Patents

Literature

48results about How to "Increase or decrease in temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

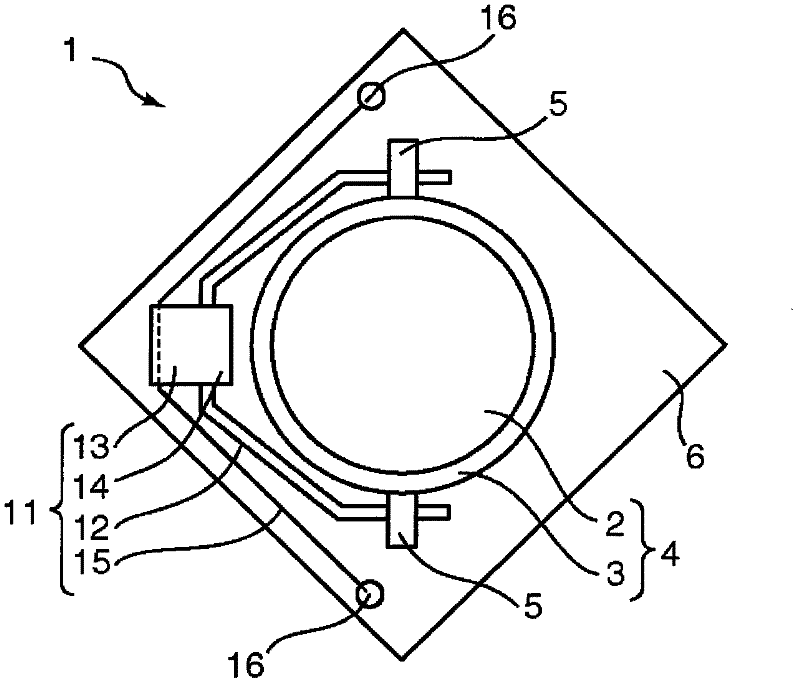

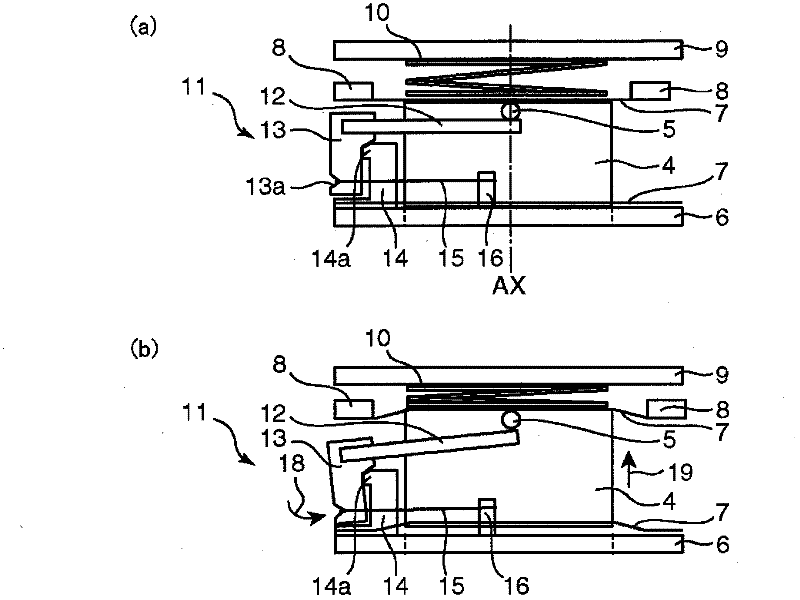

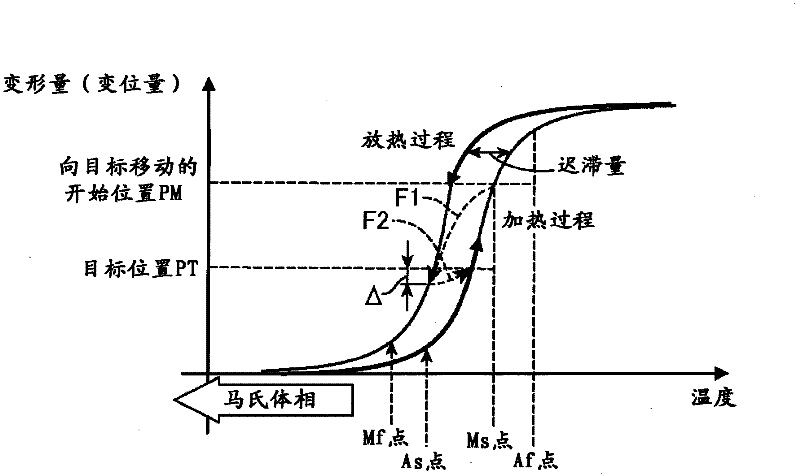

Driving device of shape memory alloy actuator, driving method thereof, and imaging device using same

InactiveCN102265032AIncrease temperatureIncrease or decrease in temperatureMachines/enginesMountingsHysteresisEngineering

The shape memory alloy actuator drive device (21) is configured such that a shape memory alloy (SMA 15) expands and contracts with temperature changes and has hysteresis for distortion characteristics of parameters regarding that expansion and contraction, wherein the parameter values corresponding to the target positions of a moving part, which is displaced and driven by the expansion and contraction of the SMA (15) as the temperature of the SMA (15) rises and falls, are measured by a measurement part and set as target parameters, the crystal phase of the SMA (15) is pre-martensitic, and the temperature of the SMA (15) is caused to rise or fall so that the parameter value measured by the measurement part passes the target parameter, after which, the temperature of the SMA (15) is again caused to rise or fall so that the parameter measured by the measurement part reaches the target parameter.

Owner:KONICA MINOLTA OPTO

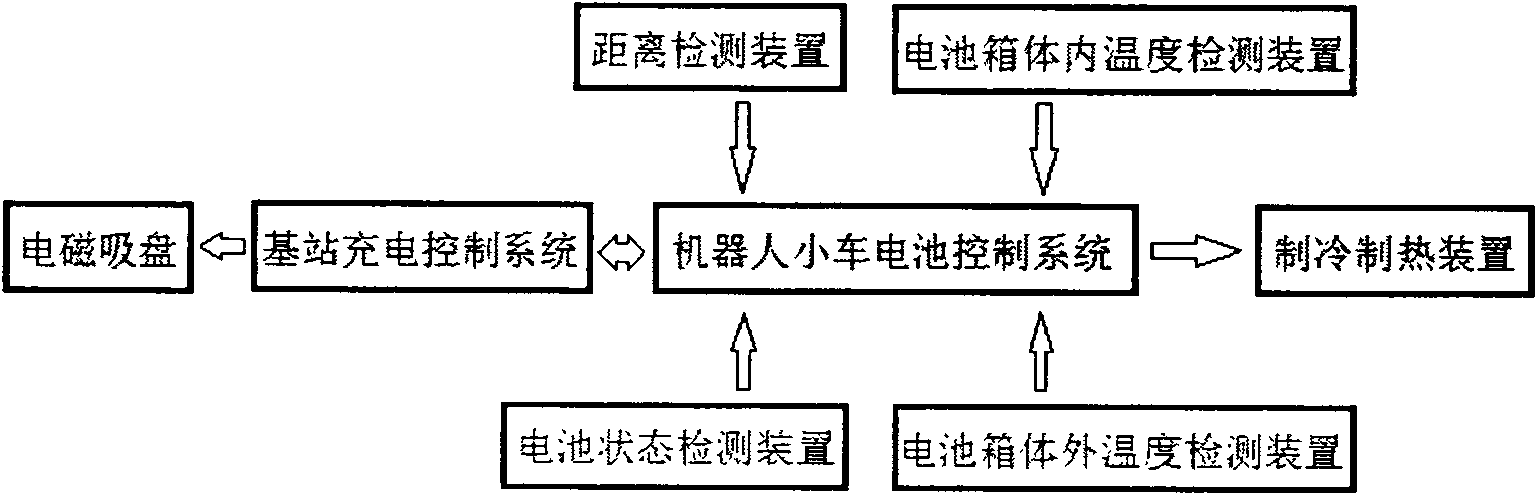

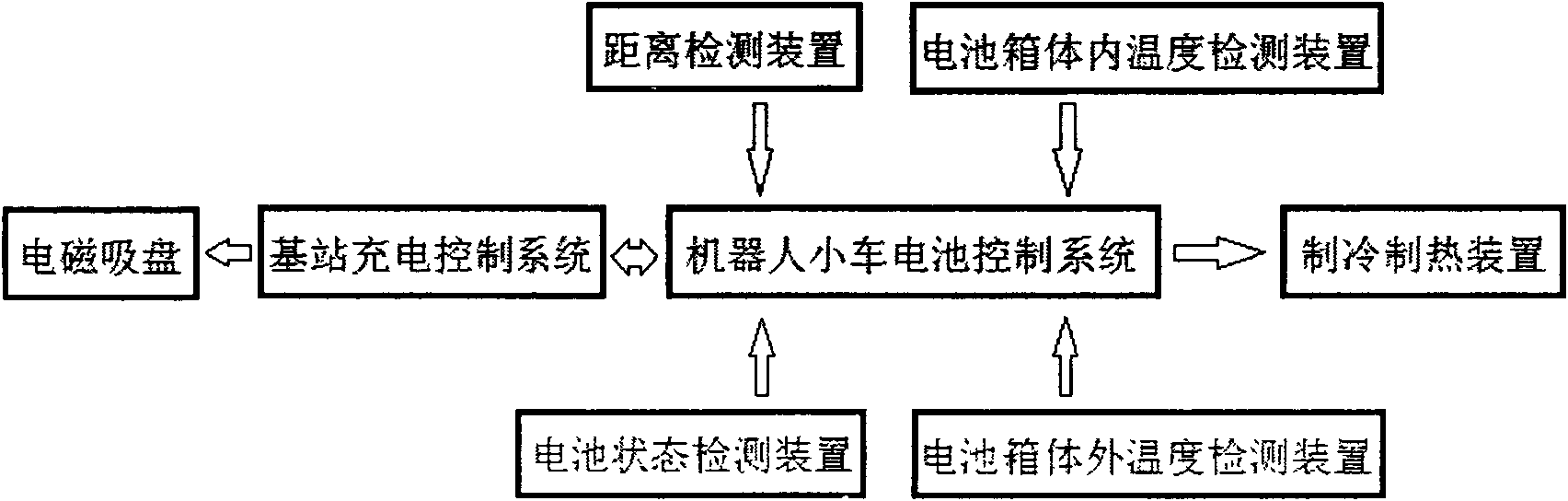

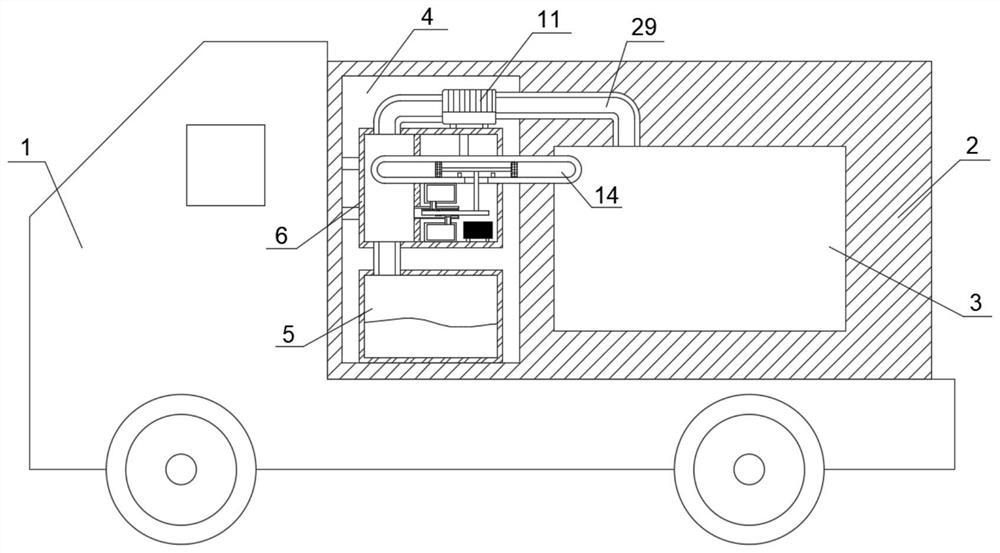

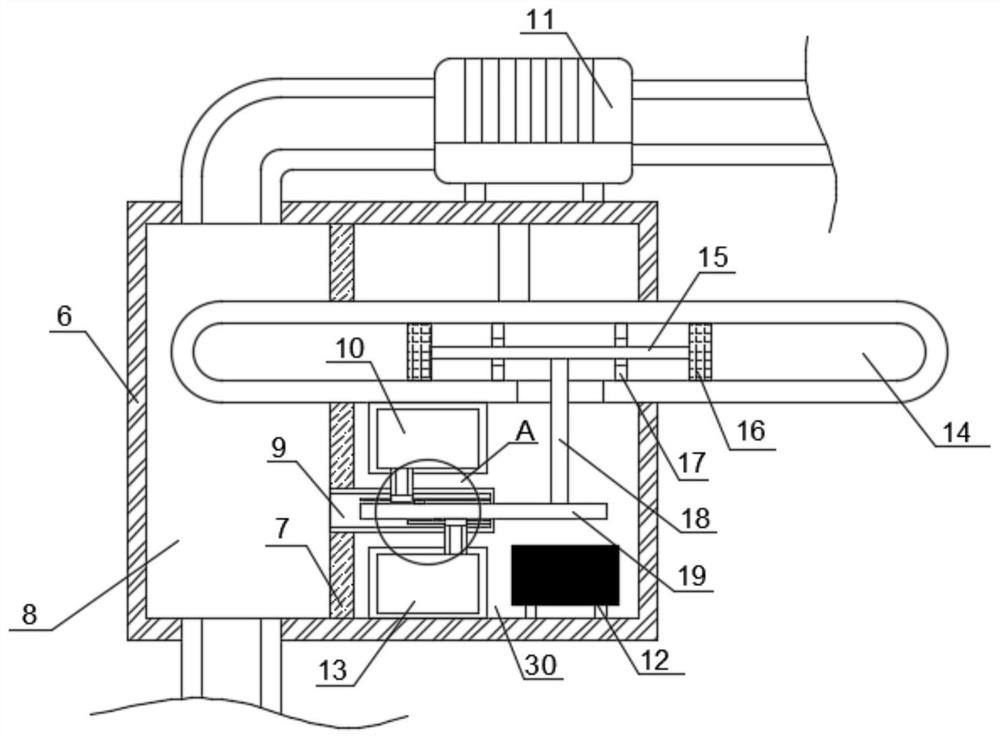

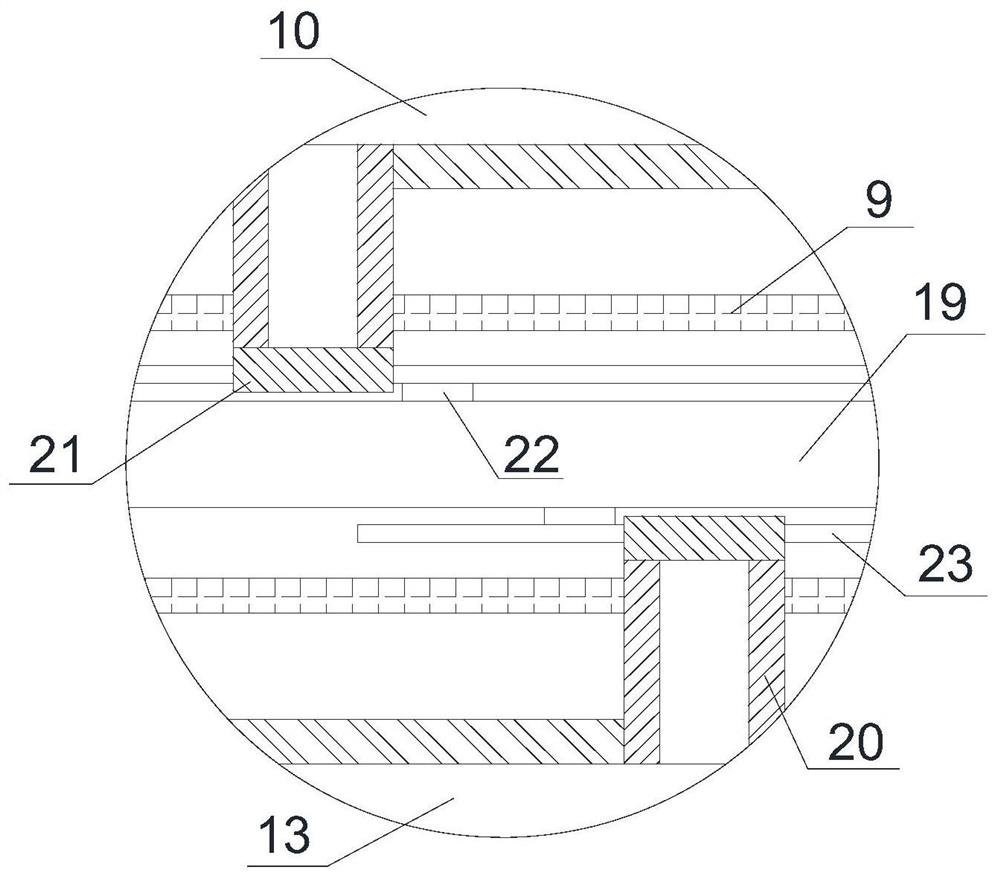

A battery intelligent management system used for a patrol robot in a transformer substation

InactiveCN102170146AIncrease or decrease in temperatureBatteries circuit arrangementsElectric powerTemperature controlTransformer

The invention relates to a battery intelligent management system used for a patrol robot in a transformer substation. The battery management system has functions of storage battery box temperature controlling, real-time battery electric quantity monitoring, low electric quantity alarming, self navigating for jointing with a charging interface in a base station of the substation, and intelligent charging. A storage battery of a robot dolly is disposed in a sealed temperature control box and the temperature in the temperature control box is maintained in a range of rated working temperature of the storage battery. When the robot dolly is patrolling and the battery is running low, an alarm is sent to the battery management system and then the robot dolly is forced to return to the base station of the substation for being charged. Then the robot dolly is employing an infrared ray tracking method or guided by an infrared range-measurement system to joint with the charging interface for being charged. In the charging process, if the robot dolly receives a patrolling order, the battery electric quantity should be checked firstly. If the electric quantity is sufficient, the temperature control device starts preheating or cooling to make the robot dolly separate from the base station for the patrolling mission, or the patrolling order is delayed to be executed until the storage battery is charged to be full.

