Water energy cleaner

A cleaner and water energy technology, which is applied in public buildings, gymnasiums, building types, etc., can solve the problems of insufficient output torque and insufficient stability of the output force, achieve large output torque and improve the utilization rate of water energy resources. , The effect of high output force stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

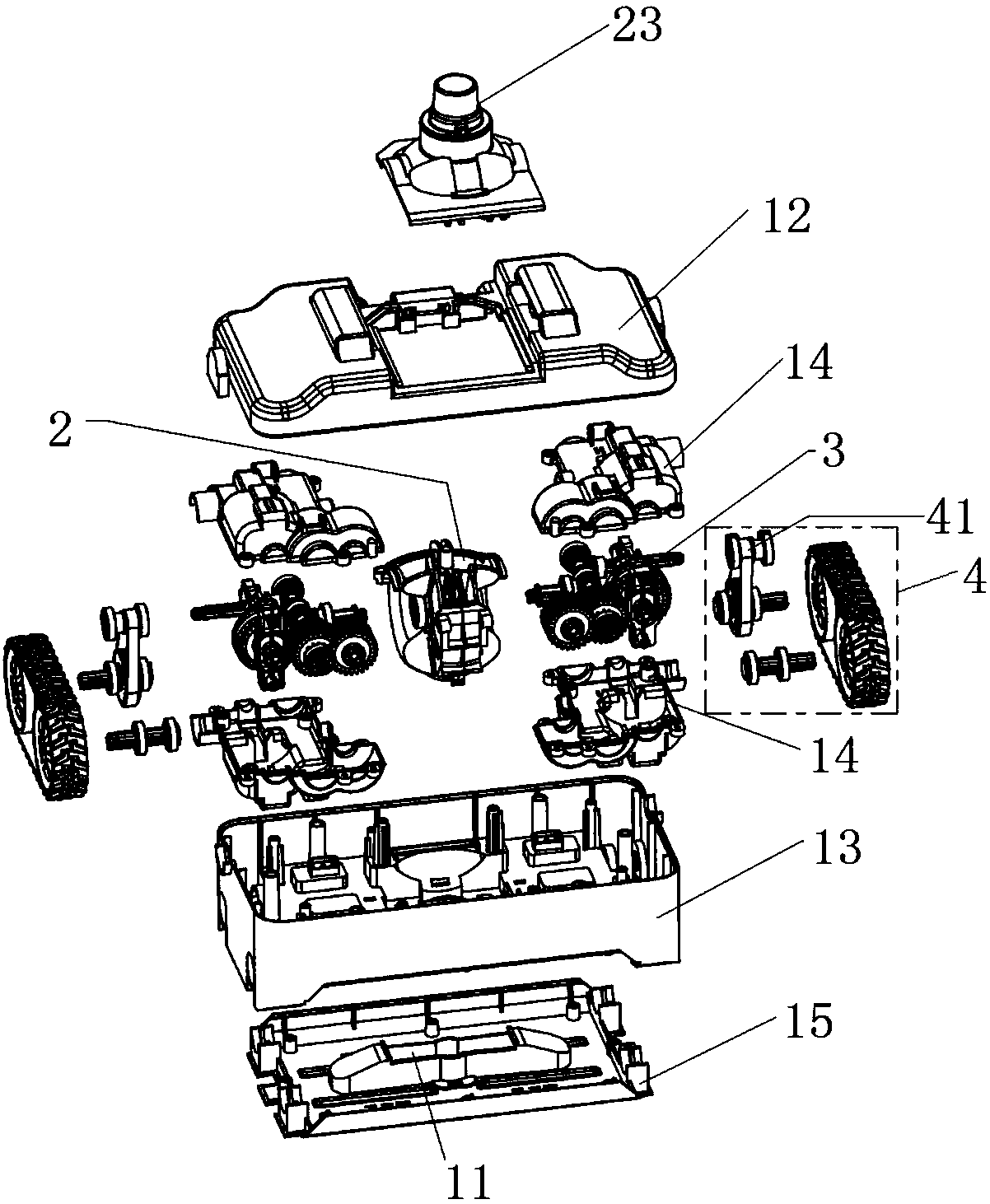

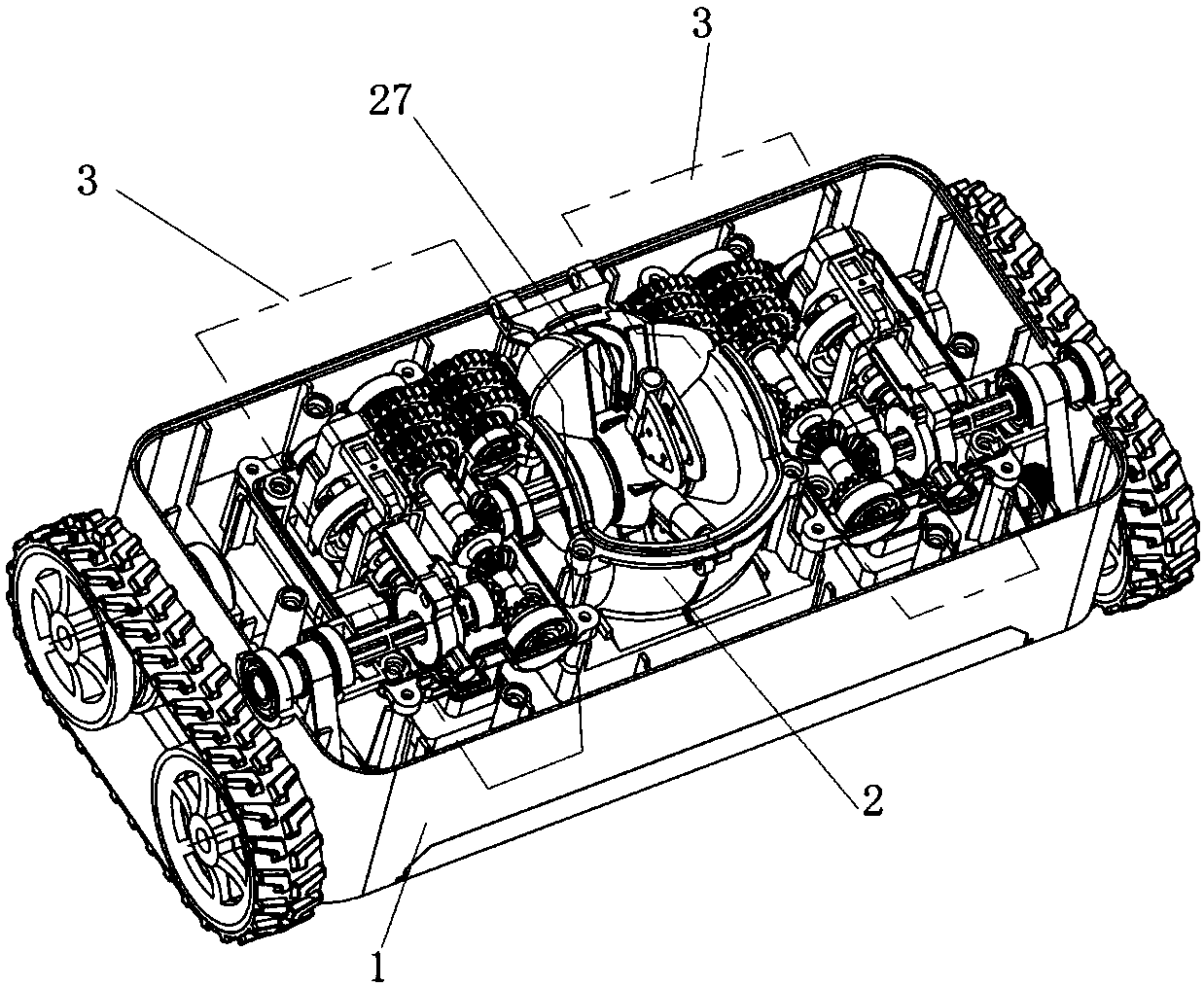

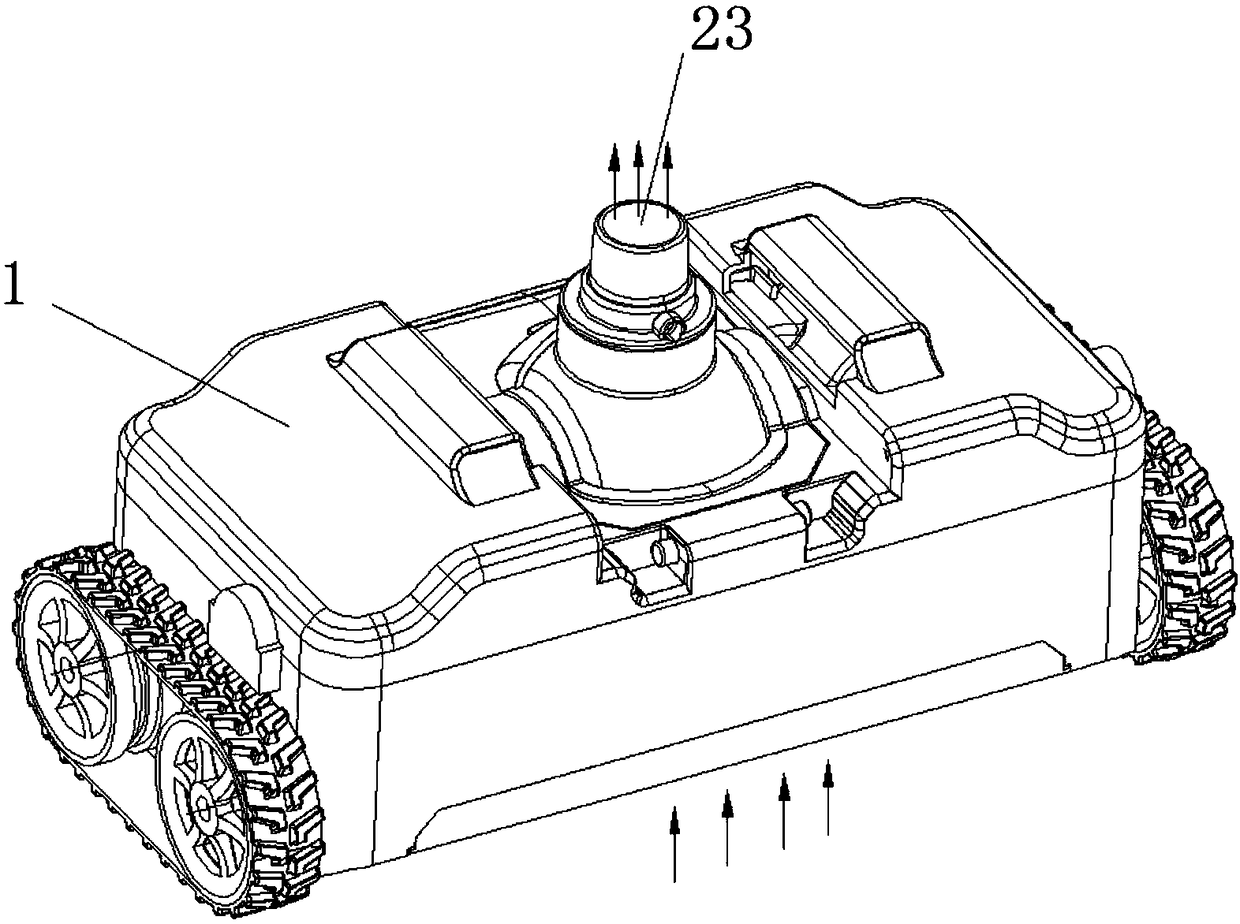

[0043] see Figure 1 to Figure 7 As shown, they are respectively the overall explosion diagram, the overall structure schematic diagram, and the water flow direction of a water energy cleaner of the present invention. figure 1 , indicating the direction of water flow figure 2 , Partial explosion diagram of hydraulic motor fan blade structure, schematic diagram of internal structure of hydraulic motor figure 1 and the internal structure of the hydraulic motor figure 2 .

[0044] like figure 1 and figure 2 As shown, a water energy cleaner includes a fixed housing 1, a hydraulic motor 2, a two-direction switching structure 3 and a power output structure 