Electrolytic small hole processing method of transient frozen ice layer

A hole processing method and ice layer technology, applied in the electrolytic processing of small holes, based on the field of electrolytic small hole processing of the frozen ice layer on the processed wall, to improve the quality of the hole, suppress stray corrosion, and slow down stray corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a specific description in conjunction with the figure:

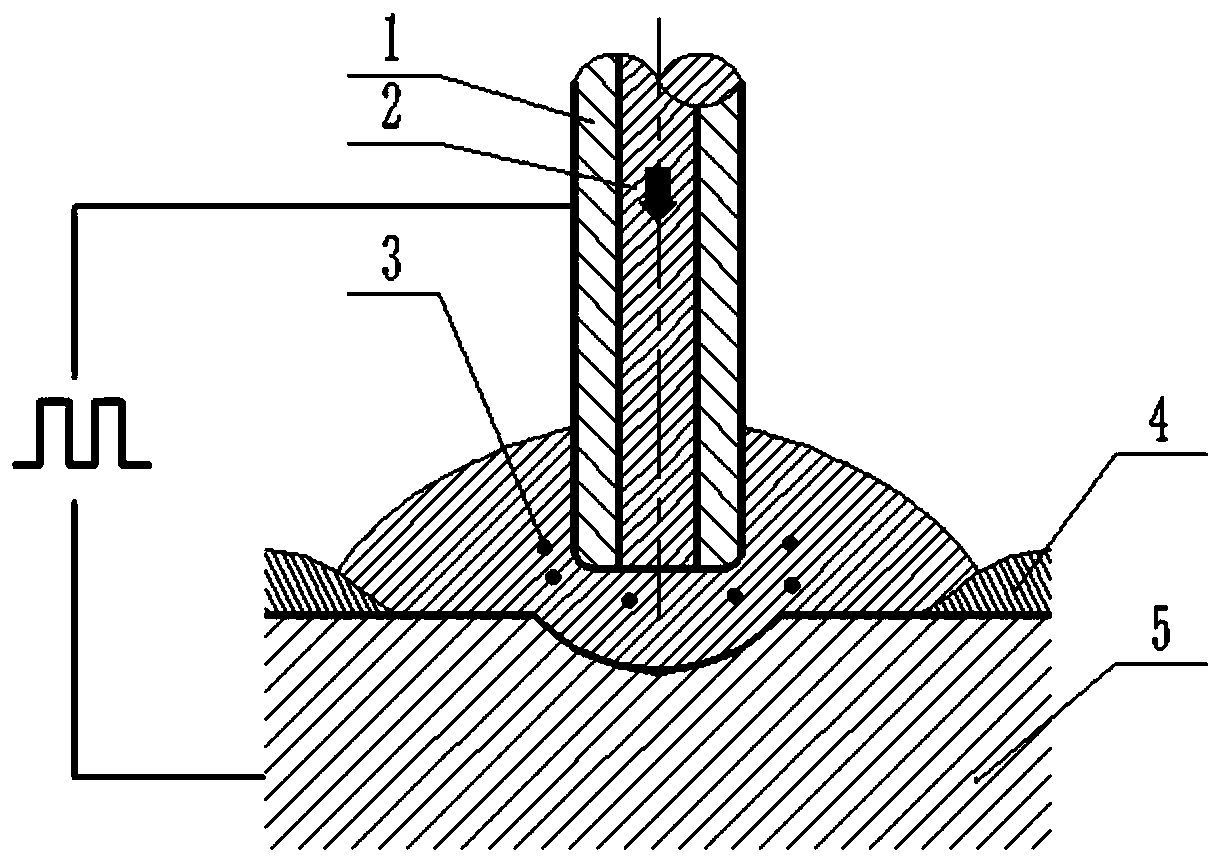

[0018] figure 1 Shows ice conditions at the beginning of processing. Because the electrolyte has a certain temperature, the ice layer is only formed in the far range from the processing area at the beginning, and the processing area is still normal electrolytic processing.

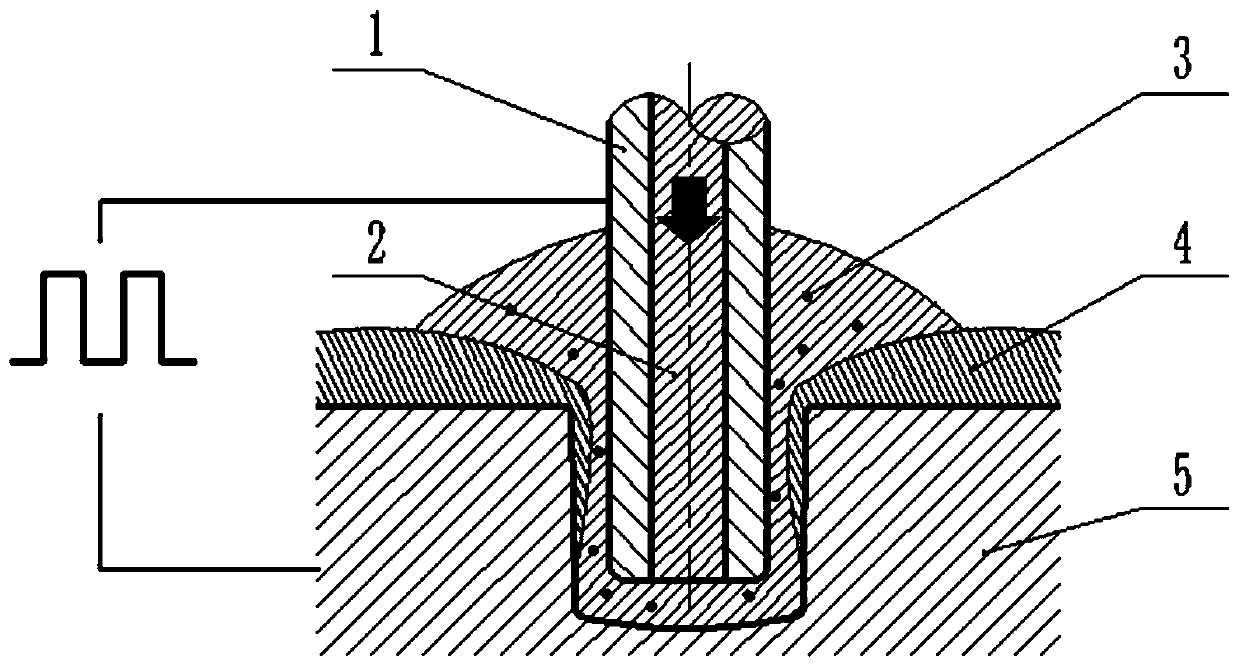

[0019] figure 2 Shows the condition of the ice layer after processing for a period of time. As the processing progresses, the small hole becomes deeper and deeper, and the flow of the working fluid backflow along the hole wall becomes longer and longer. The working fluid gradually cools, and the ice layer continues to expand from the outside to the inside, and finally covers the hole on the processed surface. wall, so that the stray corrosion around the hole wall is reduced. At the same time, since the upper surface of the hole is also covered with ice, the stray corrosion of the hole will also be suppressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com