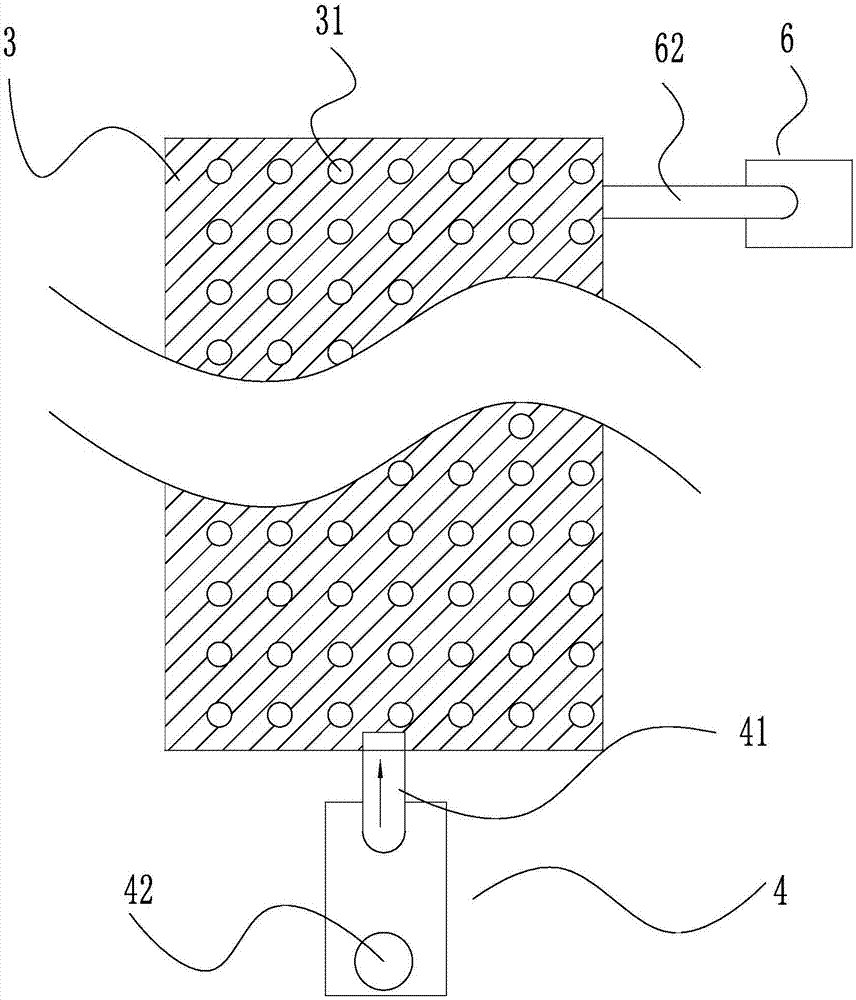

ActiveCN107278959AImprove air qualityEnvironmental complianceBird housingsAir quality indexFresh air

The invention discloses a positive ventilation henhouse. The positive ventilation henhouse comprises a henhouse body, and the henhouse body is composed of a support body and an arch roof. The positive ventilation henhouse is characterized in that the bottom of the roof is provided with a horizontal plastic film. The positive ventilation henhouse also comprises a fresh air device, which is provided with a first air outlet pipe, the orifice of the first air outlet pipe is mounted between the roof and the plastic film, and the plastic film is provided with a plurality of ventilation holes. According to the positive ventilation henhouse, fresh air is continuously conveyed inside the henhouse, and by processing the air, the air quality inside the henhouse can be effectively improved, so that the inside environment of the henhouse can well meet the requirements of chicken on healthy growth, and infection of virus diseases can be reduced.

Owner:INST OF S&T INFORMATION SHANDONG ACADEMY OFAGRI SCI

Torsional vibration damper

Owner:SCHAEFFLER TECH AG & CO KG

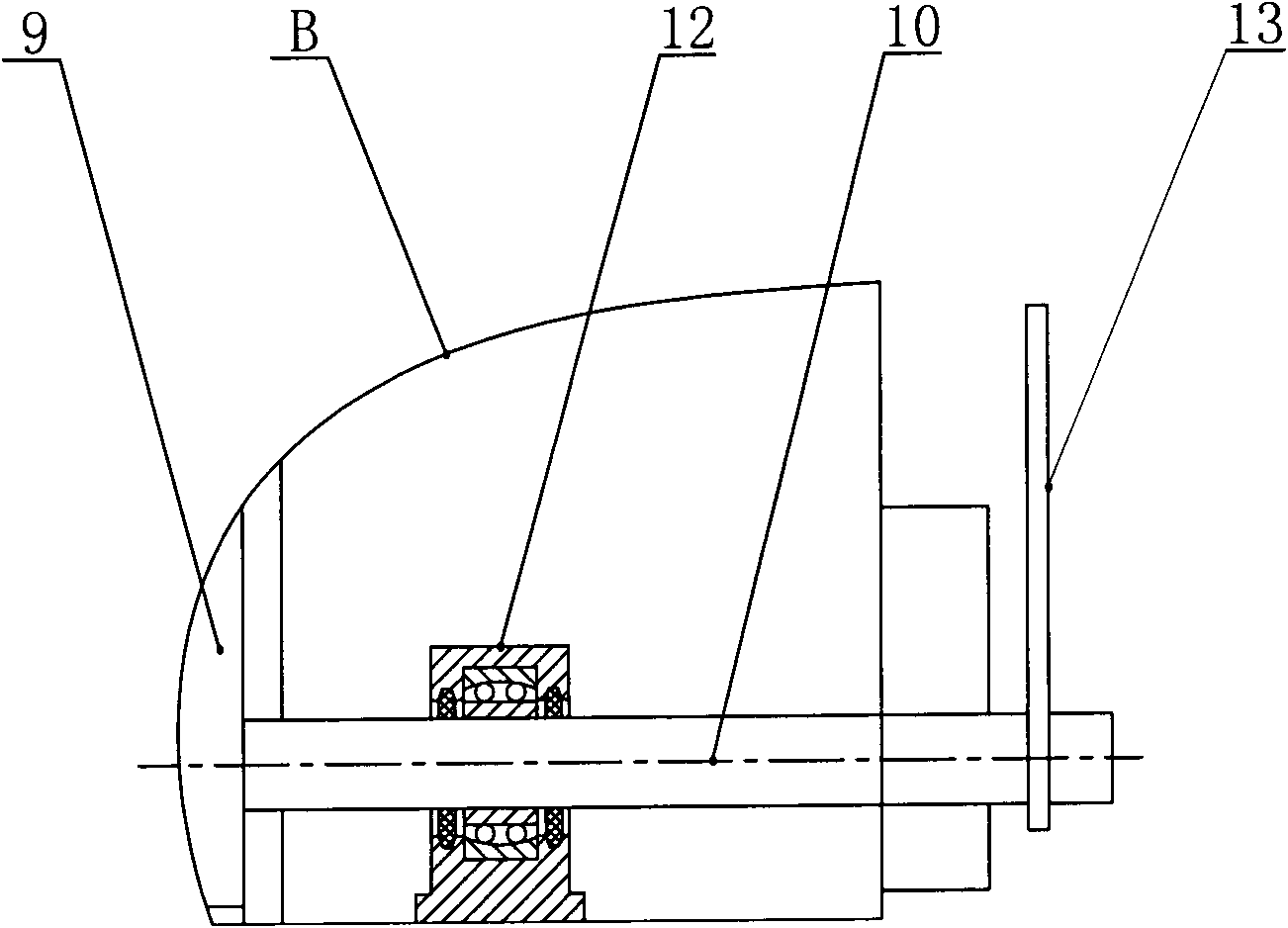

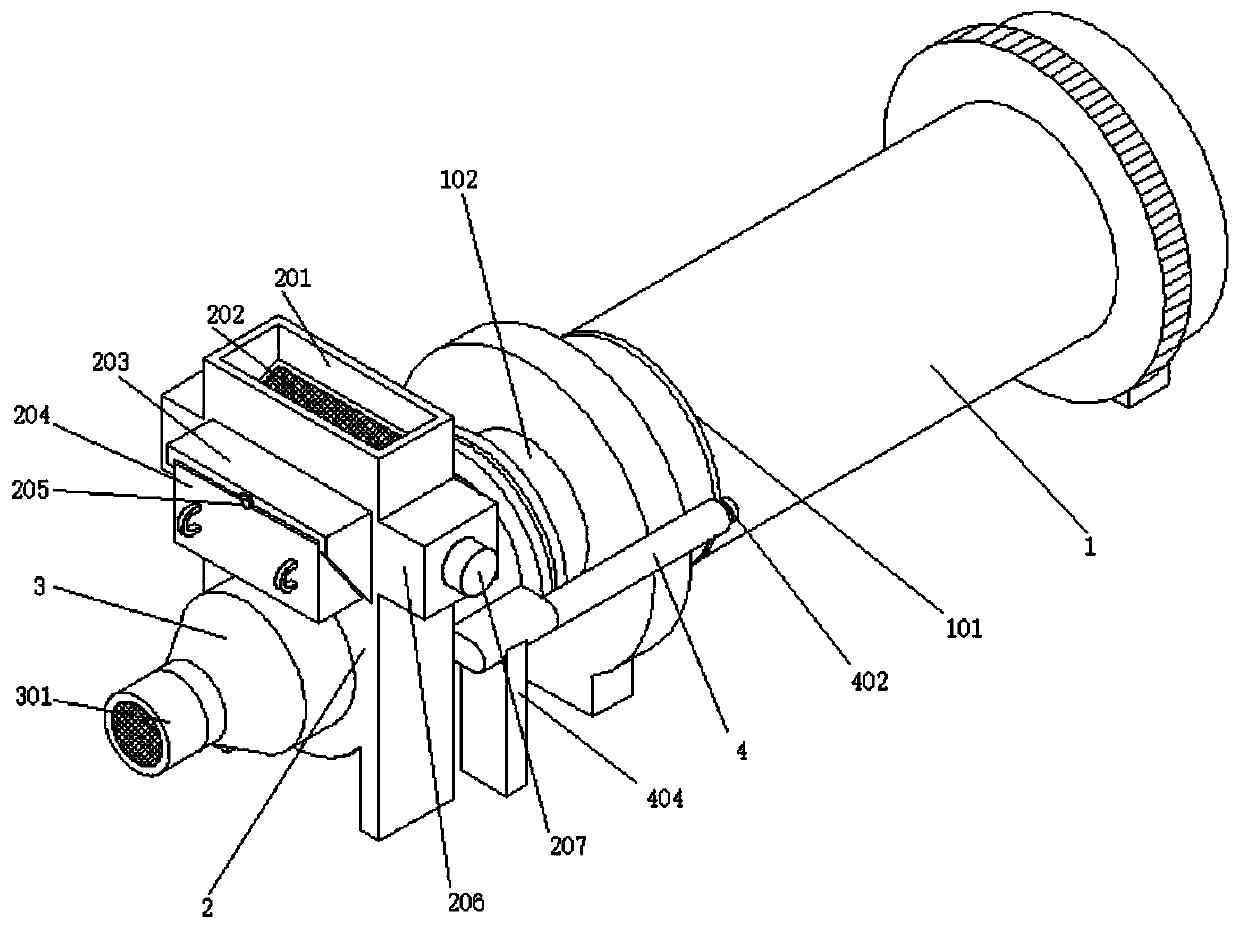

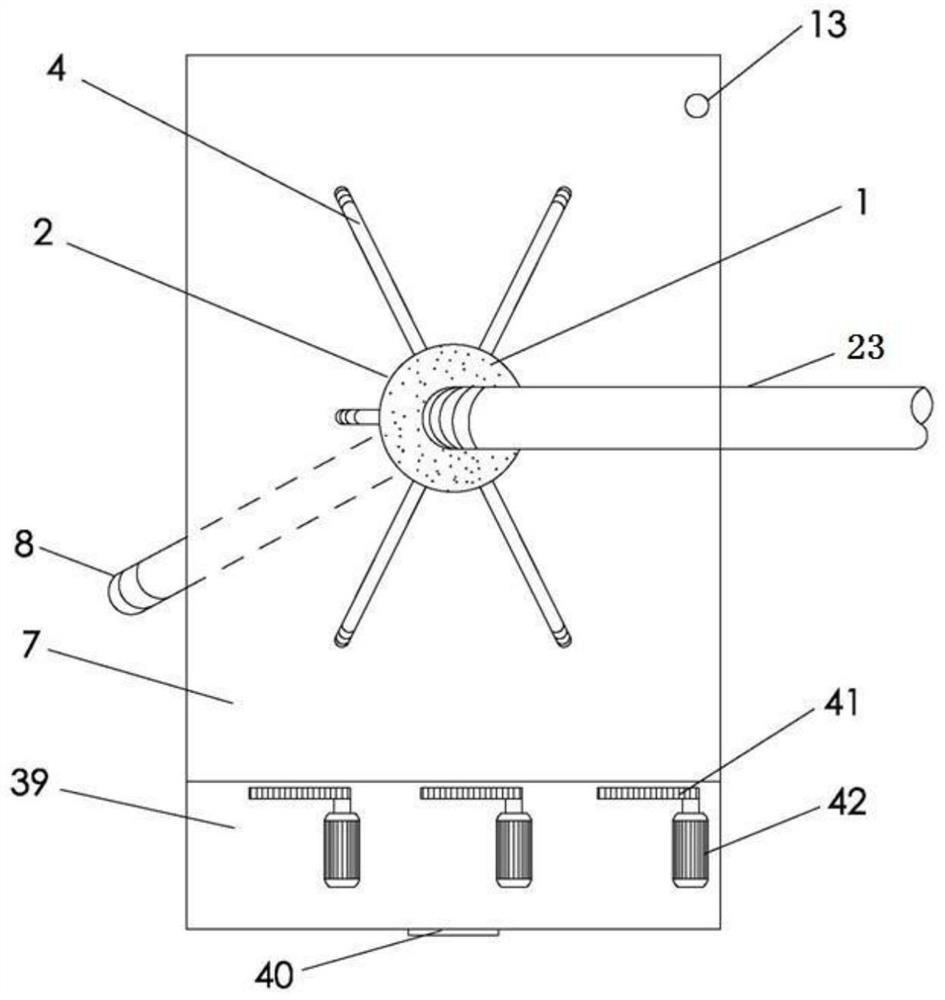

Ball mill feeding device

The invention discloses a ball mill feeding device and relates to the field of ball mills. The device comprises a ball mill, wherein a ball mill hatch is arranged at one side of the ball mill, a feeding mechanism is arranged at one side of the ball mill hatch, an air inlet mechanism is arranged at one side, away from the ball mill, of the feeding mechanism, a transmission structure is arranged atone end of the feeding mechanism, a rotating mechanism parallel to the transmission structure is arranged inside the feeding mechanism, and an outer gear is arranged at the outer side of the ball mill. According to the device, through a transmission shaft, the rotating mechanism, a transmission gear and an oblique scraping plate which are arranged, during operation of the ball mill, the outer gearat the outer side can drive a first gear to rotate, the first gear can drive the transmission shaft to rotate, a second gear is driven to rotate, the second gear drives the rotating mechanism to rotate through the transmission gear, a raw material is pushed to enter the ball mill hatch under the actions of the oblique scraping plate and gravity, the oblique scraping plate also drives the raw material to rotate, and therefore the raw material can rotationally enter the ball mill.

Owner:江西杜马机械制造有限公司

Fence for municipal engineering

ActiveCN113863776AImprove filtering effectAvoid cloggingDispersed particle filtrationPump componentsHandrailEnvironmental resource management

The invention relates to the field of municipal engineering, and discloses a fence for municipal engineering, which aims to solve the problem of low filtering efficiency caused by insufficient utilization of a filtering part when an existing fence for municipal engineering is used for filtering air. The fence comprises a fence frame, wherein a hollow rotating part is movably mounted on the inner wall of the fence frame. According to the fence, a first filtering part and the rotating part form a handrail of the fence, additionally, an air draft part exhausts air in a second filtering part, so that air around the fence frame enters the rotating part through an air inlet, the first filtering part and the second filtering part sequentially filter the air, and additionally, a driving mechanism drives the rotating part to rotate, so that the opening position of the air inlet moves relative to the first filtering part and the second filtering part, air uniformly penetrates through the side walls of the first filtering part and the second filtering part, the first filtering part and the second filtering part are fully utilized, and the air filtering effect is improved.

