Spray polyurea elastomer for mine, preparation and construction method thereof

A polyurea elastomer, mining technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as poor wear resistance, and achieve excellent flexibility, excellent adhesion, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

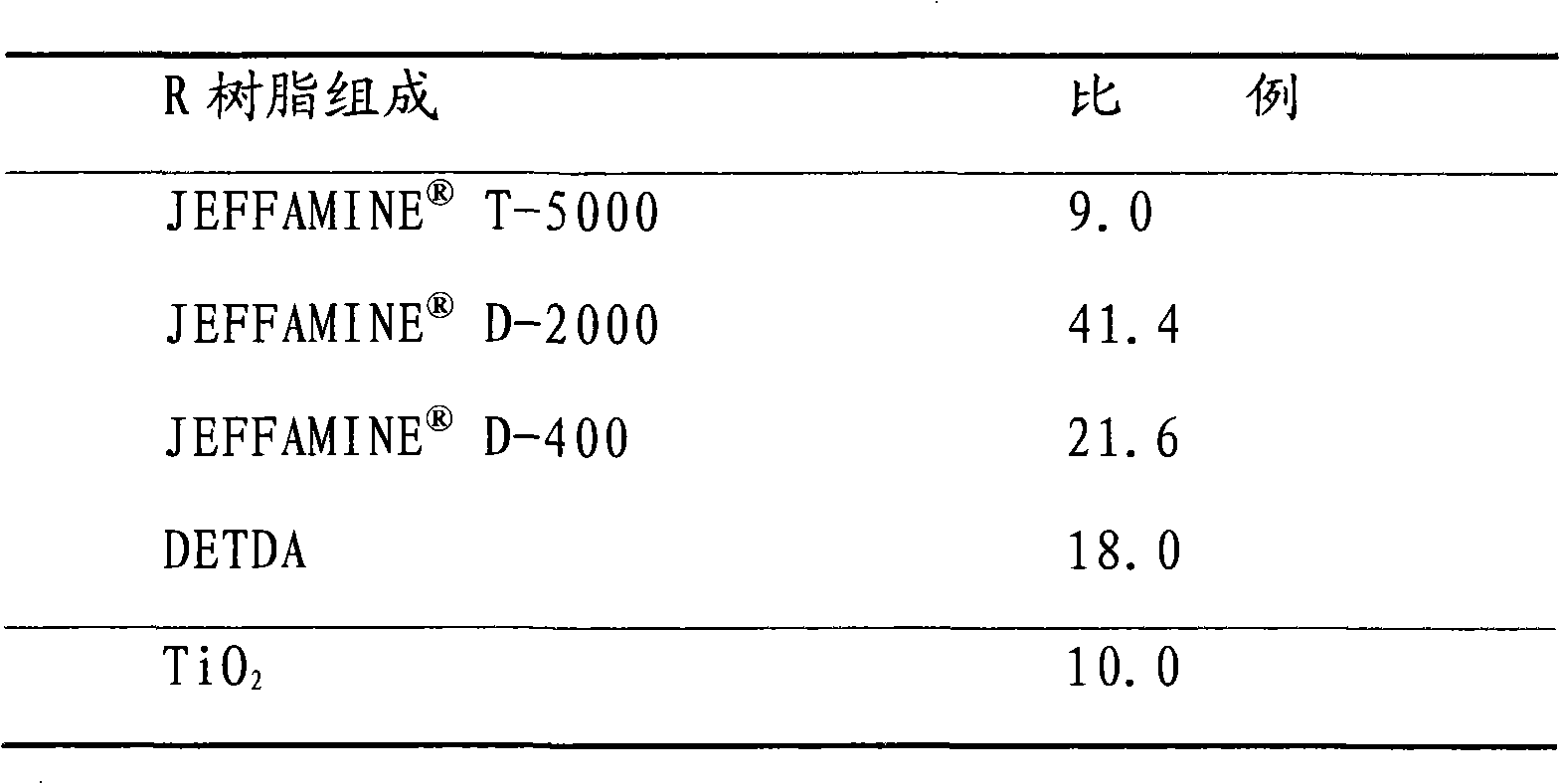

[0043] A consists of about 15 parts of 2,4'-diphenylmethane diisocyanate and 41 parts of 4,4'-diphenylmethane diisocyanate and 44 parts of polyepoxide with a molecular weight of 1000 and a functionality of 2. Propane ether diol (TDiol-1000, Tianjin Petrochemical No. 3 Plant) prepared prepolymer. The NCO content of the prepolymer was (15±0.1)%. The R component consists of T-5000 amino resin, D-2000, D-400, DETDA amino resin and TiO 2 The composition of the mixture. Accurately weigh the various raw materials in the R component according to the formula, add them into the paint tank, and stir at high speed for 30 minutes with high-speed shearing and dispersing equipment.