Owner:北京华电蜂鸟科技有限责任公司

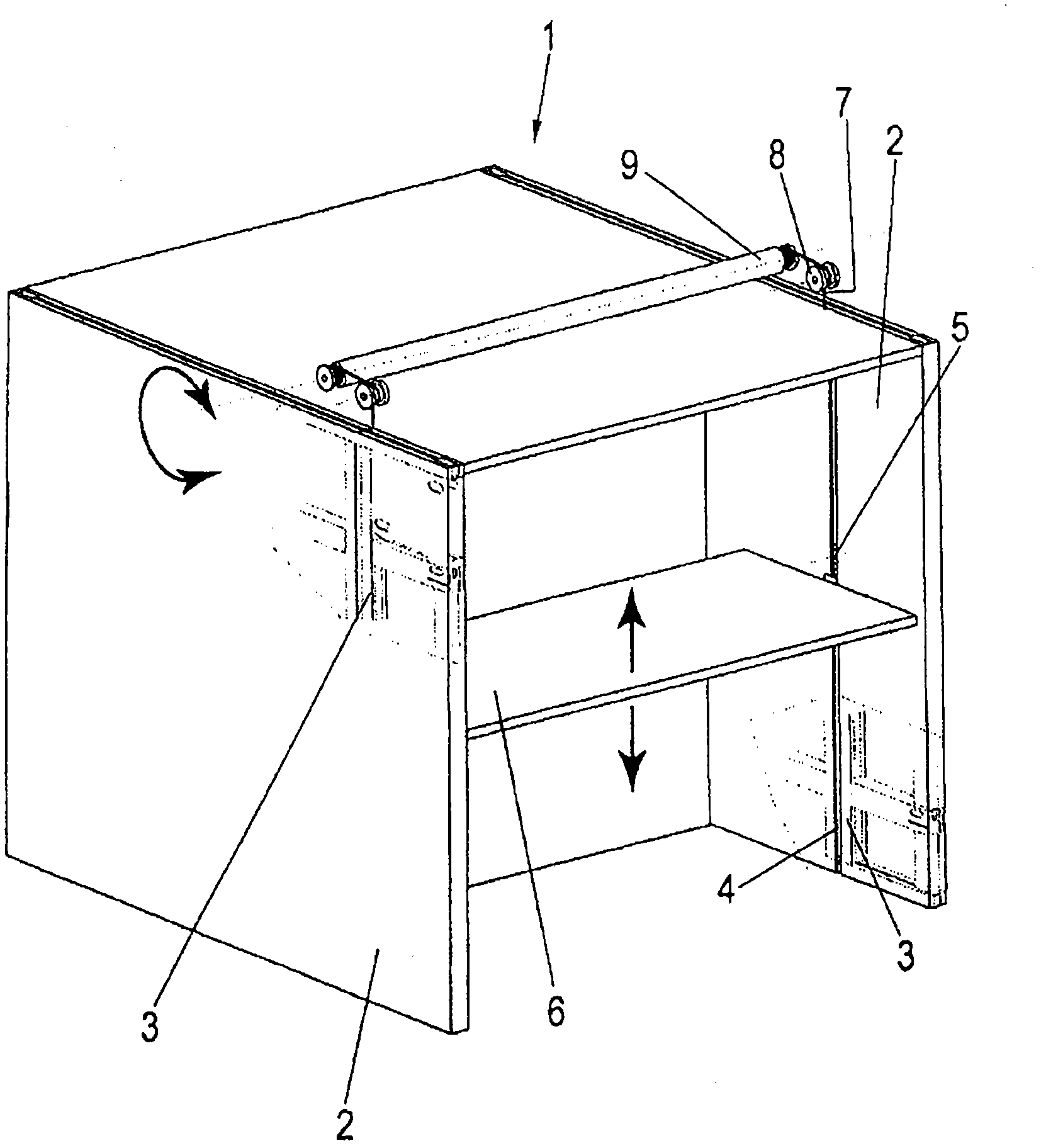

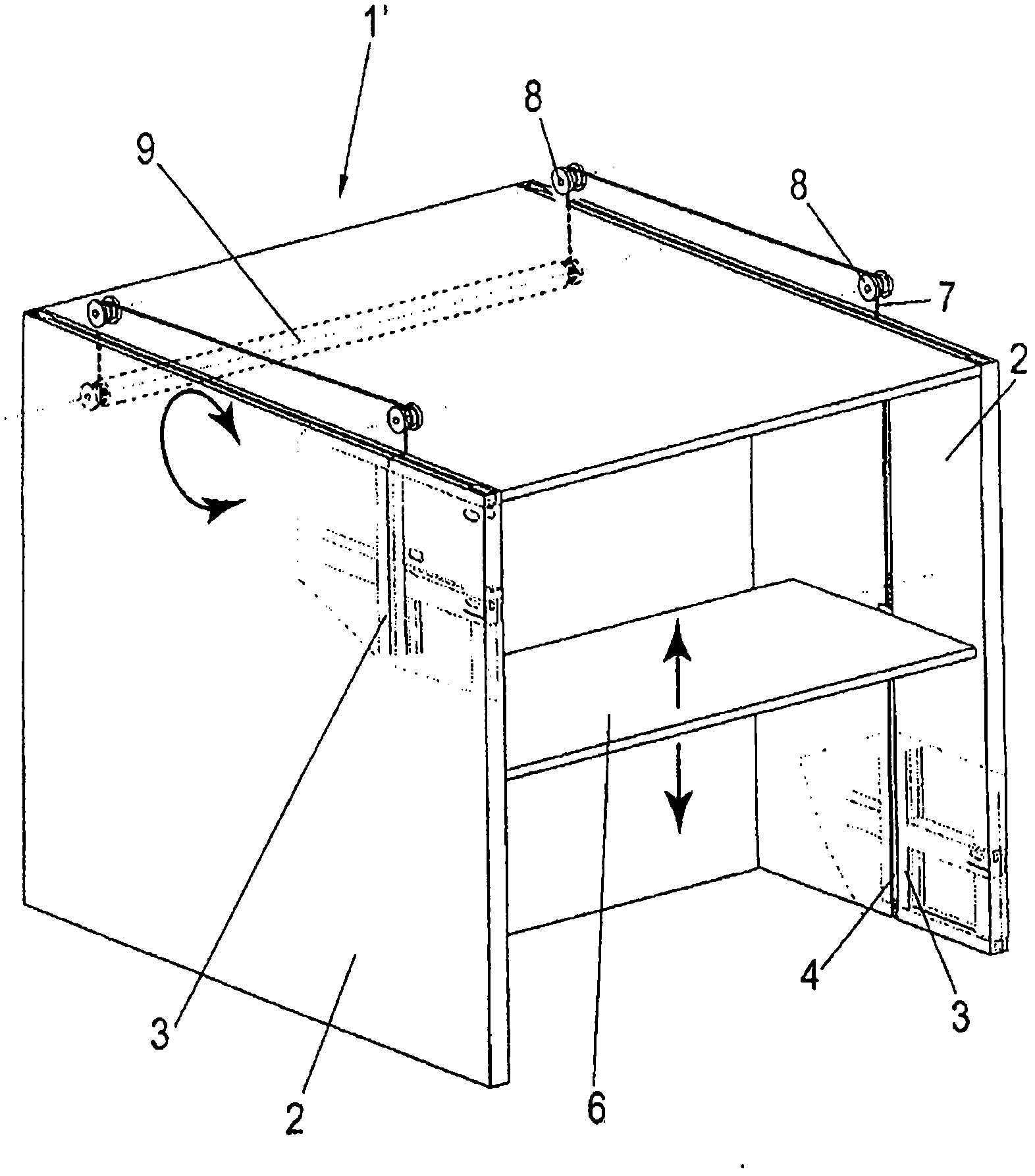

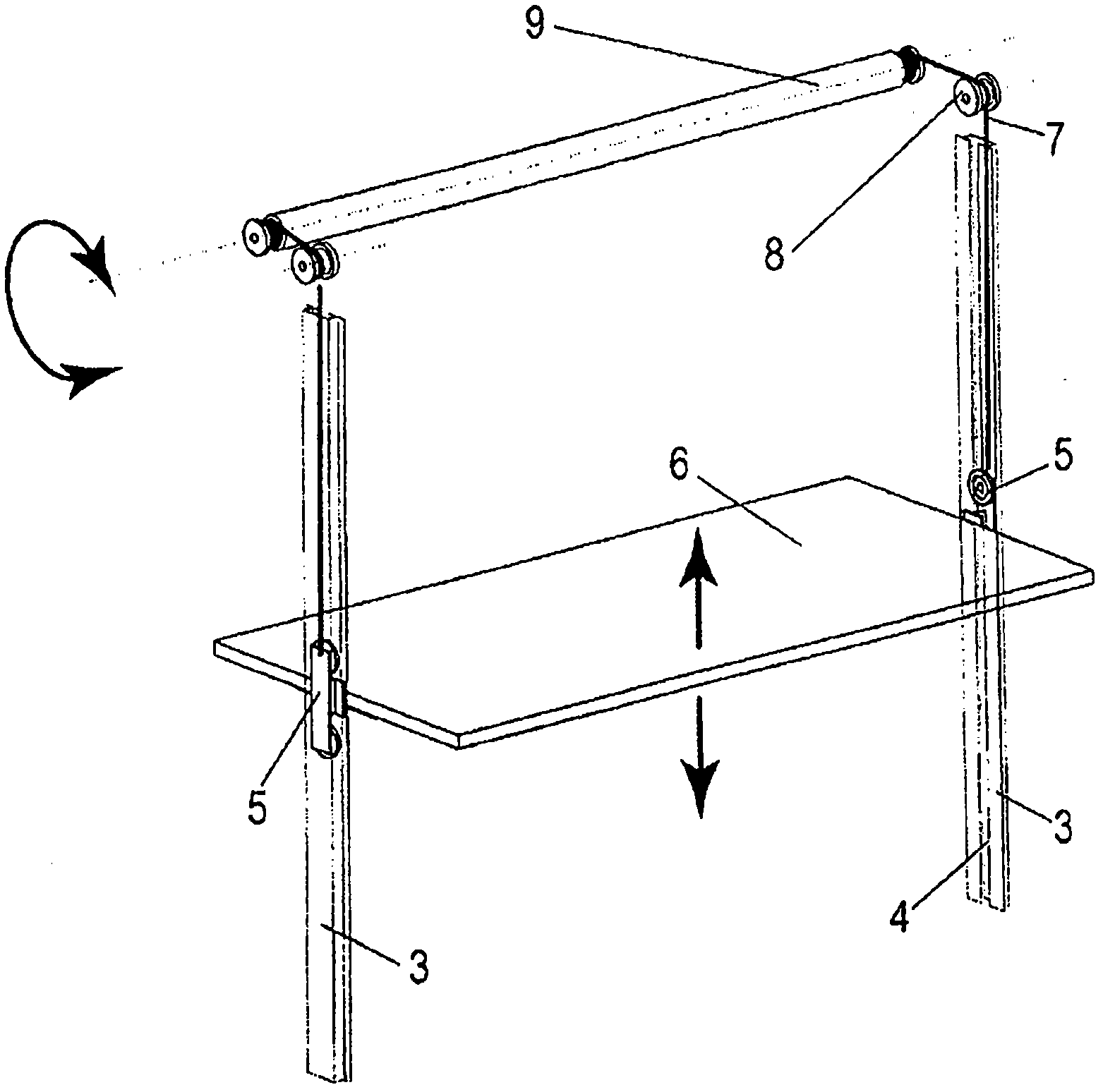

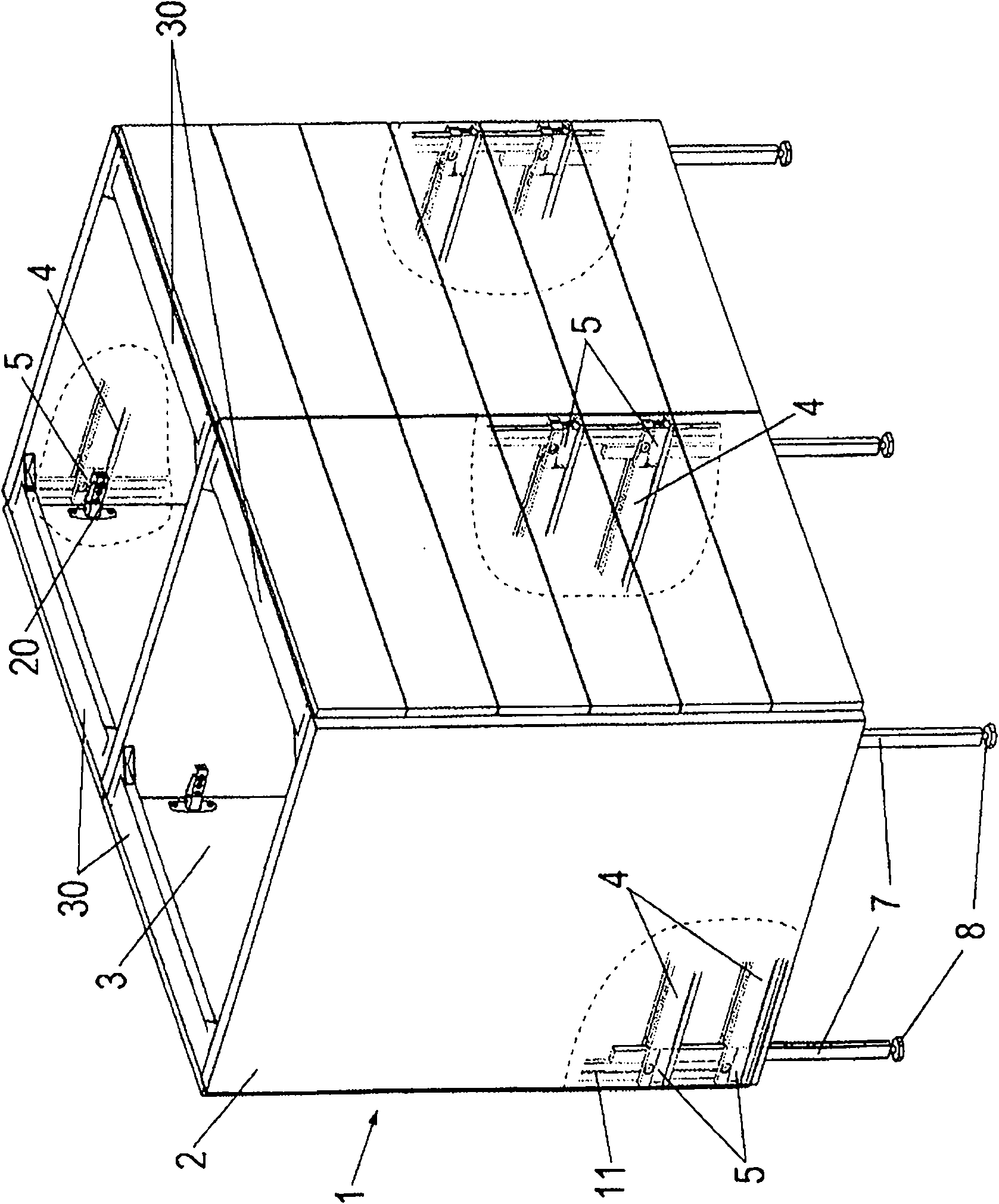

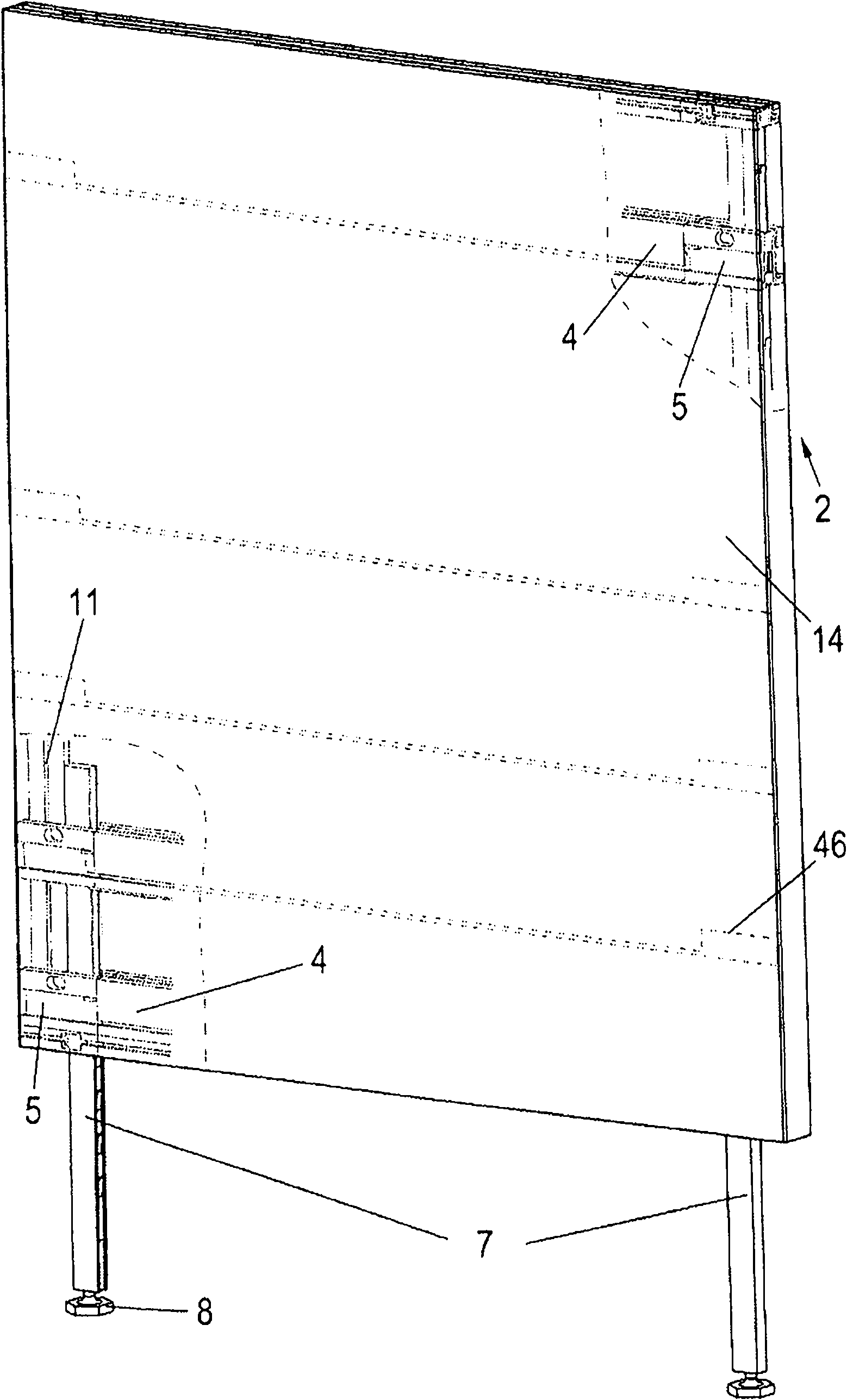

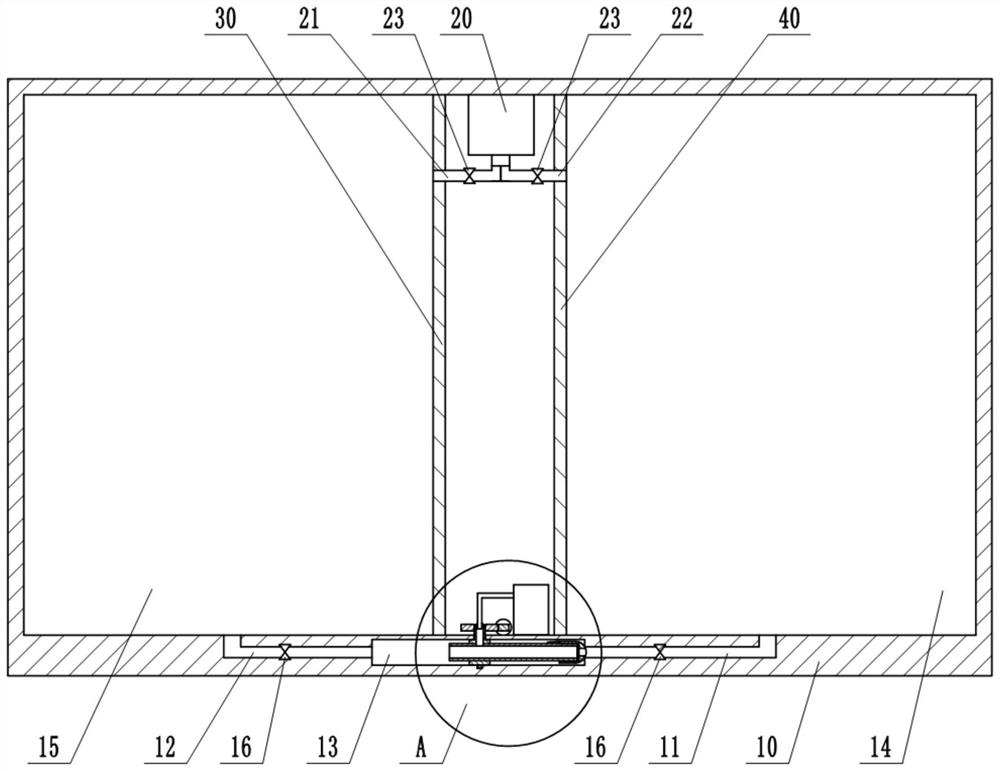

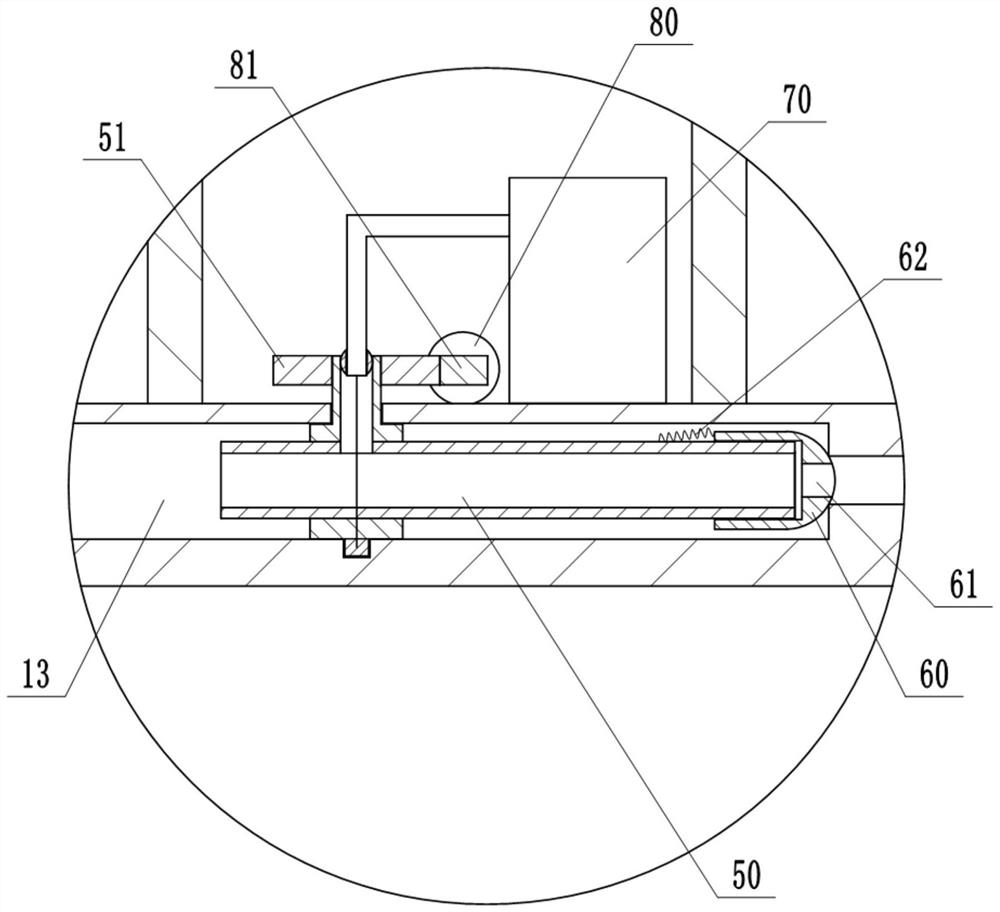

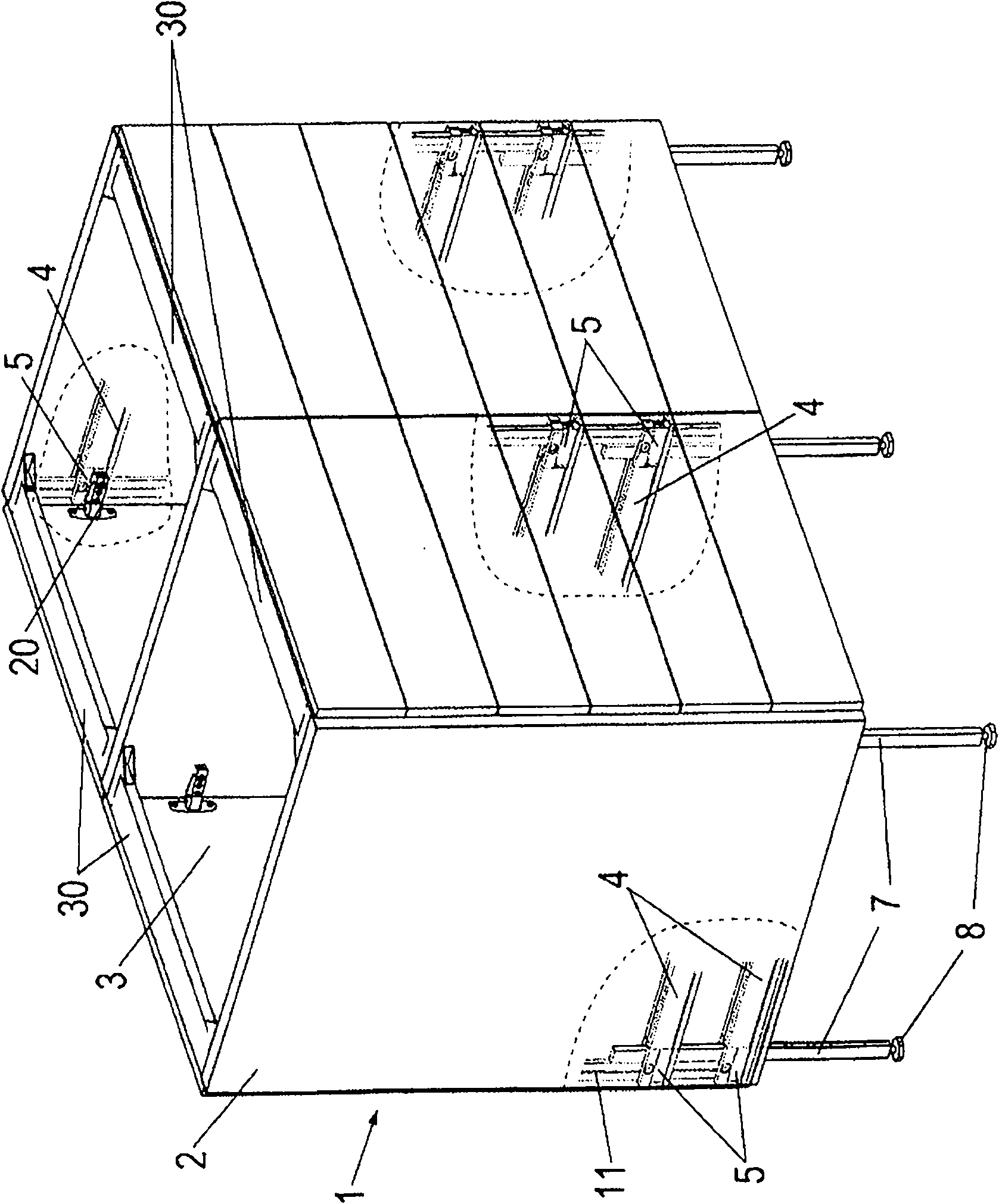

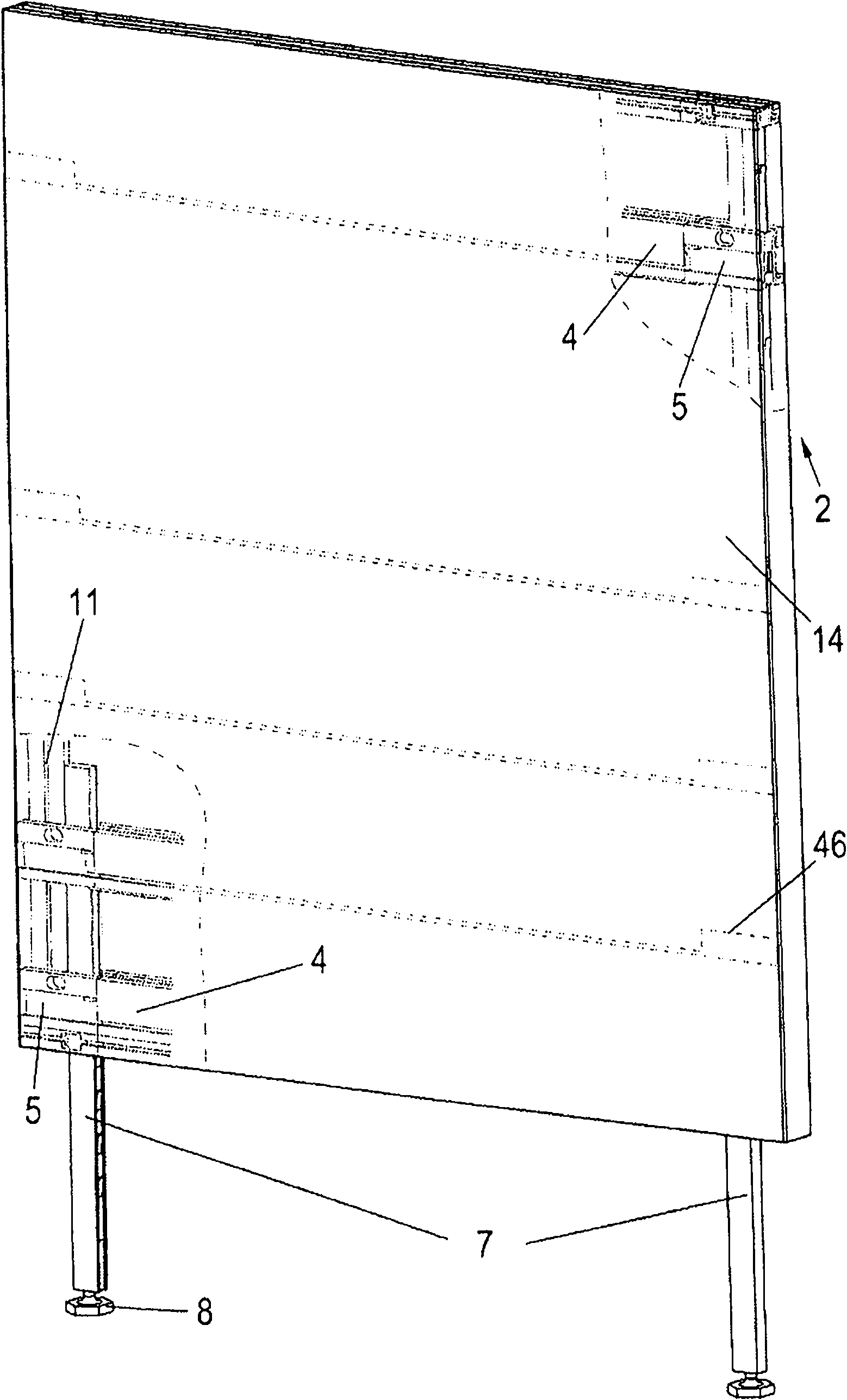

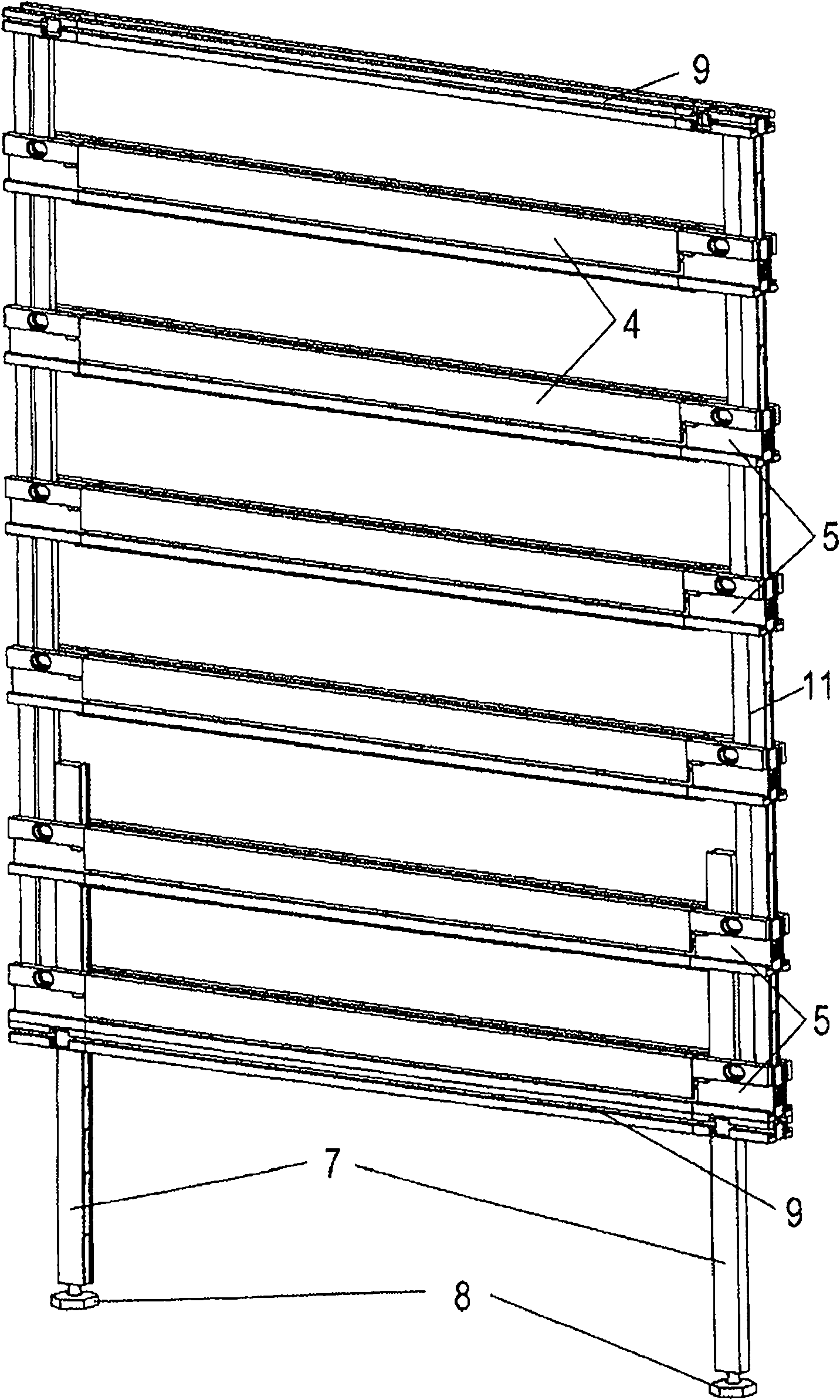

Item of furniture

InactiveCN102548451AMaintain visual appearanceUse without hindering or reducingKitchen cabinetsDismountable cabinetsMechanical engineeringEngineering

