Drying machine with cooling device and use method

A cooling device and dryer technology, which is used in dryers for static materials, local stirring dryers, dryers, etc., can solve the problems of mildew of materials, limitation of feeding time, and the speed of discharging can not be too fast. Enhance penetration, ensure no heat generation, and reduce the effect of material temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

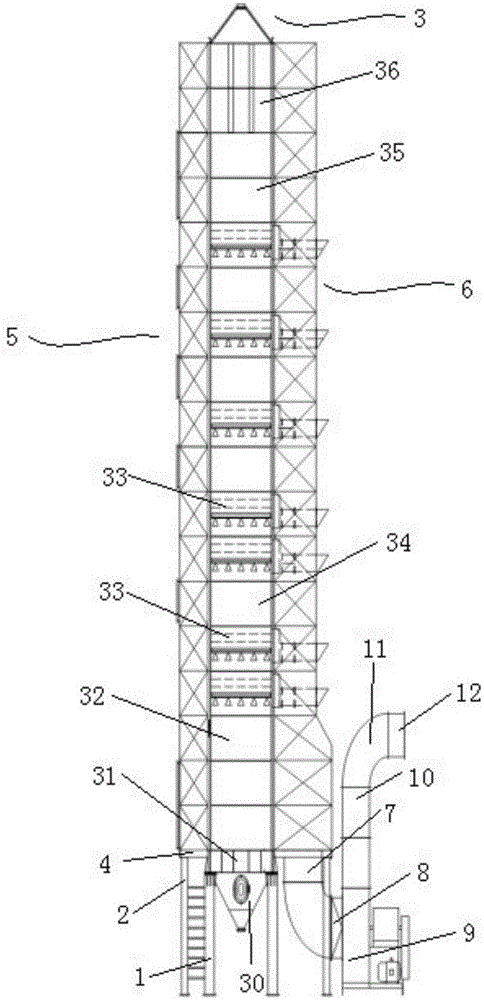

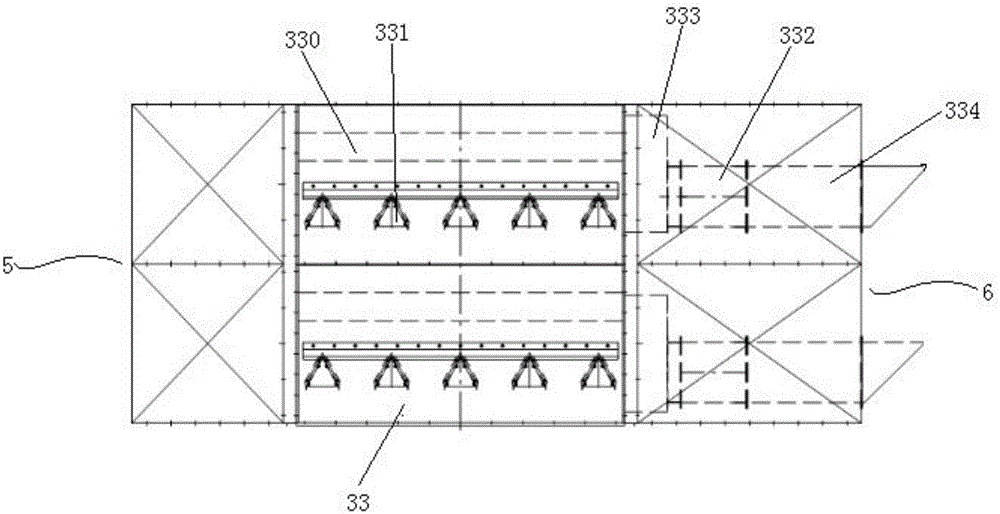

[0015] Such as figure 1 , figure 2 As shown, the present invention includes several support legs 1 that are vertically fastened on the base at equal intervals along the circumferential direction, and several support legs 1 that are vertically fastened on the base at equal intervals and are positioned on the concentric circle outside the support leg 1. The legs 2 are vertically fastened to the drying bin 3 on the leg 1, and the air inlet duct 5 that is vertically fastened on the leg 2 and located on the side of the drying bin 3 through the bracket 4 is vertically connected to the bracket 4. Straight fastening is connected on the support leg 2 and is positioned at the air outlet channel 6 on the other side of the drying bin 3 . The bottom of the air outlet channel 6 is successively connected to the air outlet straight pipe 7 and the fan reducing pipe 8 to the inlet of the induced draft fan 9, and the outlet of the induced draft fan 9 is connected to the fan outlet pipe 10, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com