Wood pallet drying device

A technology of drying device and wooden pallet, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of low drying efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

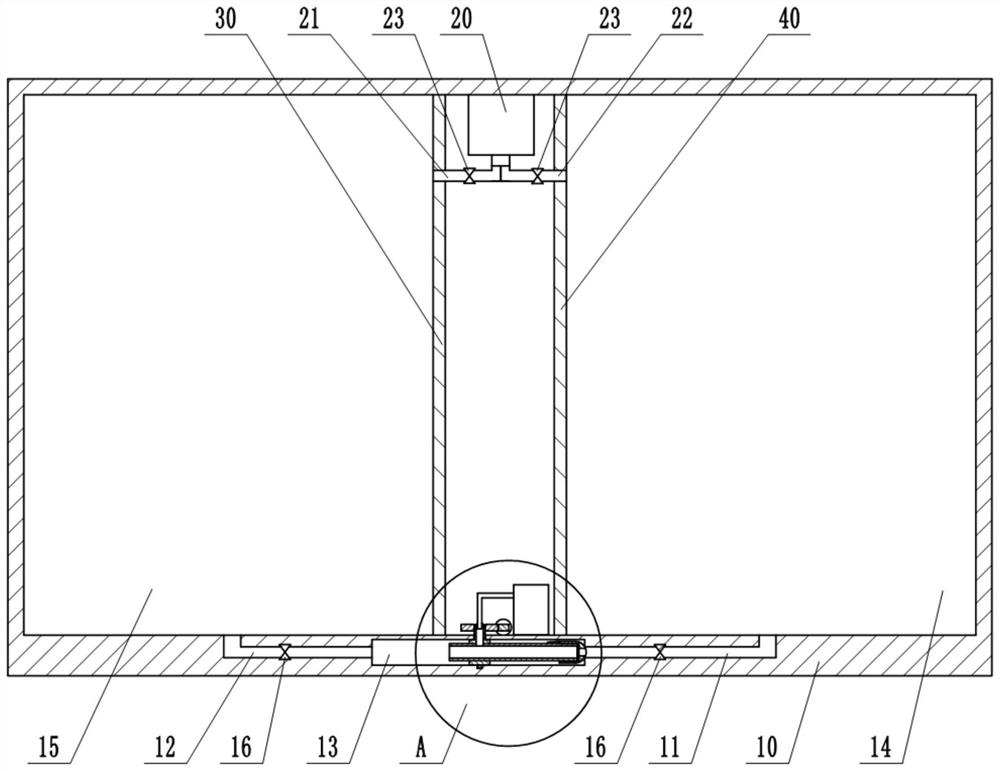

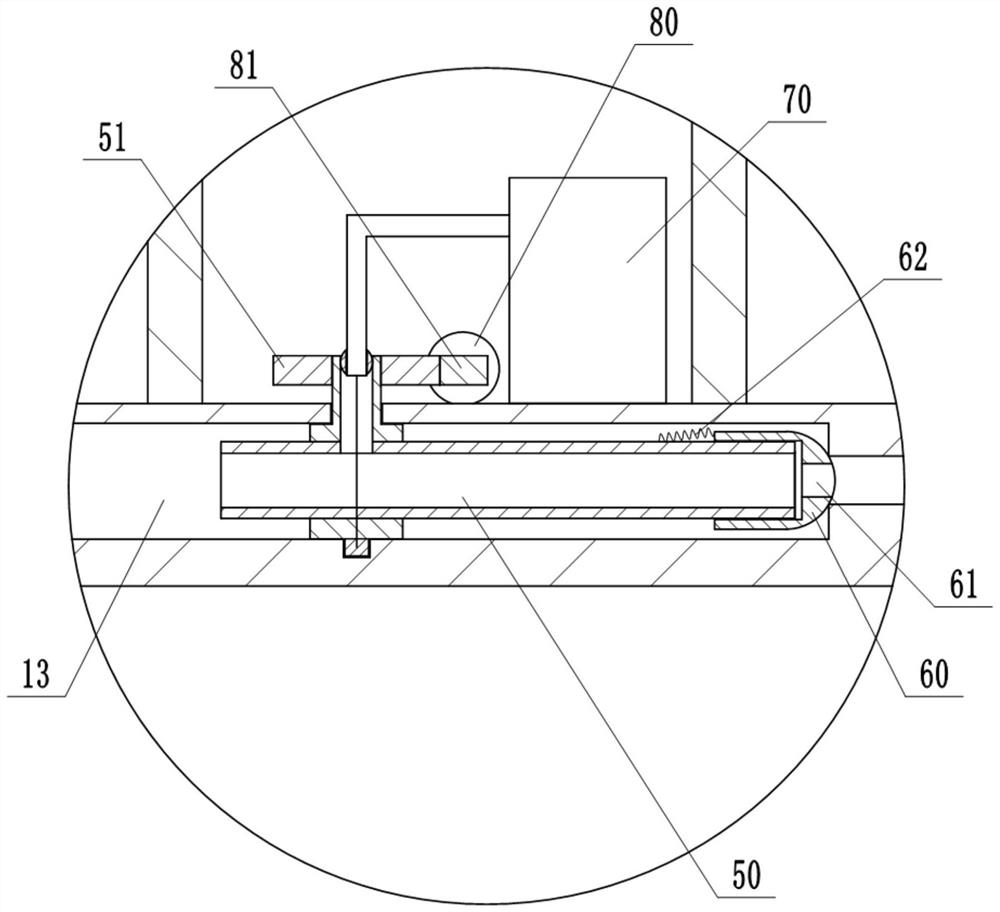

[0024] This embodiment is basically as figure 1 Shown: a wooden pallet drying device, including a drying chamber 10, a vacuum pump 20 and an energy generating mechanism installed in the drying chamber 10. The drying chamber 10 is provided with two mutually independent first drying chambers 15 and second drying chambers 14. In this embodiment, the drying chamber 10 is fixedly equipped with a first partition 30 and a second partition 40, the first partition 30 is surrounded by the left side wall of the drying chamber 10 to form the first drying chamber 15, and the second partition 40 is surrounded by the right side wall of the drying chamber 10 to form the second drying chamber 14. Opening doors are installed on the first dividing plate 30 and the second dividing plate 40, opening the opening doors on the first dividing plate 30 and the second dividing plate 40 can make the first drying chamber 15 communicate with the second drying chamber 14 .

