PLC (Programmable Logic Controller) controlled denitration device

A technology of denitration and main body, applied in the field of denitration, can solve the problems of uneven thickness of catalyst, influence reaction efficiency, insufficient reaction of nitrogen oxides, etc., and achieve the effect of improving reaction effect, improving reaction efficiency and uniform catalyst layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

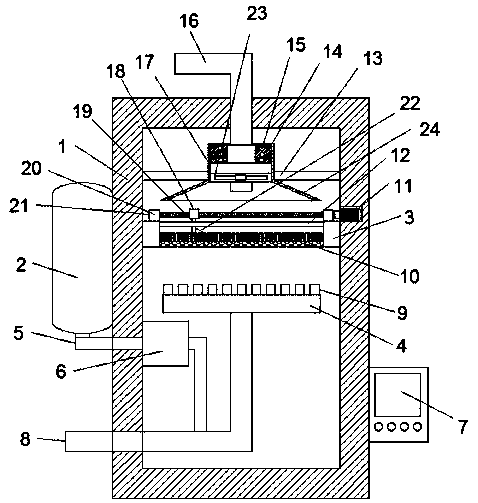

[0023] As a preferred embodiment of the present invention, a PLC controller 7 is fixed on the outside of the device main body 1, and the PLC controller 7 is electrically connected to the evaporator 6, the motor 11, the exhaust fan 23 and the electric heating rod 15 respectively.

[0024] As a preferred embodiment of the present invention, the heat conduction block 14 is a hollow cylindrical structure, and the heat conduction block 14 is made of copper or aluminum.

[0025] As a preferred embodiment of the present invention, the catalyst plate 3 is provided with a limiting rod 12 , and the connecting rod 19 passes through the limiting rod 12 .

[0026] As a preferred embodiment of the present invention, the motor 11 is a forward and reverse motor.

[0027] When the denitrification device is in use, a guide plate is arranged at the end of the smoke inlet pipe, and a plurality of smoke outlets are arranged on the upper surface of the guide plate, so that the mixed gas of flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com