Owner:浙江嘉栖建设有限公司

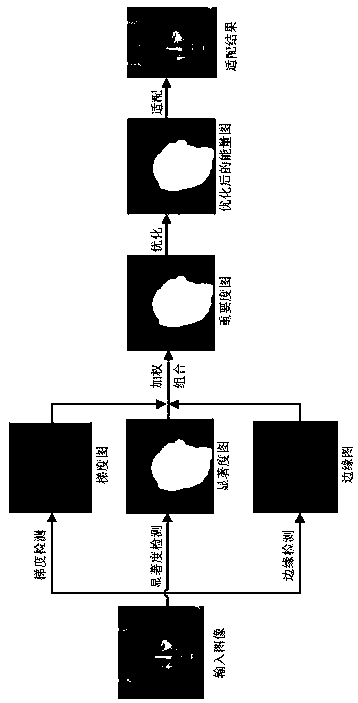

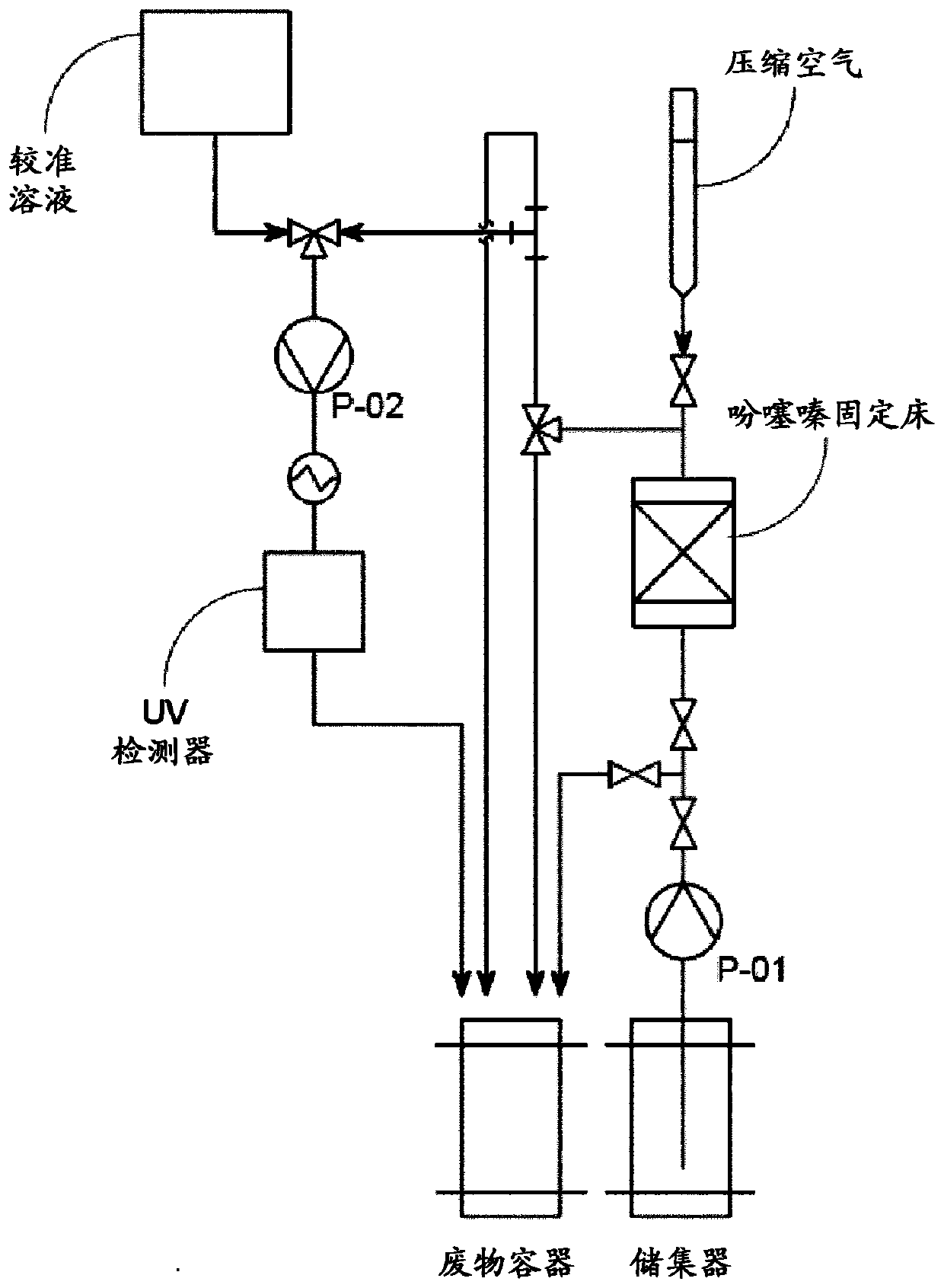

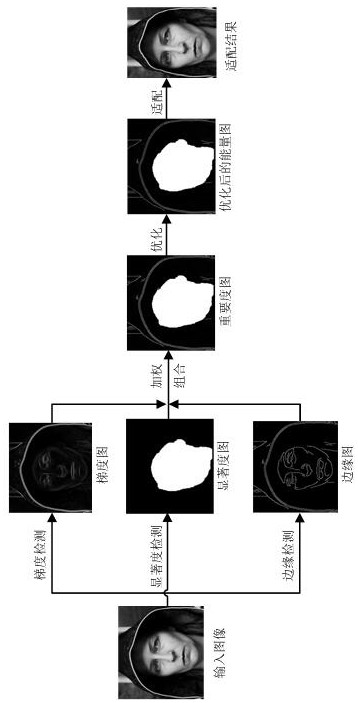

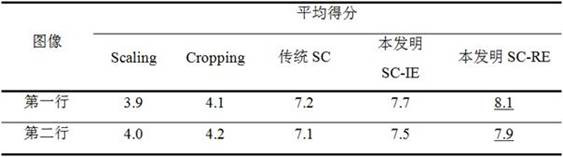

Image adaptation method based on edge vision protection

ActiveCN110853084AReduce distortionReduce interruptionsImage enhancementImage analysisPattern recognitionEngineering

The invention discloses an image adaptation method based on edge visual protection. The method comprises the following steps: S1, calculating an importance degree graph: calculating a weighted importance degree graph according to a gradient graph, a saliency degree graph and an edge line; S2, optimizing the energy diagram: taking the importance diagram as a basic energy diagram, and optimizing theenergy diagram by utilizing the visual characteristics of the inclination degree and the bending degree of the lines on the basis of the importance diagram; and S3, realizing line cutting adaptation:performing forward line cutting operation according to the optimized energy diagram to realize image adaptation. On the premise of ensuring the display effect of the significant object, the continuity and fluency of the edge and the contour are improved by keeping the shape of the edge contour of the non-significant area.

Owner:石家庄邮电职业技术学院

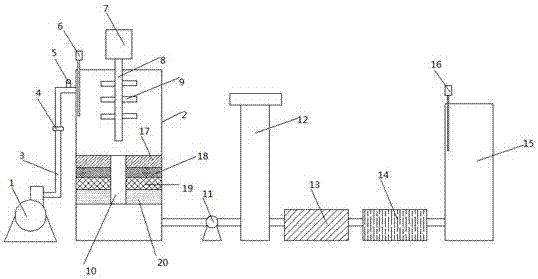

PLC (Programmable Logic Controller) controlled denitration device

InactiveCN109331656AEvenly acrossImprove responseGas treatmentDispersed particle separationProgrammable logic controllerNitric oxide

The invention discloses a PLC (Programmable Logic Controller) controlled denitration device which comprises a device main body, an ammonia gas tank and a catalyst plate, wherein a smoke inlet tube isarranged on one side of the device main body; one end of the smoke inlet tube is connected with the bottom of a guide plate inside the device main body; and a plurality of smoke outlets are formed inthe upper surface of the guide plate. When the denitration device is used, the guide plate is arranged at an end part of the smoke inlet tube, a plurality of the smoke outlets are formed in the uppersurface of the guide plate, a mixed gas of smoke and ammonia gases can be uniform, the mixed gas can uniformly penetrate through a catalyst layer on a filtering plate, and then the reaction effect canbe improved; a rotating rod is arranged on the catalyst plate, one end of the rotating rod is connected with a motor, the rotating rod is sleeved by a sleeve ring, the sleeve ring is connected with apush plate through a connecting rod, the push plate is pushed on the catalyst layer through the rotating rod, the catalyst layer is uniform, the smoke can uniformly penetrate through the catalyst layer, nitric oxides in the smoke can be sufficiently reacted, and the reaction efficiency can be improved.

Owner:西安安迈工业自动化技术有限公司

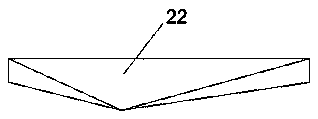

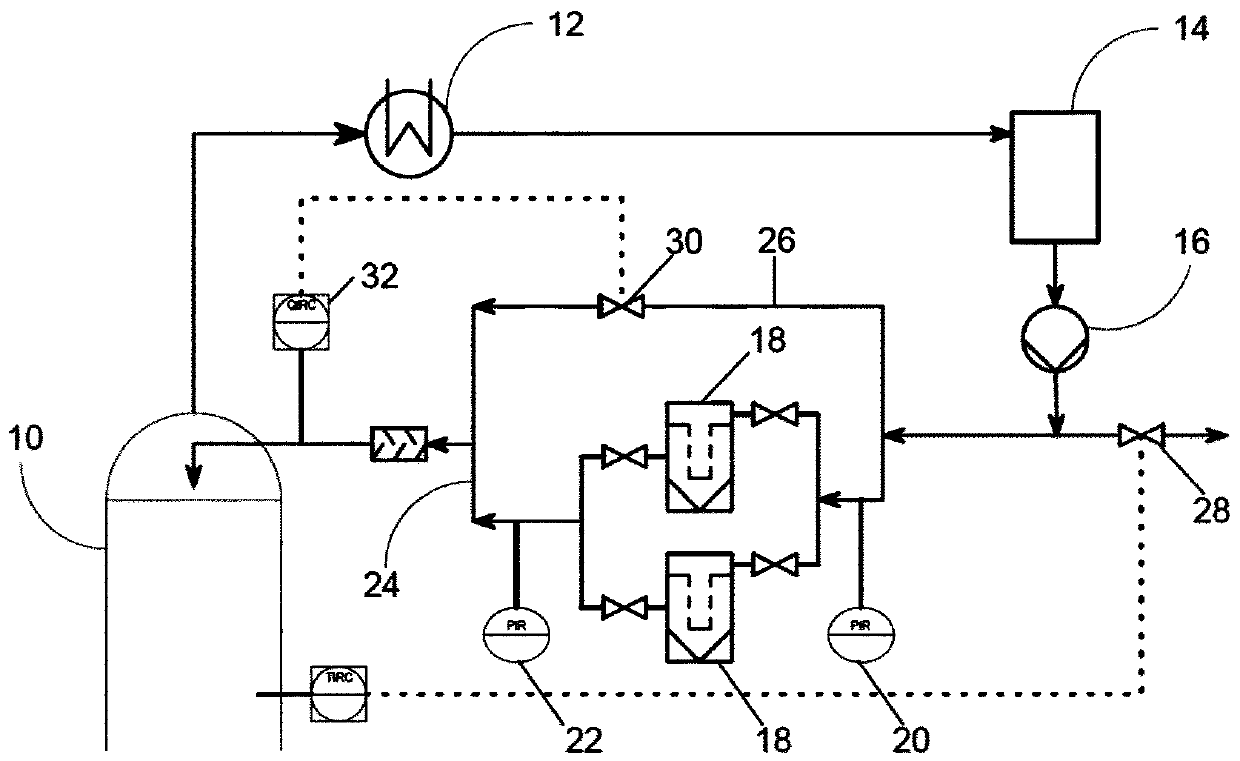

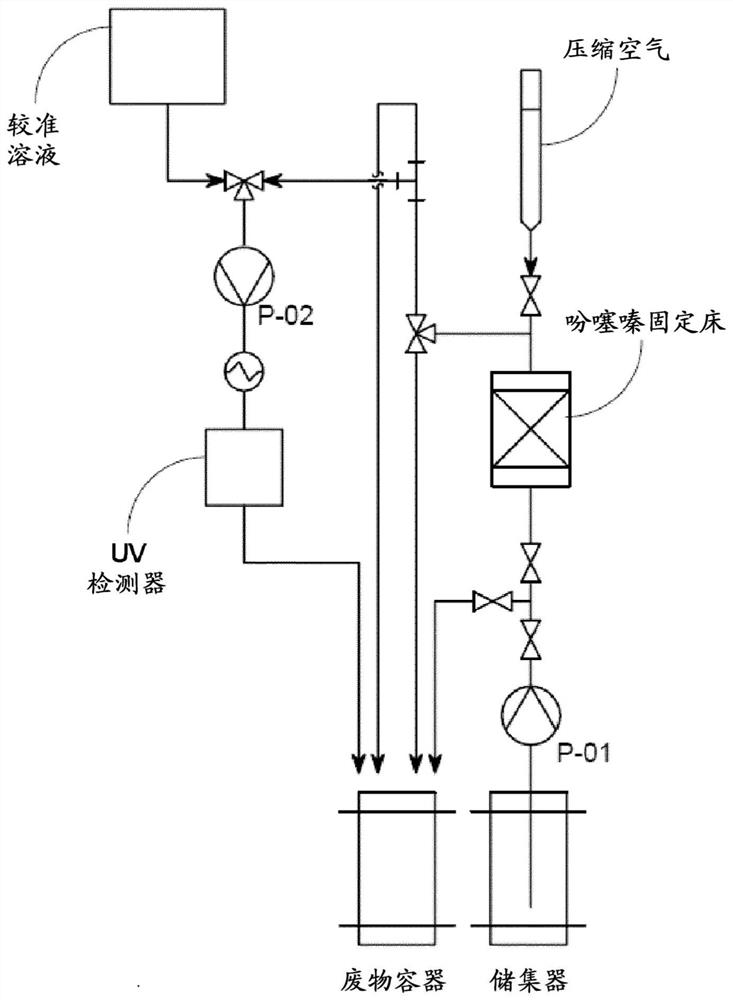

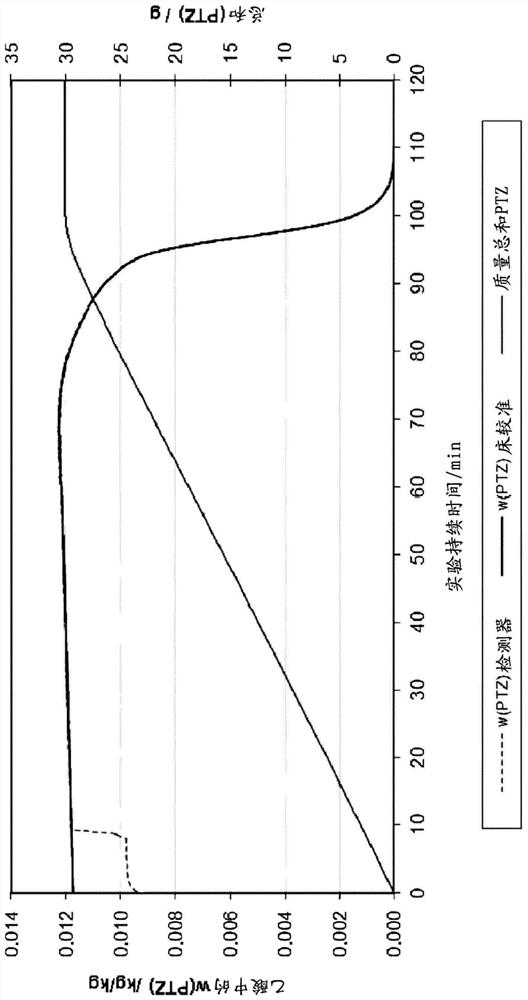

Process for continuous dissolution of a solid in a reaction medium

ActiveCN111201079AImprove solubilitySufficient concentration to dissolveOrganic compound preparationDissolving systemsPhysical chemistryFixed bed

Process for continuous dissolution of a solid in a reaction medium comprising the steps of: (a) providing a liquid by withdrawal of a portion of the reaction medium from a first reaction vessel; (b) contacting the liquid provided in step a) with the solid in a second reaction vessel to form a solution of the solid, wherein the solid in the second reaction vessel is present in the form of a fixed bed which is traversed by the liquid; and (c) recycling the solution formed in step b) into the first reaction vessel.

