Line barrier-crossing type overhead tool

An obstacle-crossing, line technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of labor-intensive labor, inconvenient operation process, prolonged operation time, etc., and achieve convenient price increase and dismantling, convenient lifting, and convenient disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

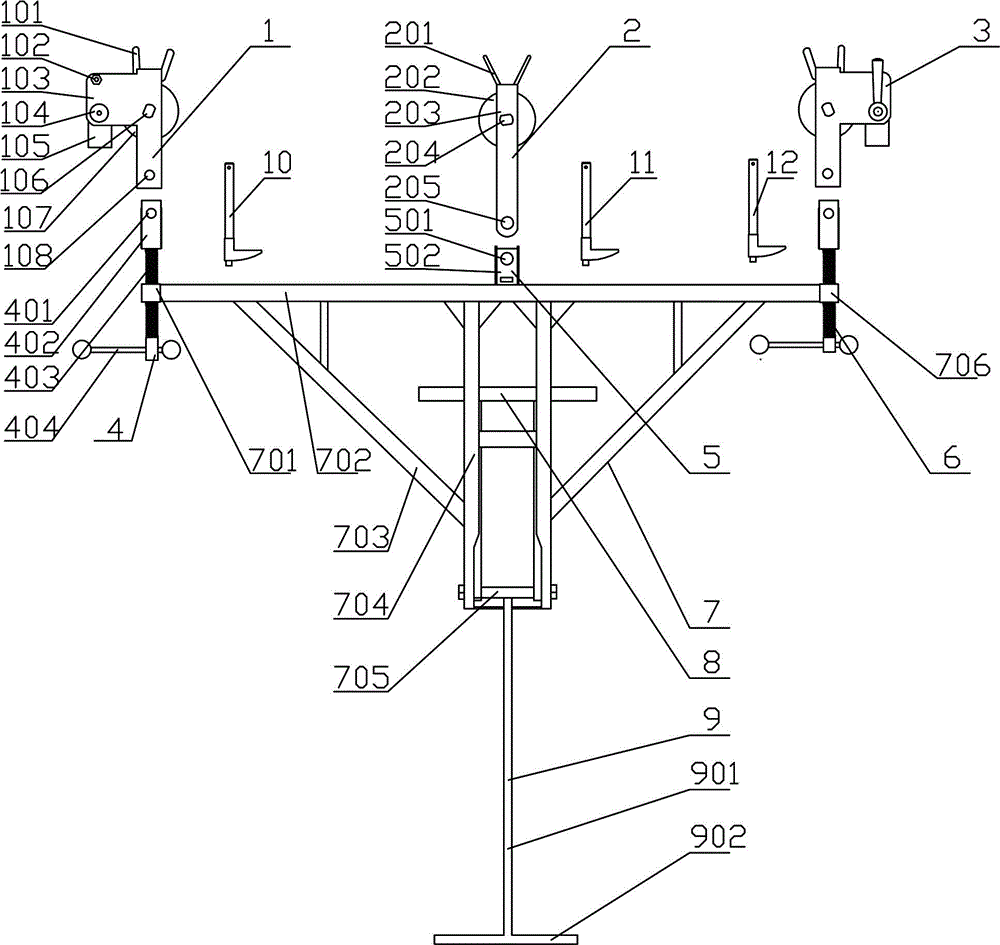

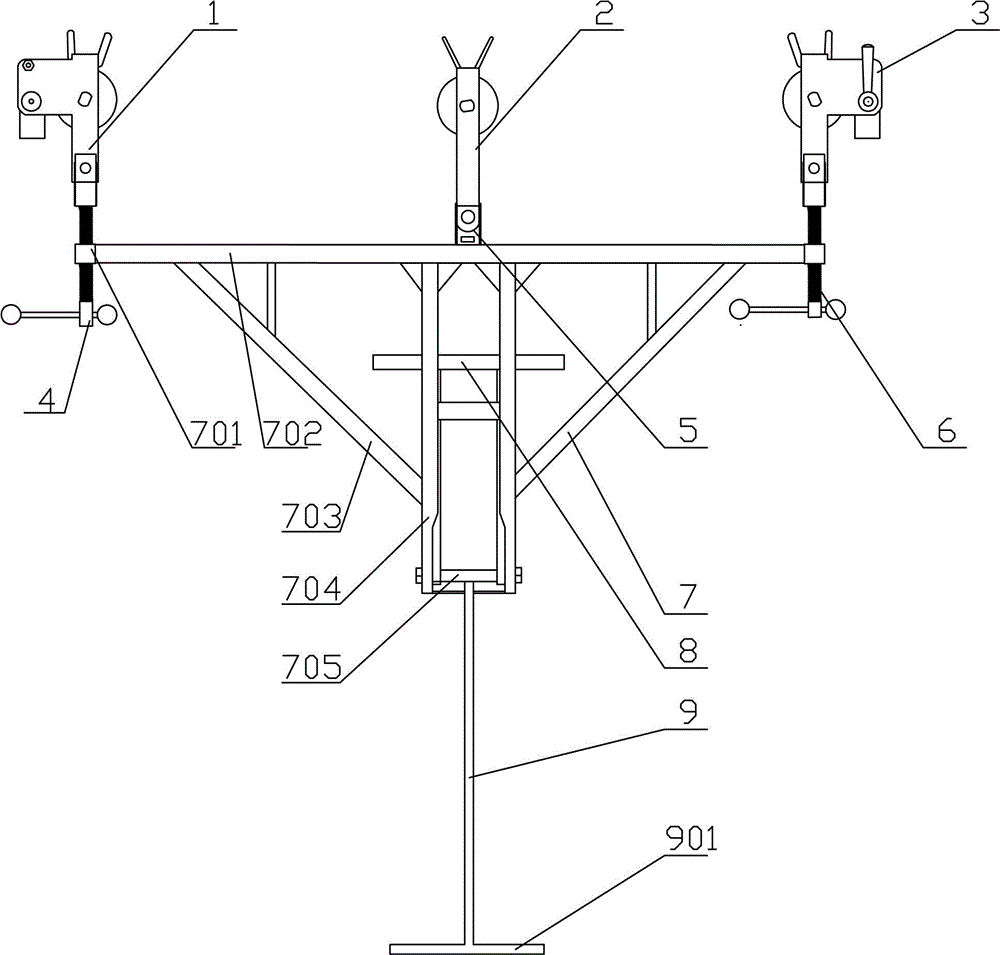

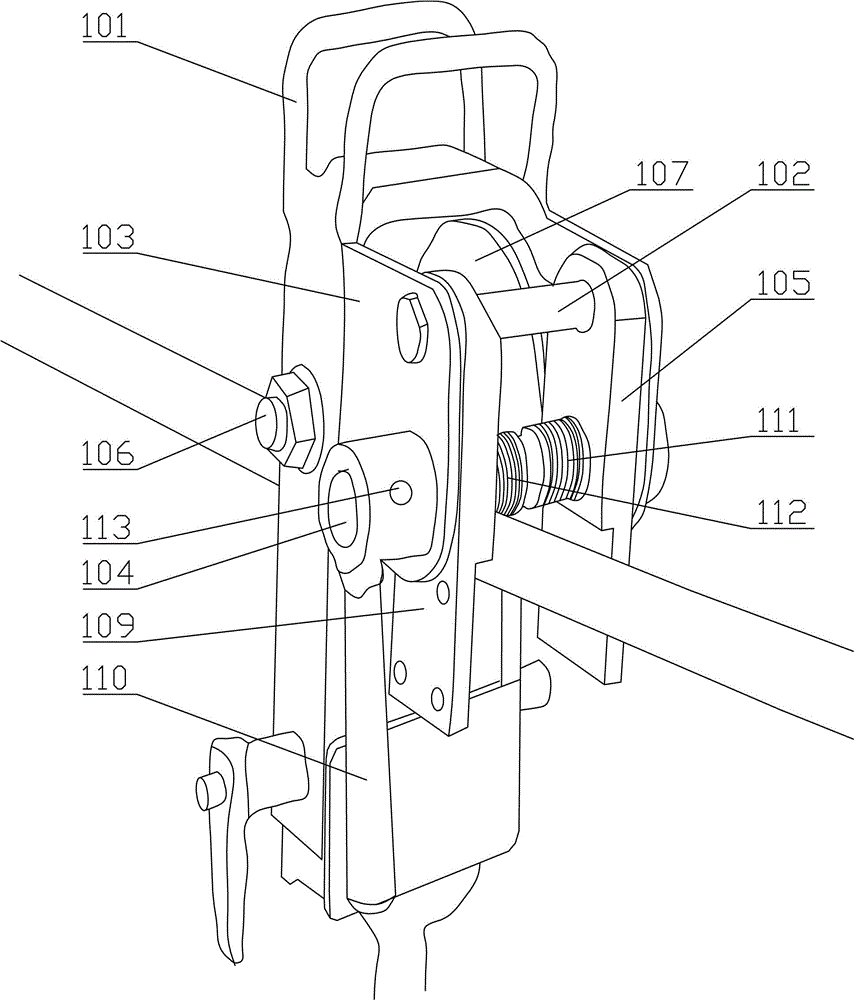

[0042] see Figure 1-5, the line obstacle-crossing flying car, which includes a frame 7, the frame 7 includes a beam 702, the left and right ends of the beam 702 are respectively processed with a left threaded hole 701 and a right threaded hole 706, and the lower end surface of the beam 702 is welded with The two vertical rods 704 arranged symmetrically have an oblique support rod 703 welded between the vertical rod 704 and the beam 702, and the bottom ends of the two vertical rods 704 are fixedly connected by a rotating shaft 705; Side elevating mechanism 4, said right threaded hole 706 is fitted with a right elevating mechanism 6, and a middle connecting device 5 is fixedly installed in the middle of the beam 702; said left elevating mechanism 4 is detachably mounted with a left pulley Device 1, the right pulley device 3 is detachably installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com