Concrete pouring guide mechanism

A technology of concrete and material guide frame, which is applied in the direction of building structure, building material processing, construction, etc., and can solve problems that affect concrete pouring processing, cannot meet the needs of building construction, and it is difficult to ensure that the concrete is scattered and distributed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

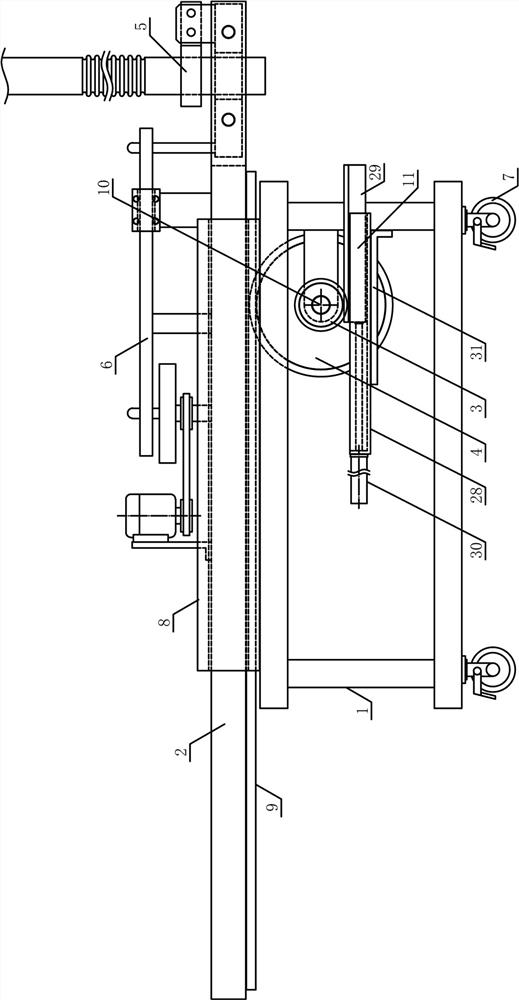

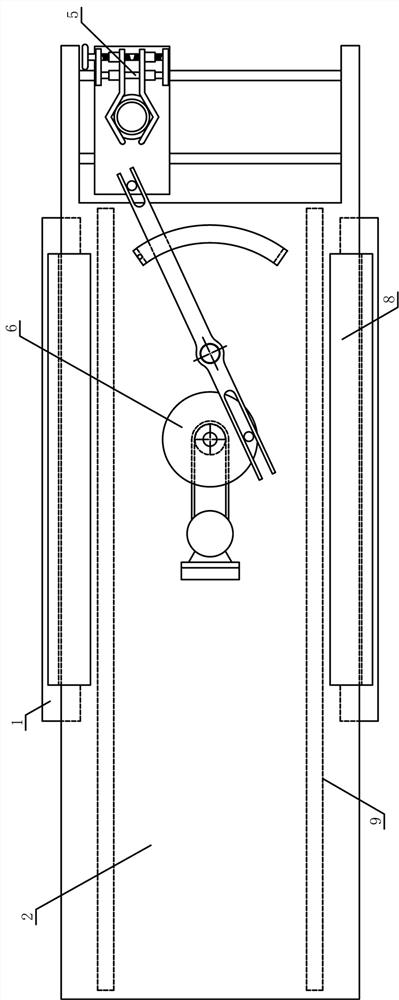

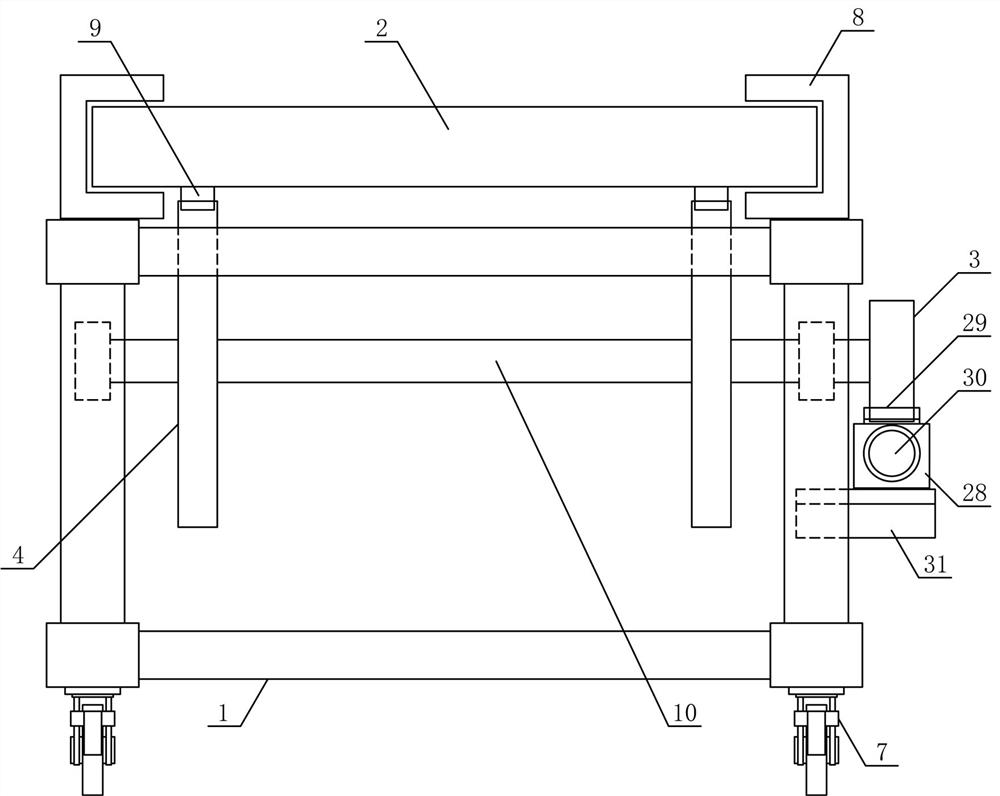

[0020]In order to further describe the present invention, a specific embodiment of a concrete pouring guide mechanism is further described below with reference to the accompanying drawings. The following examples are for explaining the present invention and the present invention is not limited to the following examples.

[0021] like figure 1 , figure 2 and image 3 As shown, a concrete pouring guide mechanism of the present invention includes a pouring guide frame 1, a reciprocating flat guide plate 2, a guide main gear 3, a guide auxiliary gear 4, a reciprocating distribution mechanism 5 and a distribution drive mechanism 6. The lower side of the frame 1 is evenly provided with a plurality of universal wheels 7 with brakes, the upper and lower sides of the pouring guide frame 1 are respectively horizontally fixed with reciprocating flat guide rails 8, and the reciprocating flat guide plate 2 is arranged on the upper side of the pouring guide frame 1. The guide plate 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com