Owner:HETTICH HLDG GMBH & CO OHG

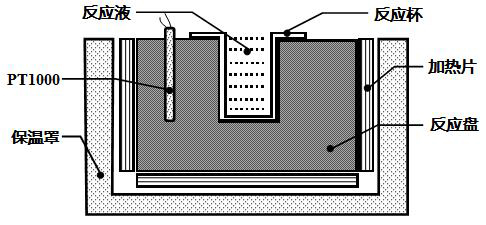

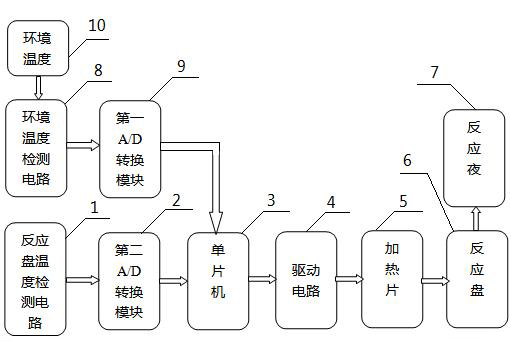

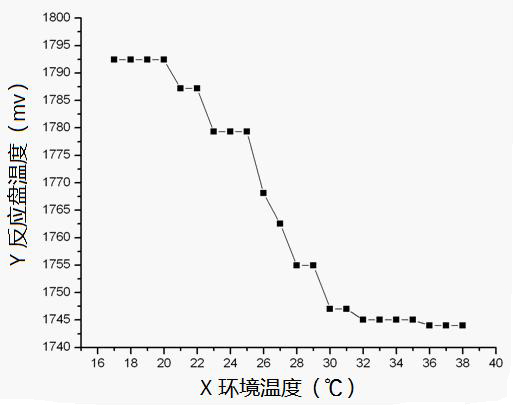

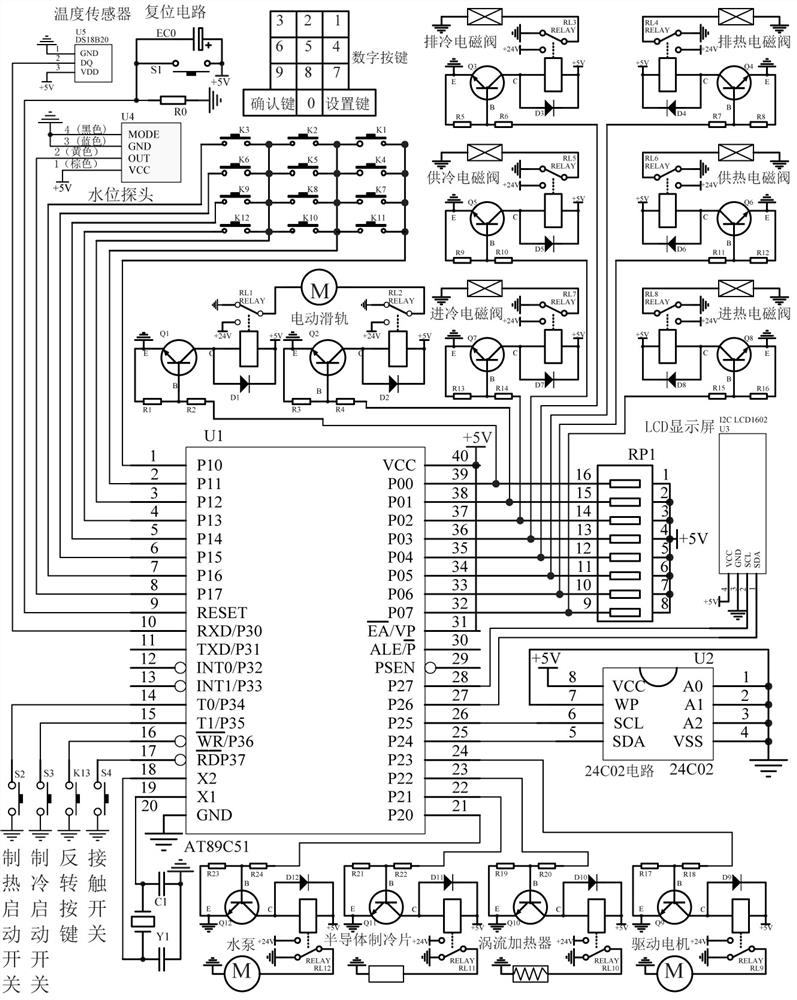

Temperature control system with environment temperature compensating function

InactiveCN102368163AImprove environmental adaptabilityHigh precisionThermometers using electric/magnetic elementsAuxillary controllers with auxillary heating devicesMicrocontrollerTemperature control

The invention discloses a temperature control system with an environment temperature compensating function. According to change of an environment temperature, the system actively changes a temperature of a reaction disc, and compensates influence of the environment temperature to a reaction solution temperature. The system comprises a reaction disc temperature detection circuit used for detecting a reaction disc temperature. The reaction disc temperature detection circuit connects with a one-chip microcomputer through a first A / D conversion module. The one-chip microcomputer connects with a drive circuit. The drive circuit connects with a heating plate. The heating plate is provided around the reaction disc. The reaction disc is embedded with a reaction cup and heats reaction solution in the reaction cup. The system also comprises an environment temperature detection circuit used for detecting the environment temperature. The environment temperature detection circuit connects with the one-chip microcomputer through a second A / D conversion module. According to the temperature control system of the present invention, requirements of high precision, fast response and good stability of temperature by a biochemistry analyzer are satisfied, and environmental adaptability of a device is improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH

Coal underground gasification method

ActiveCN103556979ARaise the ratioQuality improvementConstructionsCoal gasificationHydrogenWater vapor

The invention relates to a coal underground gasification method. The coal underground gasification method comprises the following sequential steps of (1) establishing a gas inlet passage, a gas outlet passage and a gasification passage which enables the gas inlet passage to be communicated with the gas outlet passage; (2) injecting a gasification agent through the gas inlet passage, wherein the gasification agent comprises water vapor and oxygen-enriched gas, and an initial volume ratio between the water vapor and the oxygen-enriched gas ranges from 0.5 : 1 to 4 : 1; (3) igniting a coal seam; (4) forming a new volume ratio by adjusting the ratio between the water vapor and the oxygen-enriched gas according to the characteristics of generated coal gas. According to the coal underground gasification method disclosed by the invention, a little water vapor is enabled to be carried in raw coal gas, the cost for recovering waste water in raw coal gas is reduced, the situation that the water vapor and the coal seam are in full reaction so as to generate hydrogen can be ensured, and thus the quality of coal gas can be increased; in addition, the temperature uniformity on a gasification working surface can be ensured due to reactions, i.e. exothermic reaction of oxygen and the coal seam and endothermic reaction of water and the coal seam, which are carried out in the same time, and the phenomenon that the continuous gasification of the coal seam is obstructed as gasification coal ash is melted and attached to a gasification coal wall due to over-high local temperature can be prevented from happening.

Owner:ENN SCI & TECH DEV

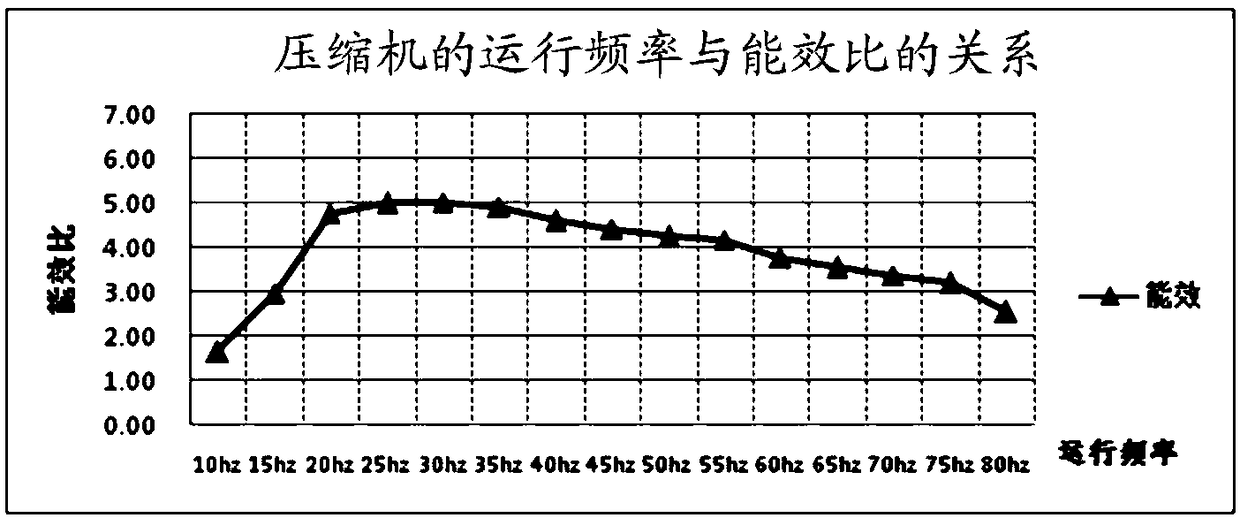

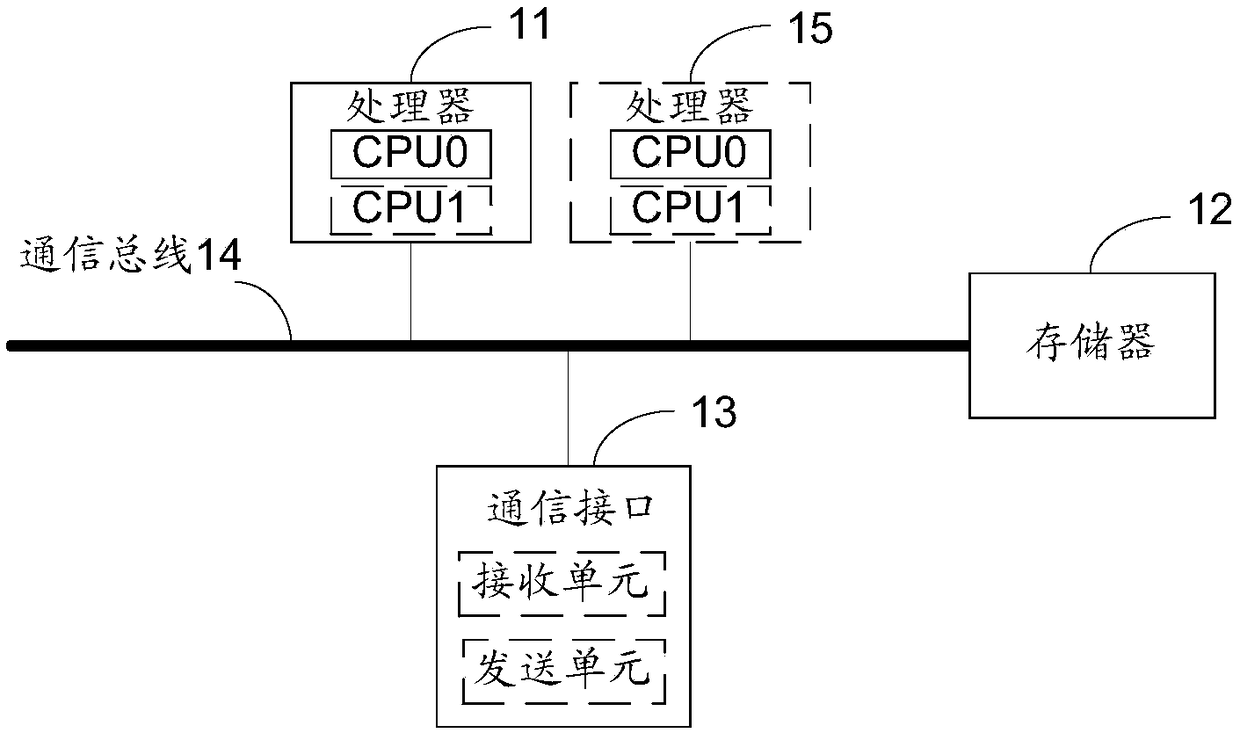

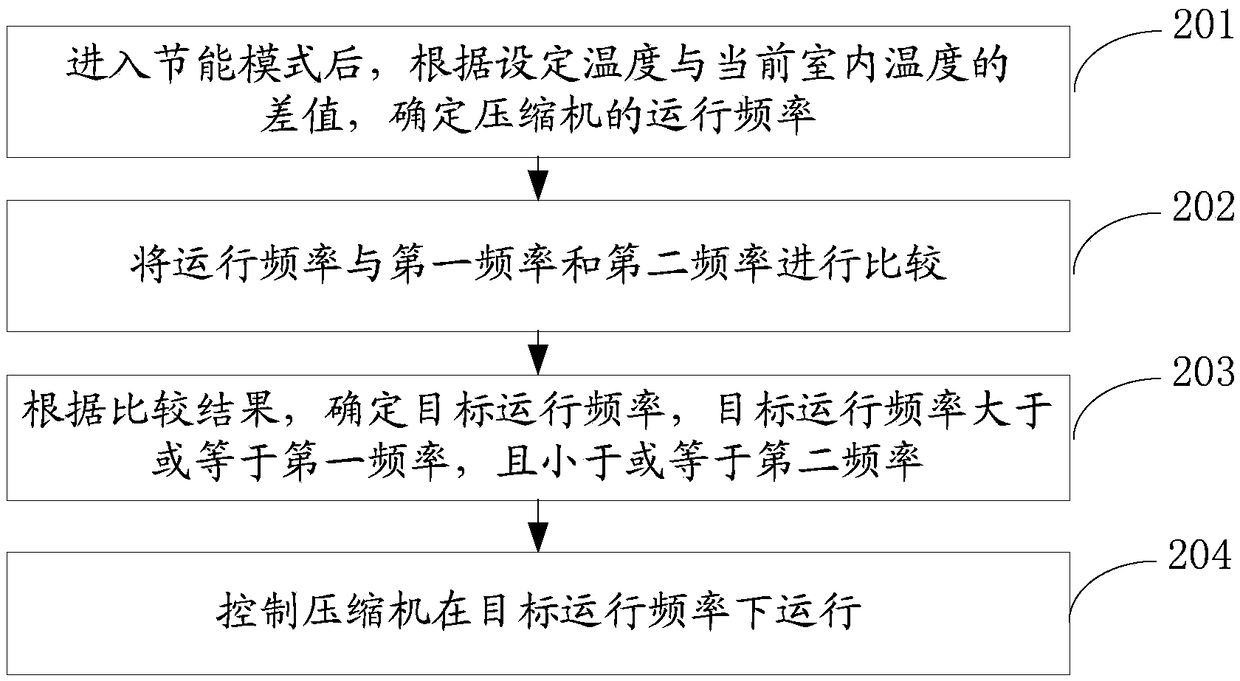

Energy-saving method and device of air conditioner

ActiveCN109405207AReduce loadLimit temperatureMechanical apparatusSpace heating and ventilation safety systemsBusiness efficiencyEngineering

The embodiment of the energy-saving method and device of an air conditioner and relates to the field of air conditioners. The problem that when the air conditioner carries out refrigerating or heating, due to the relatively low energy efficiency ratio, electric energy is wasted is solved. According to the specific scheme, after the air conditioner goes into an energy-saving mode, the running frequency of a compressor is determined according to the difference value of a set temperature and a current indoor temperature, the running frequency is compared with first frequency and second frequency,according to a comparative result, target running frequency is determined, and when the target running frequency is larger than or equal to the first frequency but smaller than or equal to the secondfrequency, the compressor is controlled to run at the target running frequency. The energy-saving method and device are used for the refrigerating or heating process of the air conditioner.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

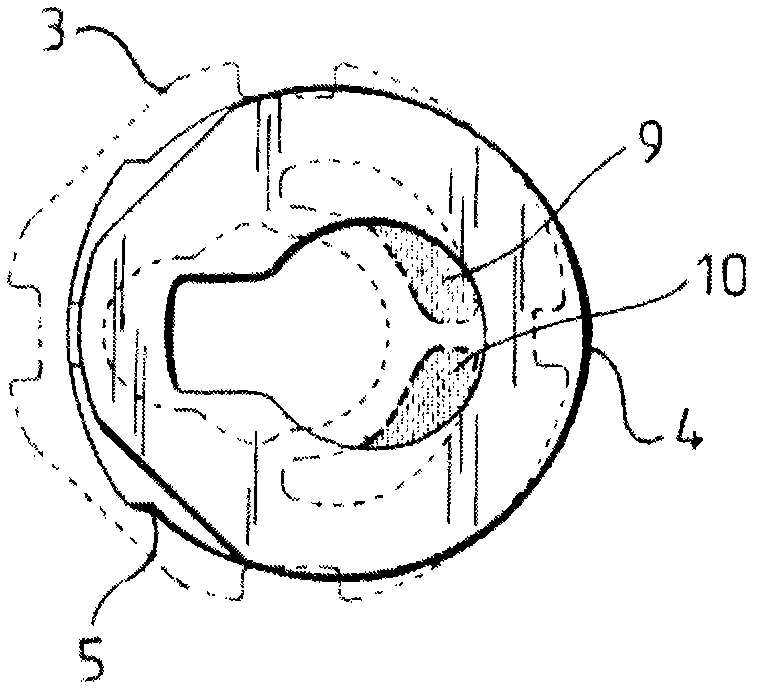

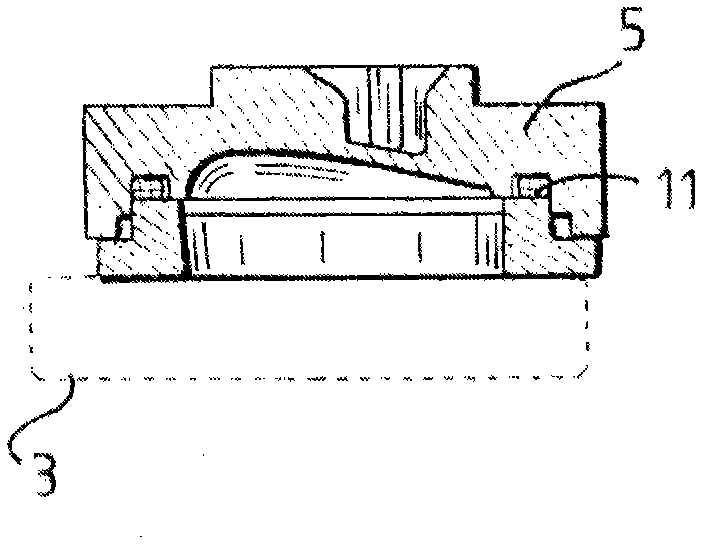

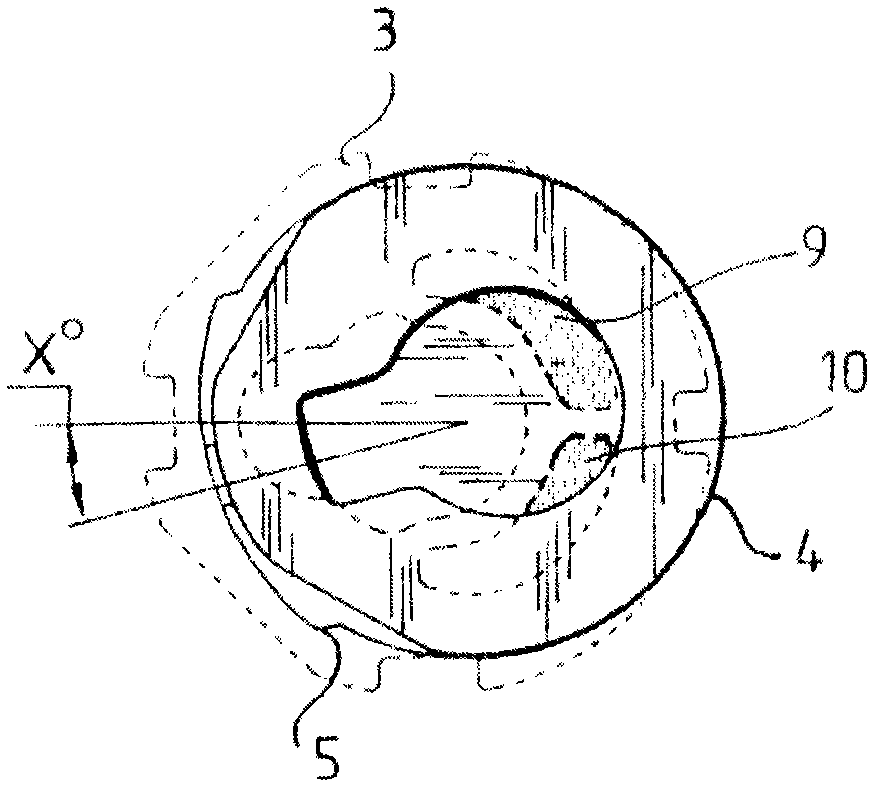

Insertion for single-grip mixing faucet with increased comfort angle range

ActiveCN102102771AIncrease or decrease in temperatureAdjust the angle rangeMultiple way valvesThin material handlingWater flowEngineering

The invention relates to single-grip mixing faucet comprising a control unit with ceramic insertion piece, so-called cartridge, one side of the cartridge is connected to a footing, the other side to an operating arm, the cartridge comprising a fixed, stationary inlet disc one side of which is connected to one side of a movable control disc and the two discs forming together a plane sealing, and forming a mixing space at the same time the opposite side of the inlet disc is in connection with the footing, whereas at the opposite side of the control disc is in driving connection with a ceramic disc mover, which, in turn, is connected to the operating arm, further on the footing cold water inlet and hot water inlet and an outlet for water flowing out are arranged. The essence of the inventionis that at the internal surface of the ceramic disc mover (5) a throttling element (8) is placed intruding into the mixing space for adjusting the angle range of the comfort region.