[0025] The vacuum pump 20 is ...

Embodiment 2

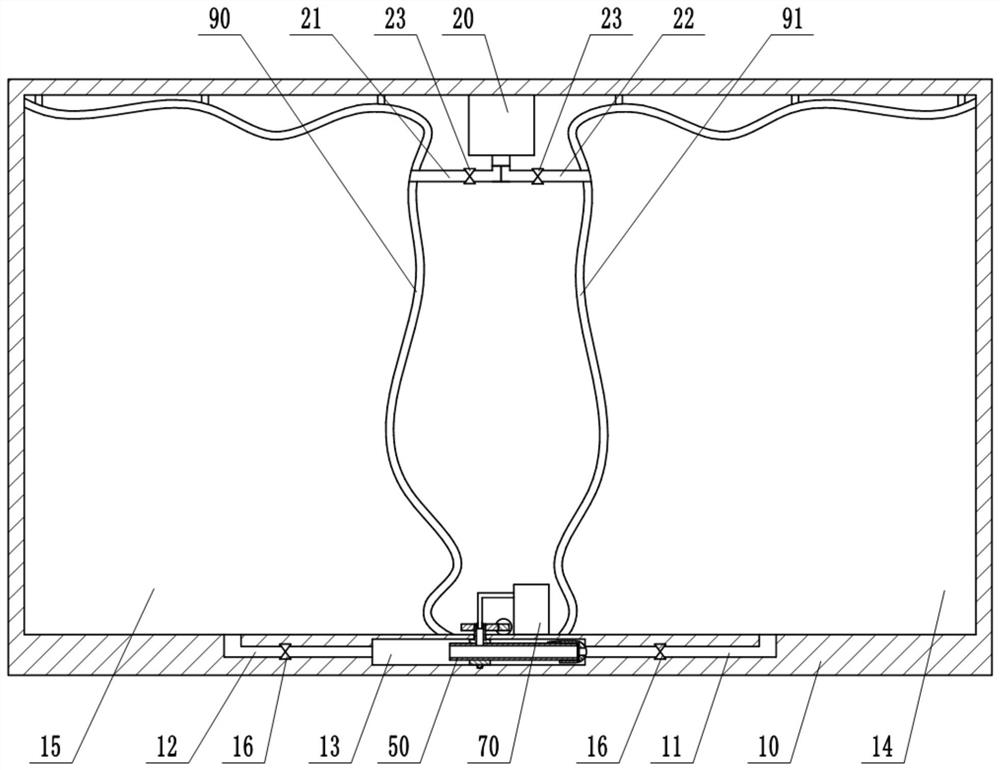

[0030] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, in this implementation, the first partition 30 and the second partition 40 are not provided in the drying chamber 10 , but the first airbag 90 and the second airbag 91 are provided. The first air bag 90 and the left side wall of the drying chamber 10 enclose the first drying chamber 15, and the second air bag 91 and the right side wall of the drying chamber 10 enclose the second drying chamber 14; Both the airbag 90 and the second airbag 91 are provided with sealing bars, which can open and seal the first airbag 90 and the second airbag 91, and the corresponding airbags can be opened by pulling the corresponding sealing bars. The first airbag 90 and the second airbag 91 are both double-layer structures. The interlayers of the first airbag 90 and the second airbag 91 are filled with air, and the thermal conductivity of the air is very low, so that the interlayer has a good heat preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com