Owner:EVONIK OPERATIONS GMBH

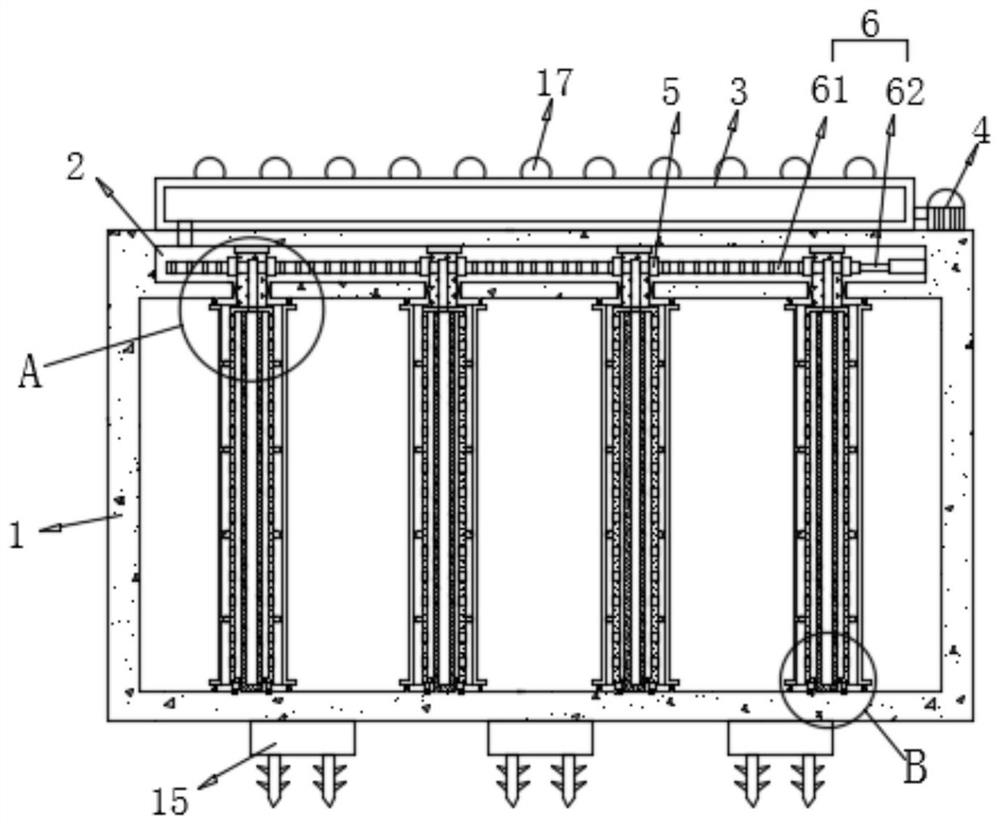

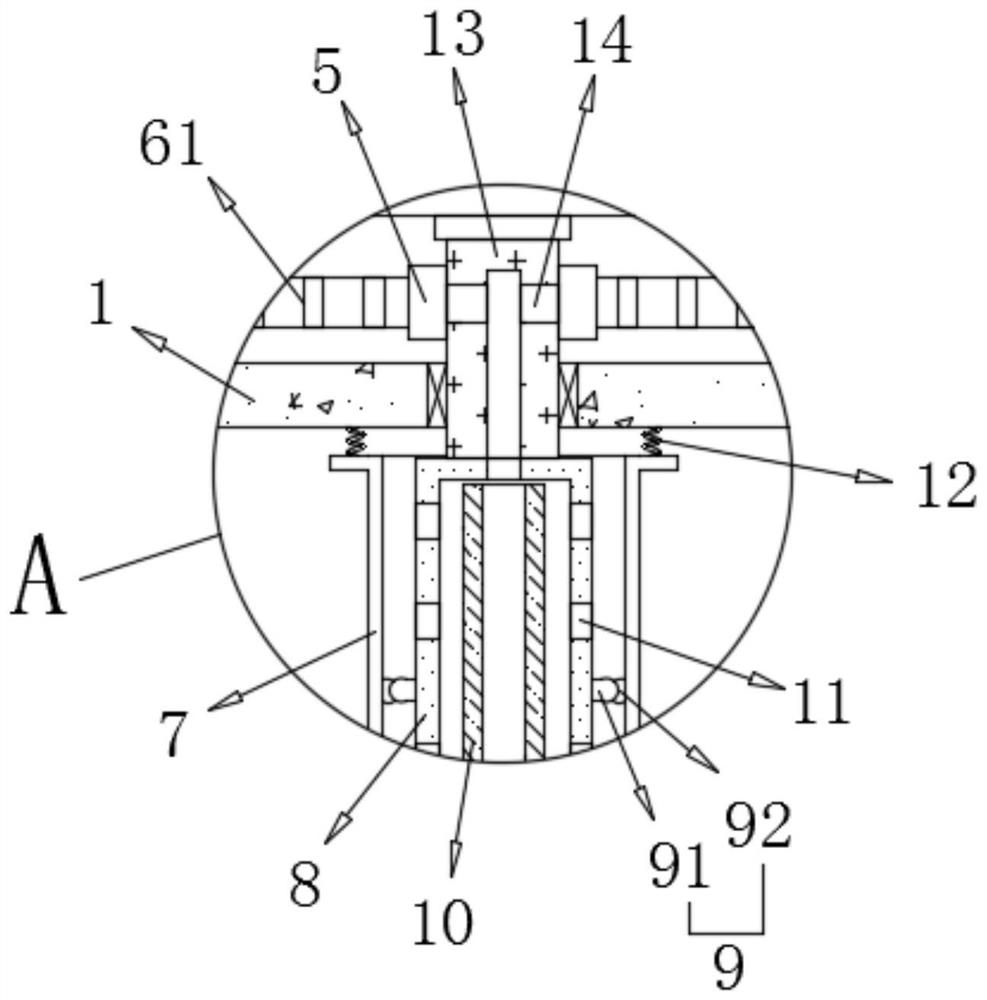

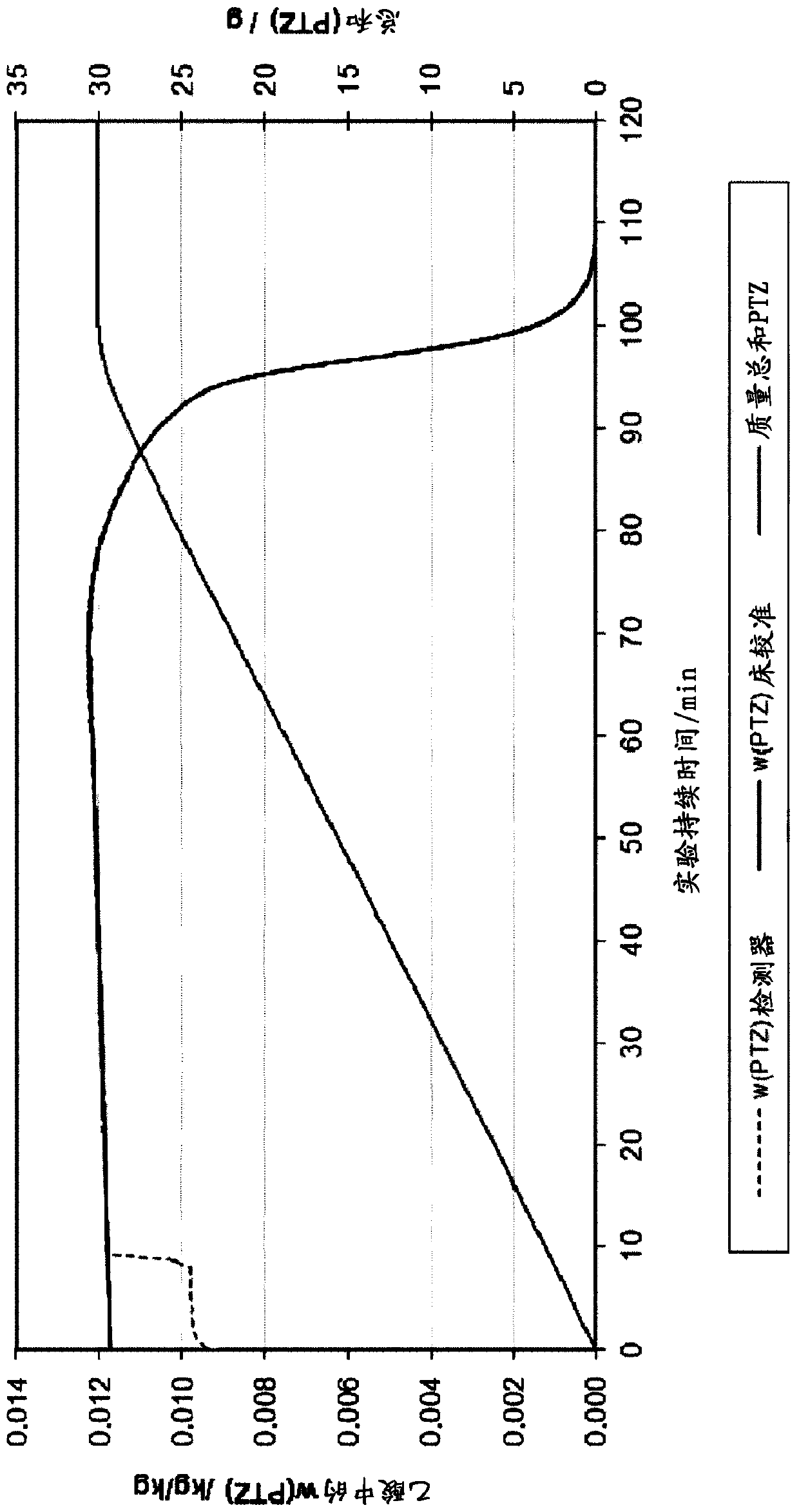

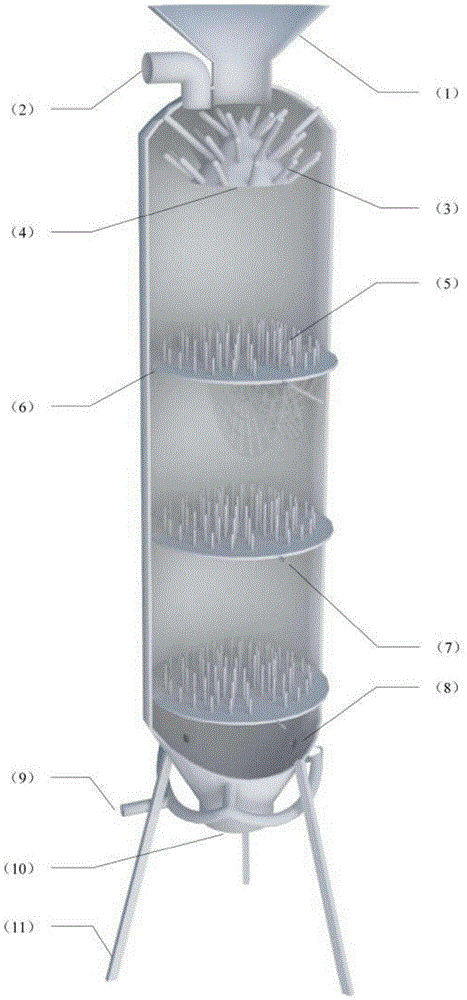

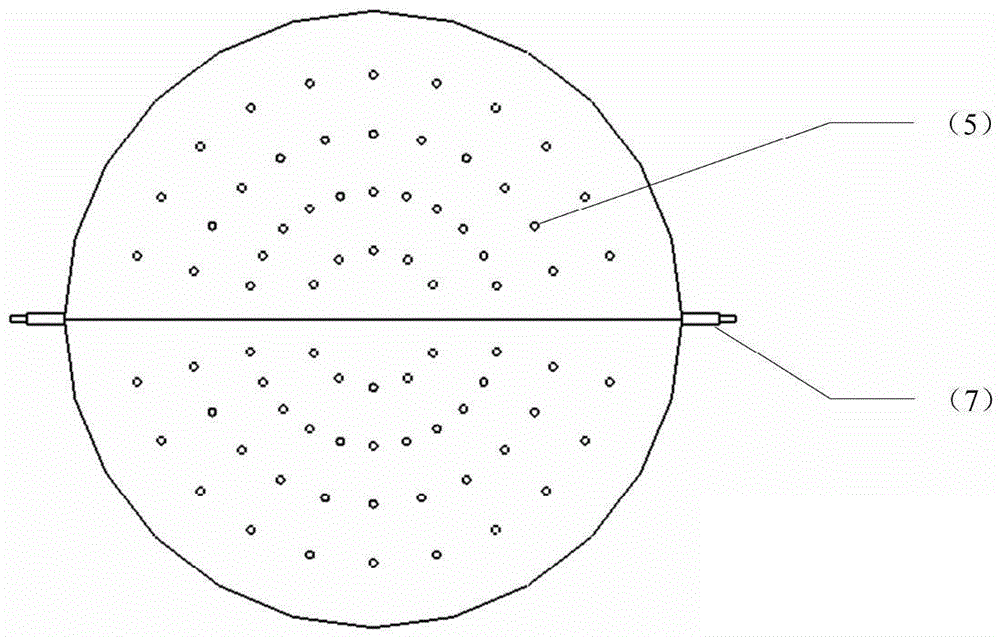

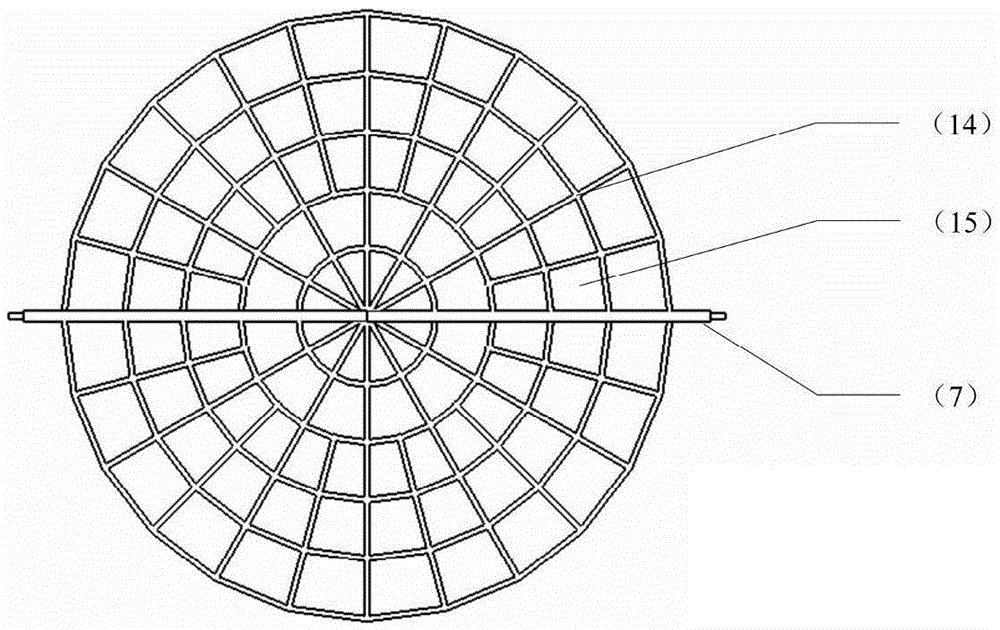

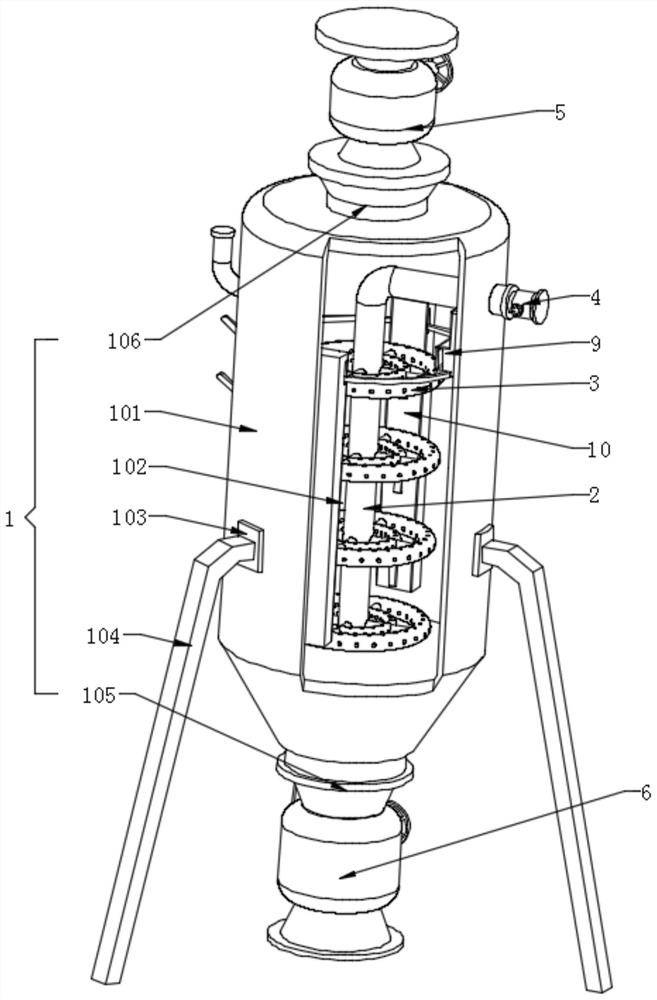

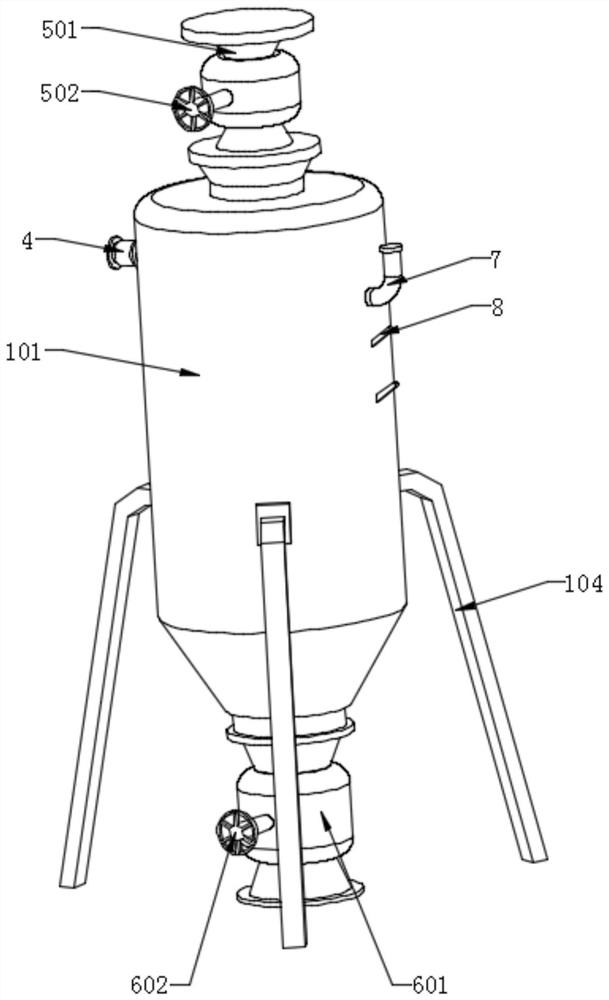

Dry-method ozone pretreatment pretreater capable of increasing straw enzymolysis saccharification ratio and method

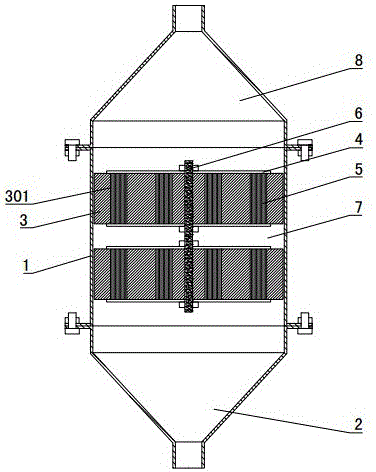

ActiveCN105624022APrevent loss of straw polysaccharide componentsImproving the efficiency of straw enzymatic hydrolysis and saccharificationBioreactor/fermenter combinationsBiological substance pretreatmentsSieveConical surface

The invention relates to a dry-method ozone pretreatment pretreater capable of increasing the straw enzymolysis saccharification ratio. The dry-method ozone pretreatment pretreater comprises a vertically arranged pretreater body, a feed hopper located on the top of the pretreater body and a discharge port formed in the bottom of the pretreater body; the feed hopper is located in the center of the pretrater top, and a diffuser is arranged under the portion beside the feed hopper in the direction perpendicular to the pretreater body; the diffuser is shaped like a circular conical surface, the vertex of the circular conical surface vertically upwards points to the center of the feed hopper, and rod-like protrusions which are perpendicular to the circular conical surface bus direction are distributed on the circular conical surface in a staggered mode; a plurality of sieve plates perpendicular to the direction of the pretreater body are arranged in the middle of the pretreater body; the sieve plates are each shaped like a mesh, and the rod-like protrusions with different heights are evenly distributed on the sieve plates and are perpendicular to the surfaces of the sieve plates. The dry-method ozone pretreatment pretreater facilitates pretreatment of semi-continuous, automatic and intelligent operation; lignin of straw subjected to ozone treatment is removed, the biodegradation rate is obviously increased, sundry bacteria and pests are killed, the storage property and fermenting property of the product are improved.

