Flue gas exchange type activated carbon desulfurization and denitrification integrated process system and application

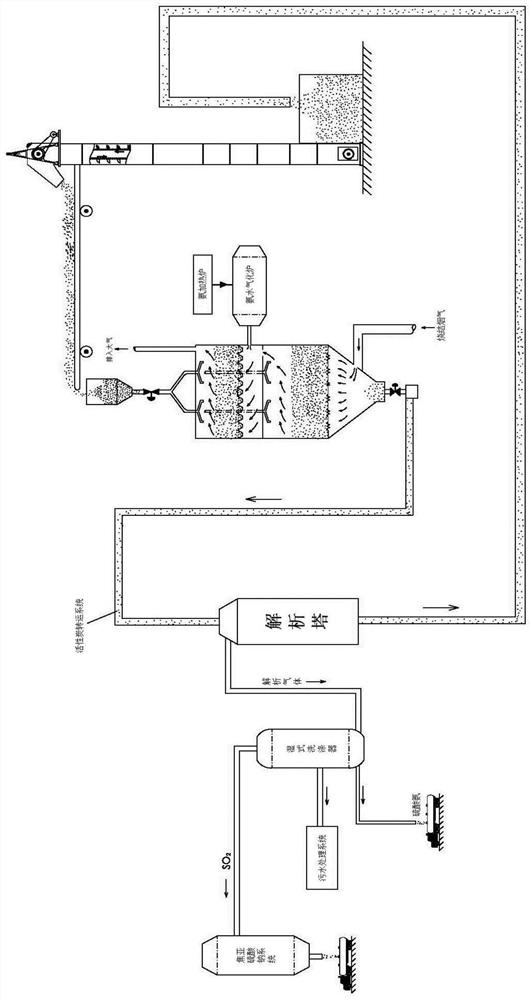

A process system, desulfurization and denitrification technology, applied in the field of activated carbon desulfurization and denitrification integrated process system, can solve the problems of large production process system structure, high equipment investment cost, high production failure rate, etc., to reduce production and operation energy consumption and simplify production The technological process and the effect of reducing construction investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

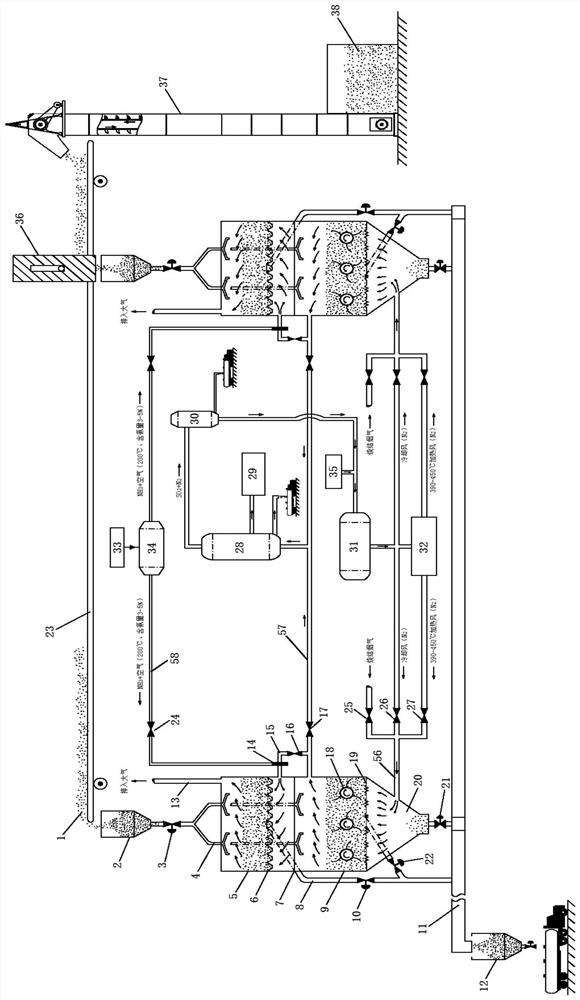

[0093] Such as figure 2 As shown, this embodiment provides a flue gas exchange type activated carbon desulfurization and denitrification integrated process system, including two adsorption towers that cooperate with each other, two identical adsorption towers, one left and one right, and the left adsorption tower is used below As an example;

[0094] The adsorption tower includes a denitrification box 5, a desulfurization box 9, and an ash hopper 20 sequentially connected from top to bottom. The denitrification box 5 and the desulfurization box 9 are separately arranged up and down, and the ash hopper 20 is connected to the bottom of the desulfurization box 9; The denitrification box 5 and the desulfurization box 9 are connected separately, with a heat insulation layer in the middle, and the ash hopper 20 is connected to the desulfurization box 9; The air guide plate 6 divides the interior of the denitrification box 5 into upper and lower parts. The bottom of the honeycomb a...

