Dry-method ozone pretreatment pretreater capable of increasing straw enzymolysis saccharification ratio and method

A technology for pretreatment and saccharification rate, applied in the field of comprehensive utilization of crop straw resources, can solve the problems of lack of straw ozone pretreatment equipment, etc., and achieve the effects of improving storage stability, low equipment requirements, and improving straw enzymatic hydrolysis and saccharification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

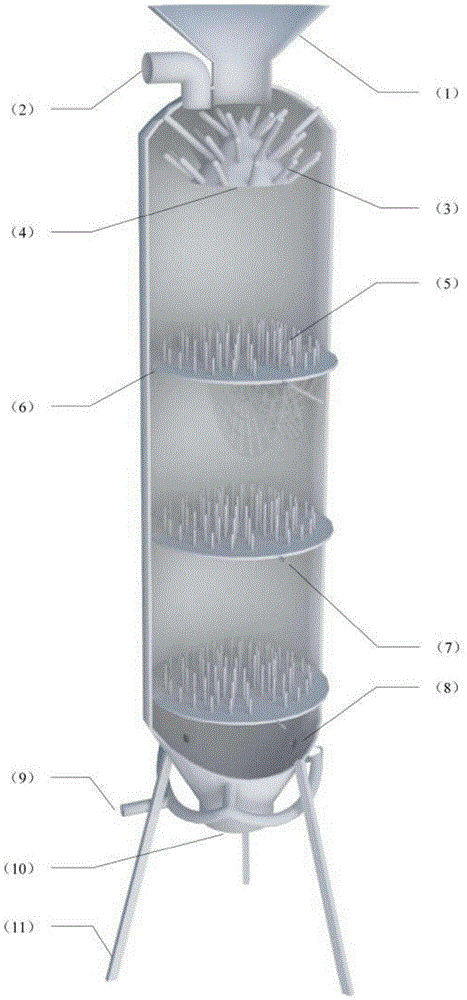

[0045] Example 1: Batch operation scheme of straw dry ozone pretreatment tower

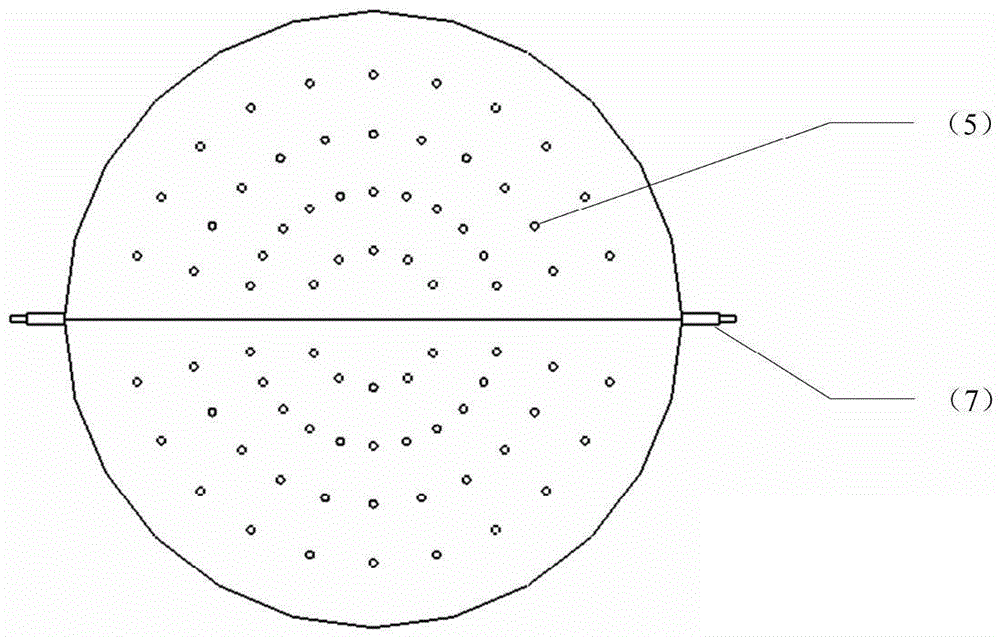

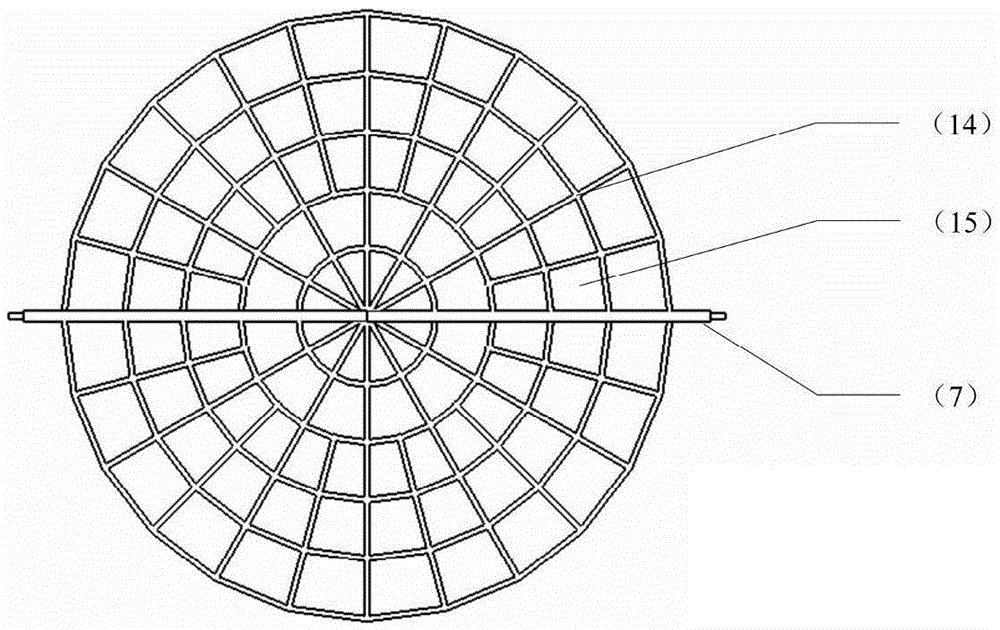

[0046] Crush the straw according to certain requirements, and adjust the moisture content of the straw powder (for details, refer to Examples 3, 4, and 5). The initial state of the pretreatment tower: the outlet 10 is closed, and the bottom sieve plate 6 is in a horizontal state, which is called "closed". The feed hopper 1 is opened, and the middle sieve plate 6 and the upper sieve plate 6 are in a vertical state, which is called “opening”. Feed to the pretreatment tower. After the material layer on the lower sieve plate 6 reaches the specified height, close the middle sieve plate 6 and continue feeding to the specified height. By analogy, the feeding of the upper sieve plate 6 is completed. After feeding, close the feed hopper 1. The ozone gas stream with specified concentration and flow rate is introduced, and the ozone concentration discharged from the pretreatment tower is monitored at the s...