Owner:JIANGNAN UNIV

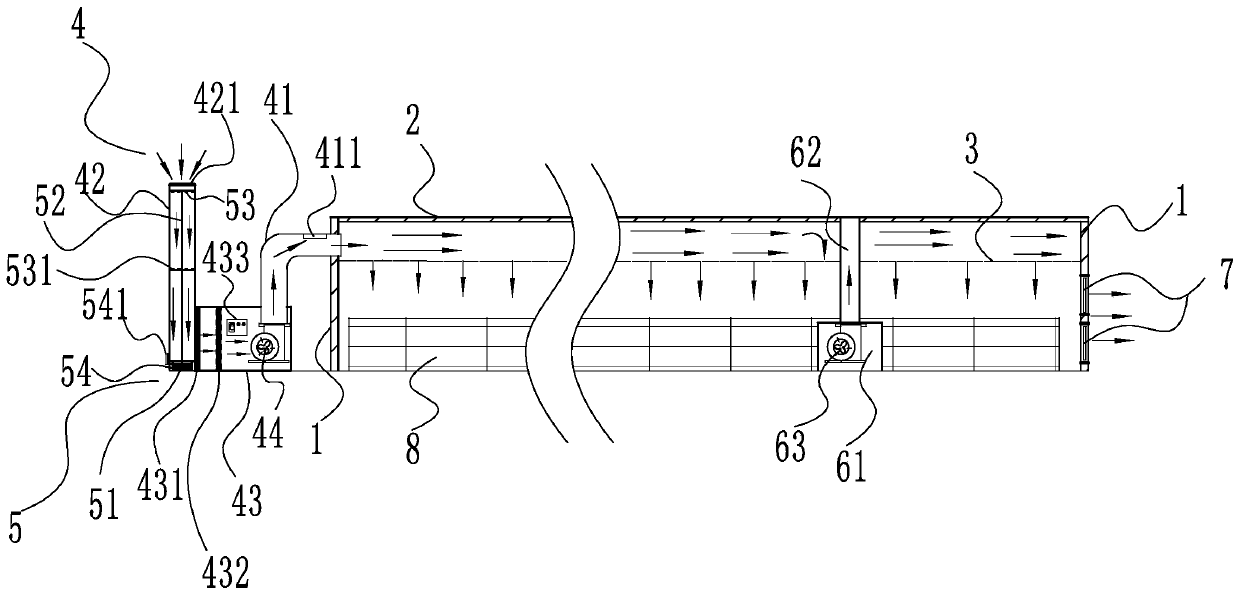

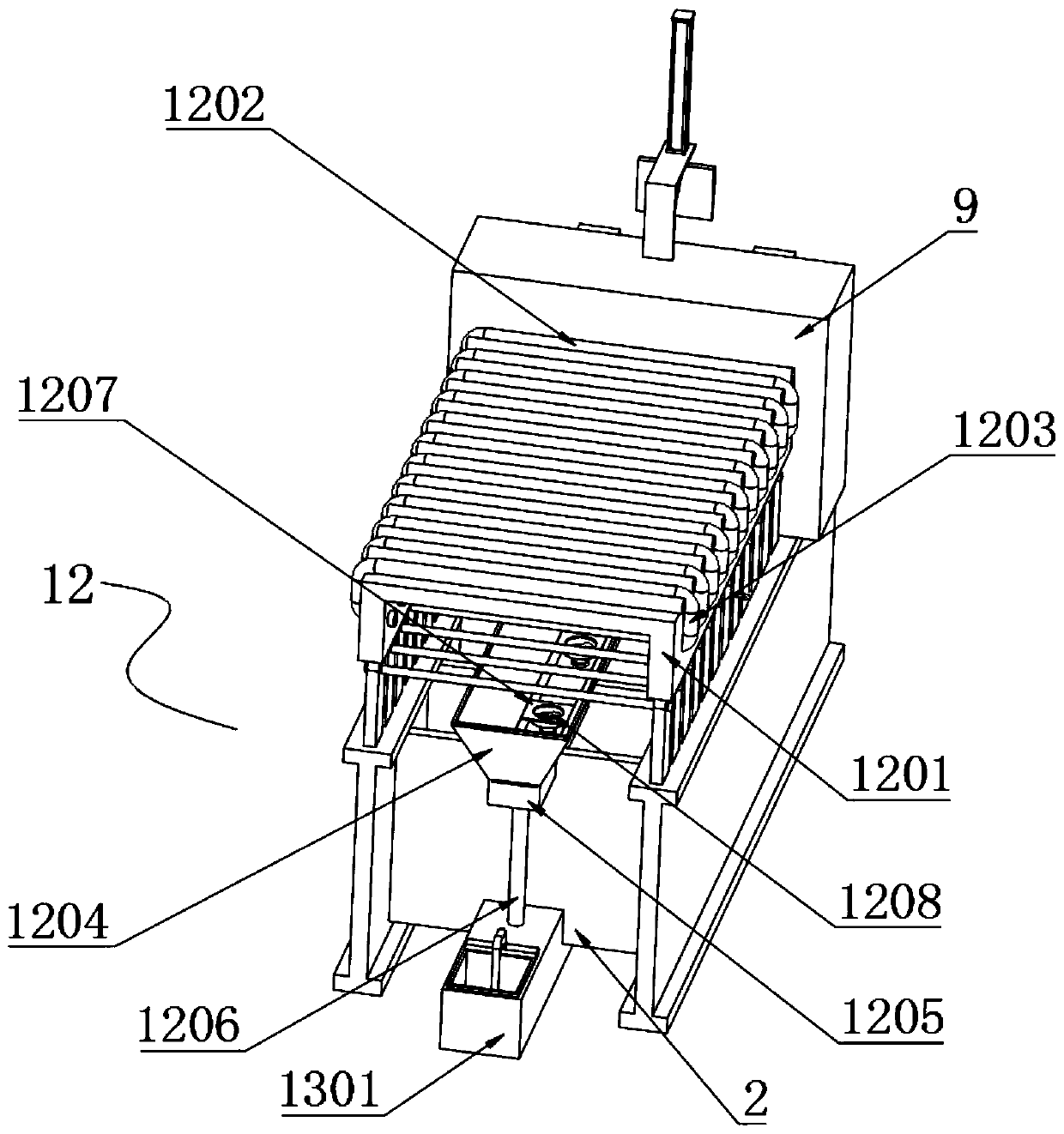

Drying device and split type power distribution cabinet with same

PendingCN114471091AStable and continuous dehumidificationContinuous dehumidificationDispersed particle separationSubstation/switching arrangement casingsThermodynamicsElectric power equipment

The invention relates to the field of electrical equipment, in particular to a drying device which comprises a body arranged between an area to be dehumidified and the atmosphere, a dehumidification part, a drying part, a drainage part and a material exchange unit are arranged in the body, the dehumidification part and the drying part are filled with drying agents, and the material exchange unit is used for exchanging filler in the dehumidification part and the drying part. The dehumidification part and the drying part are arranged in the body, the drainage part is arranged between the dehumidification part and the drying part, the dehumidification part, the drainage part and the drying part are sequentially communicated, the drainage part is used for guiding airflow to flow to the drying part from the dehumidification part, the dehumidification part is communicated with the to-be-dehumidified area, and the drying part is communicated with the atmosphere. The drying agent in the dehumidification part and the drying part is exchanged through the material exchange unit, so that the dehumidification part can stably and continuously dehumidify, and the dried airflow can pass through the drying area to dry the humid drying agent in the drying area, so that the dehumidification part and the drying part continuously exchange the drying agent. The invention further relates to a split type power distribution cabinet with the drying device.

Owner:李晓姜

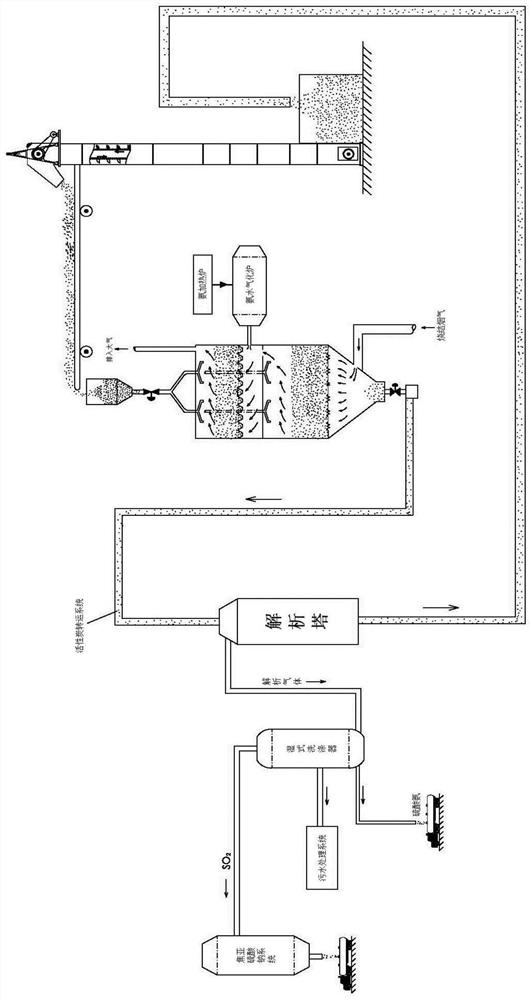

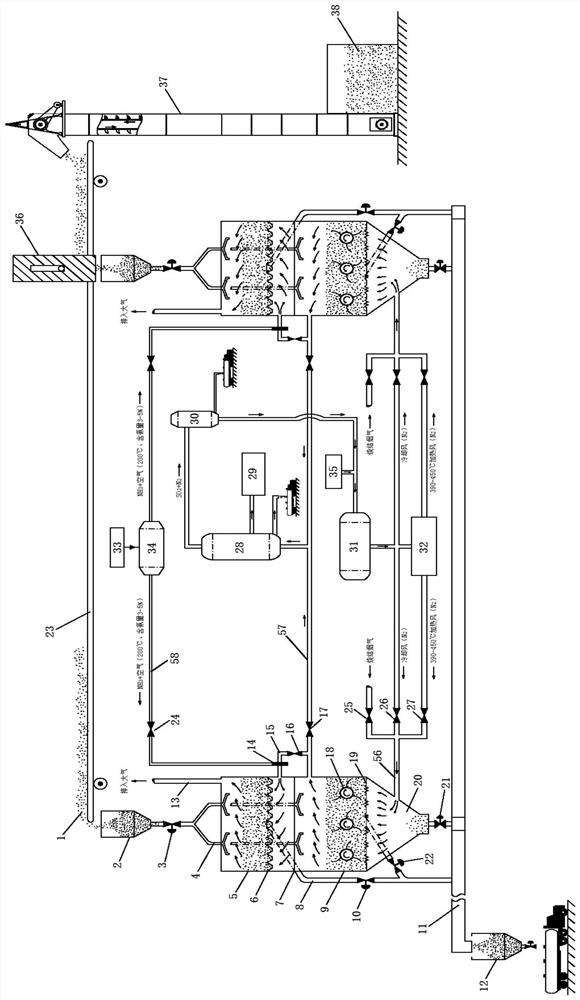

Flue gas exchange type activated carbon desulfurization and denitrification integrated process system and application

PendingCN111701394ASimplify the production processEquipment is smallEngine sealsGas treatmentActivated carbonProcess engineering

The invention relates to a flue gas exchange type activated carbon desulfurization and denitrification integrated process system and application. A desulfurization and denitrification process unit ofthe system comprises two adsorption towers with double functions of flue gas adsorption and activated carbon desorption at the same time. Each adsorption tower comprises a denitration box body, a desulfurization box body and an ash bucket bin, the denitration box body and the desulfurization box body are arranged in an up-down separation manner, and the ash bucket bin is connected to the bottom ofthe desulfurization box body; the space above a grid gas guide plate in each desulfurization box body is connected with the space below a honeycomb gas guide plate in the corresponding denitration box body through an external pipeline A; the ash bucket bins of the two adsorption towers are respectively connected with an external pipeline B; smoke outlets of the desulfurization box bodies of the two adsorption towers are respectively connected with an external pipeline C. The two adsorption towers which have completely identical functions and integrate adsorption and desorption functions are arranged, and when the flue gas adsorption function of one adsorption tower tends to be in a saturated state, the flue gas adsorption function is transferred to the other adsorption tower for replacement operation, and the adsorption tower start the activated carbon desorption and regeneration function by itself.

