Construction method for conducting high-pressure jet grouting hole guiding firstly and then conducting grouting-assisted jacked pile sinking

A technology of high-pressure rotary spraying and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficult bearing capacity and instability, improve the bearing capacity of pile ends, reduce site pollution, and shorten the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

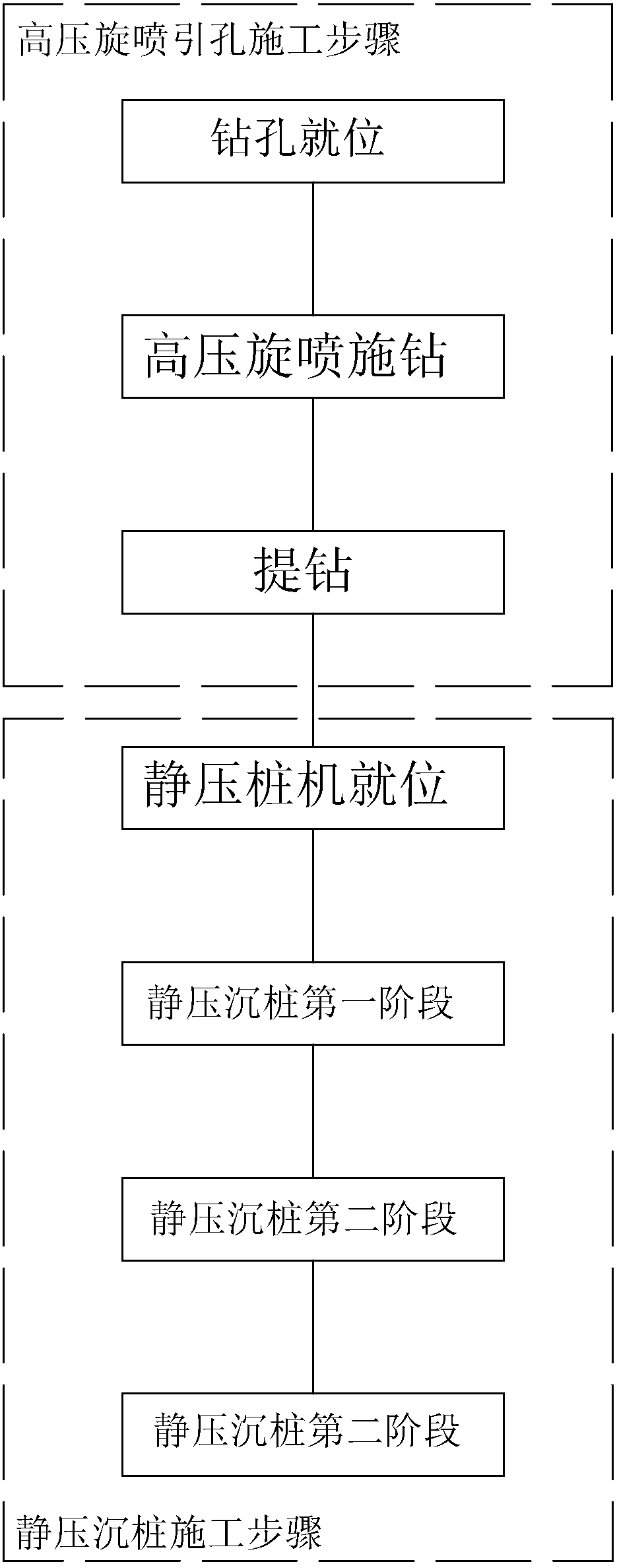

[0042] Embodiment: a method of pile sinking construction method for assisting static pressure piles by grouting after high-pressure rotary jet diverting holes, such as figure 1 As shown, the construction of the pressure-rotation injection hole and the static pressure pile sinking construction, the high-pressure rotation injection hole includes the following steps,

[0043] 1) Drilling in place

[0044] After the measurement and positioning is completed, move the high-pressure rotary jet drilling rig to the designated pile position, align the drill bit to the center of the hole position, and level the drilling rig at the same time, place it stably and horizontally, and the verticality deviation of the drill pipe is not more than 1% to 1.5%.

[0045] 2) Drilling with high-pressure rotary spraying

[0046] The upper part of the pile position is drilled downwards based on the principle of less water spraying or no water spraying. The pressure value of the pressure pump is set to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com