Owner:KEROX IPARI & KERESKEDELMI

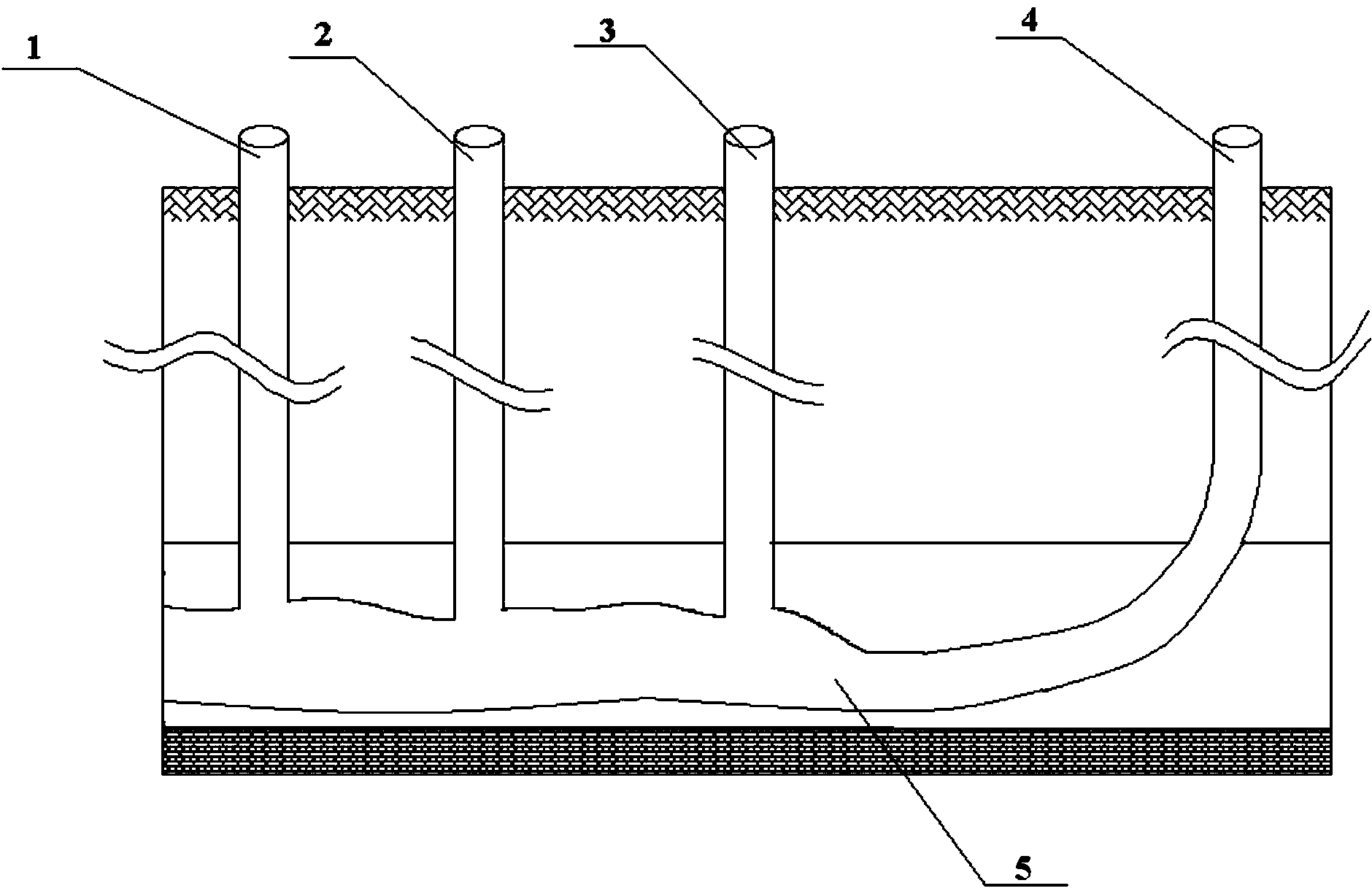

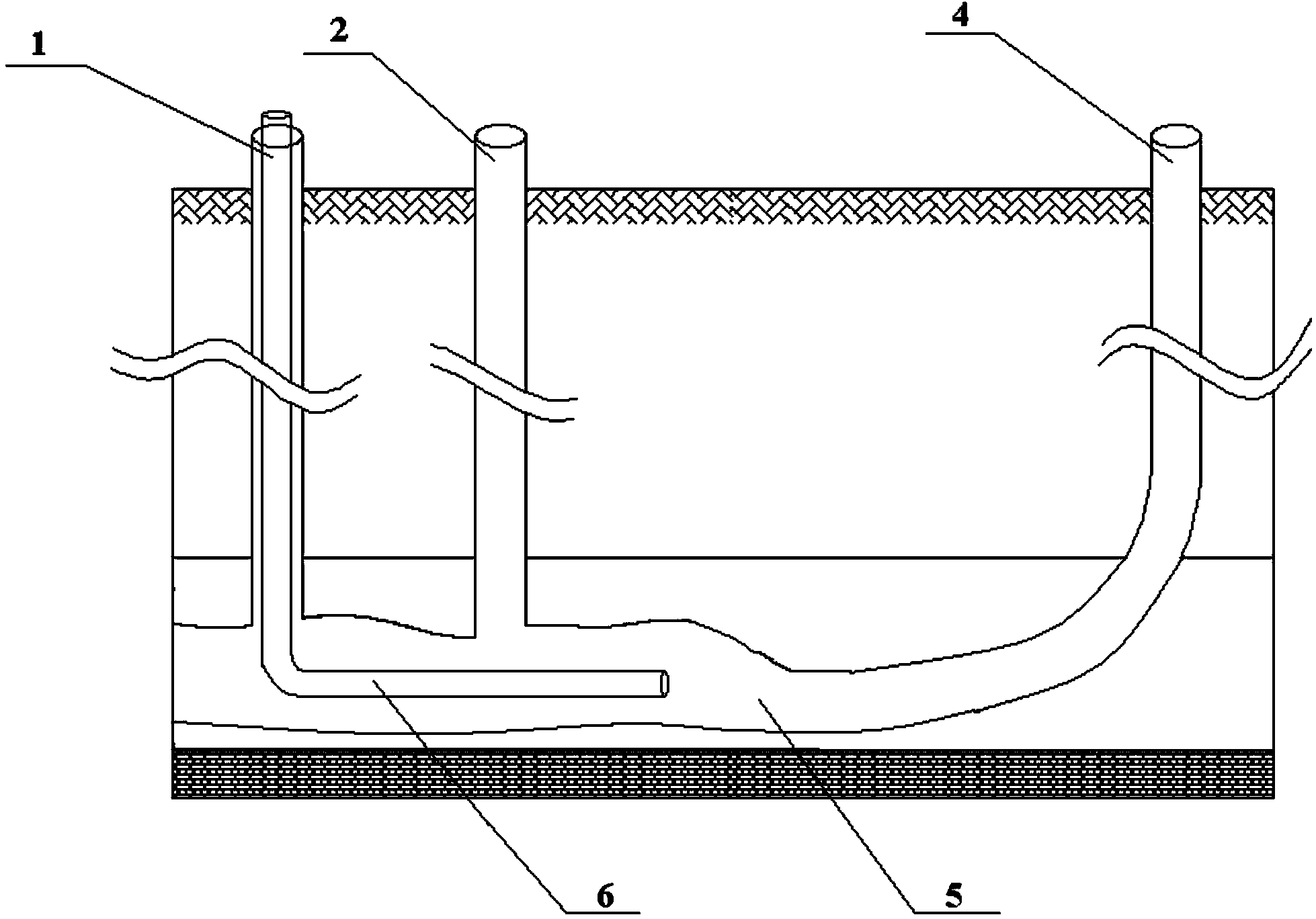

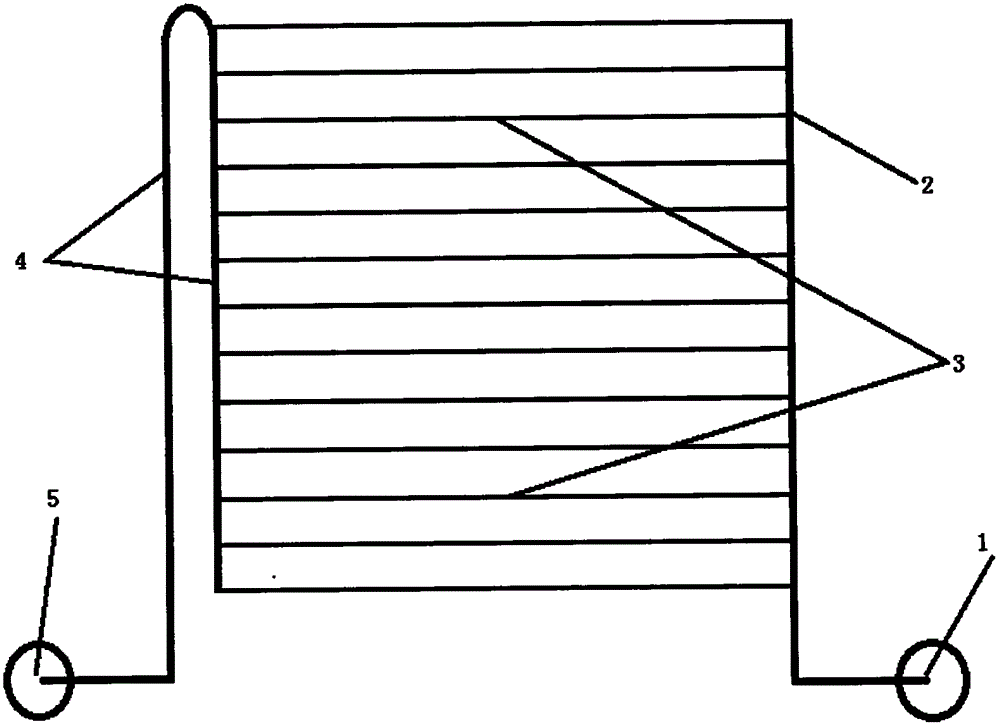

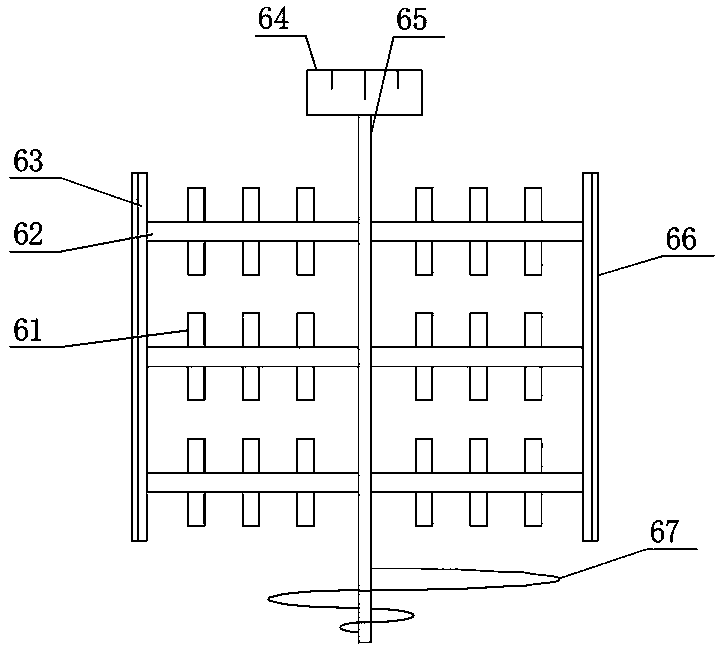

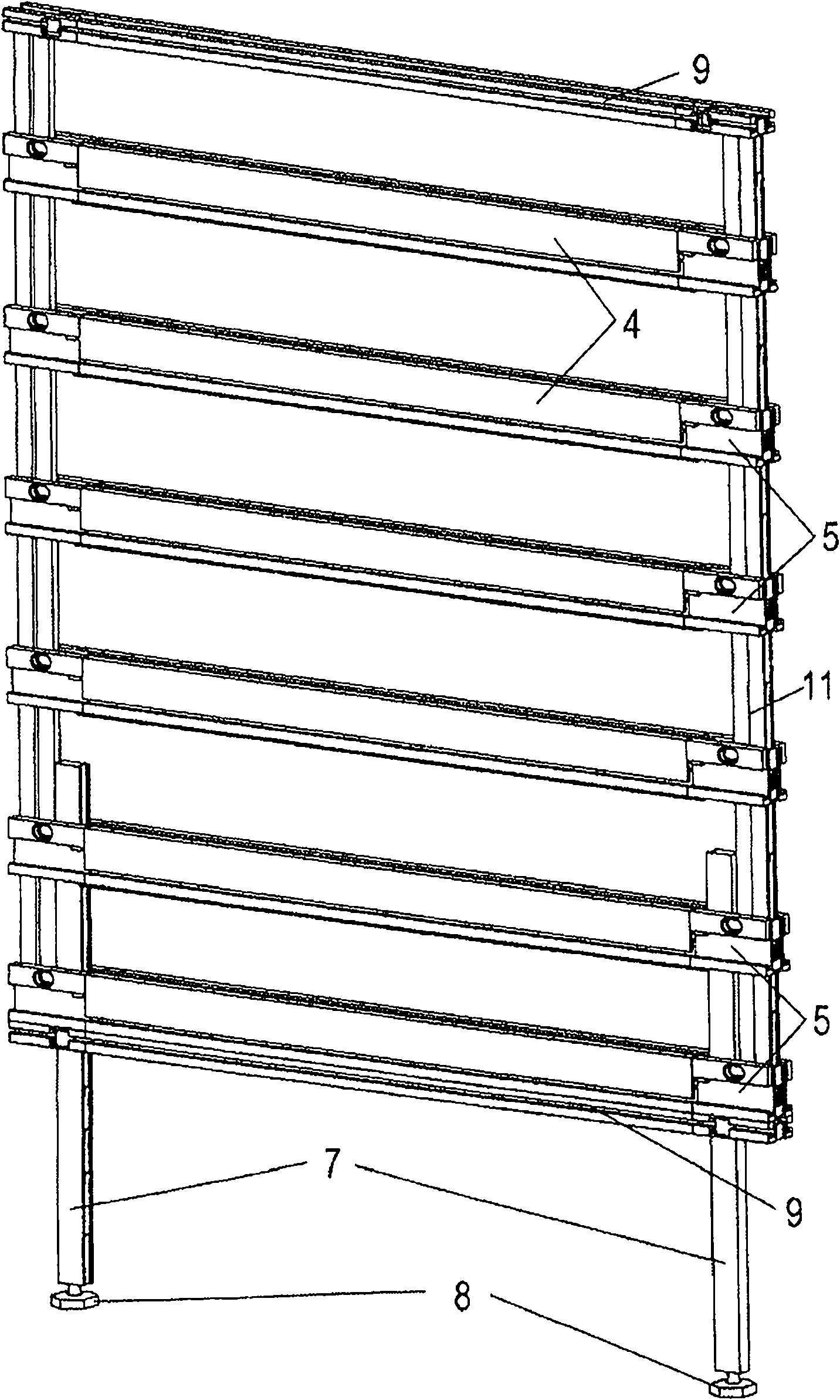

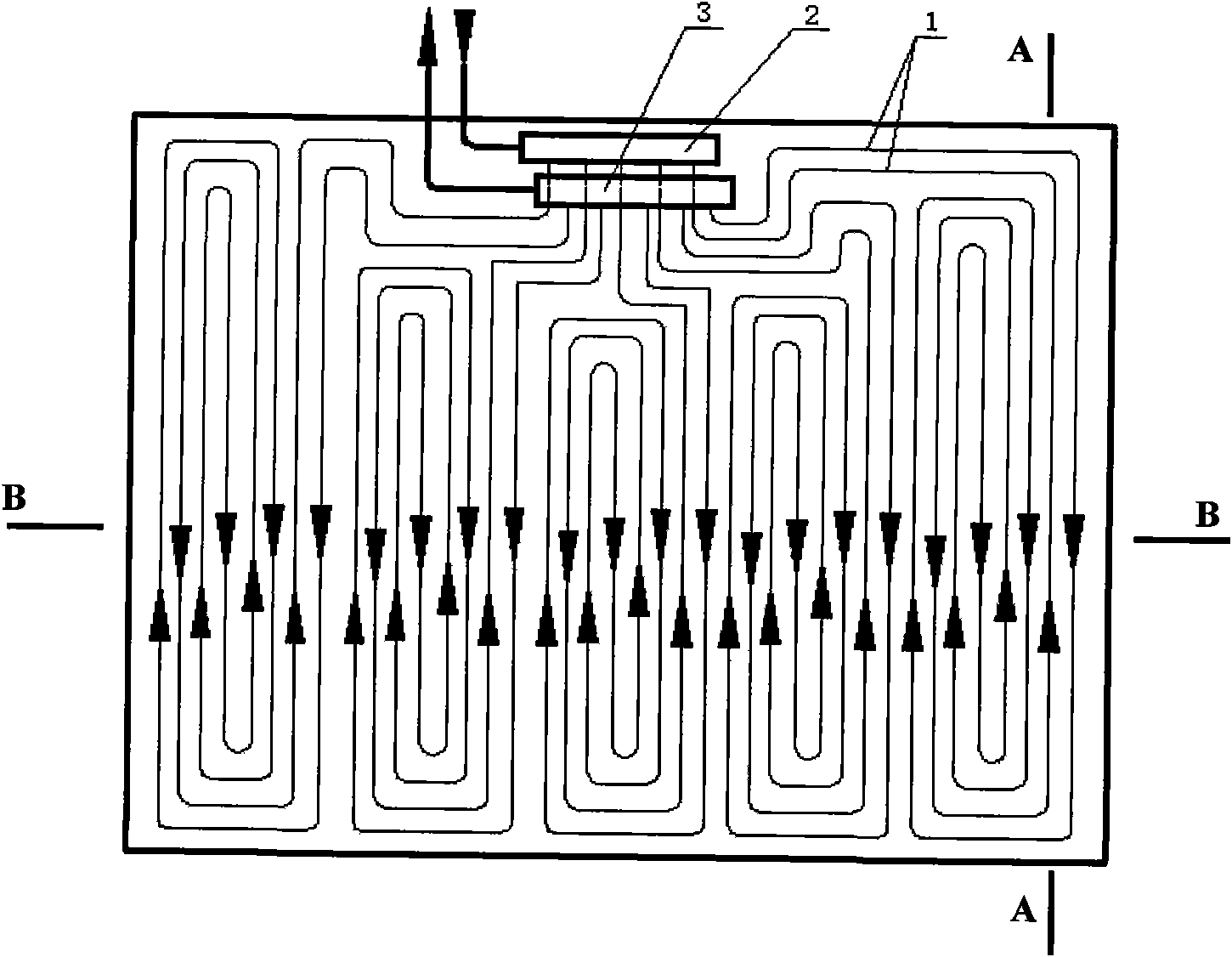

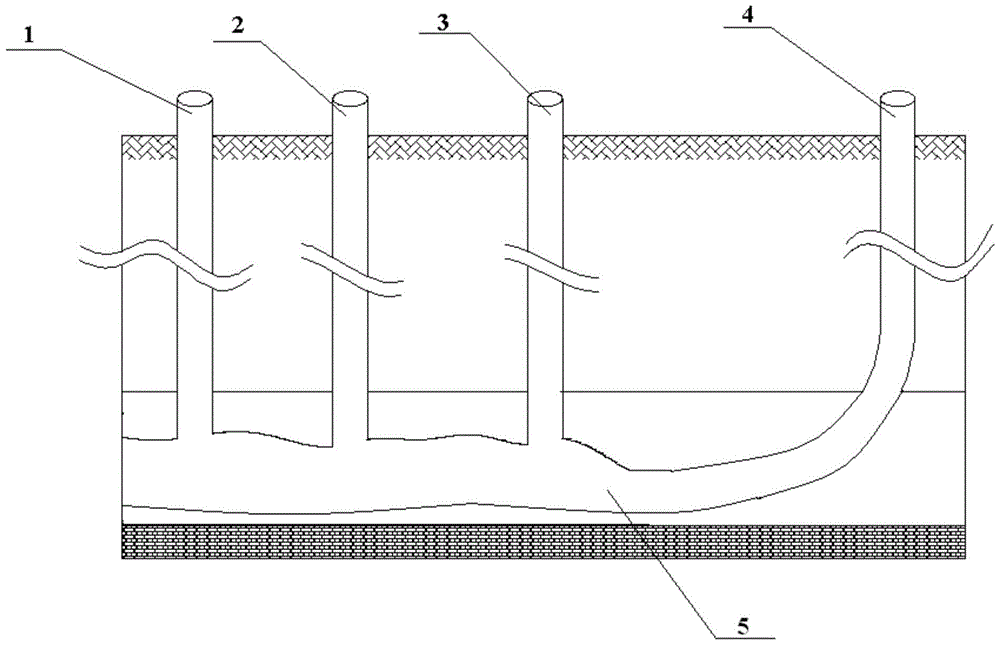

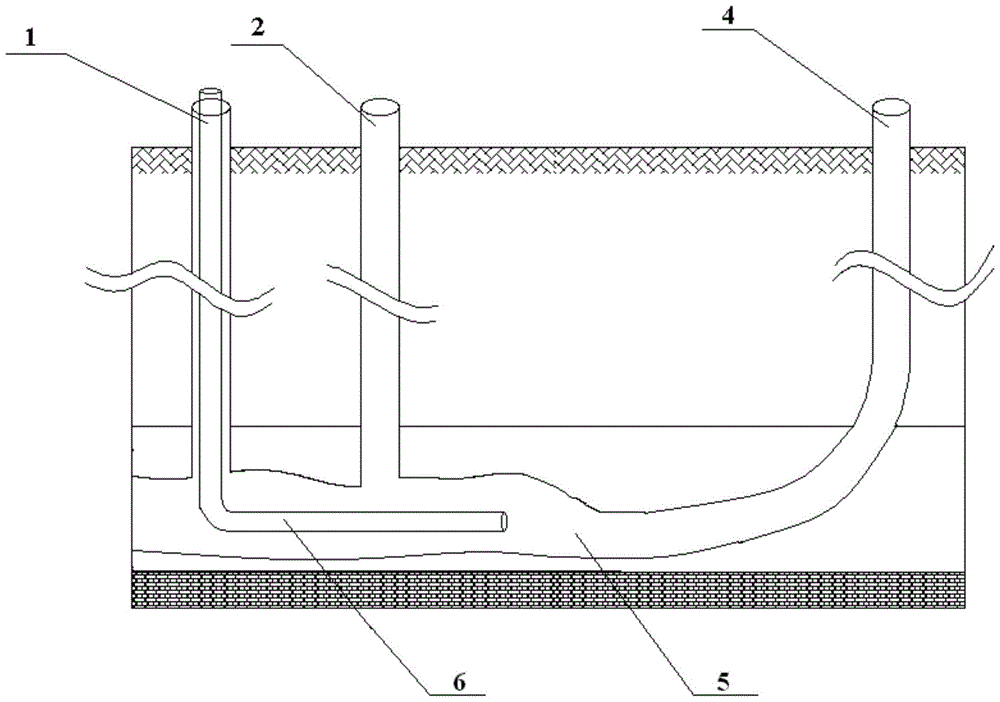

Greenhouse energy-saving auxiliary temperature control system

InactiveCN102715044AIncrease or decrease in temperatureReduce the temperatureClimate change adaptationSaving energy measuresTemperature controlGreenhouse

The invention discloses a greenhouse energy-saving auxiliary temperature control system, which comprises a water supply well, a main water supply pipe, heat exchange pipes, a main water return pipe and a water return well and is characterized in that the main water supply pipe and the main water return pipe are in parallel arrangement, the heat exchange pipes are vertically and uniformly connected with the main water supply pipe and the main water return pipe, the two ends of each heat exchange pipe are respectively connected with the main water return pipe and the main water supply pipe, the main water supply pipe is connected to a submersible pump positioned in the water supply well, and the main water return pipe is connected to the water return well. When the greenhouse energy-saving auxiliary temperature control system is adopted, the temperature in a greenhouse can be more efficiently and accurately regulated, the system utilizes the temperature differences between the underground water and the natural temperature for raising or lowering the temperature in the greenhouse, the great nonregenerative resource waste can be prevented, and the effect of protecting the environment can also be reached, so the temperature regulating cost of the greenhouse is further reduced, good economic benefits can be generated, in addition, the structure is simple, and the popularization and the use are convenient.

Owner:李泮禄

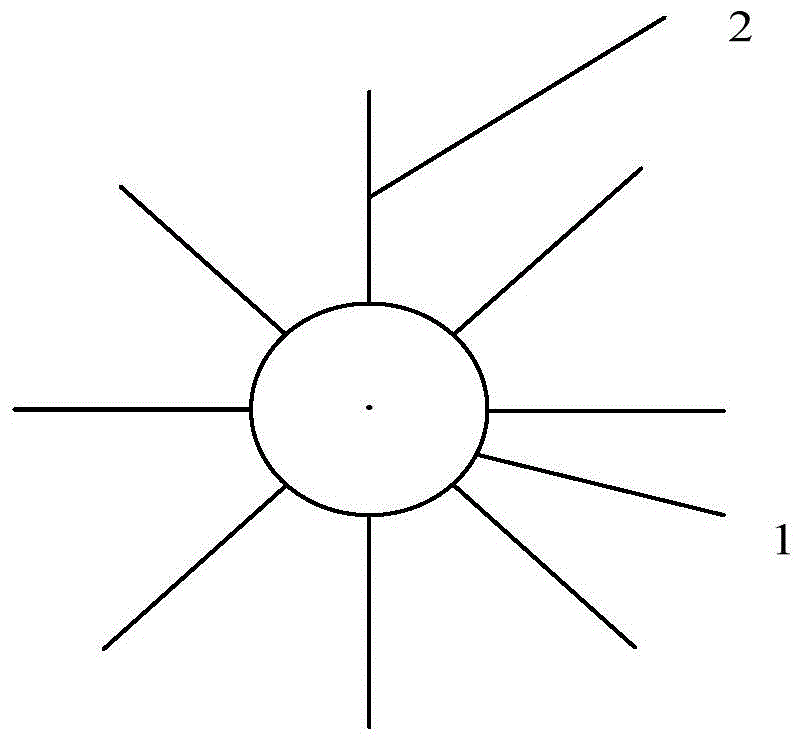

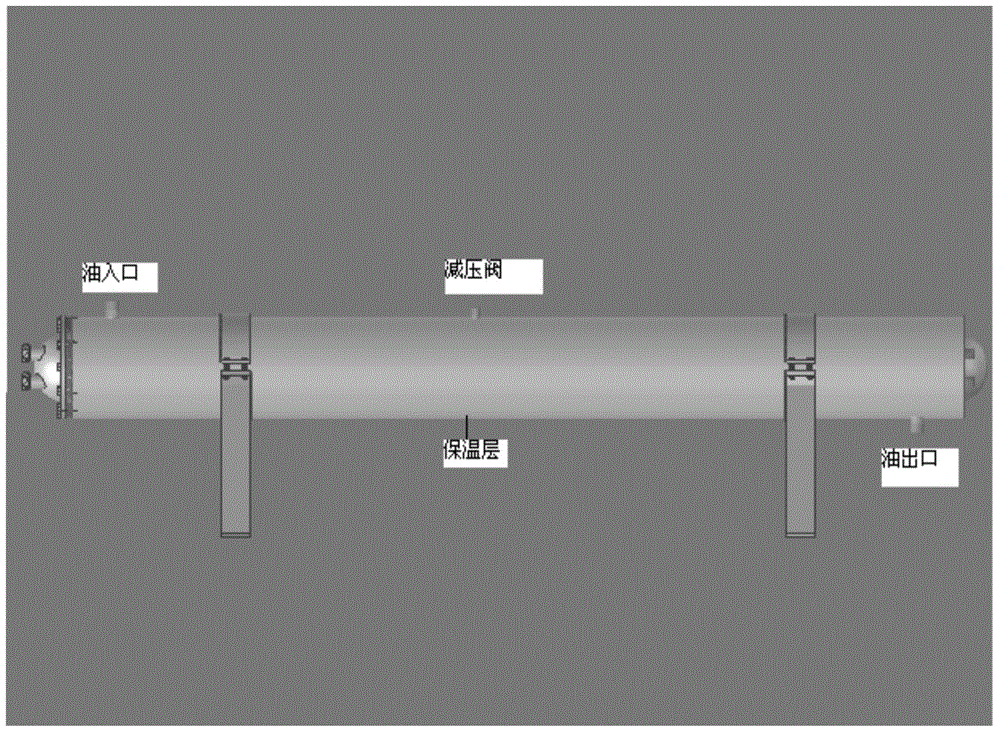

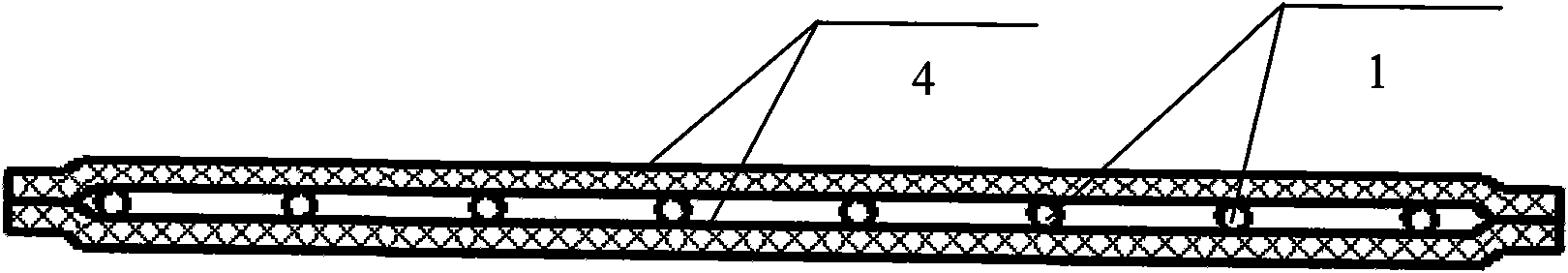

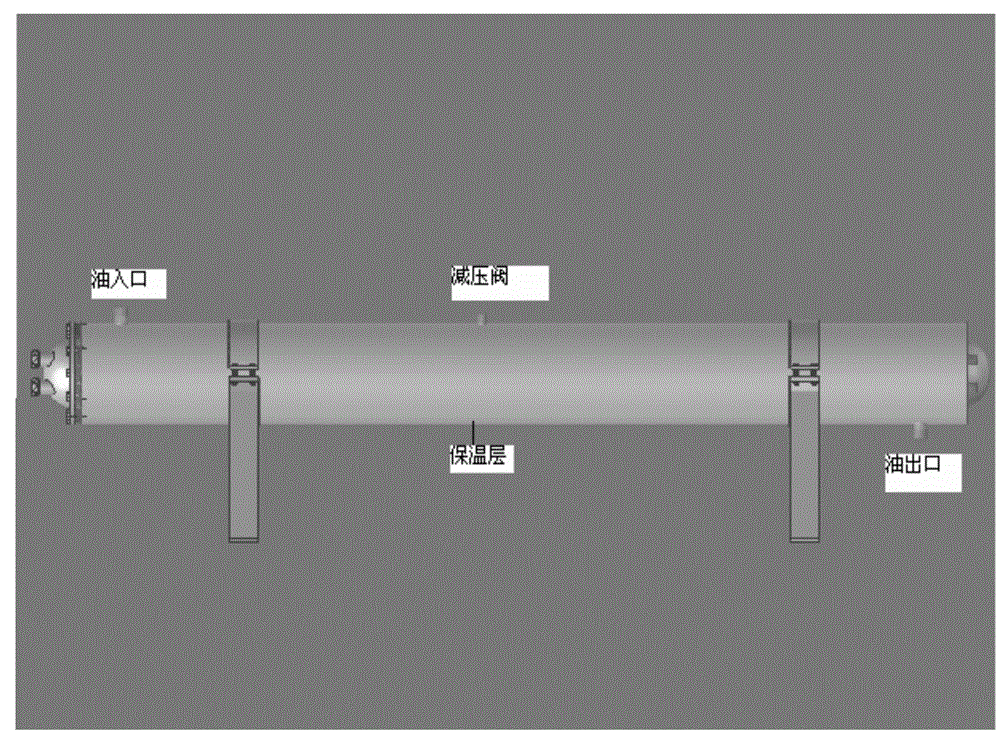

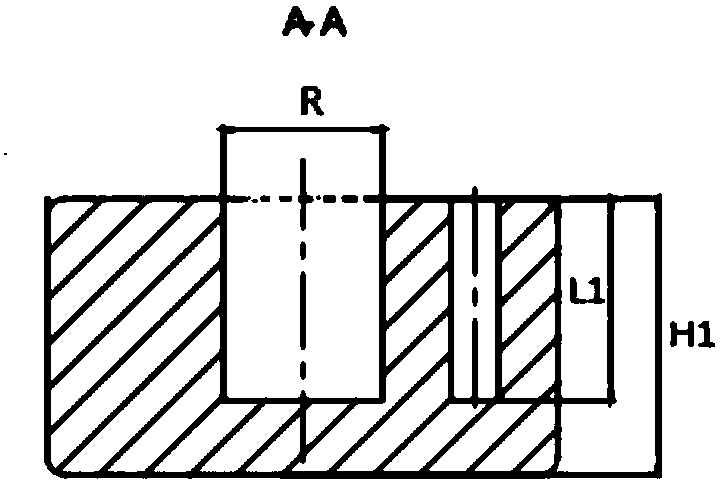

Heatable pipeline for liquid conveying

The invention discloses a heatable pipeline for liquid conveying, and belongs to the technology of pipeline heating. The pipeline is characterized in that a fluid heat transfer device is installed in a cavity of the pipeline; the axial direction of a tubular heat source supply component is parallel with that of the pipeline; the fluid heat transfer device comprises the tubular heat source supply component and a slabby heat pipe; one end, which is along the heat conduction direction of the heat pipe, of the slabby heat pipe is connected with the outer wall of the tubular heat source supply component in a heat transfer way, and the other end of the slabby heat pipe serves as a free end; the connection in a heat transfer way indicates that the slabby heat pipe is directly connected with the outer wall of the tubular heat source supply component; the slabby heat pipe is a slabby heat pipe disclosed in the China Patent 200910207418.9 or the divisional application 201110309983.3 thereof. The pipeline is used for liquid conveying, can properly heat liquid, and is particularly applied to the conveying of liquid easy to solidify.

