Torsional vibration damper

A technology of torsional vibration and shock absorber, applied in spring/shock absorber manufacturing, spring/shock absorber, vibration suppression adjustment, etc., can solve problems such as confusion of assembly conveyor belts, and achieve the effect of limiting material input and space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

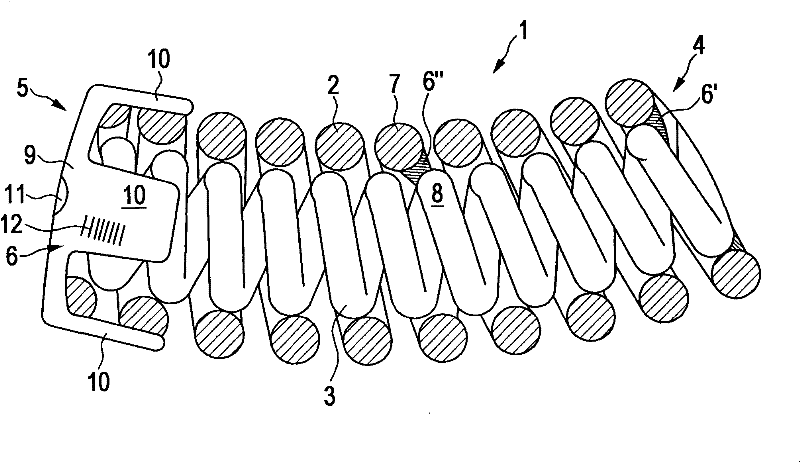

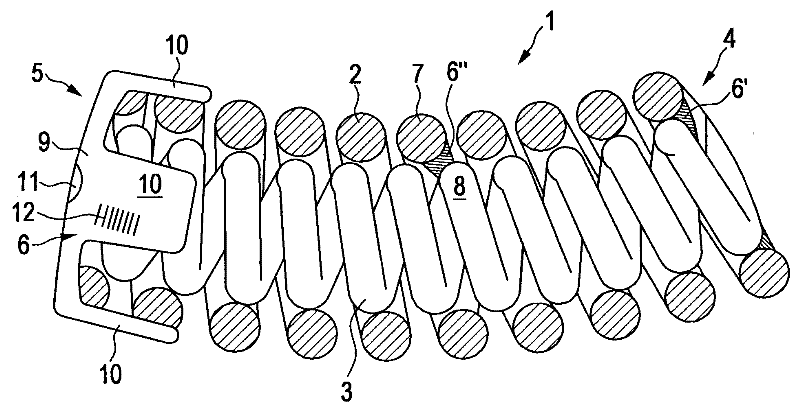

[0024] The invention is described in detail with the aid of a single figure. The figure shows a shortened arcuate energy store 1 which is installed, for example, in a dual-mass flywheel or another torsional vibration damper. it goes without saying, figure 1 The advantageous embodiments of are correspondingly also used for non-bending energy stores. In the exemplary embodiment shown, the energy store 1 has two helical springs nested inside one another, namely an outer spring 2 and an inner spring 3 . The two helical springs have two common end faces 4 , 5 which each have a differently shaped adhesive connection 6 , 6 ′ shown in an exemplary embodiment. It goes without saying that the adhesive connection 6 , 6 ′ can be implemented identically on only one end face or mixedly on both end faces 4 , 5 or uniformly on both end faces 4 , 5 . In the case of using an adhesive connection 6', this adhesive connection can also be at one place between the end faces 4, 5 between the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com