Owner:山东耀华能源投资管理有限公司

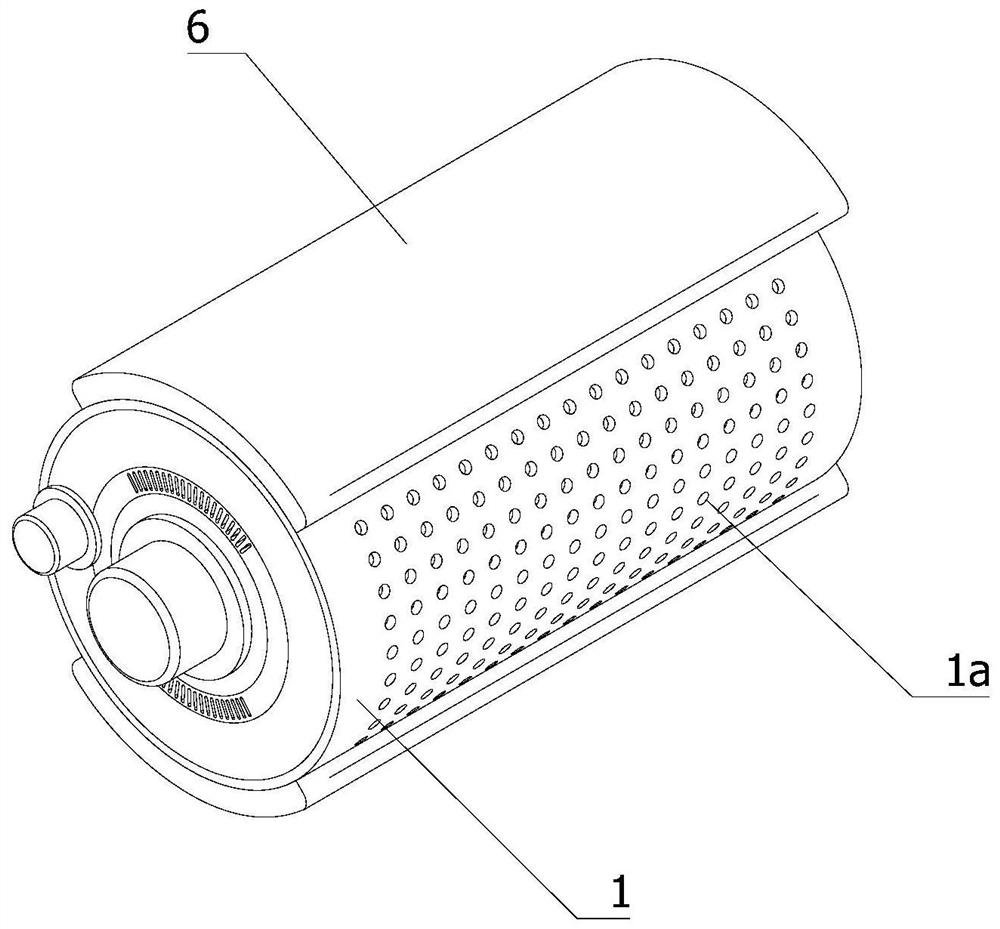

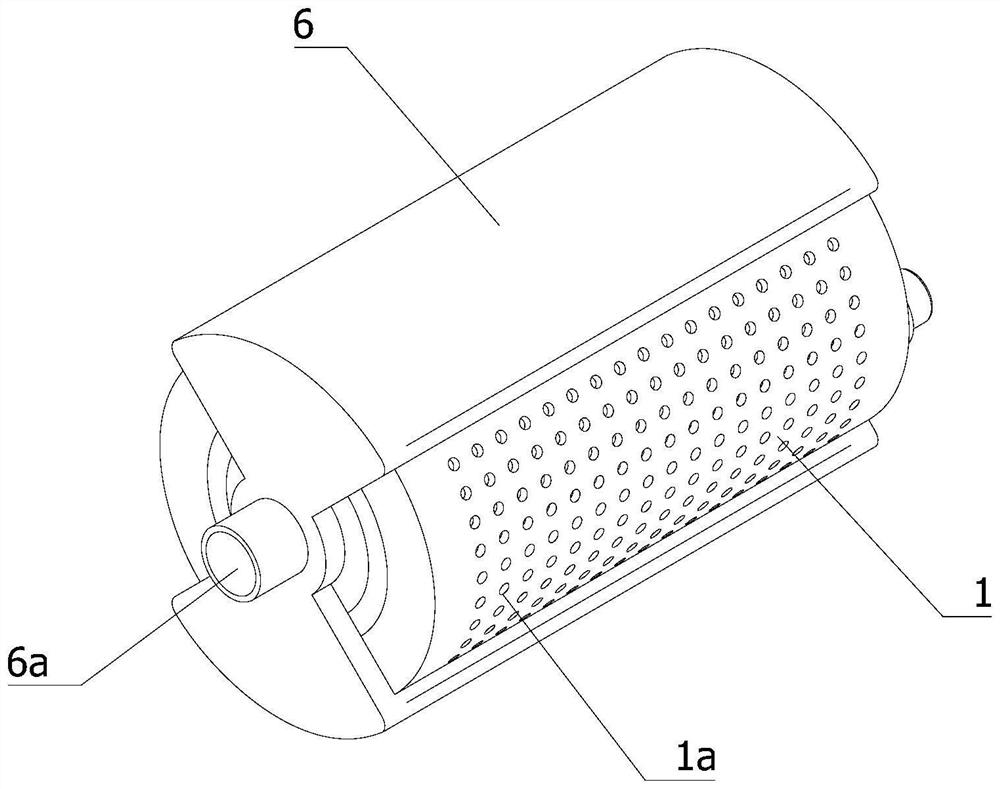

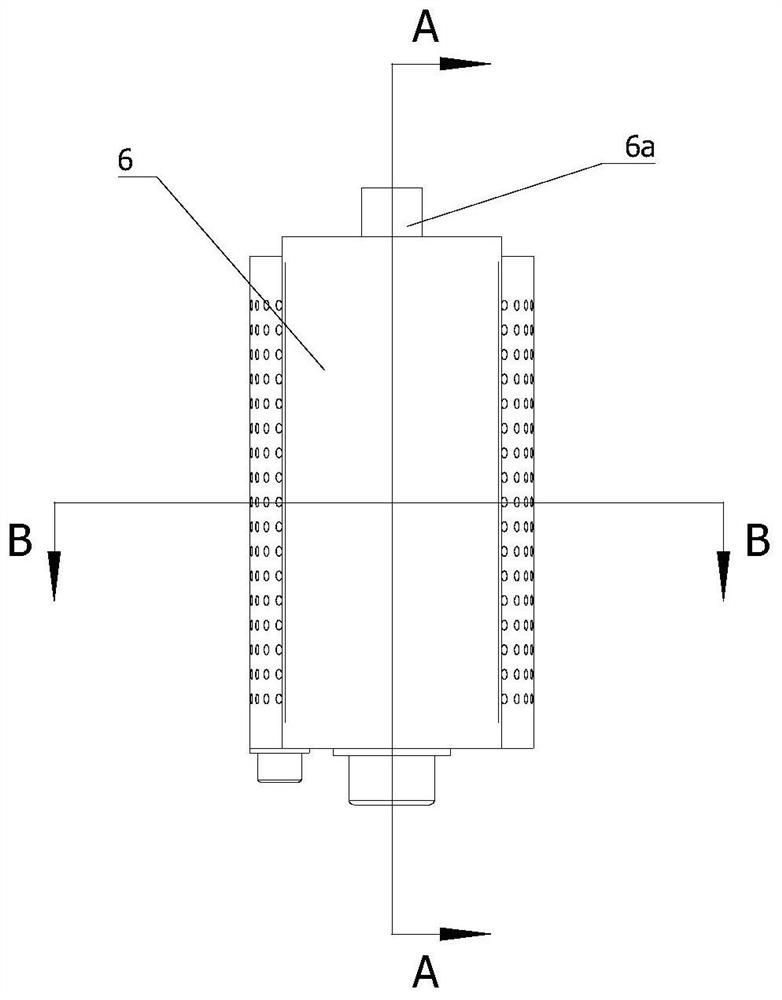

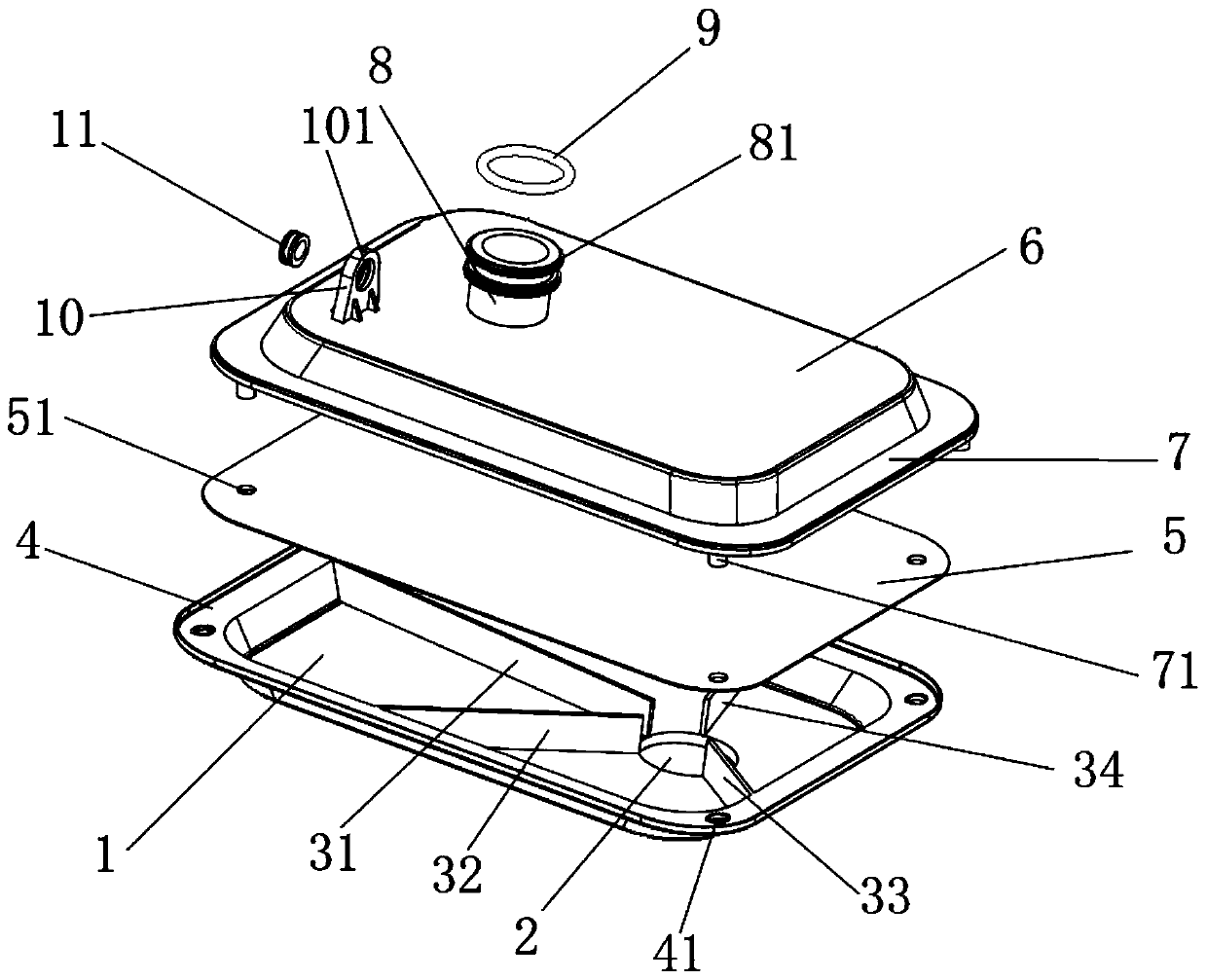

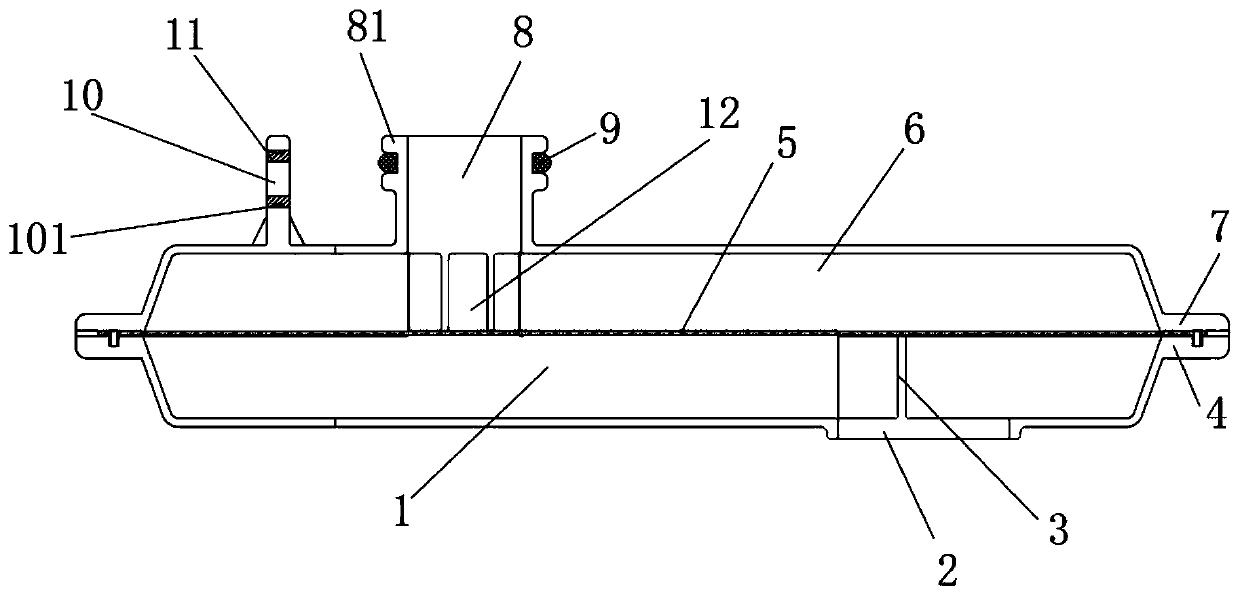

Novel suction type oil filter

InactiveCN110478955AEvenly acrossImprove efficiencySeparation devicesStationary filtering element filtersL-shellFilter element

The invention discloses a novel suction type oil filter, which comprises a lower shell, a filter element and an upper shell; a mounting groove is formed in the center of the bottom of the lower shell;an oil inlet is formed in the bottom, close to the center of the right side, of the lower shell. A first flow dividing device is fixedly connected to the position, close to the oil inlet, in the lower shell. The top of the lower shell is fixedly connected with a lower connecting plate; the bottom of the upper shell is fixedly connected with an upper connecting plate; the upper connecting plate isfixedly inserted into the inner wall of the lower connecting plate, a filter element is fixedly connected between the upper connecting plate and the lower connecting plate, the upper connecting plateand the lower connecting plate are welded and fixed, an oil outlet pipe fixedly communicates with the center, close to the left side, of the top of the upper connecting plate, and a second flow dividing device is fixedly connected to the position, close to the oil outlet pipe, of the bottom of the upper connecting plate. In the invention, the inlet and outlet of oil are reasonably distributed, the phenomenon that residues are prone to being locally gathered at an oil outlet of an original filter bag type filter element is avoided, and meanwhile the use efficiency of the filter element is improved.

Owner:安徽省锦瑞汽车部件有限公司

High-efficiency sewage treatment device

InactiveCN107879545AEasy to handleEffectively process data records, which is convenient for people to use, stirringWater contaminantsTreatment involving filtrationWastewaterInlet valve

A high-efficiency sewage treatment device includes a strong self-priming sewage pump and a filter tank. The strong self-priming sewage pump is connected to the filter tank through a sewage pipeline. The sewage pipeline is provided with a water inlet valve and a flow meter. The filter tank is provided with a stirring device and a first water quality detector. The stirring device includes a driving motor and a rotating shaft. One end of the rotating shaft extends out of the filtering tank to connect with the driving motor. A stirring blade is provided, and a filter mechanism is also provided inside the filter tank, which includes a central filter cylinder and a multi-stage filter layer. The design of the stirring device can effectively stir the sewage so that it can pass through the filter mechanism evenly. prevent it from clogging.

