Pressing cap structure of hydraulic jar

A technology of jar and cap structure, which is applied to wellbore/well components, earth-moving drilling, etc., can solve the problems of loosening and withdrawing of screw 3, straining and jarring cylinder, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

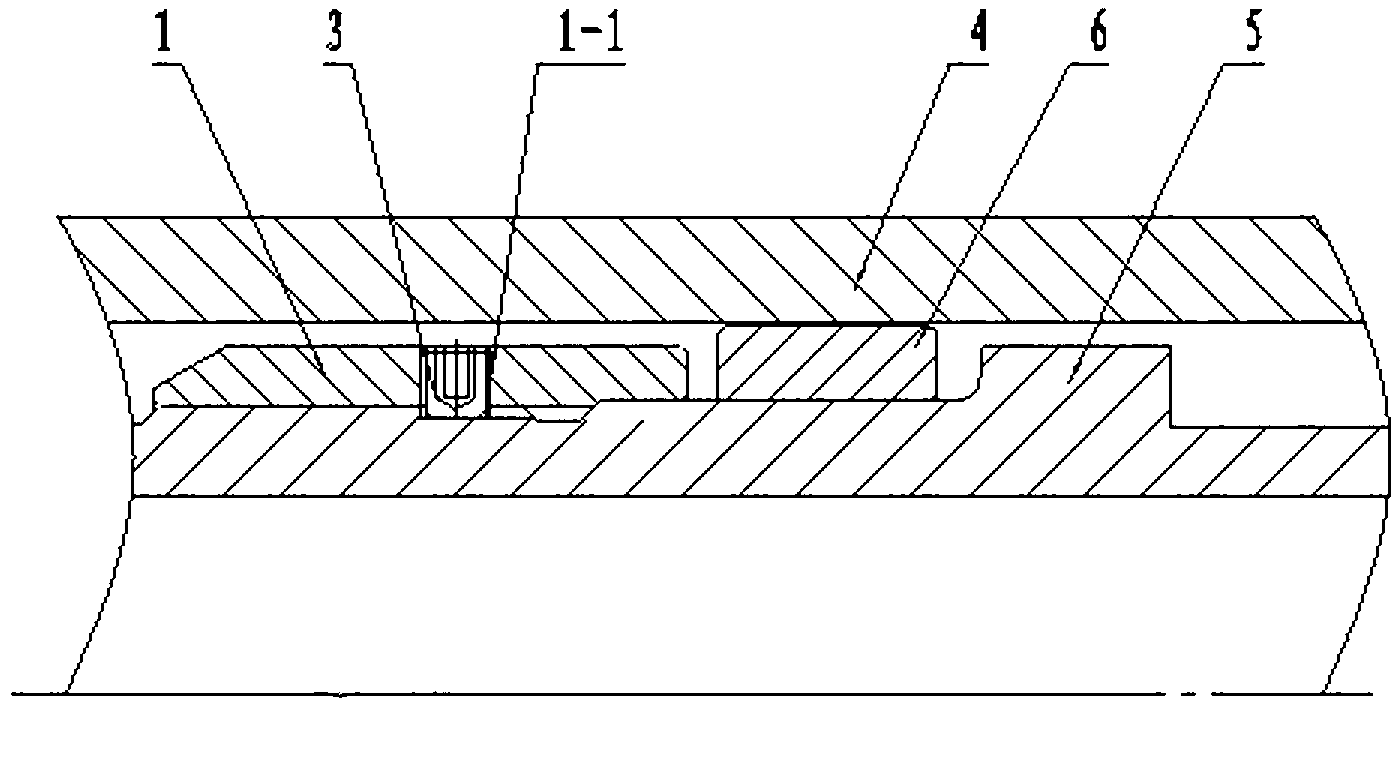

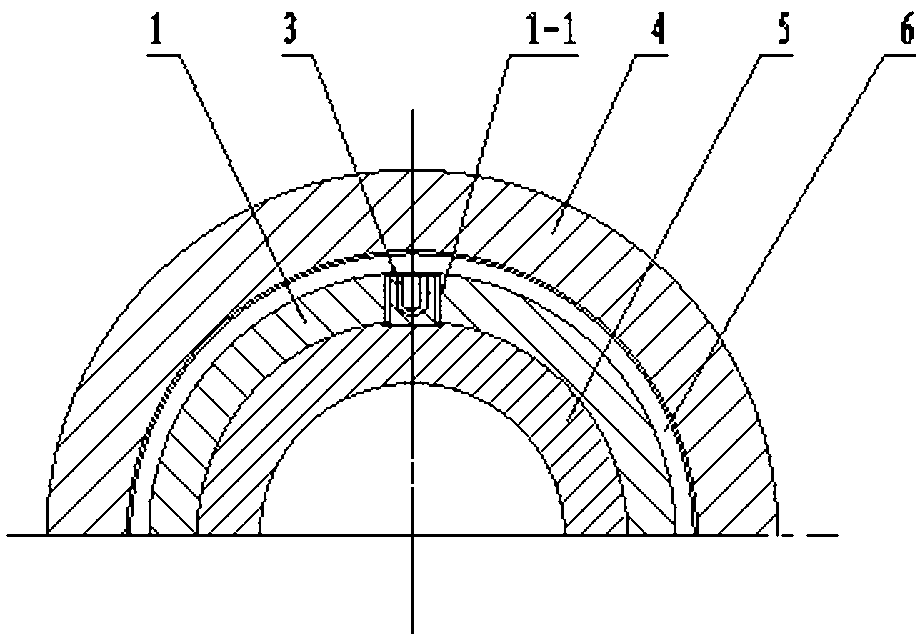

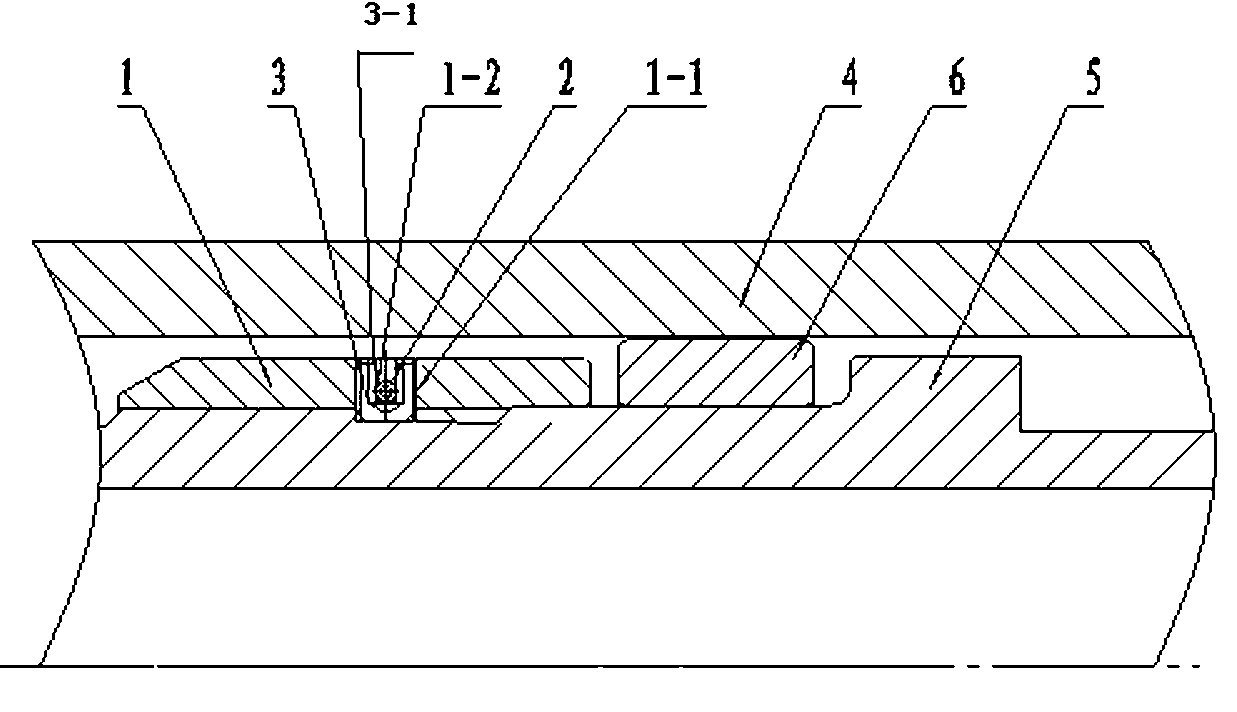

[0028] see image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, the pressure cap structure of the hydraulic jar of the present invention includes a pressure cap 1 for limiting the axial movement of the overflow piston 6, a shock cylinder 4 and a mandrel 5, and the pressure cap 1 is set in the shock fluid. On the mandrel 5 in the cylinder 4, the radial direction of the pressure cap 1 is provided with a screw hole 1-1, and the pressure cap 1 is fixedly connected with the mandrel 5 by tightening the screw 3 in the screw hole 1-1, and it is characterized in that: Including the connecting pin 2, a through hole 1-2 is opened on the pressure cap 1 perpendicular to the direction of the screw hole 1-1, and a groove 3-1 matched with the through hole 1-2 is opened on the screw 3. The connecting pin 2 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com