Owner:南宁市磁汇科技有限公司

Glue feeding device with stirring function for LED lamp production

InactiveCN109908803AGuarantee product qualityPrevent precipitationRotary stirring mixersMixer accessoriesSpiral bladeEngineering

The invention discloses a glue feeding device with a stirring function for LED lamp production and belongs to the technical field of LED lamps. The glue feeding device comprises a storage tank, a pressure gage is arranged at one end of the upper surface of the storage tank, a glue feeding pipe is arranged on one side of the pressure gage, an air pump is arranged at the other end of the upper surface of the storage tank, a first connecting pipe is arranged at the connection of the storage tank and the air pump, a main glue supply pipeline is arranged at the bottom end of the storage tank, a branched pipeline is arranged on the lower surface of the main glue supply pipeline, a first valve is arranged at the end, far away from the main glue supply pipeline, of the branched pipeline, and supporting legs are arranged on two sides of the storage tank. A stirring mechanism is arranged on the glue feeding device, so that a user can stir glue in the storage tank through a stirring rod, a spoiler and spiral blades on the stirring mechanism, so that the condition that a precipitate is generated as glue is stored for a long time is avoided, glue in different height layers is consistent in quality, and therefore, the production quality of the glue feeding device is guaranteed.

Owner:肇庆市星动传说自动化技术有限公司

Furniture wall and item of furniture

InactiveCN102421331AConstitute stableIncrease or decrease in temperatureWallsFurniture partsEngineeringStructural engineering

Owner:HETTICH HLDG GMBH & CO OHG

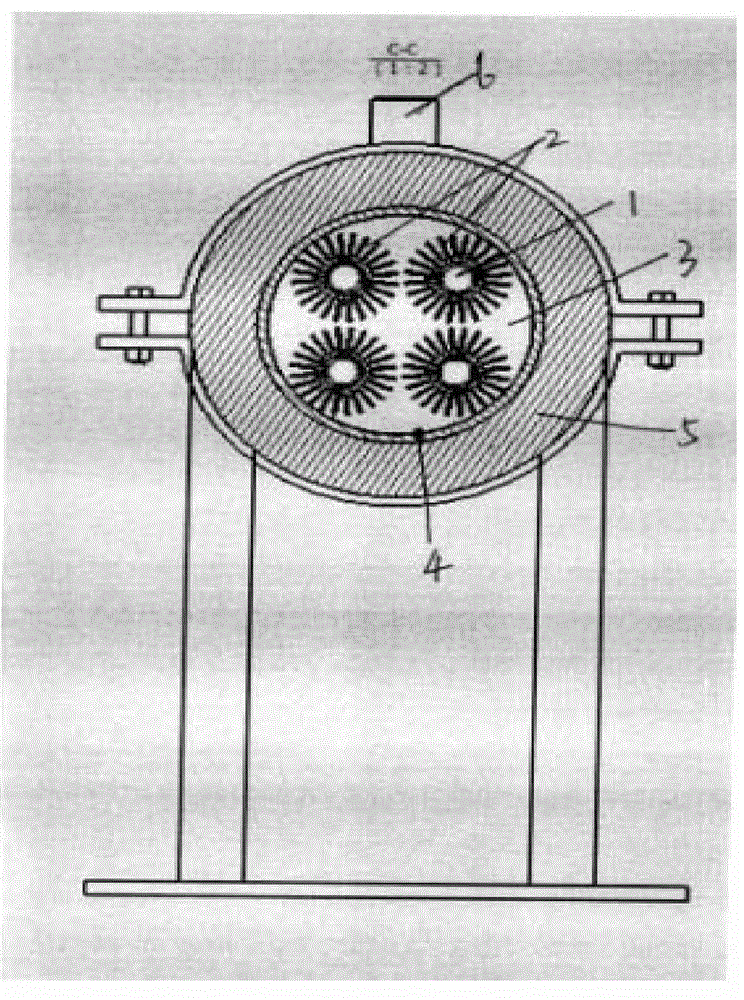

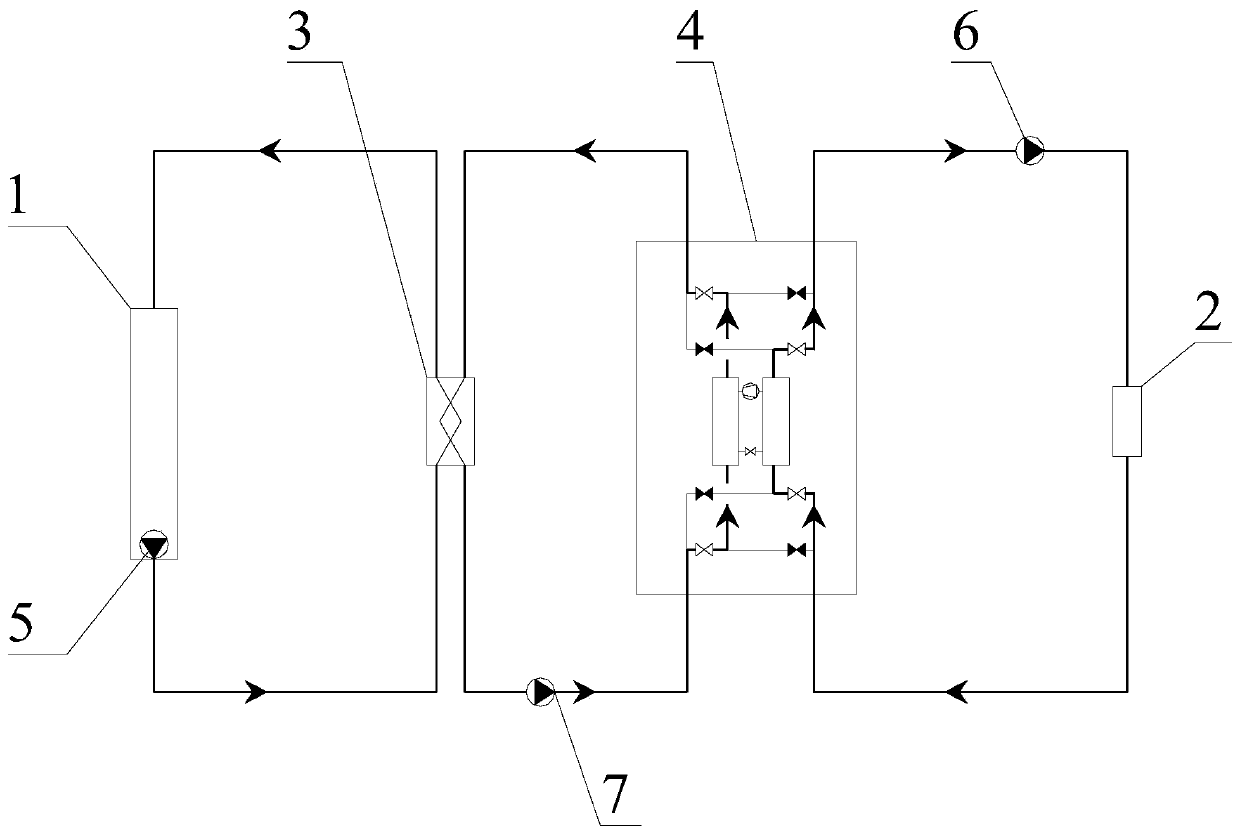

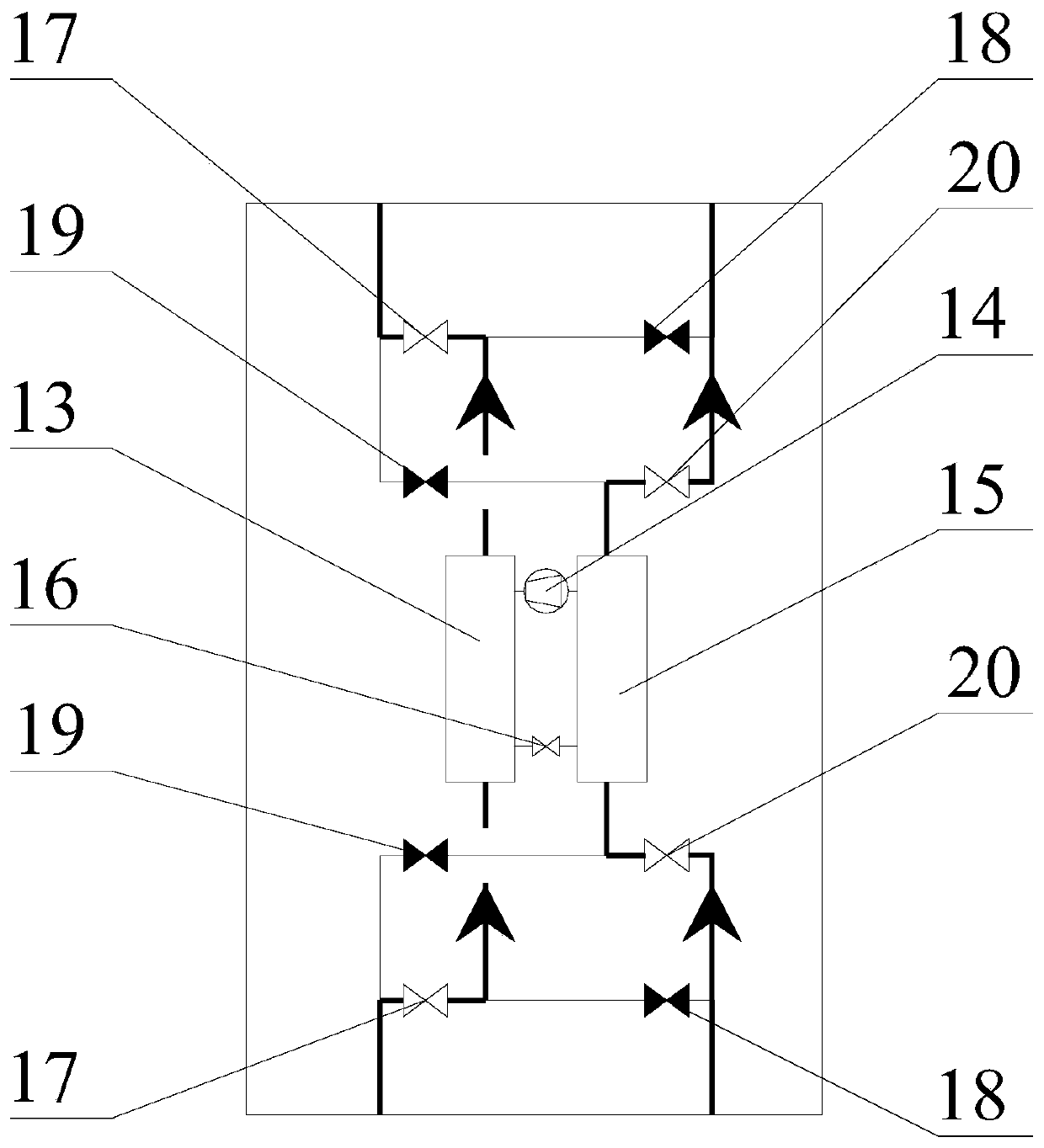

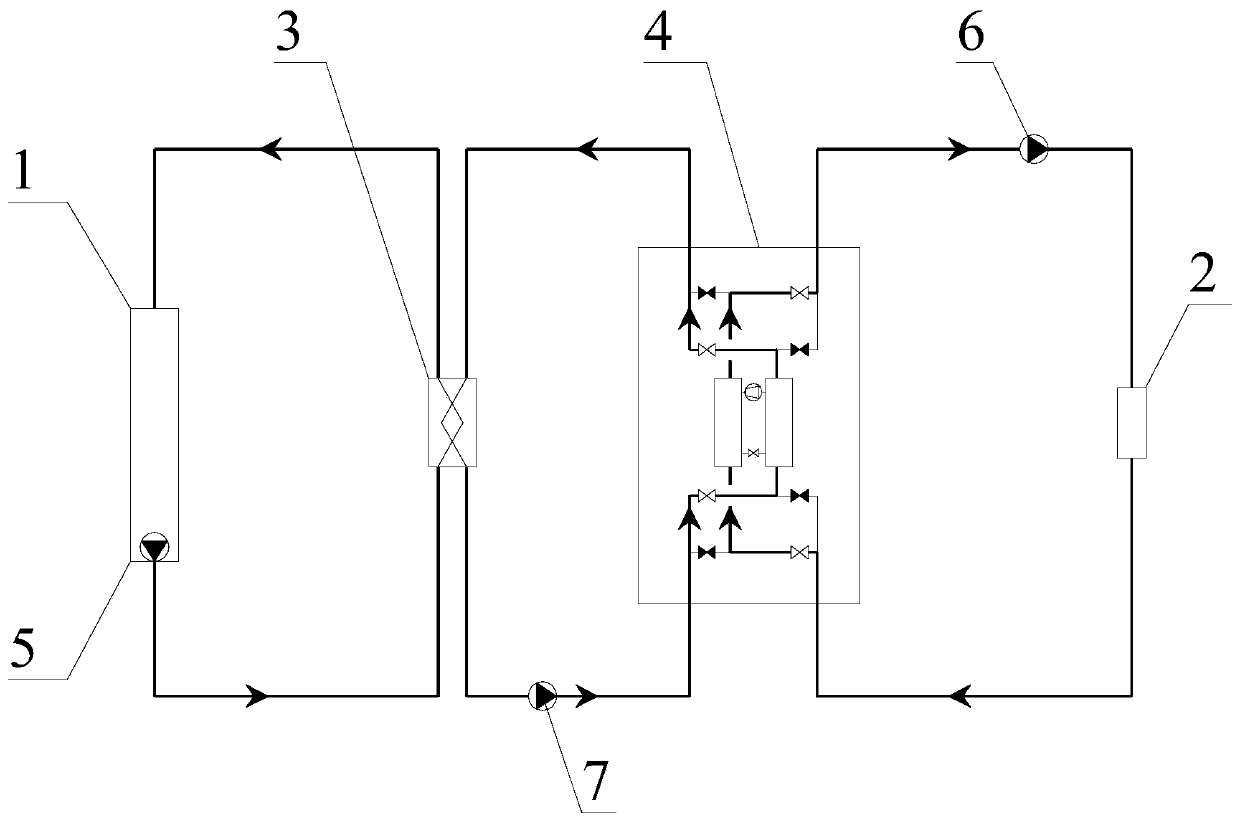

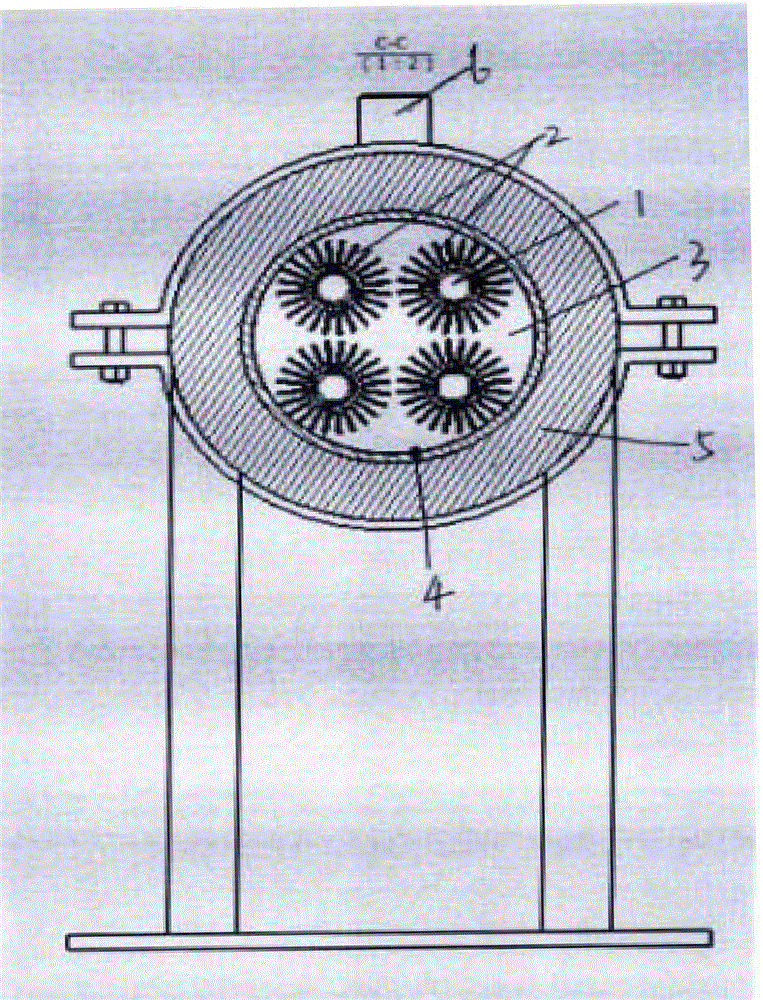

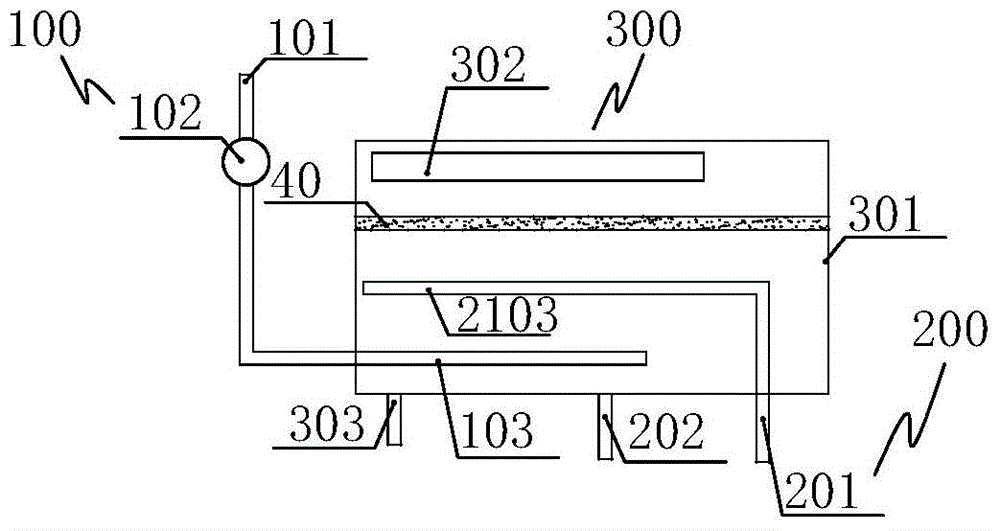

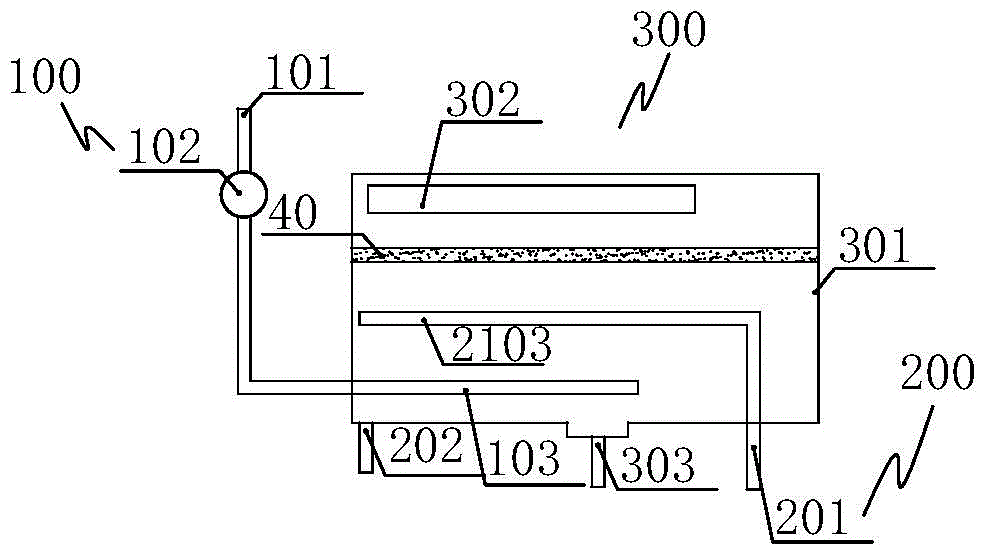

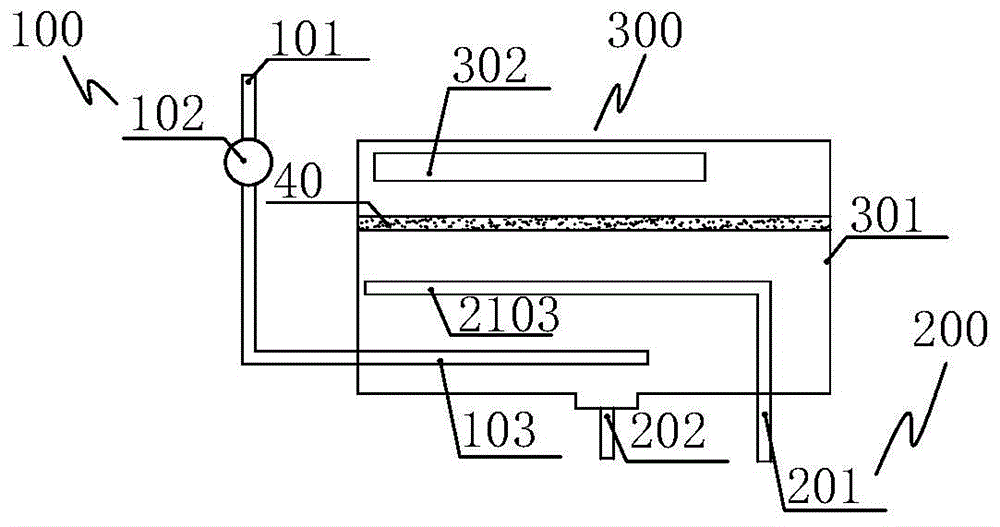

Dirty water source heat pump system

PendingCN110057000AAchieve circular flowIncrease or decrease in temperatureDucting arrangementsMechanical apparatusWater source heat pumpSuction force

The invention discloses a dirty water source heat pump system. The dirty water source heat pump system comprises a dirty water circulation system, an intermediary circulation system, a tail end circulation system, a dirty water source heat exchanger and a water source heat pump unit, wherein the dirty water source heat exchanger comprises a shell, a heat exchange pipe assembly capable of rotatingin the shell and a driving device for driving the heat exchange pipe assembly to rotate forward and reversely. Through the arrangement, after the dirty water enters the shell, the dirty water is rotated under driving of the heat exchange pipe assembly to form a downward rotational flow, so that downward suction force is generated on suspended or floating kind impurities, then the suspended or floating kind impurities are discharged, and the problem of blockage caused by suspended matters or floating objects is avoided; and the heat exchange pipe assembly rotates forwards and reversely in an alternate mode so that the scouring direction of the dirty water on the outer surface of the heat exchange pipe assembly can be changed, then impurities wound around the heat exchange pipe assembly falloff under the reverse scouring effect of the dirty water and can be discharged along with the dirty water, then the winding type dirt blockage is effectively removed, so that the influence caused bythe blockage problem of the dirty water source heat exchanger on the dirty water source heat pump system is reduced.