Owner:陈连娣

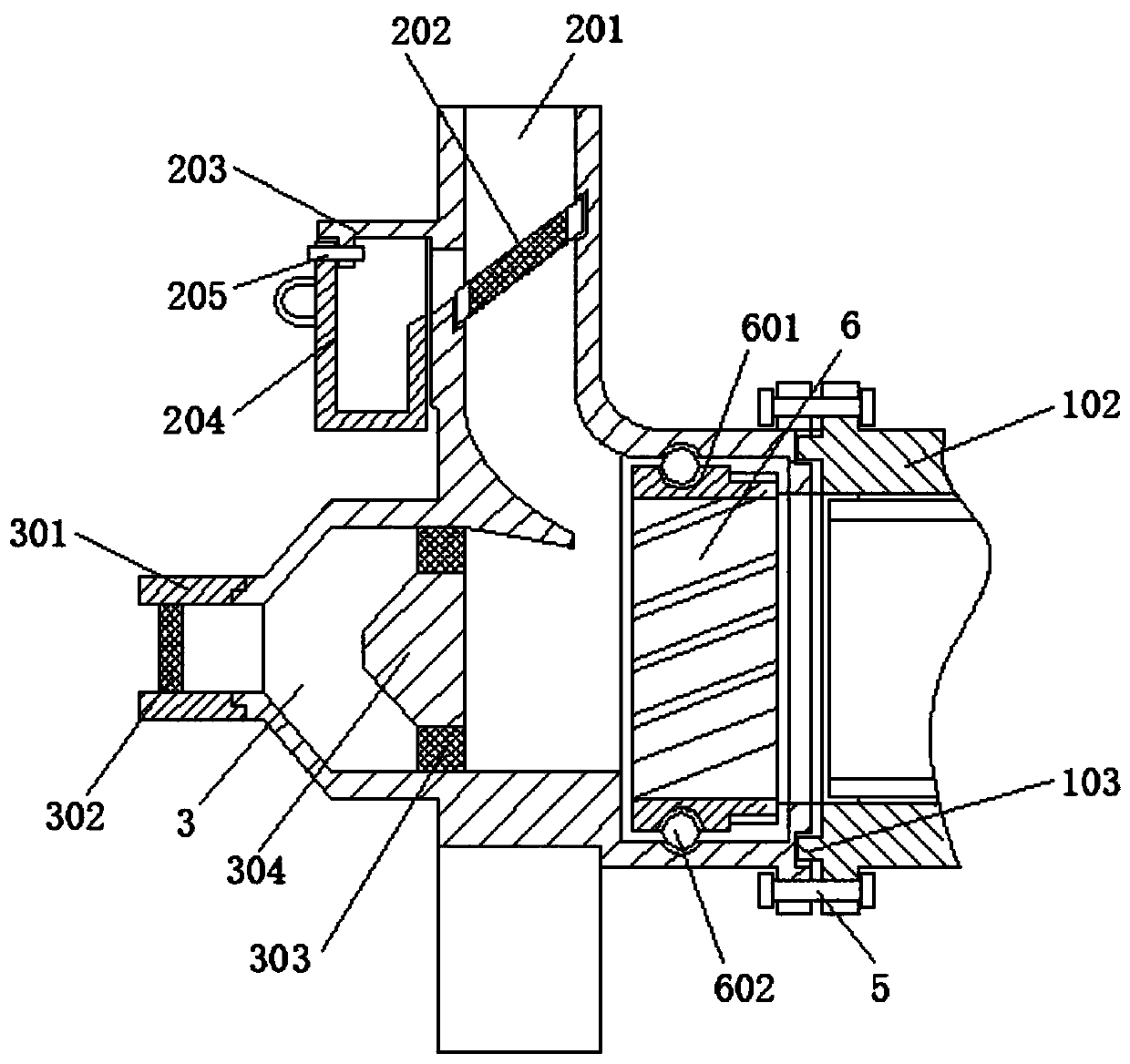

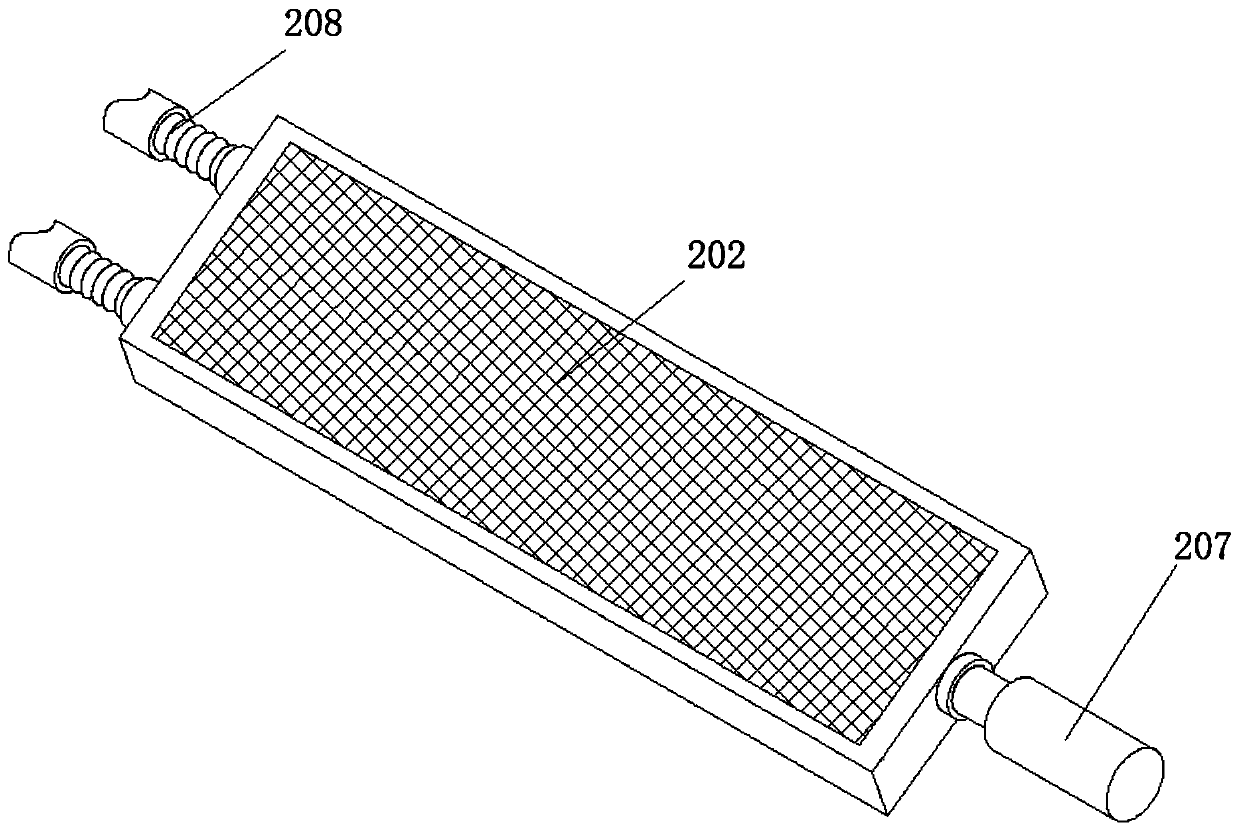

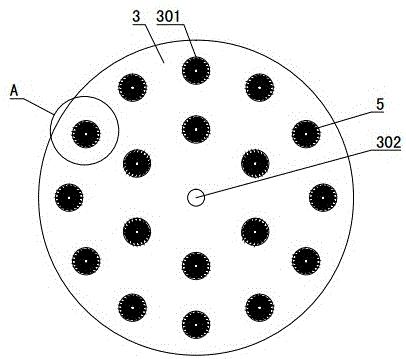

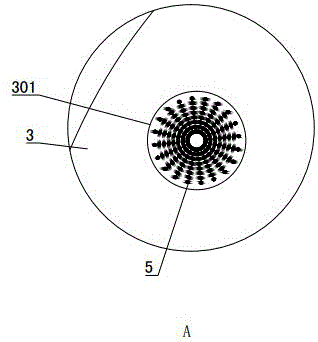

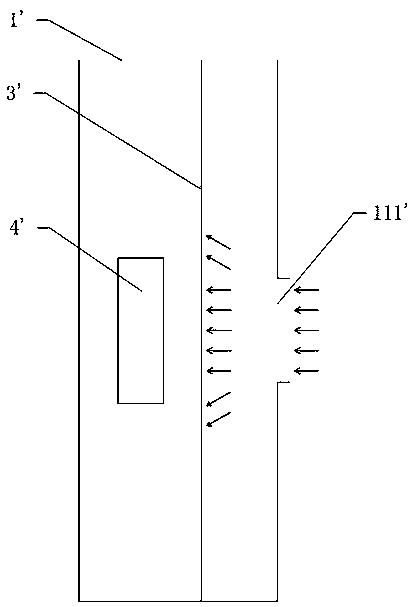

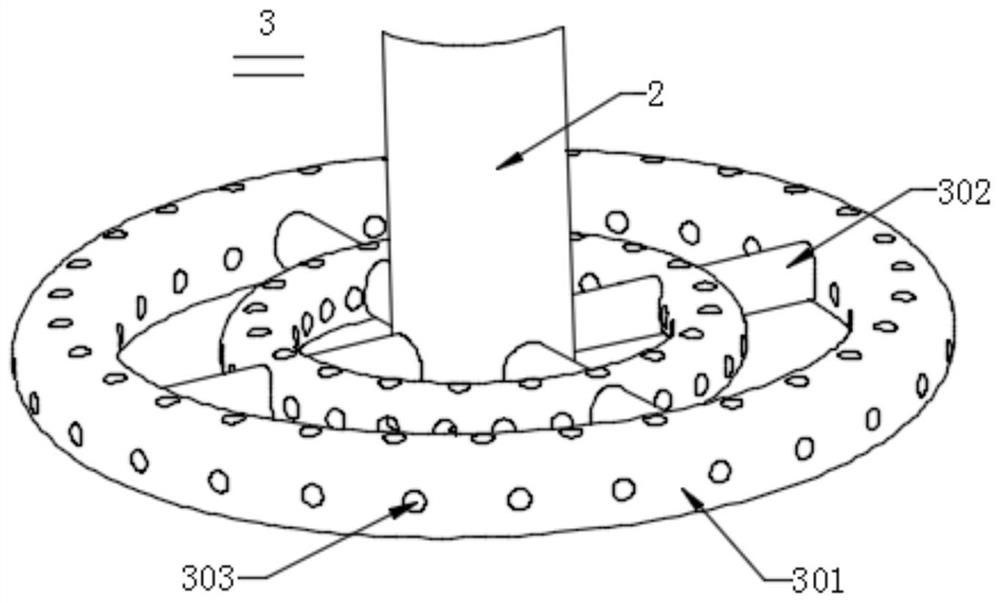

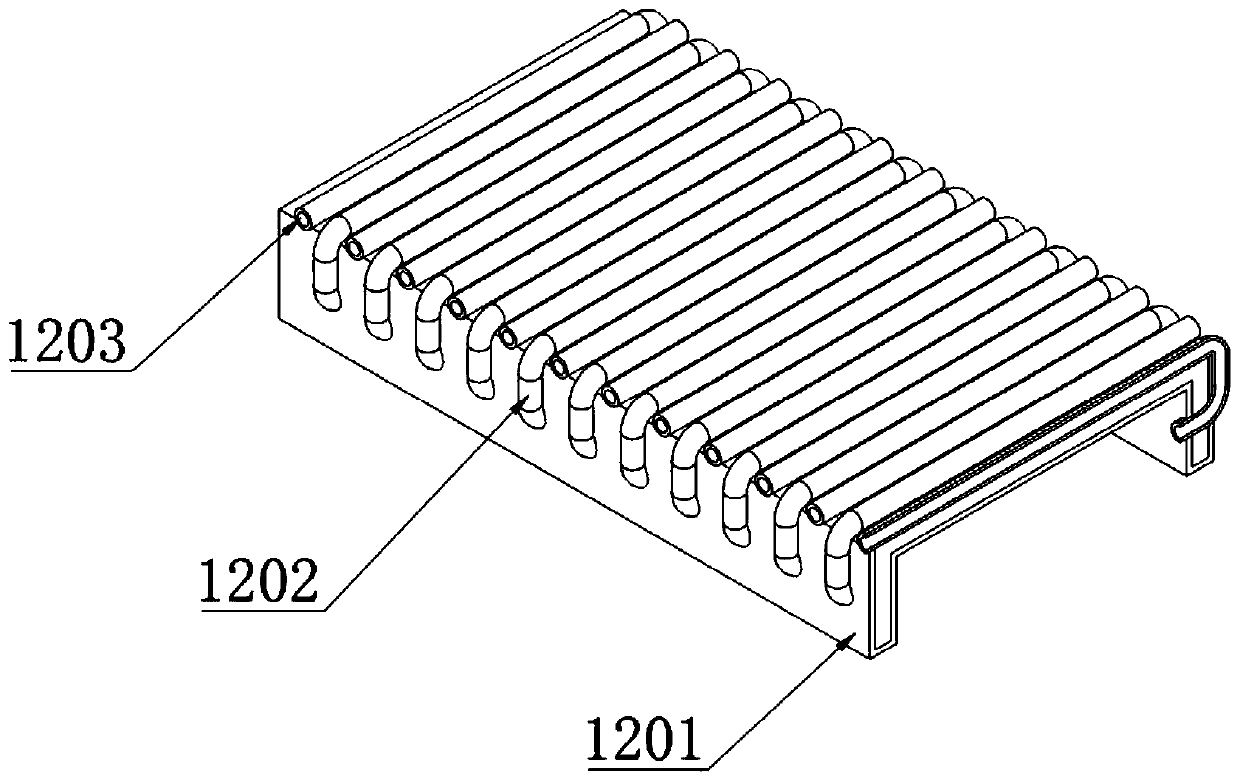

Magnetizing module of suspended linear superconductive oil-gas magnetizing modifier

ActiveCN106837620AUniform transmissionEnsuring the flux superconducting effectInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringMagnetic flux

The invention discloses a magnetizing module of a suspended linear superconductive oil-gas magnetizing modifier and belongs to the technical field of fuel-gas energy-saving equipment. The magnetizing module is characterized by comprising magnets (3) and paramagnetic linear superconductive wires (5), wherein the magnets (3) are provided with axial channels (301); the paramagnetic linear superconductive wires (5) are arranged in the channels (301) along the axial direction; and fuel passes through the channels (301), flows through the magnets (3) and is magnetized by the magnets (3). The magnetizing module disclosed by the invention has the advantages that the paramagnetic linear superconductive wires are arranged in the channels, so that the magnetic-flux superconductive effect is ensured, magnetic superconduction is uniformly transmitted into the paramagnetic linear superconductive wires, and further the condition that the fuel can be better magnetized and cut to generate fission and form small particle size is guaranteed.

Owner:山东源动力环保科技有限公司

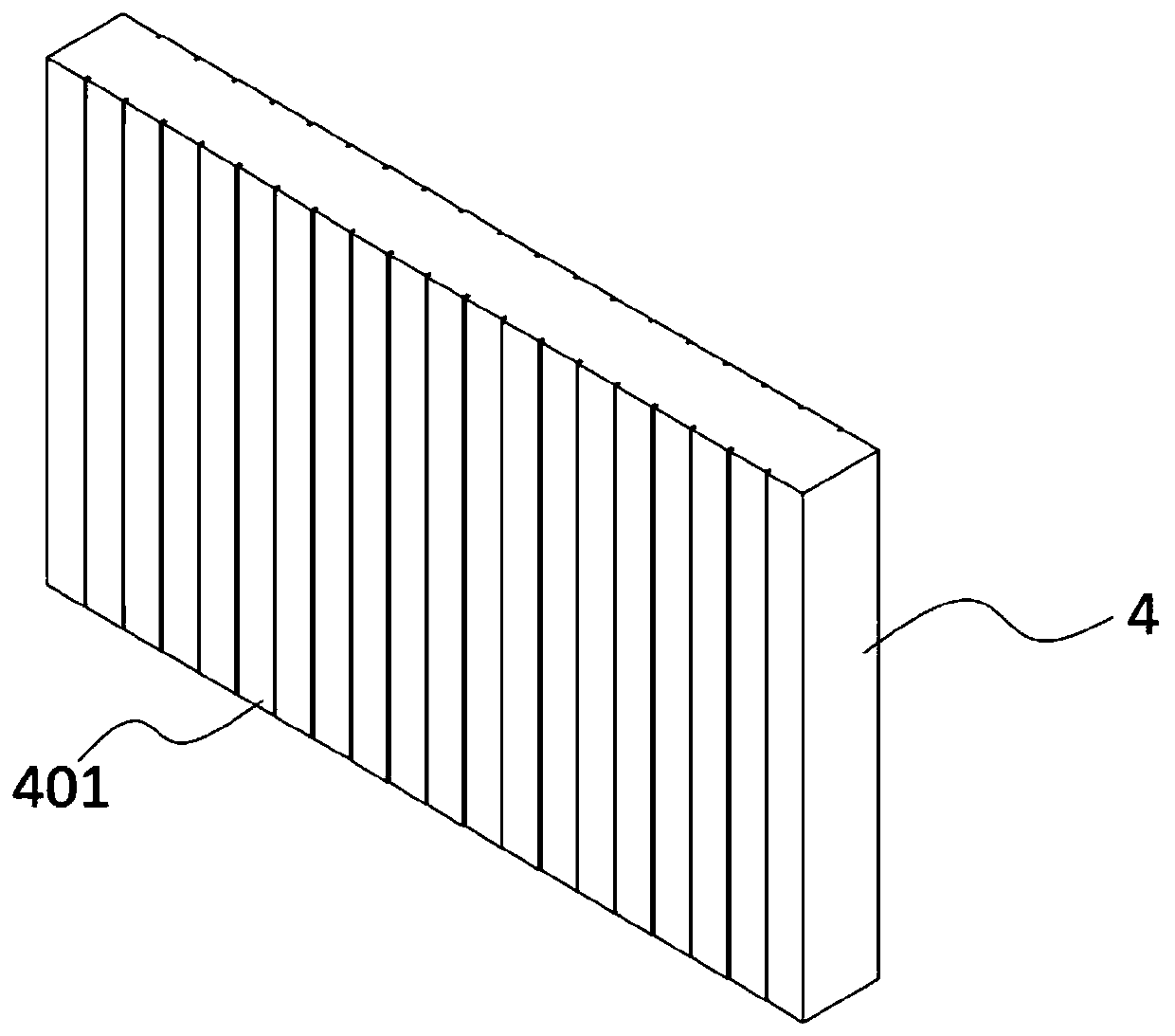

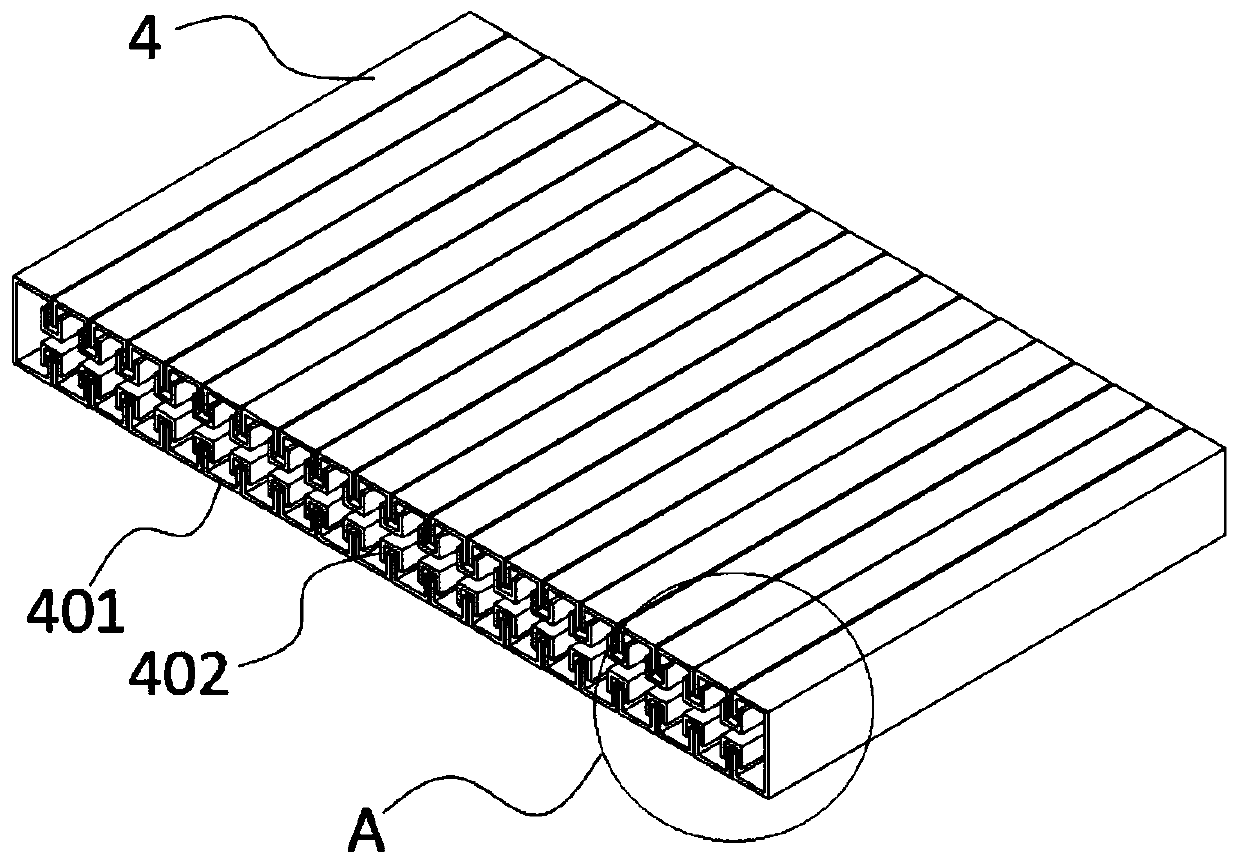

Air conditioner

ActiveCN104848418ASmall form factorSmall footprintLighting and heating apparatusSpace heating and ventilation detailsEngineeringCavity conditioner

The invention discloses an air conditioner comprising a housing, a wind wheel, an electric motor, and a heat exchanger. The housing is provided with an air inlet and an air outlet, with an air guide plate being arranged at the air outlet. The wind wheel is arranged inside the housing; at least a part of the wind wheel recesses along its rotating axis direction to form a concave portion; and the rotating axis of the wind wheel is orientated along the front and the back directions. The electric motor is used for driving the wind wheel to rotate; and the electric motor is installed inside the concave portion of the wind wheel. The heat exchanger is arranged inside the housing; and the heat exchanger is arranged on the left side and / or the right side of the wind wheel. The air conditioner according to the embodiment of the invention is small in size, uniform in air inlet of the heat exchanger, and high in heat exchanging efficiency.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