[0044] The isocyanate index of this system was 1.10. The specific ratio is shown in the table below.

[0045]

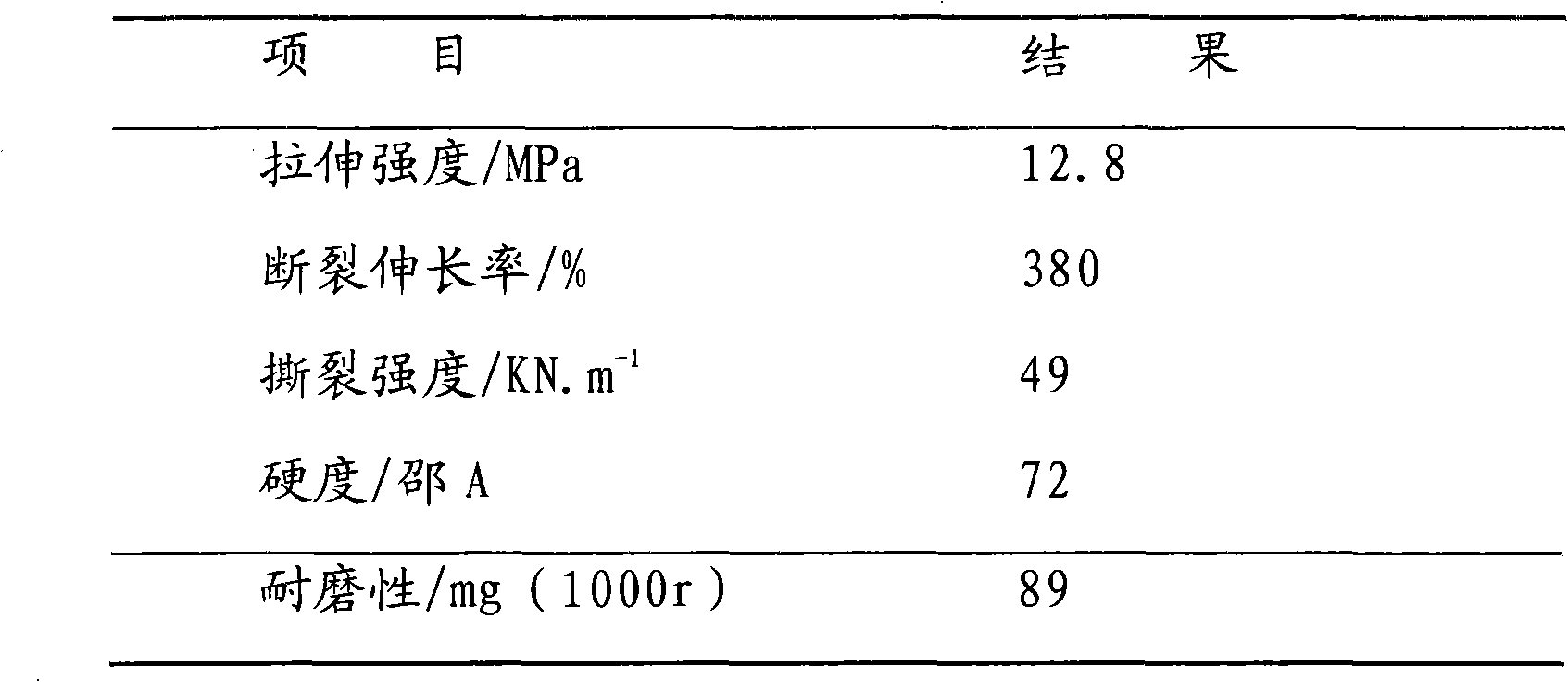

[0046] A and R components are sprayed with high-pressure collision mixing spraying equipment at a volume ratio of 1:1. Spray the coating onto a PVC panel coated with a release agent. Aft...

