Process for realizing grouting consolidation for aggregates filled in cavities of strata and jetting drill bit

A formation cavity and drill bit technology, which is applied in drill bits, earth-moving drilling, drilling equipment, etc., can solve problems such as drilling deflection, stuck accident, and leakage of isolating casing flushing fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

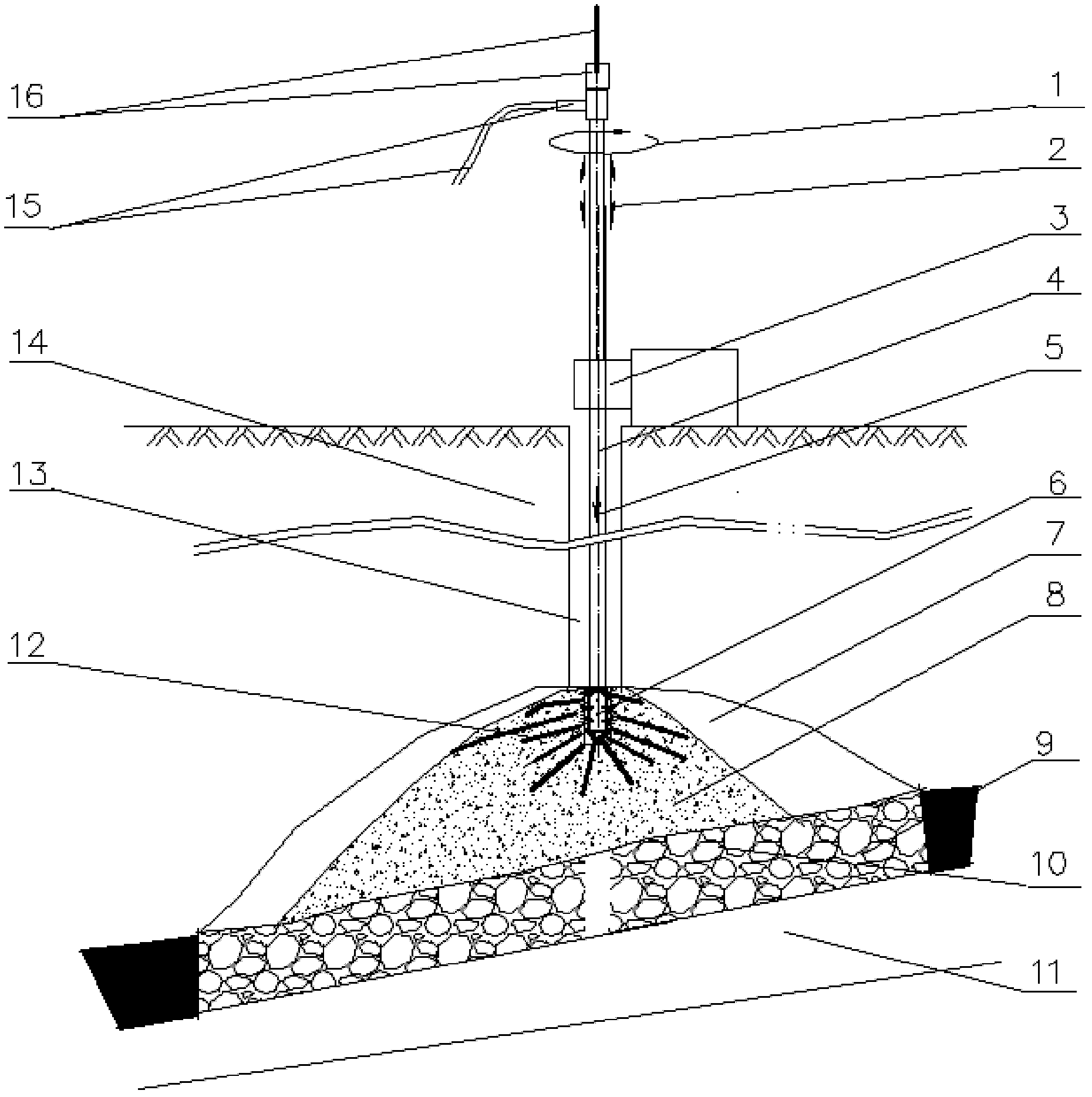

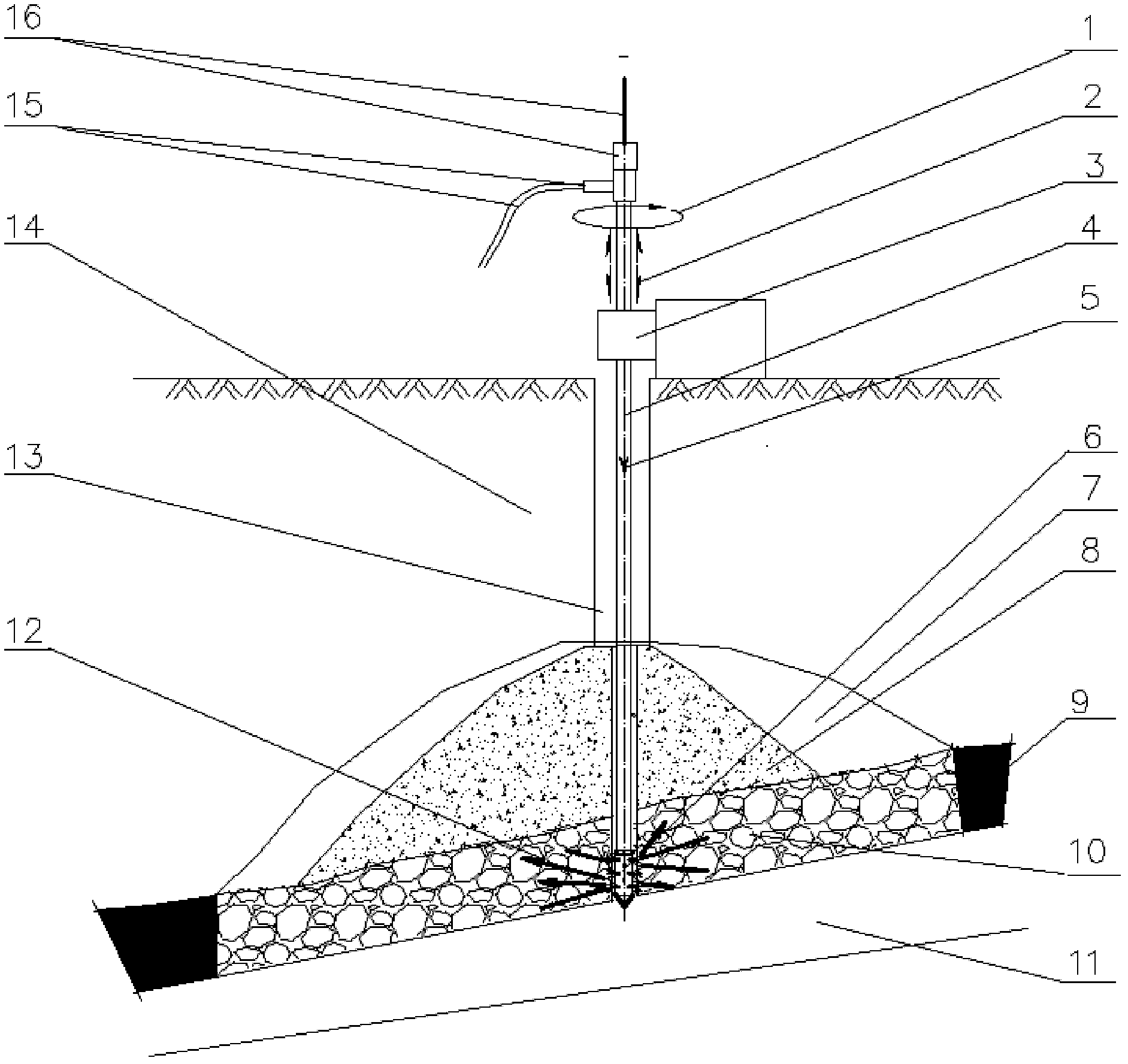

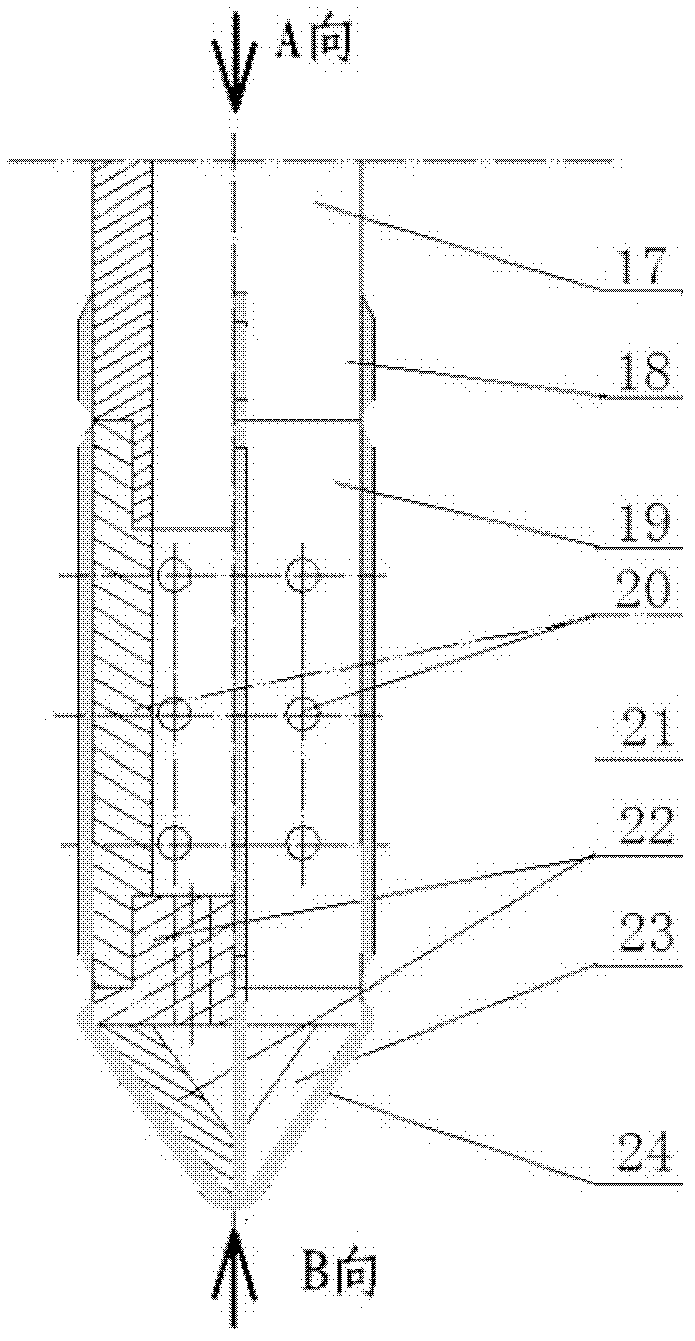

[0078] At 8:30 on July 1, 2006, when the 10404(2) working face of Jinan Huamei Mining Co., Ltd. was pushed out 40m, water came out. On July 5, the water inrush point of the night shift was 2601m 3 / h, and there is a tendency to continue to increase, flooding the north wing of the mine and causing the north wing to stop production. Aiming at the water outflow situation of the 10th layer coal, a water shutoff plan for grouting and water shutoff boreholes constructed from the ground was formulated. However, according to the analysis of the hydrogeological data of the working face, two of the four designed boreholes (Note 1 and Note 4) respectively pass through the three-layer goaf of Coal 8, Coal 9 and Coal 10, and one borehole (Note 3) It is necessary to pass through the goaf of Coal 8 and Coal 9. Three boreholes were actually constructed, namely Note 1, Note 3 and Note 4.

[0079] The depth and thickness of the bottom boundary of the three-layer goaf coal seam are: Coal 8: 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com