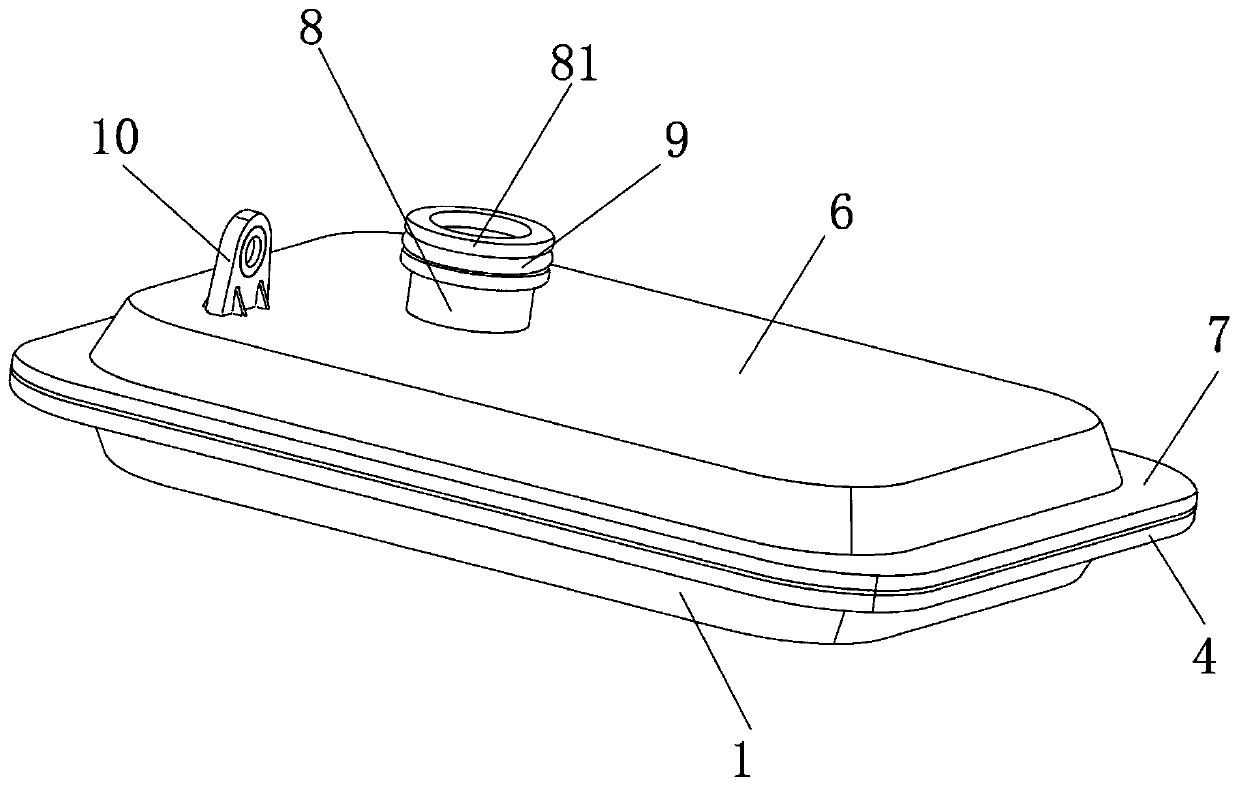

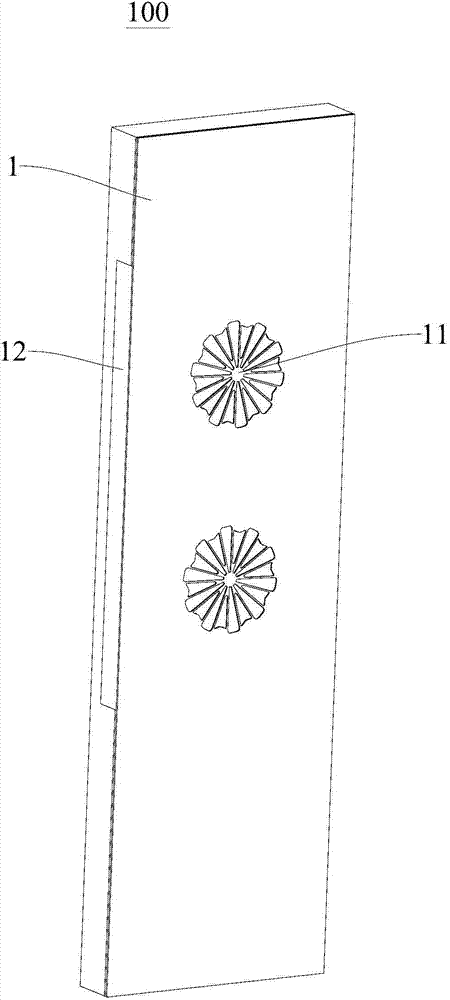

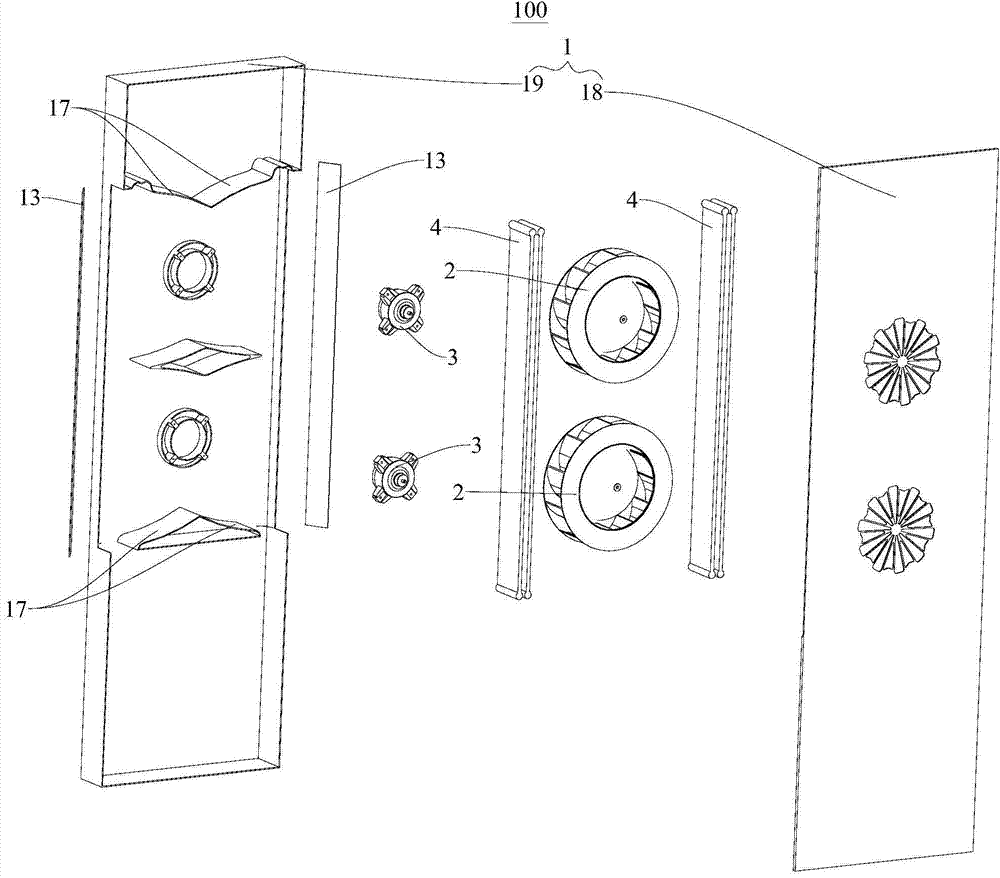

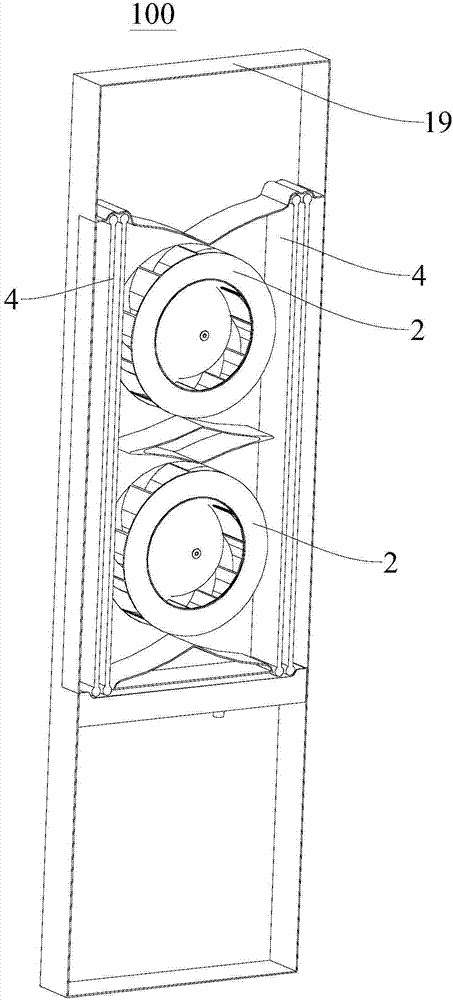

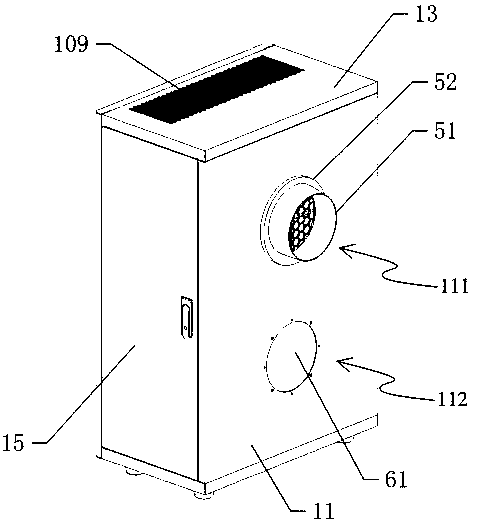

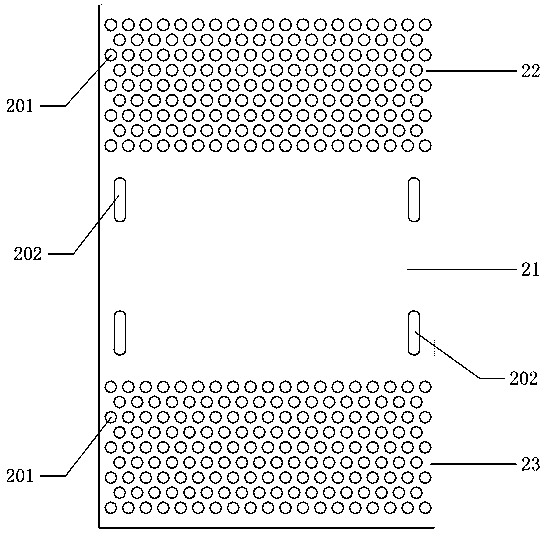

a new fan

ActiveCN108302618BCompact structureIncrease the cross-sectional areaMechanical apparatusLighting and heating apparatusFresh airEngineering

The invention discloses a fresh air ventilator. The fresh air ventilator comprises a shell, a filter element and a draught fan, wherein the filter element and the draught fan are arranged in the shell; a first air inlet is formed in the upper portion of a front door panel of the shell; an air uniformizing plate is detachably arranged on the inner side of the front door panel of the shell; the middle portion of the air uniformizing plate is provided with a windproof area; the upper portion and the lower portion of the air uniformizing plate are provided with an upper ventilating area provided with a plurality of vent holes and a lower ventilation area provided with a plurality of vent holes; the filter element is located between the inlet side of the draught fan and the air uniformizing plate. The fresh air ventilator provided by the invention achieves the air distribution and air uniformizing effects and can guarantee that fresh air passes through the filter element uniformly, and it is guaranteed that the overall structure of the fresh air ventilator is compact; accordingly, the whole filter element is fully utilized, and the service life of the filter element is longer.

Owner:广东艾瑞克林科技有限公司

A kind of positive pressure ventilation greenhouse chicken coop

The invention discloses a positive ventilation henhouse. The positive ventilation henhouse comprises a henhouse body, and the henhouse body is composed of a support body and an arch roof. The positive ventilation henhouse is characterized in that the bottom of the roof is provided with a horizontal plastic film. The positive ventilation henhouse also comprises a fresh air device, which is provided with a first air outlet pipe, the orifice of the first air outlet pipe is mounted between the roof and the plastic film, and the plastic film is provided with a plurality of ventilation holes. According to the positive ventilation henhouse, fresh air is continuously conveyed inside the henhouse, and by processing the air, the air quality inside the henhouse can be effectively improved, so that the inside environment of the henhouse can well meet the requirements of chicken on healthy growth, and infection of virus diseases can be reduced.

Owner:INST OF S&T INFORMATION SHANDONG ACADEMY OFAGRI SCI

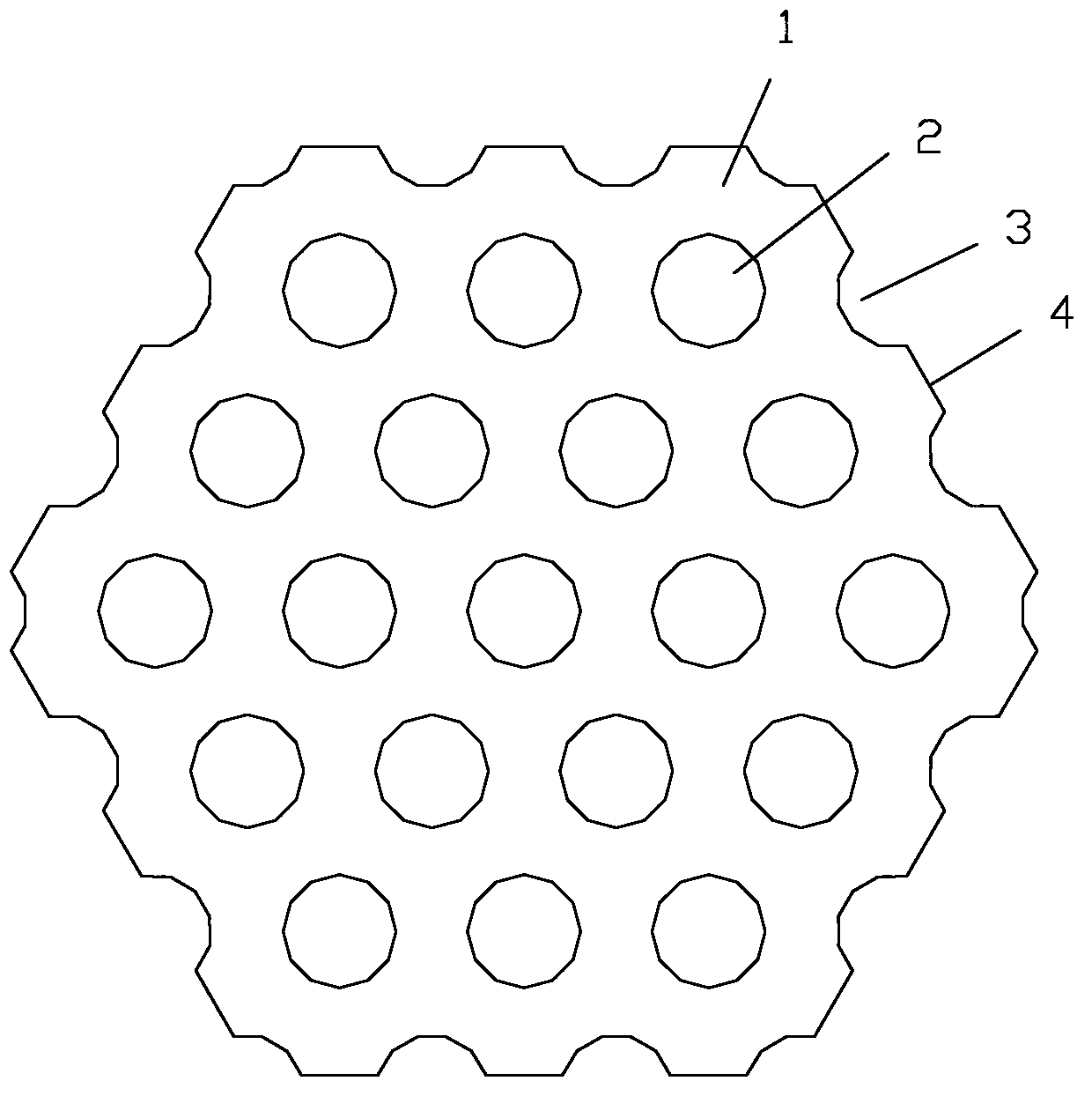

Checker brick for hot blast stove

The invention relates to a checker brick for a hot blast stove. Checker brick holes are formed in the end surface of a checker brick body, a locating groove and a locating pin are arranged on the peripheral surface of the checker brick body, and the depth of the locating groove is less than the length of the locating pin; and cold air can be distributed secondarily according to the pressure after the cold air enters the hot blast stove, and can pass through the checker brick evenly, therefore, a uniform heating effect can be achieved, and the heat of the checker brick can be effectively utilized.

Owner:XINXING HEBEI ENG & RES INC

Method for continuously dissolving a solid in a reaction medium

ActiveCN111201079BImprove solubilitySufficient concentration to dissolveOrganic compound preparationDissolving systemsPhysical chemistryFixed bed

Owner:EVONIK OPERATIONS GMBH

A biomass steam explosion device

ActiveCN112553936BEvenly acrossUniform temperatureRaw material divisionThermodynamicsElectric power equipment

A biomass steam explosion device provided by the present invention includes a steam explosion device, an internal steam main pipeline, a steam pipeline in a tank, a steam-driven linkage device, a material turning device and a connecting ring. The internal steam main pipeline is fixedly installed on Inside the steam explosion device, the steam pipeline in the tank is uniformly fixed and installed on the outer surface of the internal steam main pipeline, and the steam pipeline in the tank is fixed and installed inside the steam explosion device. The steam-operated linkage device is fixedly installed on the inner top of the steam explosion device, the material turning device is evenly fixed on the inner wall of the steam explosion device, and the connecting rings respectively move through the steam-operated linkage device and the material turning device. Device; the invention can ensure that the steam can pass through the material evenly, increase the penetration of the material accumulated at the bottom and the edge, and at the same time prevent the material from adhering to the inner wall, and finally do not need additional electric equipment to realize the material turning work.