Embodiment 2

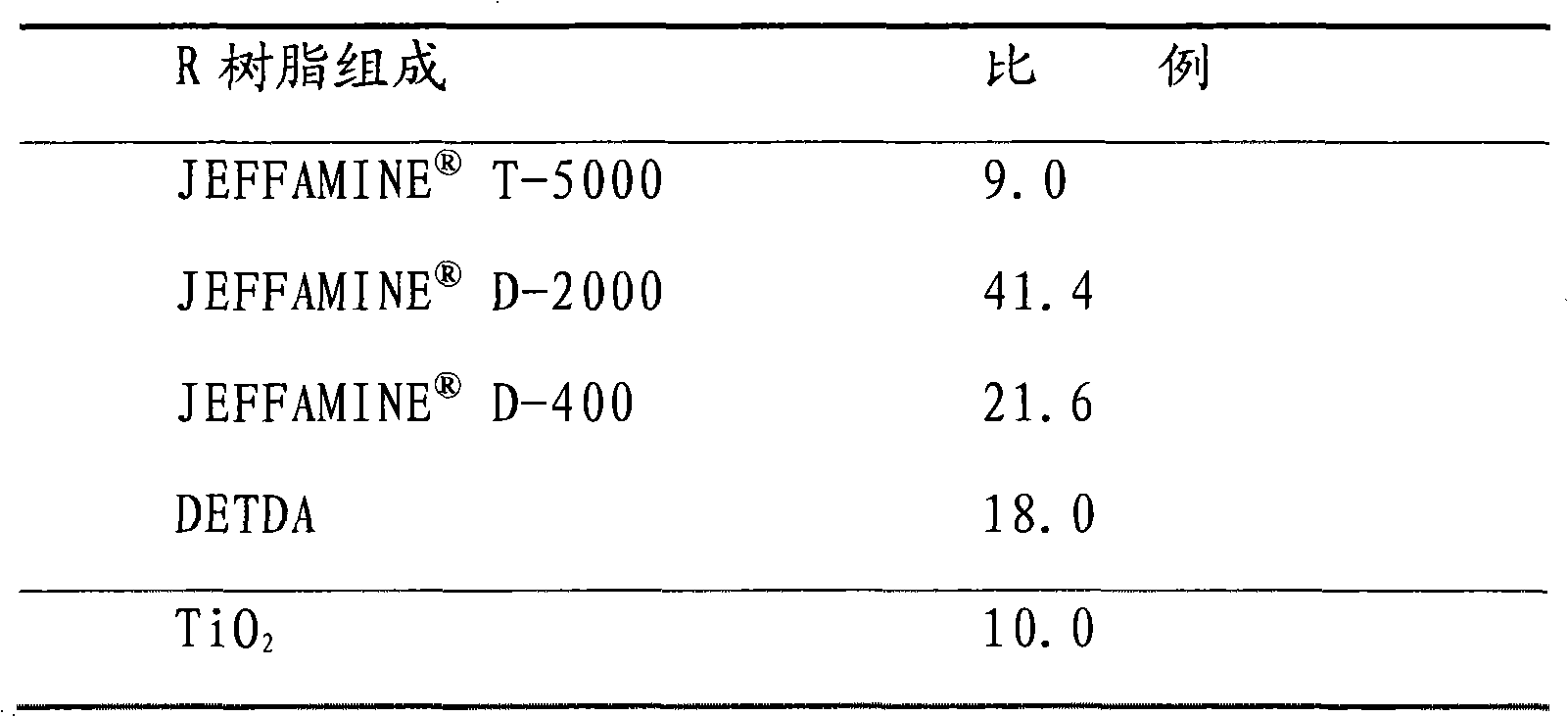

[0050] A consists of about 15 parts of 2,4'-diphenylmethane diisocyanate and 41 parts of 4,4'-diphenylmethane diisocyanate and 44 parts of polytetrahydrofuran ether with a molecular weight of 1000 and a functionality of 2. Alcohol (PTMG-1000, BASF, Germany) prepared prepolymer. The NCO content of the prepolymer is (15±0.1)%, and the viscosity at 25° C. is about 1200 cps. The R component consists of T-5000 amino resin, D-2000, D-400, DETDA amino resin and TiO 2 The composition of the mixture. Accurately weigh the various raw materials in the R component according to the formula, add them into the paint tank, and stir at high speed for 30 minutes with high-speed shearing and dispersing equipment.

[0051] The isocyanate index of this system was 1.10. The specific ratio is shown in the table below.

[0052]

[0053] A and R components are sprayed with high-pressure collision mixing spraying equipment at a volume ratio of 1:1. Spray the coating onto a PVC panel coate...

Embodiment 3

[0057] A consists of about 30 parts of 2,4'-diphenylmethane diisocyanate and 26 parts of 4,4'-diphenylmethane diisocyanate and 44 parts of polytetrahydrofuran ether with a molecular weight of 1000 and a functionality of 2 Diol (PTMG-1000, BASF, Germany) prepared prepolymer. The NCO content of the prepolymer is (15±0.1)%, and the viscosity at 25° C. is about 1200 cps. The R component consists of T-5000 amino resin, D-2000, D-4000, DETDA amino resin, TiO 2 , mica powder mixture. Accurately weigh the various raw materials in the R component according to the formula, add them into the paint tank, and stir at high speed for 30 minutes with high-speed shearing and dispersing equipment.

[0058] The isocyanate index of this system was 1.10. The specific ratio is shown in the table below.

[0059]

[0060] A and R components are sprayed with high-pressure collision mixing spraying equipment at a volume ratio of 1:1. Spray the coating onto a PVC panel coated with a releas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com