Embodiment 2

[0047] Example 2: Semi-continuous operation scheme of straw dry ozone pretreatment tower

[0048] Crush the straw according to certain requirements, and adjust the moisture content of the straw powder (for details, refer to Examples 3, 4, and 5). The initial state of the pretreatment tower and the feeding operation are the same as in Example 1. The ozone gas stream with specified concentration and flow rate is introduced, and the ozone concentration discharged from the pretreatment tower is monitored at the same time. When the concentration of ozone discharged from the pretreatment tower is not zero, stop feeding the ozone, open the discharge port 10 and the bottom sieve plate 6, and discharge the bottom sieve plate 6 material. Close the bottom sieve plate 6 and the discharge port 10 again, and open the middle sieve plate 6 at the same time, so that the material originally positioned at the middle sieve plate 6 is placed on the bottom sieve plate 6 . By analogy, put the mate...

Embodiment 3

[0049] Example 3: Dry ozone pretreatment scheme 1 for corn stalks

[0050] In this scheme, the operation of pretreatment tower adopts batch type. The corn stalks are coarsely crushed and passed through a 20-mesh sieve, and then finely crushed and passed through a 300-mesh sieve. Adjust the moisture content of straw powder to 60%. Treat under the conditions of ozone concentration 60mg / L and air flow 5L / min. The lignin degradation rate of the final straw reaches 75%, and the cellulose hydrolysis rate reaches 80% (10% for untreated straw).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com