4, the bottom of the fixed housing 1 is provided with a water suction port 11, and the hydraulic motor 2 is placed in the center of the fixed housing 1, and the two direction switching structures 3 are respectively arranged on both sides of the hydraulic motor 2, and the power output structure 4 is connected to the directi...

Embodiment 2

[0051] As a kind of water energy cleaner as mentioned above, the difference of this embodiment is that, as Figure 9 , Figure 12 and Figure 13 As shown, the direction switching structure 3 includes a gear transmission structure, a switching structure guiding part 31 and a switching structure movable part 32 . The gear transmission structure includes a transmission shaft 331, a reduction gear set 332, a motor output transmission shaft 333 and a power output shaft 334. The transmission shaft 331 is provided with a coaxial sector gear A 3311 and opposite sector gears B 3312 and Sector gear C3313, the reduction gear set 332 is sleeved on the end of the transmission shaft 331, the motor output transmission shaft 333 is meshed with the sector gear A3311, and one end of the power output shaft 334 is placed on the sector gear B 3312 and the sector gear Between C 3313. The switching structure guide 31 is provided with a coaxial gear 311 and a guide groove 312 , and the gear 311 is...

Embodiment 3

[0055] As mentioned above, the difference between this embodiment and Embodiment 1 is that the fan blade 27 is a fan blade 27 whose periphery is made of soft rubber material. During the dirt suction process, there will be garbage cards On the edge of the fan blade 27, but due to the good flexibility of the soft rubber material, the garbage can pass through the inlet channel 24 from the fan blade 27 under the thrust of the water flow, and then be discharged from the water outlet 23. This prevents the fan blade 27 from being stuck by rubbish during operation, thereby affecting the power of the hydraulic motor.

[0056] The baffle 26 is a baffle 26 made of soft rubber. When the fan blade 27 is closed, it passes through the baffle 26 and enters the flow channel sealing cavity. When the fan blade 27 is not closed in place, the fan blade 27 will collide with the edge of the groove of the baffle 26, but because the soft rubber material has good flexibility, it can prevent the fan bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com