Owner:燕河能源技术(北京)股份有限公司

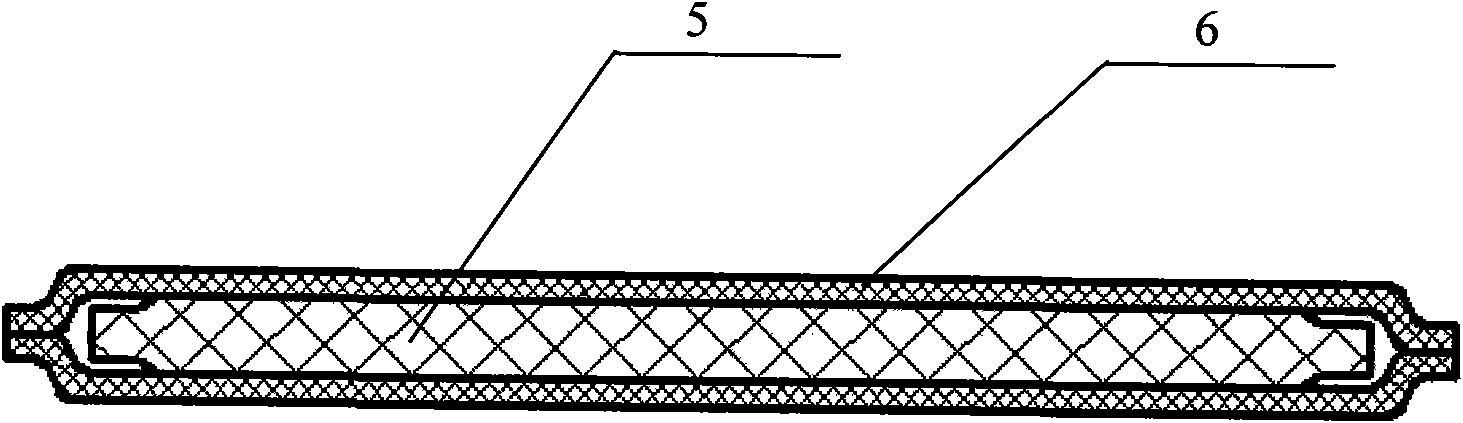

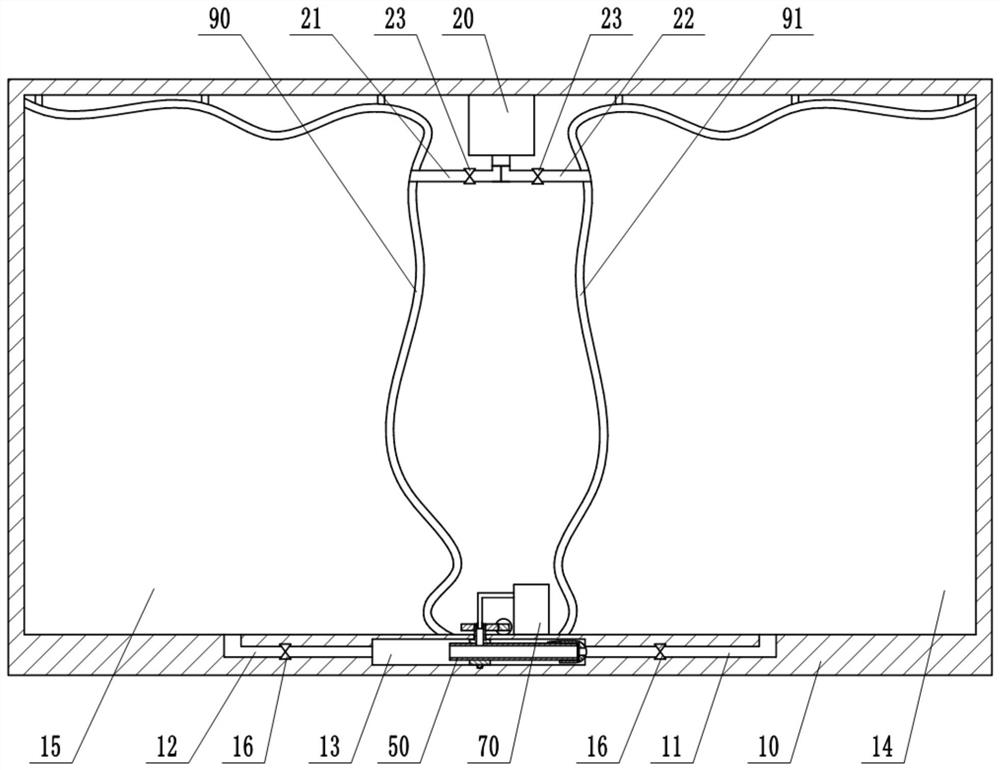

Mattress with temperature controlled by water

InactiveCN101574209AIncrease or decrease in temperatureTemperature controlStuffed mattressesSpring mattressesTemperature controlEngineering

The invention discloses a mattress with temperature controlled by water, comprising a heat exchanger core and a heat exchanger sleeve. The heat exchanger core consists of hoses, fabric for holding the hoses inside, a water knockout vessel and a water collector, wherein the hoses are divided into a plurality of water passages by the water knockout vessel and the water collector. The heat exchanger sleeve consists of an upper layer of fabric and a lower layer of fabric. The invention adopts the multi-passage design, therefore, even if part of the water passages are blocked, the whole water passages can not be blocked and can be continuously used. The diameters of the selected hoses can be greatly reduced, and the hoses can be densely distributed so that the mattress is softer, the temperature is more uniform, and the thickness, the volume and the production cost of the mattress are all reduced. The mattress has an inside structure and an outside structure, thereby being very convenient to clean and maintain.

Owner:刘安全

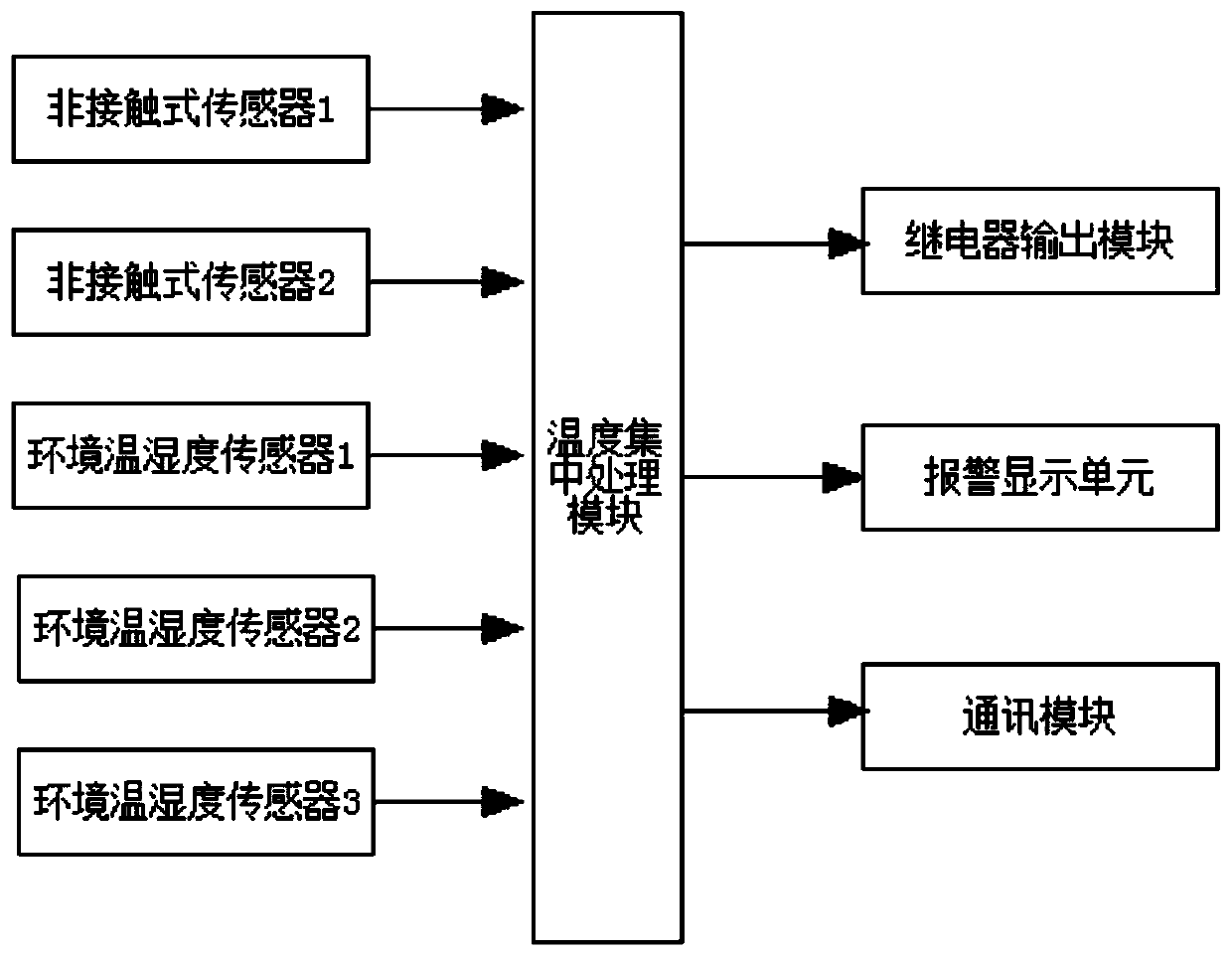

Temperature monitoring device for main loop connector of direct-current switch cabinet

PendingCN111585197AIncrease or decrease in temperatureAdjustable temperatureSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsData transmissionEngineering

The invention discloses a temperature monitoring device for a main loop connector of a direct-current switch cabinet. The device comprises a non-contact sensor, an environment temperature and humiditysensor, a temperature centralized processing module, a relay output module and an alarm display unit. The non-contact sensor is arranged beside a current-carrying conductor in the switch cabinet andis used for measuring the temperature of the current-carrying conductor; the environment temperature and humidity sensor is arranged in a small chamber in the switch cabinet and is used for measuringthe environment temperature and humidity in the small chamber; the non-contact sensor and the environment temperature and humidity sensor are both connected with the temperature centralized processingmodule so as to transmit measured data to the temperature centralized processing module. The temperature centralized processing module is connected with the relay output module and the alarm displayunit, and when the temperature and the humidity are abnormal, the alarm display unit gives an alarm and controls the fan or the heater to perform temperature and humidity reverse adjustment through the relay output module.

Owner:杭州德睿达电气有限公司

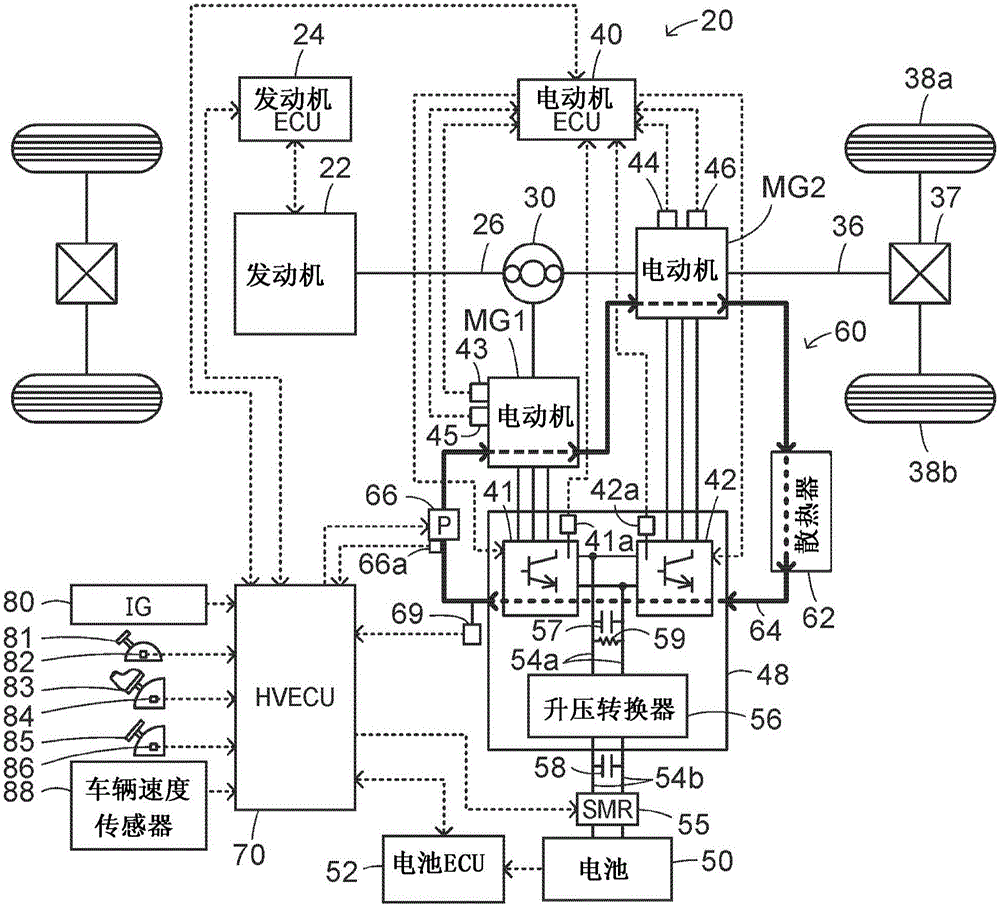

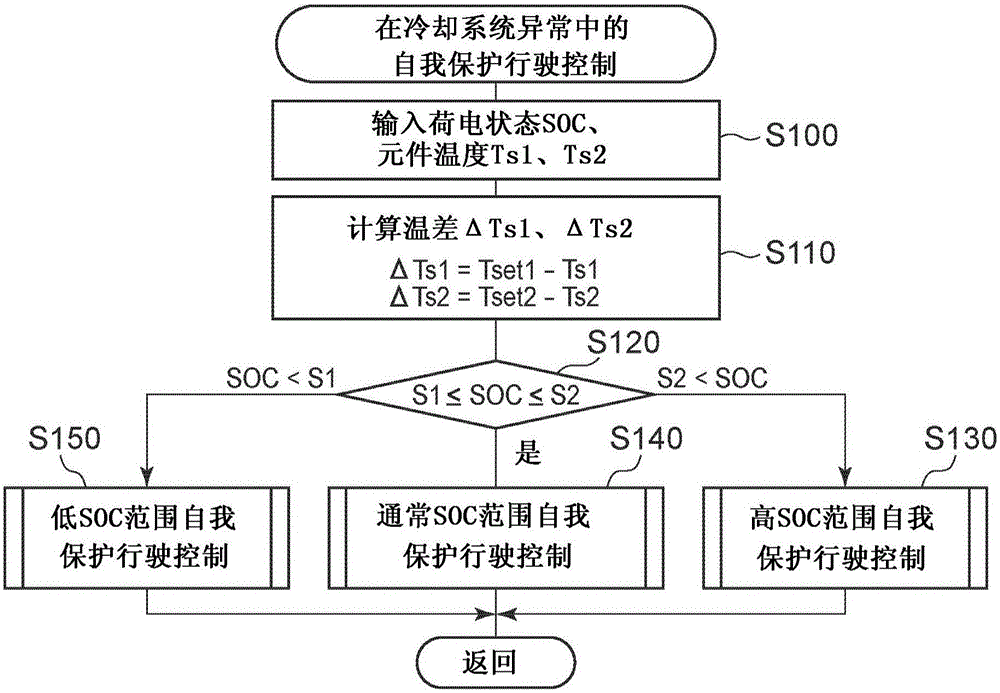

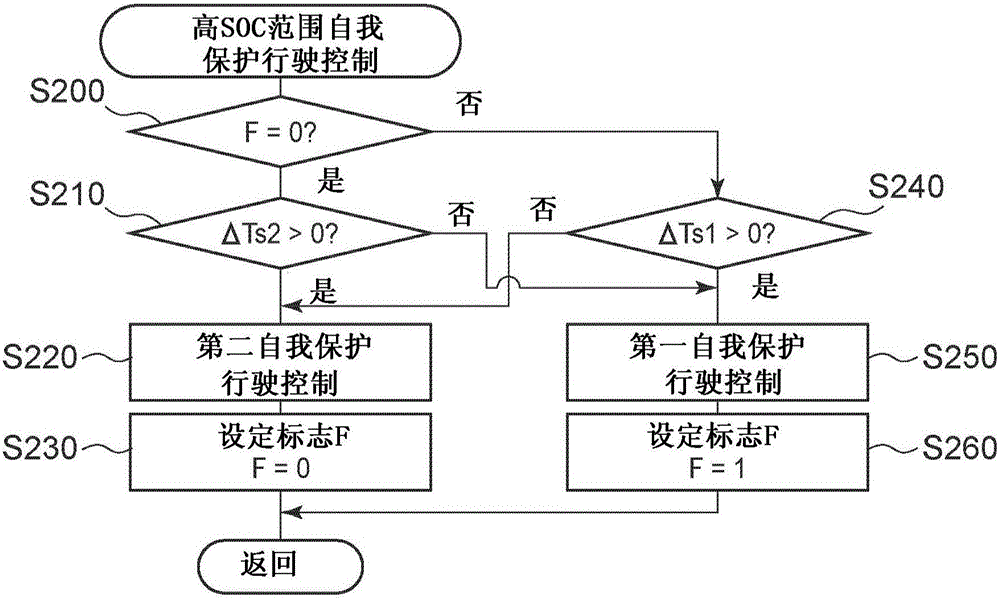

Hybrid vehicle

InactiveCN106004869AIncrease temperatureIncrease or decrease in temperatureHybrid vehiclesElectric devicesInverterState of charge

An electronic control unit included in a hybrid vehicle is configured to switch between first limp home travel control and second limp home travel control based on a first temperature difference, a second temperature difference, and a state of charge when abnormality occurs to a cooler. The first temperature difference is a value that is obtained by subtracting an element temperature of a first inverter from a first load rate limit temperature at which load rate limitation is applied to a first motor. The second temperature difference is a value that is obtained by subtracting an element temperature of a second inverter from a second load rate limit temperature at which the load rate limitation is applied to a second motor.

Owner:TOYOTA JIDOSHA KK

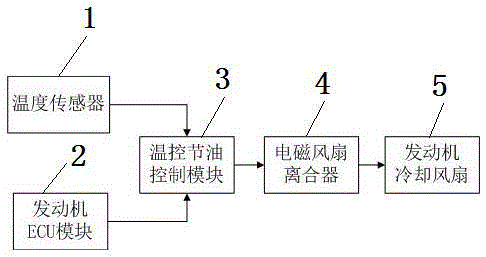

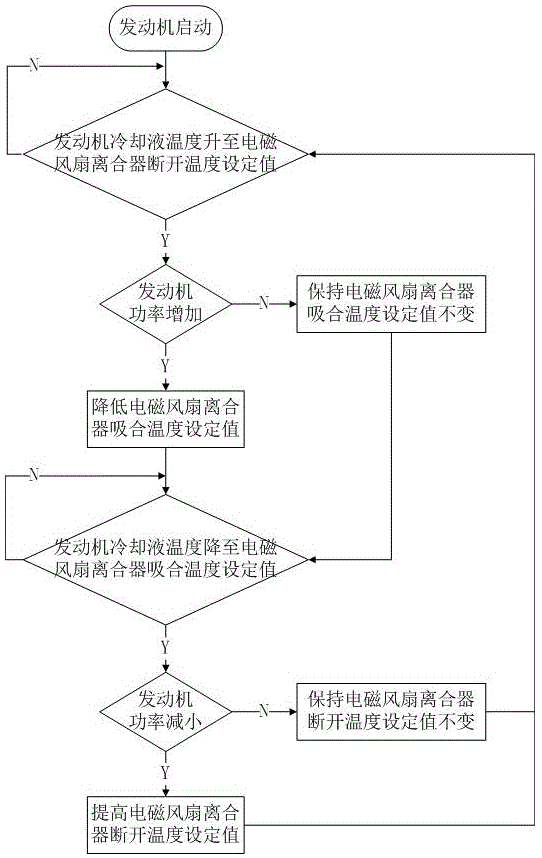

Automobile engine intelligent temperature control and fuel saving control system and method

ActiveCN103982290BReduce power consumptionIncrease or decrease in temperatureCoolant flow controlMachines/enginesTemperature controlControl system

The invention provides a system and method for intelligent temperature control oil saving control of an automobile engine. The system comprises a temperature sensor, an engine ECU module, a temperature control oil saving control module and an electromagnetic fan clutch. According to engine coolant temperature information monitored by the temperature sensor in real time and engine power variation trend information monitored by the engine ECU module in real time, the temperature control oil saving control module adjusts set values of engaging temperature and disengaging temperature of the electromagnetic fan clutch in a timely mode and outputs orders to control the electromagnetic fan clutch to be engaged or disengaged according to the current set values of the engaging temperature and the disengaging temperature of the electromagnetic fan clutch and the engine coolant temperature. The invention further provides the method for intelligent temperature control oil saving control of the automobile engine. The phenomenon that the engine coolant temperature is rapidly increased or reduced due to increase or reduction of engine power can be effectively avoided, an engine is in the optimal work temperature state all the time, and work efficiency of an engine cooling system is improved.

Owner:ANHUI ANKAI AUTOMOBILE

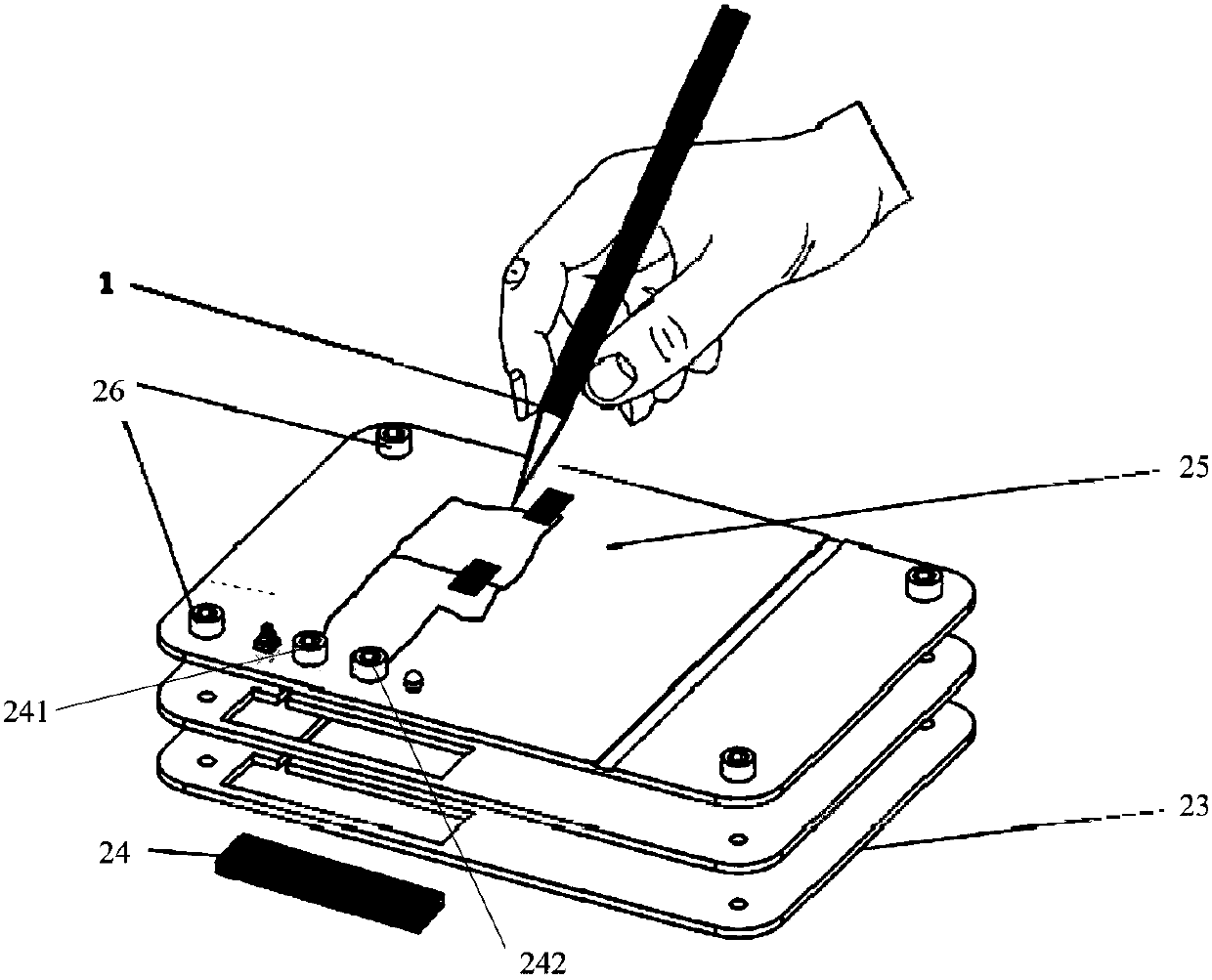

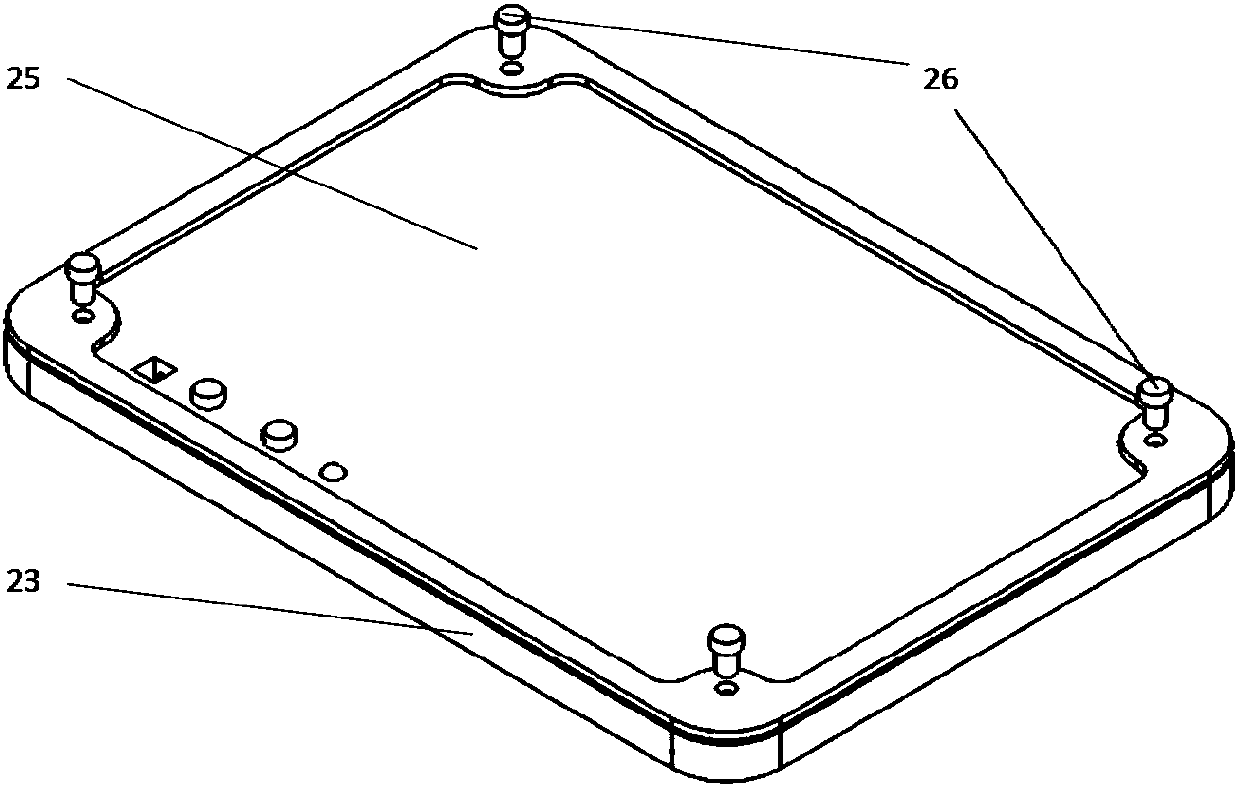

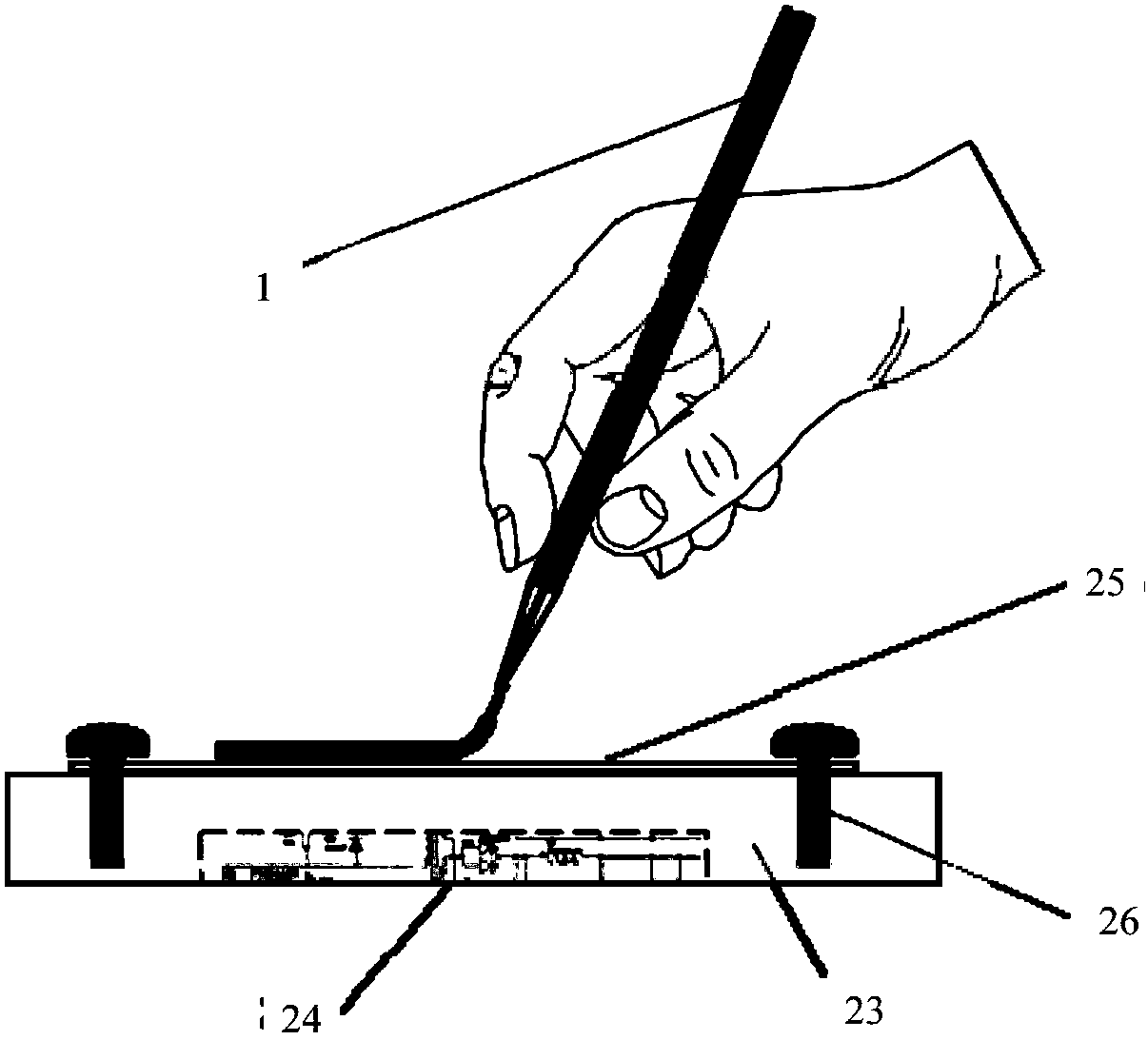

Handwriting system and handwriting method for electronic circuit, and electronic circuit

ActiveCN107643837ALow costConvenient power supply testInput/output processes for data processingHandwritingLiquid metal

The invention discloses a handwriting system and handwriting method for an electronic circuit, and the electronic circuit. The handwriting system of the electronic circuit comprises a circuit handwriting board and a liquid metal handwriting pen, wherein the circuit handwriting board comprises a bottom board, a handwriting substrate and a control circuit arranged on the bottom board; the control circuit comprises an anode electrode and a cathode electrode; in addition, the anode electrode is connected to the anode of an external power supply; the cathode electrode is connected to the cathode ofthe external power supply; the liquid metal handwriting pen is full of metal which is liquid at a preset temperature for writing and forming a circuit of a preset shape on the handwriting substrate;one end of the circuit, which is formed by handwriting, of the preset shape is connected to the anode electrode of the control circuit; and the other end of the circuit is connected to the cathode electrode of the control circuit. By use of the system, the liquid metal handwriting pen with different functional pen points is used for drawing the electronic circuit on the handwriting board, materials can be saved, and the manufacture efficiency of the electronic circuit is improved.