Embodiment 2

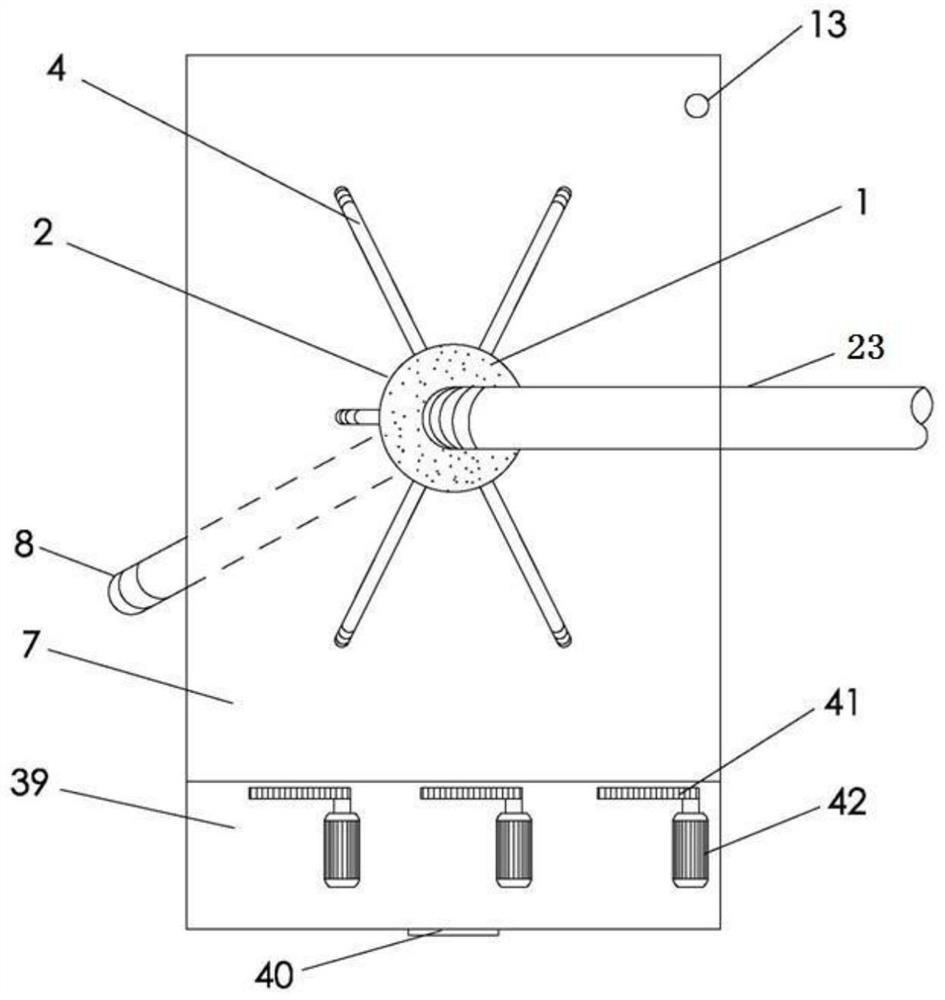

[0115] Repeat Example 1, the difference is that three agitators 18 are arranged in the desulfurization box, and the agitators 18 are located 10 cm above the grid air guide plate 19 . The three agitators are installed equidistantly in the same horizontal direction in the desulfurization box.

[0116] The agitator 18 includes a stirring paddle, a rotating shaft, a driving chain 41 and a motor 42, the stirring paddle is installed on the rotating shaft by welding, one end of the rotating shaft is connected to the inner wall of the desulfurization box, and the other end of the rotating shaft passes through the desulfurization box It is connected with the output shaft of the motor through a driving chain 41, and the two ends of the rotating shaft are fixed in the fixed bearings on the inner wall of the desulfurization box.

[0117] The outer wall of the desulfurization box body 9 is provided with a motor airtight compartment 39, the motor, drive chain and the end of the rotating sha...

Embodiment 3

[0119] Repeat Example 1, the difference is that the wet scrubber is also connected to the sewage treatment system 29, and the sewage treatment system uses conventional equipment. After the washing solution in the wet scrubber reaches a certain concentration, it is discharged to the sewage treatment system for purification treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com