Owner:上海汉禾生物新材料科技有限公司 +1

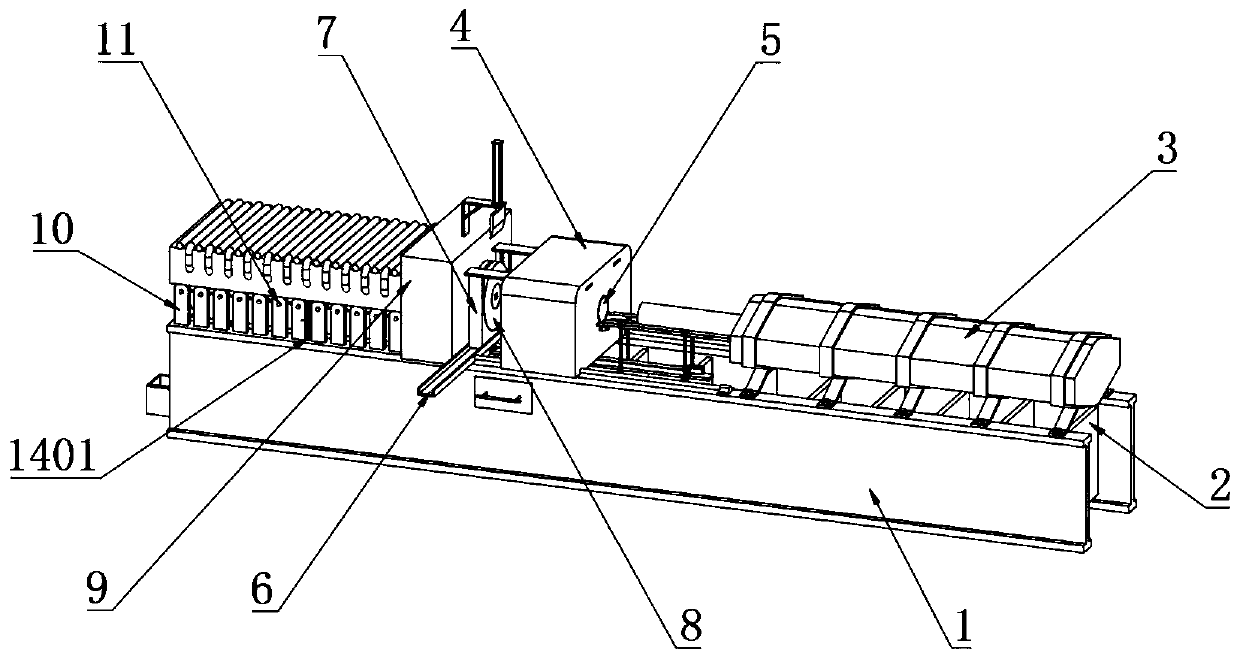

An environmentally friendly high-precision aluminum alloy profile extrusion machine

ActiveCN110711790BEasy to useRapid coolingEdge grinding machinesGas treatmentHydraulic cylinderThermodynamics

The invention discloses an environment-friendly high-precision aluminum alloy profile extruder which comprises a base frame, a hydraulic cylinder, a material liner and a die. An abutting block is welded to the side, corresponding to a slide way, of the top end of the base frame. A cooling mechanism is arranged on one side of the abutting block. A cooling water box is welded to the top of the surface of one side of the abutting block. A second air inlet pipe staggered with a first air inlet pipe is arranged on the surface of the outer side of the cooling water box. An air inlet cover is weldedto the top end of a carrying box. A plurality of exhaust pips are inserted in the bottom end of the carrying box in a penetrating mode. A supporting plate is installed at the position, corresponding to the exhaust pipes, of the top in the carrying box. A draught fan is installed in the middle of the supporting plate. The input end of the draught fan is electrically connected with the output end ofan external power supply. Waste and scraps are carried by a drawer and a filter screen to be recycled, polluting substances generated at a high temperature are absorbed through a filtering mechanism,the harm of the waste, scraps and polluting substances to the environment is effectively avoided, and the environmental protection aim is realized.

Owner:浙江埃尔法流体科技有限公司

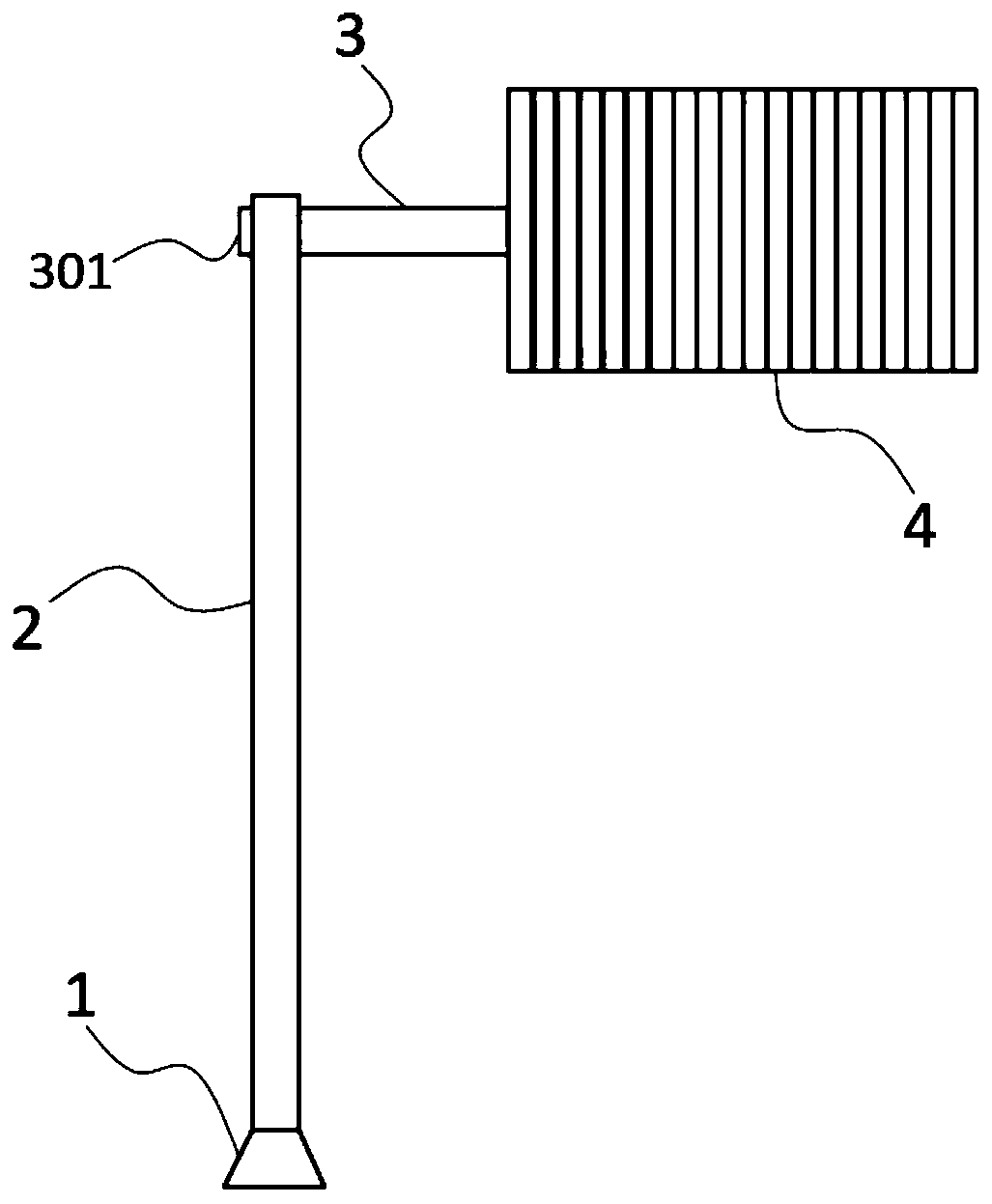

A windproof and fall-resistant sign

The invention discloses a wind-preventing and falling-resisting indicating plate, and relates to the field of manufacturing of indicating plates. The wind-preventing and falling-resisting indicating plate comprises a base, a supporting rod, a connecting rod and an indicating plate body, wherein the supporting rod is fixedly connected to the upper surface of the base; penetrating grooves are formedin one end of the surface of the supporting rod; a clamping block is arranged on one end surface of the connecting rod, and is in interference fit with the penetrating grooves; the clamping block isconnected with the inner wall of the supporting rod through springs; first U-shaped grooves are formed in the bottom of the indicating plate side by side; a second U-shaped groove is formed in edges of every two adjacent first U-shaped grooves in a sleeving manner; a return passage is formed between each first U-shaped groove and the corresponding second U-shaped groove. According to the wind-preventing and falling-resisting indicating plate disclosed by the invention, a return passage is formed between each first U-shaped groove and the corresponding second U-shaped groove, so that wind can uniformly penetrate through the wind-preventing and falling-resisting indicating plate, the resistance on the wind-preventing and falling-resisting indicating plate in strong wind is reduced, the phenomenon that the wind-preventing and falling-resisting indicating plate is deformed is effectively avoided, and the traffic safety hidden dangers are avoided.

Owner:浙江亚泰电力科技有限公司

Belt type circulating dryer

InactiveCN102121783BEvenly acrossImprove uniformityDrying solid materials with heatDrying gas arrangementsEngineeringConveyor belt

The invention discloses a belt type circulating dryer, which belongs to the technical field of feed processing machinery. A material layer is laid on a conveyor belt of the belt type circulating dryer. An air distribution chamber is formed below the conveyor belt. A hot air inlet of the air distribution chamber is positioned at one end of the width direction of the conveyor belt. An outlet air duct of a circulating fan is vertically downwards communicated with the hot air inlet of the air distribution chamber, and a suction mouth air duct of the circulating fan is communicated with an air duct above the material layer. A group of deflectors is arranged at a turning. The group of deflectors is arranged in the air distribution chamber, each deflector is extended along the length direction of the conveyor belt, and the deflectors are uniformly distributed along the width direction of the conveyor belt. Rotating shafts are arranged on each deflector respectively, and each rotating shaft is hinged to own rotating shaft pedestal respectively. Each rotating shaft pedestal is arranged on a bottom plate of the air distribution chamber. One end of the rotating shaft is extended out of a machine body, and an extended end is provided with an adjusting handle for adjusting an angle of the corresponding deflector. The belt type circulating dryer makes uniform a gas flow in a material, and ensures low gas flowing resistance and low energy consumption.

Owner:JIANGSU MUYANG GRP CO LTD

An image adaptation method based on edge vision protection

ActiveCN110853084BReduce distortionReduce interruptionsImage enhancementImage analysisSaliency mapSalient objects

Owner:石家庄邮电职业技术学院

Drying machine with cooling device and use method

ActiveCN105066600AReduce the temperatureGuaranteed not to heat upDrying solid materialsDrying machines with local agitationAtmosphereWaste management

The invention relates to a drying machine with a cooling device. The drying machine comprises a drying bin connected to a base in a fastened mode, an air inlet duct disposed on one side of the drying bin and an air outlet duct disposed on the other side of the drying bin. The drying bin comprises a discharging unit, cooling units, tempering units, drying units, a stoving unit and a storage unit, wherein the discharging unit is located at the bottom end of the drying bin; the cooling units are arranged on the discharging unit; the tempering units and the drying units are sequentially arranged on the cooling units in an alternative mode; the stoving unit and the storage unit are arranged on the tempering units or the drying units in sequence. The upper portion in each tempering unit is provided with an upper ventilation duct communicated with the air inlet duct. The portion, under the corresponding upper ventilation duct, in each tempering unit is provided with a plurality of lower ventilation ducts communicated with the atmosphere. A fan communicated with the corresponding upper ventilation duct is arranged in the inner portion, corresponding to each tempering layer, of the air outlet duct. An air outlet of each fan penetrates through the air outlet duct to be communicated with the atmosphere.

Owner:四川奥凯农装科技有限公司

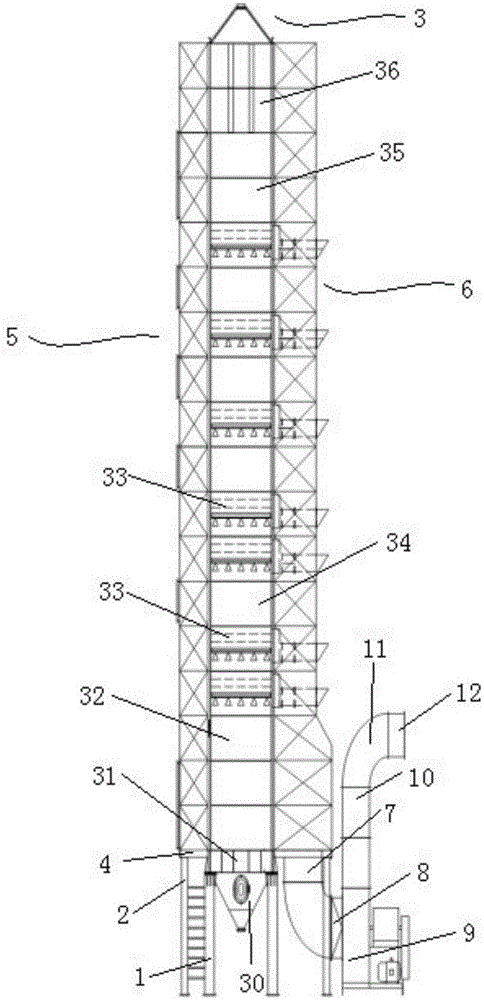

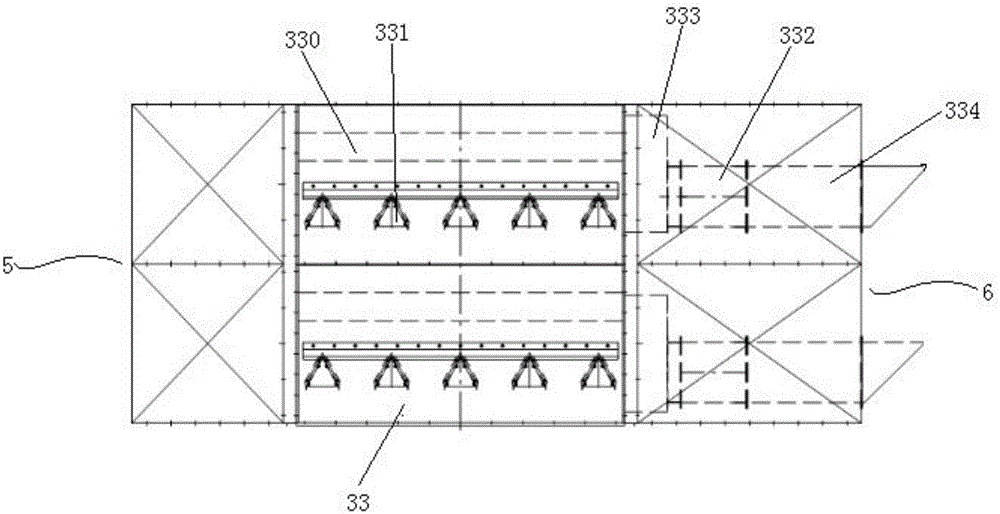

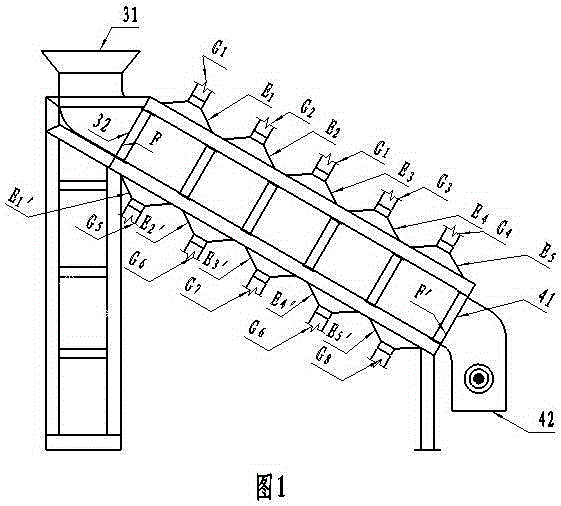

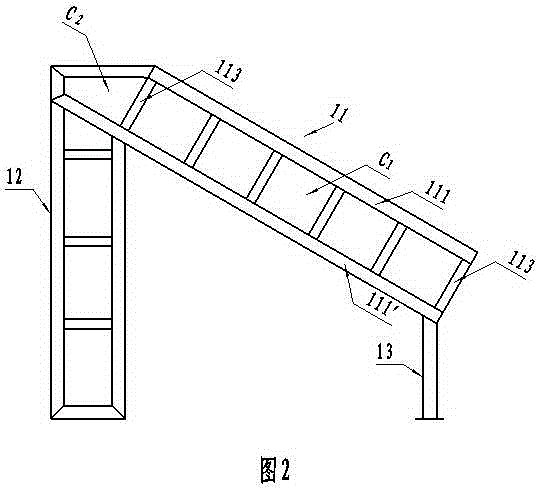

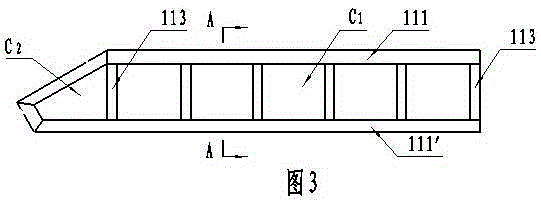

Inclined tunnel type grain dryer

InactiveCN106546085AReduce drying costsConsistent thicknessSeed preservation by dryingHeating arrangementManufacturing cost reductionGrain storage

The invention discloses an inclined tunnel type grain dryer. The inclined tunnel type grain dryer comprises a frame support, a grain drying tunnel box body, a grain storage box, a grain discharging device, a plurality of upper air inlet and outlet connectors, a plurality of lower air inlet and outlet connectors and a plurality of air conveying pipes. The first air conveying pipe communicates with the first upper air inlet and outlet connector and the third upper air inlet and outlet connector. The second air conveying pipe communicates with the second upper air inlet and outlet connector. The third air conveying pipe communicates with the fourth upper air inlet and outlet connector and an air heat exchanger. The fourth air conveying pipe communicates with the fifth upper air inlet and outlet connector. The fifth air conveying pipe communicates with the first lower air inlet and outlet connector. The sixth air conveying pipe communicates with the second lower air inlet and outlet connector and the fourth lower air inlet and outlet connector. The seventh air conveying pipe communicates with the third lower air inlet and outlet connector. The eighth air conveying pipe communicates with the fifth lower air inlet and outlet connector and an air cooler. Through the inclined tunnel type grain dryer, resistance of hot air passing through grain layers can be greatly lowered; heat energy waste is greatly reduced, and the grain drying cost is greatly lowered; and the structure is simple, and the manufacturing cost is greatly lowered.

Owner:JILIN TEACHERS INST OF ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com