Owner:BEIJING DREAM INK TECH CO LTD

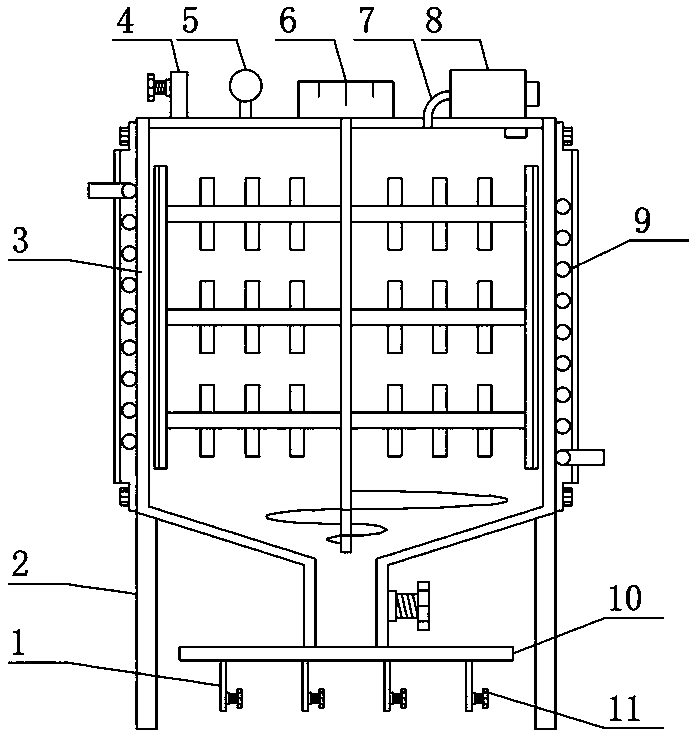

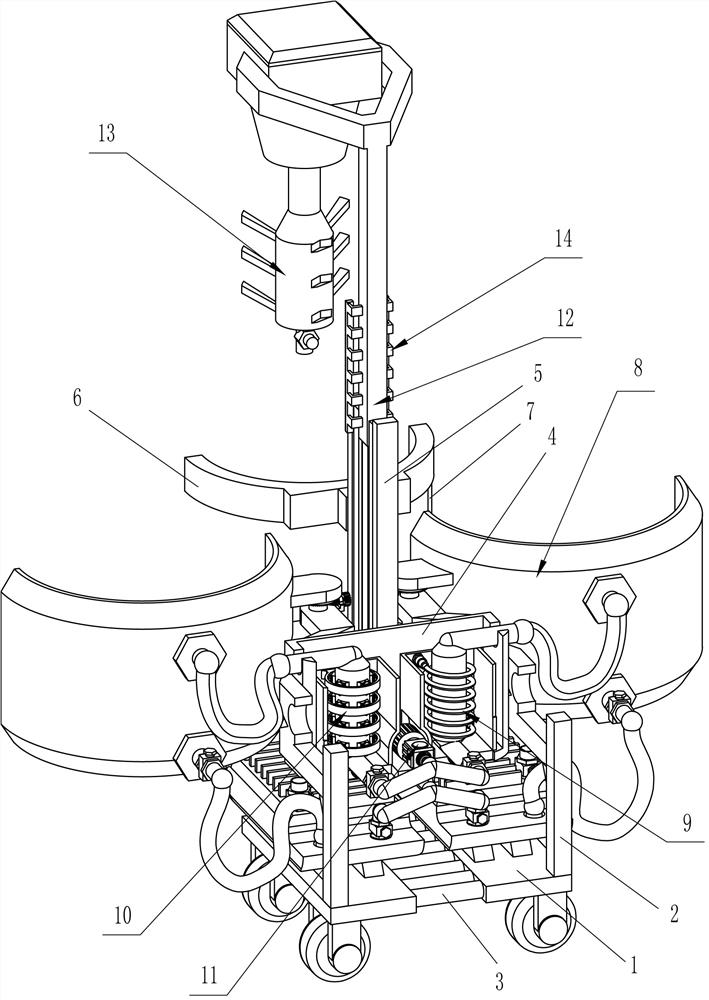

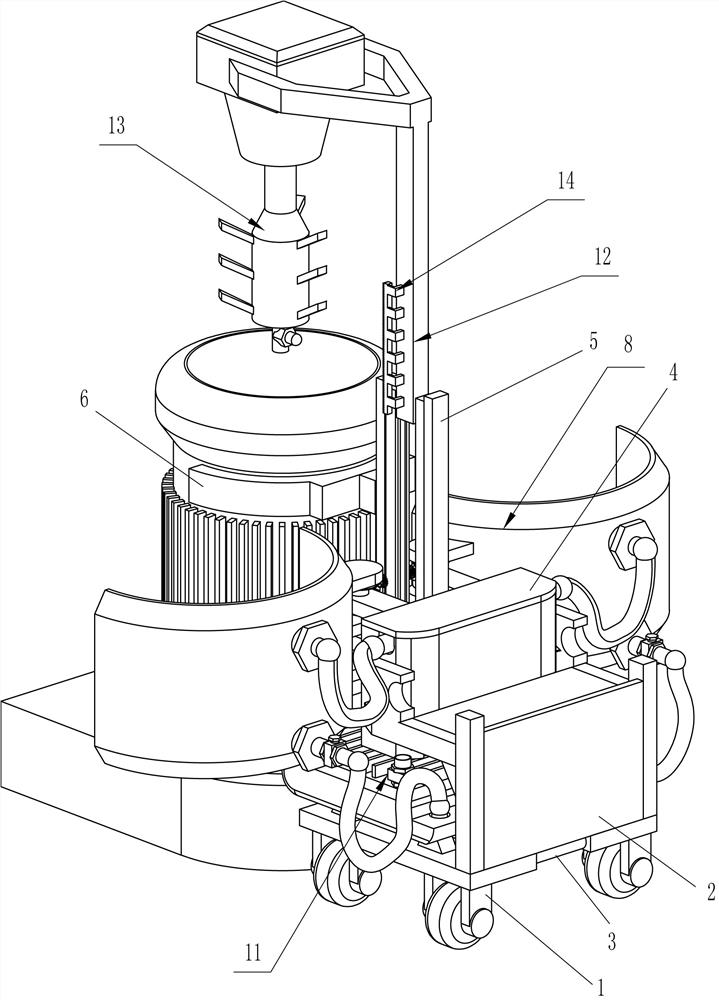

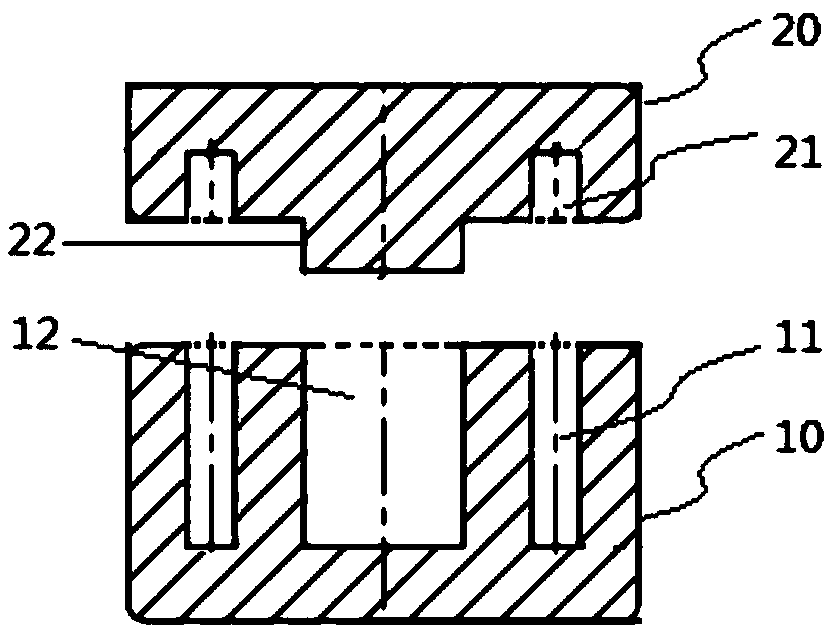

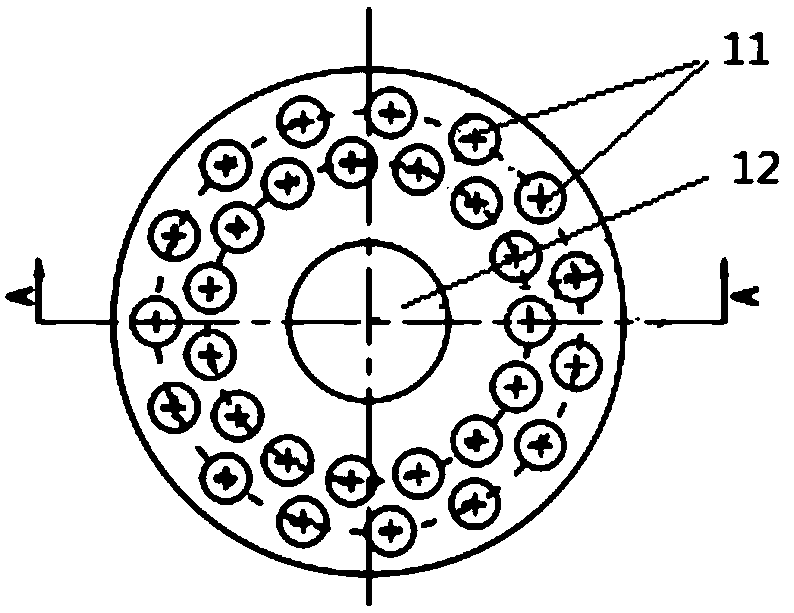

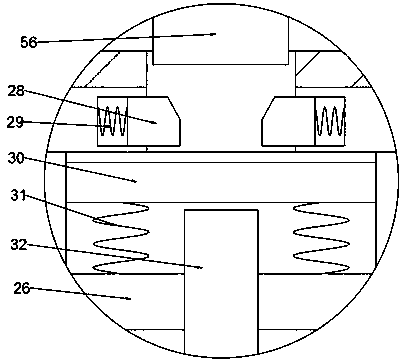

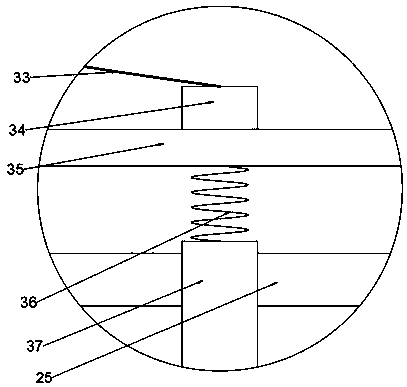

Intelligent temperature adjusting equipment in wine brewing fermentation process

PendingCN113481074AAffect qualityTime-consuming and laborious to solveTemperatue controlWine preparationTemperature controlProcess engineering

The invention relates to brewing equipment, in particular to intelligent temperature adjusting equipment in a wine brewing fermentation process. The technical problem of the invention is to provide the intelligent temperature adjusting equipment for the wine brewing fermentation process, which can quickly control the temperature in a brewing container, is high in effect taking speed of temperature control, and is consistent in temperature of the brewing container at different positions. According to the technical scheme, the intelligent temperature adjusting equipment in the wine brewing fermentation process comprises frames; a vertical frame is arranged on one side of each frame; a control box is arranged between the frames; a mounting plate is arranged on one side of each vertical frame; and each mounting plate is of a structure with two interlayers. By adopting the mode that a detection device extends into a fermentation tank to detect the temperature, manual stretching of hands is not needed in the detection process, and it is avoided that impurities on the hands of workers fall into the fermentation tank to affect the wine production quality.

Owner:黄桂英

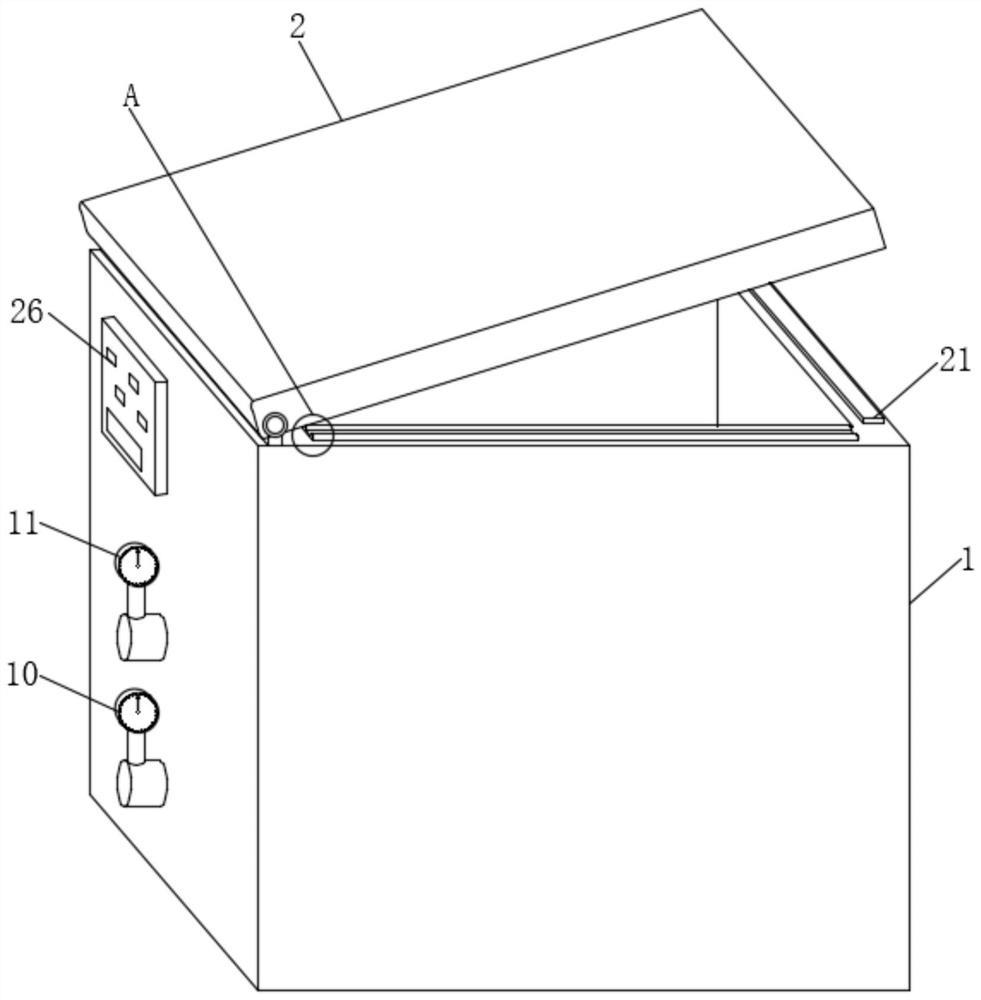

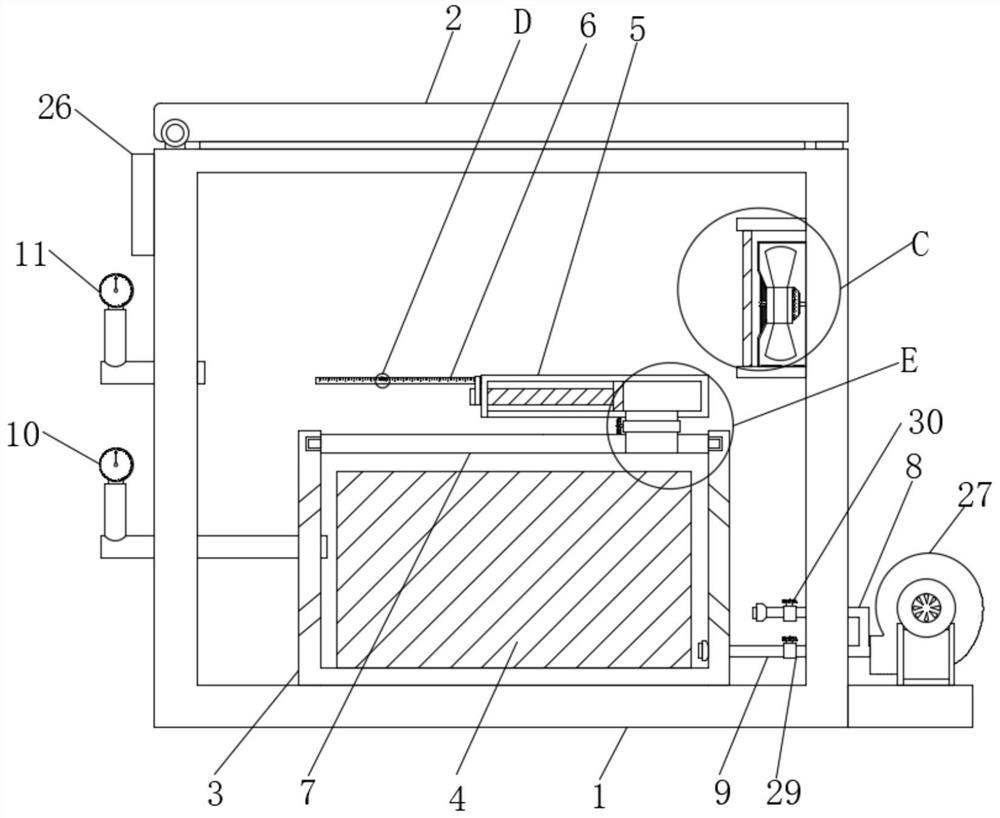

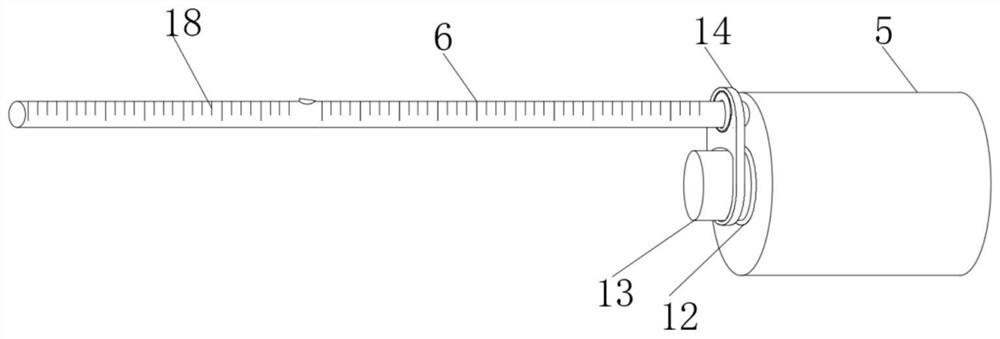

New energy battery multistage performance detection device

PendingCN112198439AProtect cooling efficiencyIntuitive understanding of distributionElectrical testingStructural/machines measurementNew energyEngineering

The invention discloses a new energy battery multistage performance detection device, belongs to the technical field of battery detection equipment, and is characterized in that the new energy batterymultistage performance detection device comprises a box body, a cover plate is hinged to the top of the box body, a protection shell is fixedly connected to the inner bottom wall of the box body, anda battery body is fixedly connected to the inner bottom wall of the protection shell. A first sliding groove is formed and matched with the a T-shaped rod, so that a closed space is formed between the T-shaped rod and the first sliding groove, expanded air is exhausted through heat dissipation holes of the protective shell along with heat accumulation in the protective shell and heat expansion and cold contraction of air, and air which does not penetrate out of the heat dissipation holes in time enters a detection pipe through the top of a sealing plate; the T-shaped rod is pushed leftwards to drive a connecting plate to move, the top of the connecting plate moves on a standard rod, and the heat dissipation condition in the protective shell can be visually known by reading scales on the surface of the standard rod.

Owner:杜亮

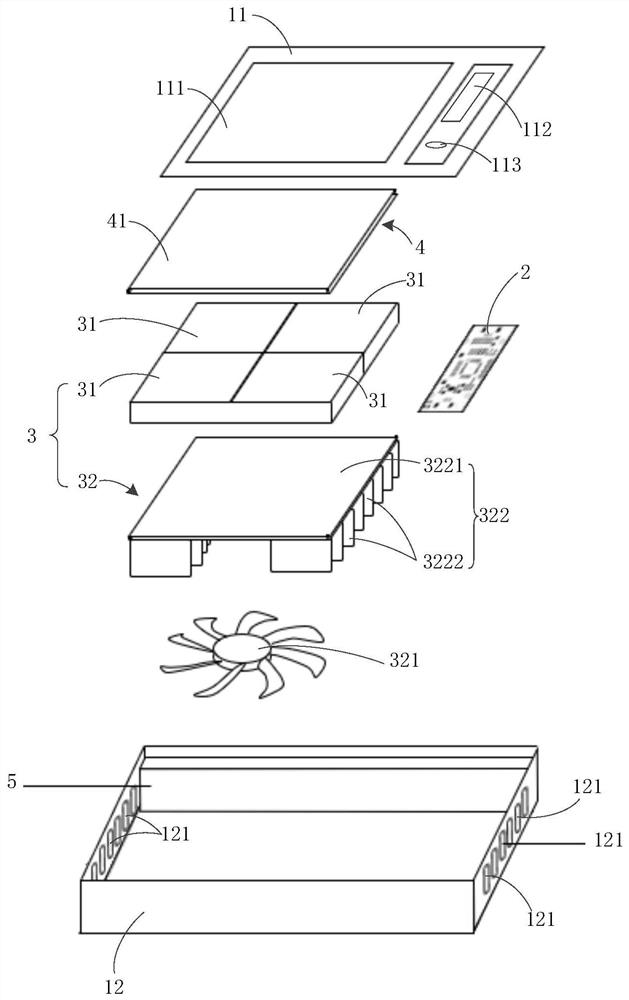

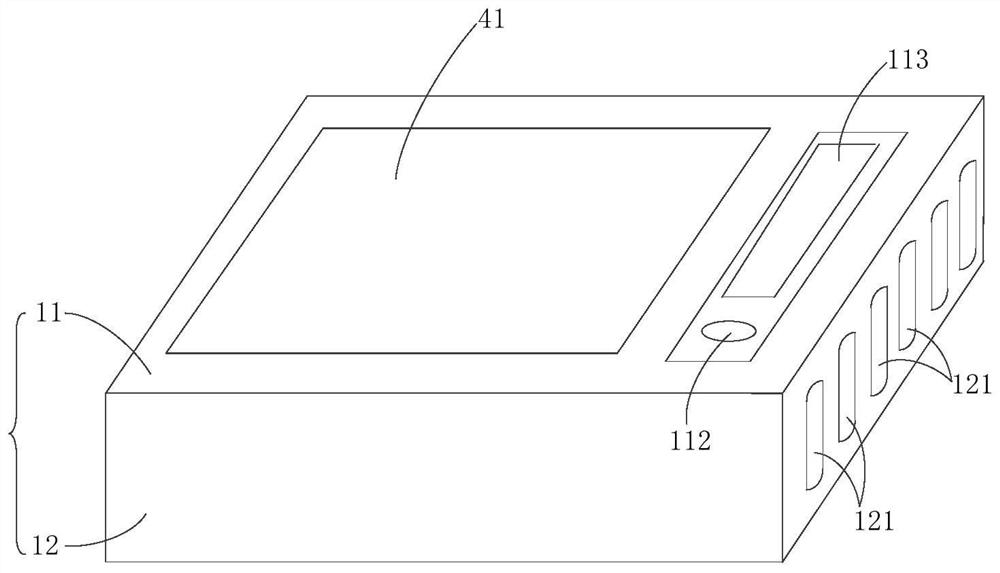

Temperature control device for biological research

PendingCN113467541AIncrease temperatureIncrease or decrease in temperatureTemperatue controlBiologyTemperature control

The invention relates to a temperature control device for biological research. The temperature control device comprises a shell, and a controller, a temperature control structure and a temperature sensor arranged in the shell; the temperature control structure and the temperature sensor are electrically connected with the controller, a heat conduction plate is arranged on the upper end face of the temperature control structure, the upper end face of the heat conduction plate is used for containing an experiment vessel, the temperature sensor is used for collecting the temperature of the heat conduction plate, the controller is used for controlling the temperature control structure to work according to the temperature collected by the temperature sensor, and the temperature control structure is used for adjusting the temperature of the heat conduction plate, so that the temperature of the experiment vessel in contact with the heat conduction plate is increased or reduced to a preset temperature. According to the temperature control device for biological research, the temperature of the heat conduction plate and the temperature of the experiment vessel can be accurately controlled, the temperature of the heat conduction plate and the temperature of the experiment vessel are kept within the preset temperature, and therefore a safe and pollution-free low-temperature operation environment is created for basic research of biological reaction.

