Sheet welding technology of high-power laser welding equipment

A laser welding and thin plate welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the welding quality of thin plates, difficulty, inconvenient splicing gap at the welding seam of two thin plates, etc., to achieve optimal welding Process, improve quality, fast and accurate positioning and fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

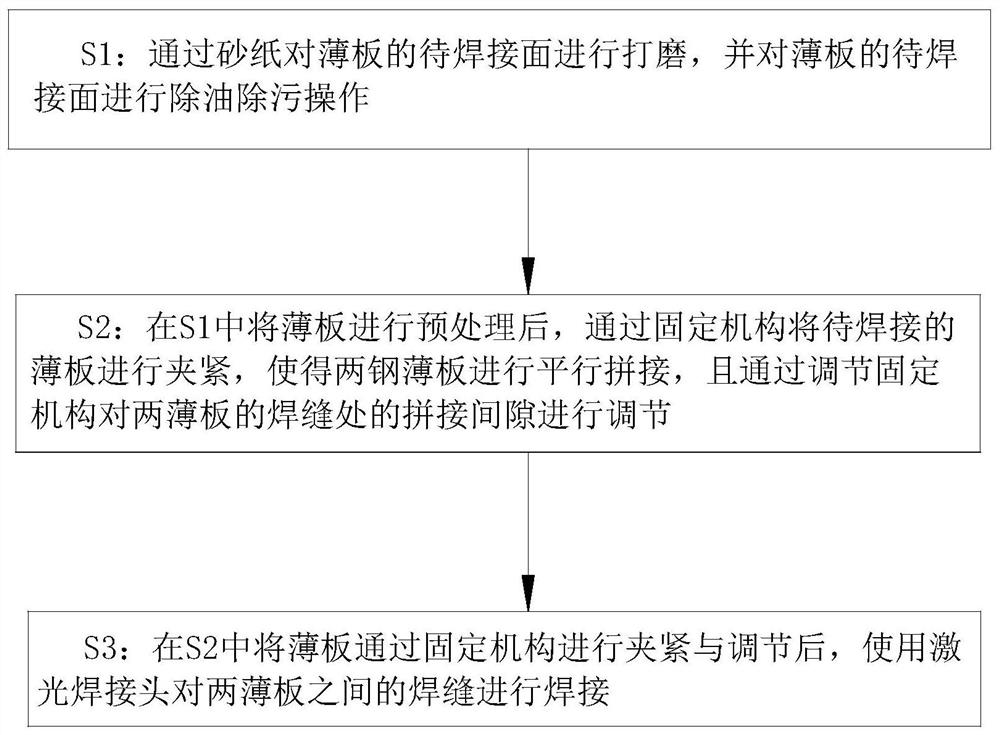

Method used

Image

Examples

Embodiment approach

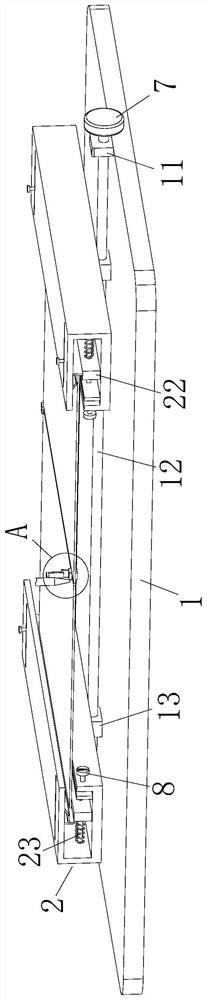

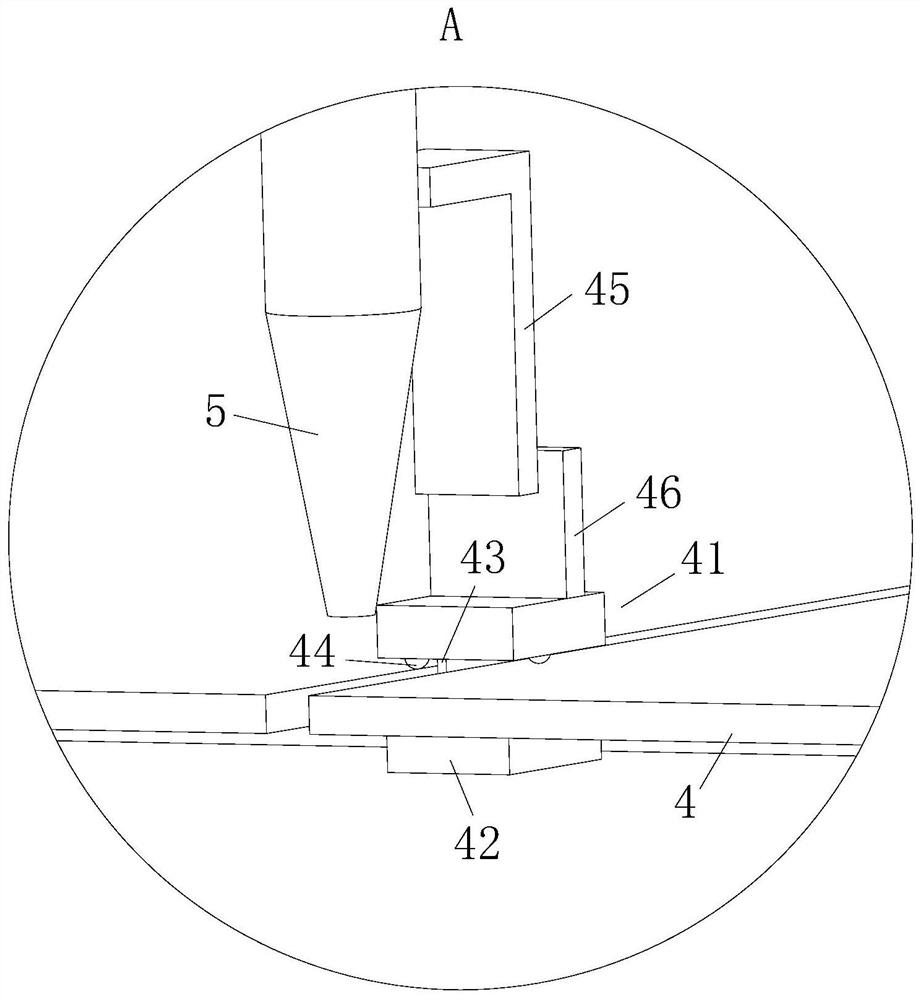

[0034] As an embodiment of the present invention, the end of the ball screw 12 is connected with a turntable 7, and the side of the support table 11 corresponding to the turntable 7 is provided with a dial, and the ball screw 12 drives the sliding table when it rotates once. 13 The moving distance is 1 mm; during work, in order to make the distance between the weld gap between the two thin plates 4 more precise control, at this time by setting the turntable 7 and the dial, and at the same time by setting the ball screw 12 to drive the slide plate 22 for one rotation The step value allows the staff to control the welding seam of the two thin plates 4 by controlling the rotation angle of the turntable 7 and the corresponding step value of the slide table 13 on the dial. The weld gap value between them further improves the convenience and practicability of the fixing mechanism in use.

[0035] As an embodiment of the present invention, the two ends of the side wall of the fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com