Owner:BEIHANG UNIV +1

Wood pallet drying device

InactiveCN112050565AAvoid consumptionDissipate quicklyDrying solid materials without heatDrying gas arrangementsEngineeringAir compressor

The invention belongs to the technical field of wood drying, and particularly relates to a wood pallet drying device. The wood pallet drying device comprises a drying chamber, a vacuum pump and an energy generation mechanism. A first drying cavity and a second drying cavity are arranged in the drying chamber; an air suction end of the vacuum pump is connected with a first branch pipe and a secondbranch pipe; the first branch pipe communicates with the first drying cavity, and the second branch pipe communicates with the second drying cavity; the energy generation mechanism comprises an air compressor, a vortex tube and a driving unit; a rotating cavity, a first air duct and a second air duct are formed in the bottom of the drying chamber, the first air duct and the second air duct both communicate with the rotating cavity, the first air duct communicates with the first drying cavity, the second air duct communicates with the second drying cavity, and one-way air outlet valves are arranged on the first air duct and the second air duct; the vortex tube is rotationally connected with the interior of the rotating cavity; a nozzle of the vortex tube penetrates through the bottom of thedrying chamber and is located in the drying chamber; and the air compressor communicates with the nozzle of the vortex tube. When the wood pallet drying device is used for drying a wood pallet, waterin the wood pallet is rapidly dissipated, so that the drying efficiency is high, the effect is good, and consumed time is short.

Owner:重庆龙浩木业有限责任公司

Fluid heat transferring device

InactiveCN104455893AImprove protectionSave energyPipe heating/coolingIndirect heat exchangersEngineeringHeat pipe

The invention discloses a fluid heat transferring device, and belongs to a pipeline heating technology. The fluid heat transferring device is characterized by comprising a tubular heat source supply component and platy heat pipes which can be connected with the outer wall of the tubular heat source supply component in a heat transferring mode along the end in the heat transferring direction, and the other end of each platy heat pipe is a free end. The device is arranged in the rear middle of a pipeline in the axial direction of the pipeline, heat can be transferred from the center of the pipeline to the wall of the pipeline so as to evenly heat fluid passing through the pipeline, and the fluid heat transferring device is used in the pipeline, can evenly heat the fluid in the pipeline, and achieves safe and energy-saving effects.

Owner:南宁市磁汇科技有限公司

Cell cryopreservation box

PendingCN108990965AImprove cryopreservation survival rateImprove insulation effectDead animal preservationHigh cellEngineering

The invention discloses a cell cryopreservation box. The cell cryopreservation box comprises a box body and a box cover. A plurality of first cryotube holes for storing cryotubes and a fixed hole arearranged in the box body. The height of the first cryotube holes is smaller than that of the cryotube. The fixed hole is arranged in the center of the box body. The box cover is provided with second cryotube holes corresponding to the first cryotube holes of the box body. The center of the box cover is provided with a fixed raised block corresponding to the fixed hole. The shape and size of the fixed raised block of the box cover are matched with those of the fixed hole of the box cover. The cell cryopreservation box has good heat preservation performances, slowly increases or decrease the temperature in the cryotube hole, guarantees the slow cooling of the cells in a refrigerator at -80 DEG C and ensures the high cell cryopreservation survival rate. The cell cryopreservation box is free of a cryopreservation liquid in the cryopreservation device, is environmentally friendly and has no pollution.

Owner:四川妙和生物科技有限公司

Spray type air conditioner and air conditioning method

ActiveCN103591659BSimple but efficientEasy to adjustSpace heating and ventilation safety systemsLighting and heating apparatusMulti pollutantEngineering

The invention relates to spraying type air conditioning equipment and an air conditioning method. The spraying type air conditioning equipment used for conditioning to-be-treated air in a space comprises a first air conditioner body. The first air conditioner body comprises a first box system, a first air system and a first spraying type liquid system. The first box system comprises a first box provided with an outlet of treated air. The first air system is used for delivering the to-be-treated air into the first box. The first spraying type liquid system is used for delivering first liquid into the first box and spraying or discharging the first liquid in the first box to the air delivered into the first box. The to-be-treated air is in contact with the first liquid in the first box. The first liquid physically or chemically or biologically reacts with one or more kinds of pollutants in the to-be-treated air so as to purify the to-be-treated air. The spraying type air conditioning equipment is simple in structure, high in efficiency and convenient for conditioning.

Owner:CHINA IPPR INT ENG

Furniture wall and item of furniture

InactiveCN102421331BConstitute stableIncrease or decrease in temperatureWallsFurniture partsStructural engineeringMechanical engineering

Owner:HETTICH HLDG GMBH & CO OHG

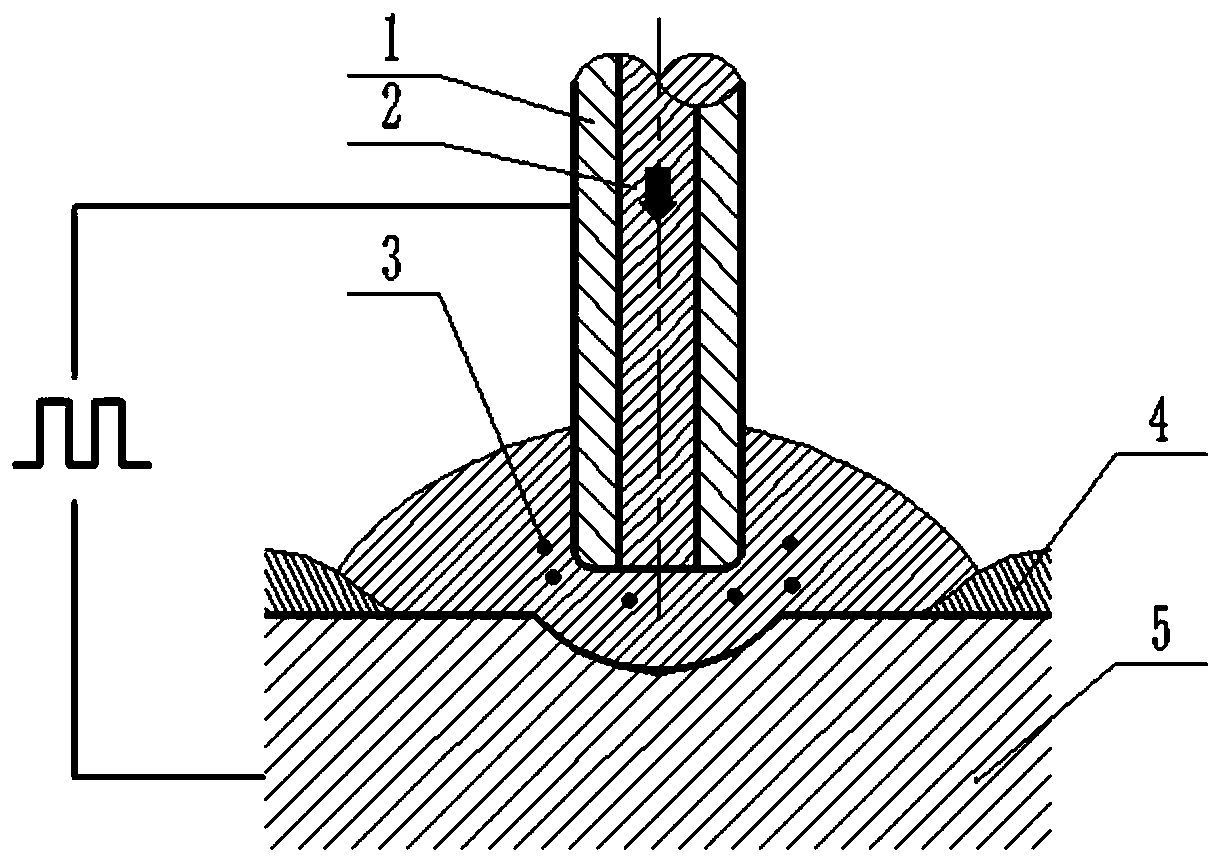

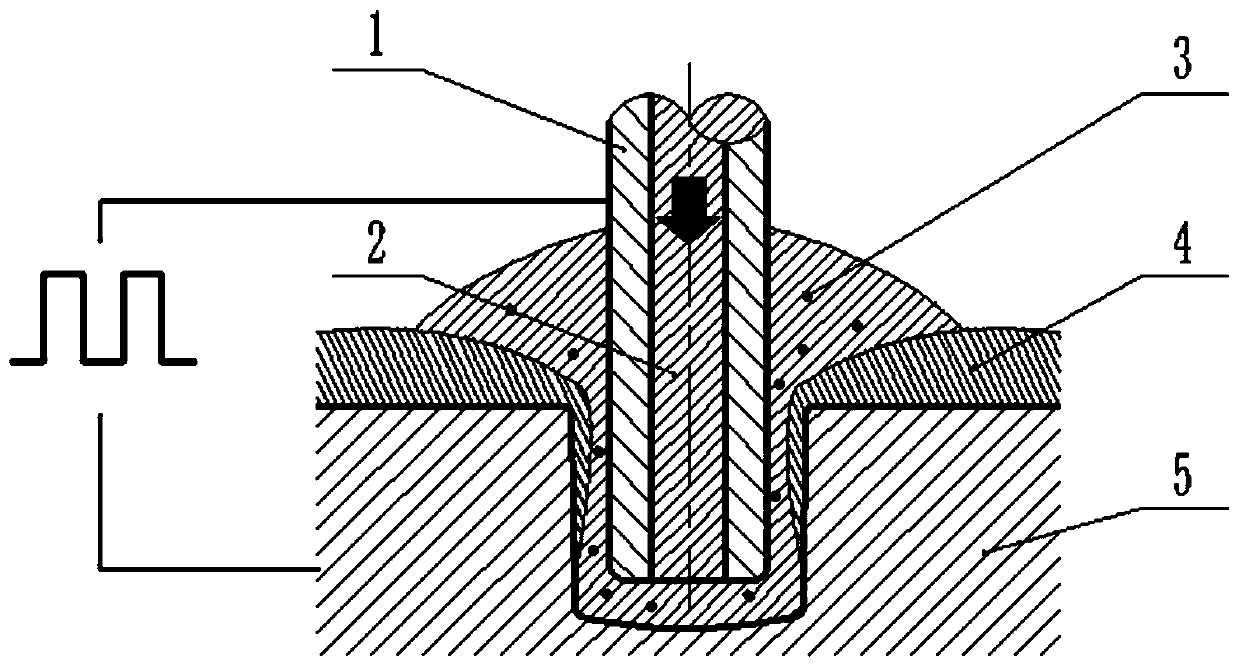

Electrolytic small hole processing method of transient frozen ice layer

The invention discloses an electrolytic small hole processing method of a transient frozen ice layer, and belongs to the field of special processing. The electrolytic small hole processing method is characterized in that when a low-temperature workpiece is impacted by positive-flow electrolyte, the temperature of the electrolyte is cooled in the backflow process, the electrolyte is transiently frozen into ice when reaching the freezing point, and the ice is wrapped around the periphery of the processed hole wall and the periphery of the hole. Due to the reduction of the ionic activity at low temperature, the electrochemical dissolution phenomenon at the wrapping part of the ice layer almost disappears, the phenomenon of stray corrosion at the hole wall and the hole opening can be effectively relieved, and processing of small holes with high quality and small taper can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cold-chain logistics transportation compartment temperature and humidity real-time monitoring equipment

ActiveCN114063689AIncrease or decrease in temperatureSimple structureSimultaneous control of multiple variablesCold chainTemperature control

The invention discloses cold-chain logistics transportation compartment temperature and humidity real-time monitoring equipment which comprises a monitoring cavity arranged in a vehicle body, a compartment is fixedly arranged on the vehicle body, the monitoring cavity is fixedly arranged in the compartment, a water tank is fixedly arranged at the bottom of the monitoring cavity, a moisture control cavity is fixedly arranged in the monitoring cavity, the moisture control cavity is located on the water tank, a heat insulation plate is fixedly arranged in the moisture control cavity and divides the moisture control cavity into an air guide cavity and a temperature adjusting cavity, the lower side wall of the air guide cavity is fixedly connected with the upper side wall of a water tank through a guide pipe, and the guide pipe penetrates through the lower side wall of the air guide cavity and the upper side wall of the water tank. A regulator is fixedly arranged in the temperature adjusting cavity, and a moisture temperature sensing device and a moisture temperature control device are further fixedly arranged in the temperature adjusting cavity. By means of the special humidity and temperature adjusting device, humidity flowing into the storage cavity is kept consistent with the original temperature in the storage cavity, and the influence on transported objects is reduced.

Owner:王光文

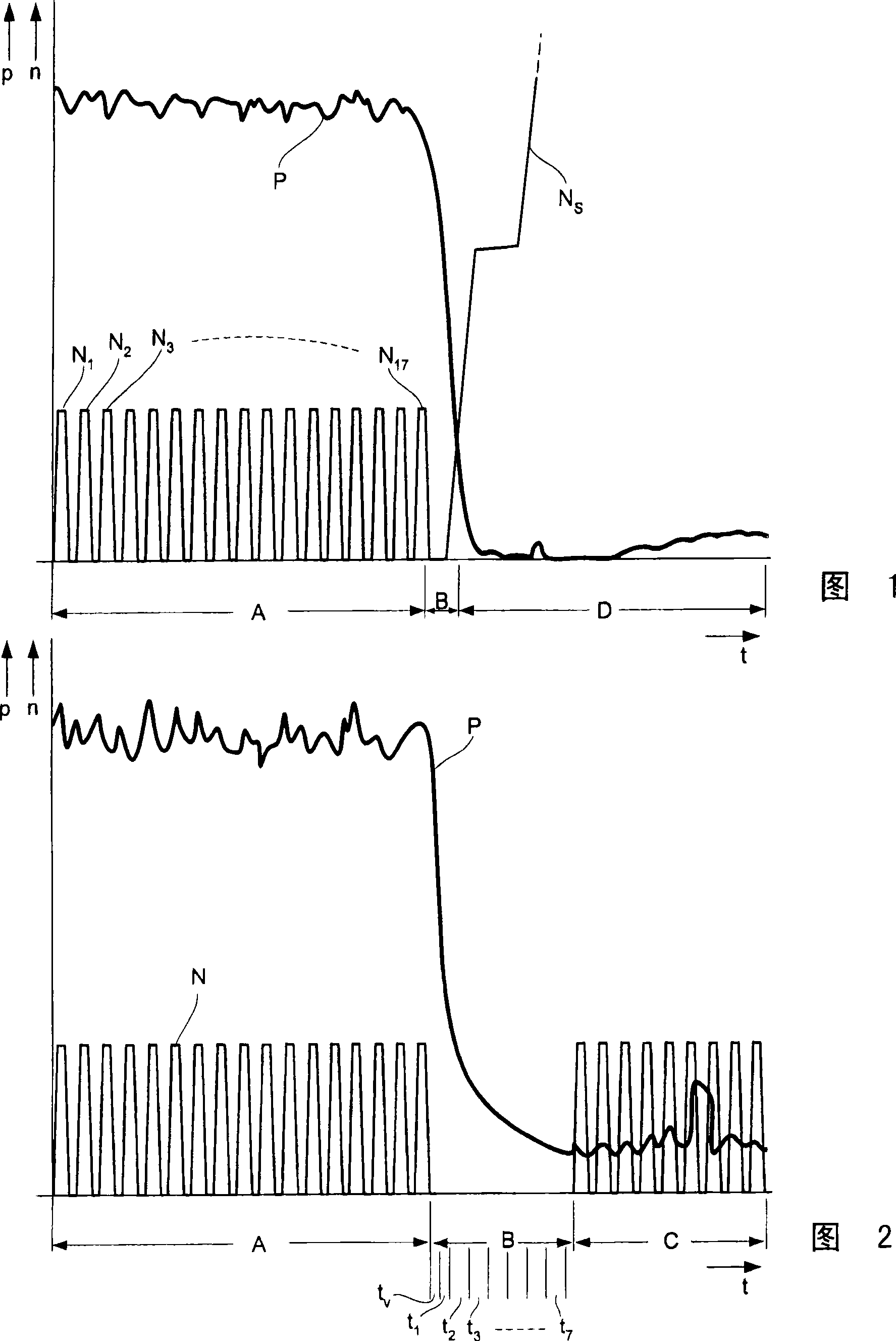

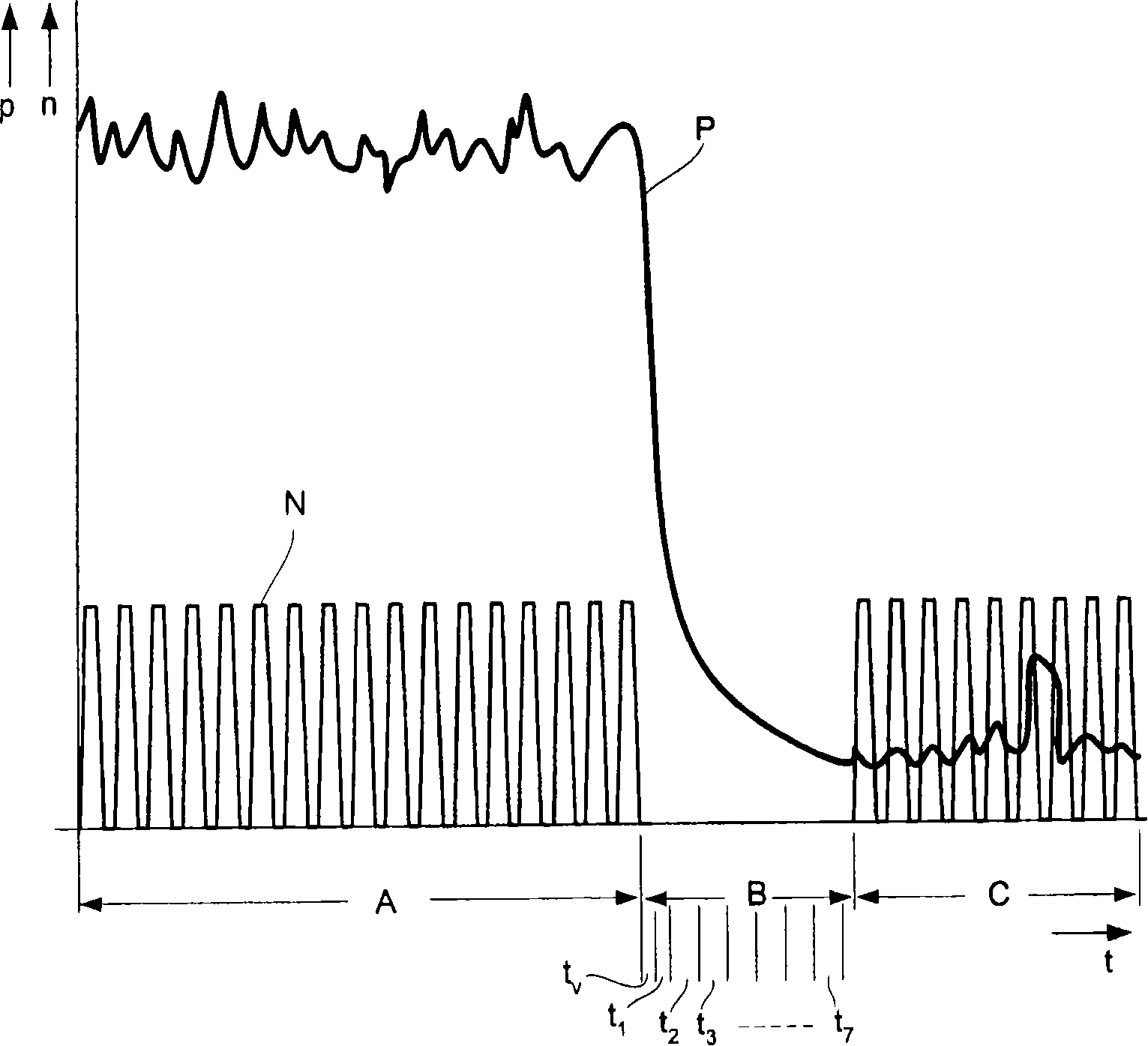

Method for removing foam from the washing container of a drum-type washing machine

InactiveCN1671910BEfficient removalIncrease or decrease in temperatureOther washing machinesControl devices for washing apparatusEngineering

The invention relates to a process for removing foam in a lye container as a result of a program step, provided for dehydrating the lye container, with a lye discharge system arranged on the floor of the lye container with a lye pump and with a sensor for determining the level of the liquid in the lye container, whereof the sensor signal p is recorded during operation of the lye pump. According to the inventive method, the foam is detected in a detection range in such a way that through determining a change rate (Deltap / Deltat) of a curve (p / t) of the sensor signal, and through determining a component of the curve (p / t) of the sensor signal, the component is a specific change of the change rate (Deltap / Deltat), and through comparing the successive level gradients of (Deltap1 / Deltat1 to Deltap2 / Deltat2,..., Deltapn-1 / Deltatn-1 to Deltapn / Deltatn; wherein a foam-treating measure that is adapted to the type of the component is initiated if the component is present.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

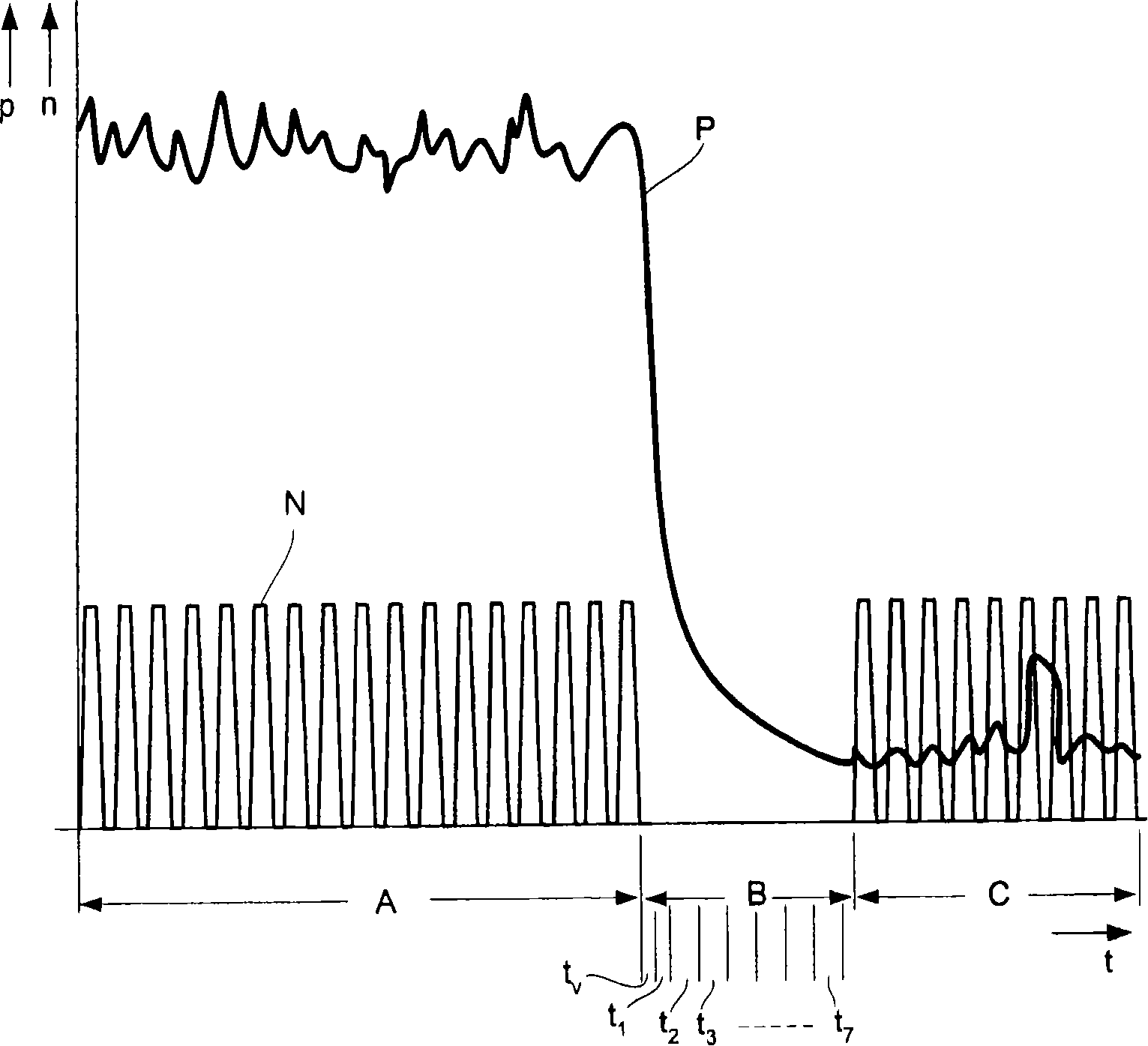

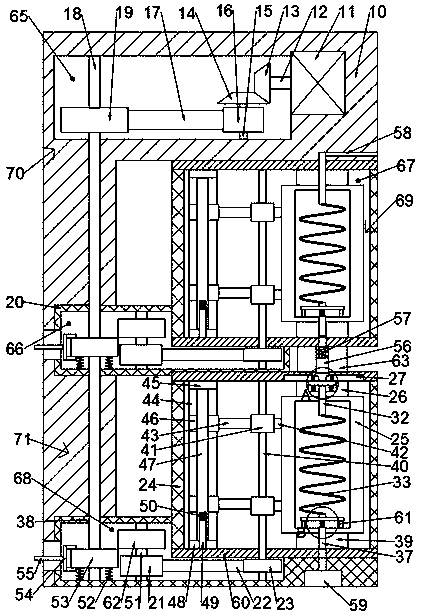

Electric heating converter capable of adjusting heat

InactiveCN111050428AStable and suitable temperatureIncrease or decrease in temperatureOhmic-resistance heating detailsHeating element shapesThermodynamicsMachine

The invention discloses an electric heating converter capable of adjusting heat. The electric heating converter comprises a machine body; a power cavity 65 is formed in the machine body 10; a first machine shell 20 is arranged in the machine body 10; an upper adjusting cavity 66 is formed in the first machine shell 20; a second machine shell 38 is arranged on the lower side of the machine body 10;a lower adjusting cavity 68 is formed in the second machine shell 3; two electric heating bodies 60 are arranged on the right side of the machine body 10; conversion cavities 67 are formed in the electric heating bodies 60; a power device 70 for providing power is arranged in the power cavity 65. The converter can adjust heat at will; after the heat is adjusted, it can be guaranteed that proper and stable heat is generated; a heat preservation effect can be achieved; and objects can be rapidly heated and warmed.

Owner:金华表征电子科技有限公司

Underground Coal Gasification Method

ActiveCN103556979BReduce contentIncrease temperatureConstructionsCoal gasificationHydrogenWater vapor

Owner:ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com