Intelligent temperature adjusting equipment in wine brewing fermentation process

A technology for fermentation process and equipment adjustment, which is applied in wine preparation, alcohol beverage preparation, biochemical equipment and methods, etc. It can solve the problems of inconsistent temperature of brewing container, difficulty in controlling the temperature of brewing container, and slow effect, so as to avoid Time-consuming and labor-intensive, the effect of improving mobility and speeding up temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

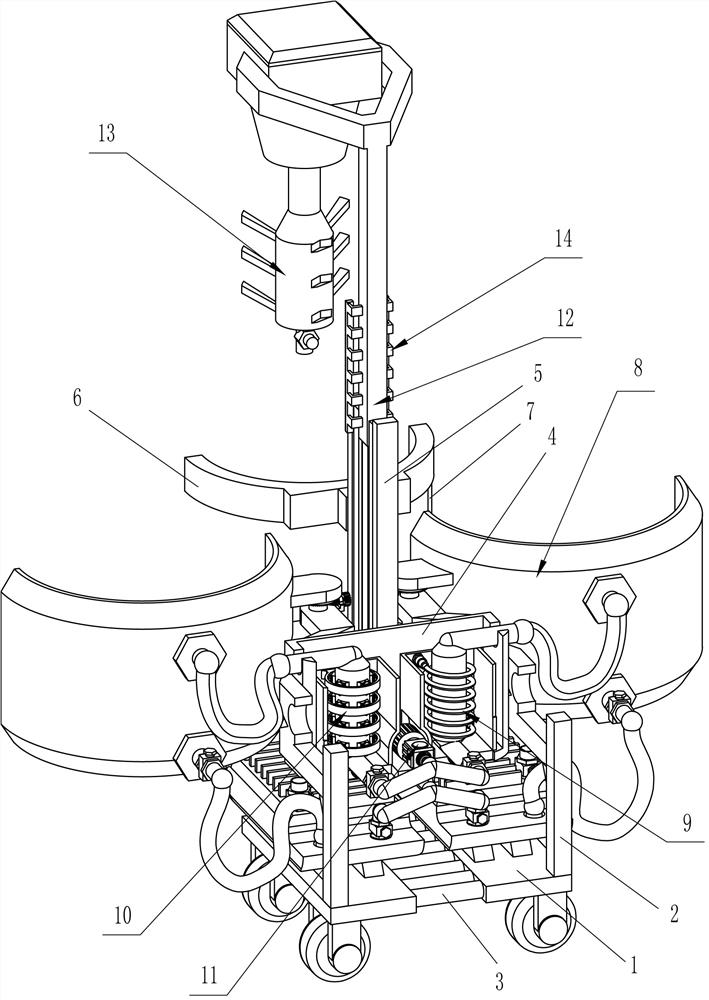

[0038] A temperature intelligent adjustment device for wine brewing and fermentation process, such as Figure 1-5As shown, it includes a vehicle frame 1, a vertical frame 2, a control box 3, a mounting plate 4, a support frame 5, an arc frame 6, a contact switch 61, a water level probe 7, an enclosure device 8, a heating device 9, and a refrigeration device 10 , liquid supply device 11 and detection device 12, specifically:

[0039] A vertical frame 2 is provided in front of the upper side of the vehicle frame 1, a control box 3 is provided on the lower side wall of the vehicle frame 1, and a mounting plate 4 is provided on the rear side of the vertical frame 2. The mounting plate 4 is a structure with two compartments, and the vehicle frame 1 There is a supporting frame 5 on the rear side, an arc-shaped frame 6 is arranged in the middle part of the rear side of the supporting frame 5, a contact switch 61 is arranged in the middle part of the rear side of the arc-shaped frame ...

Embodiment 2

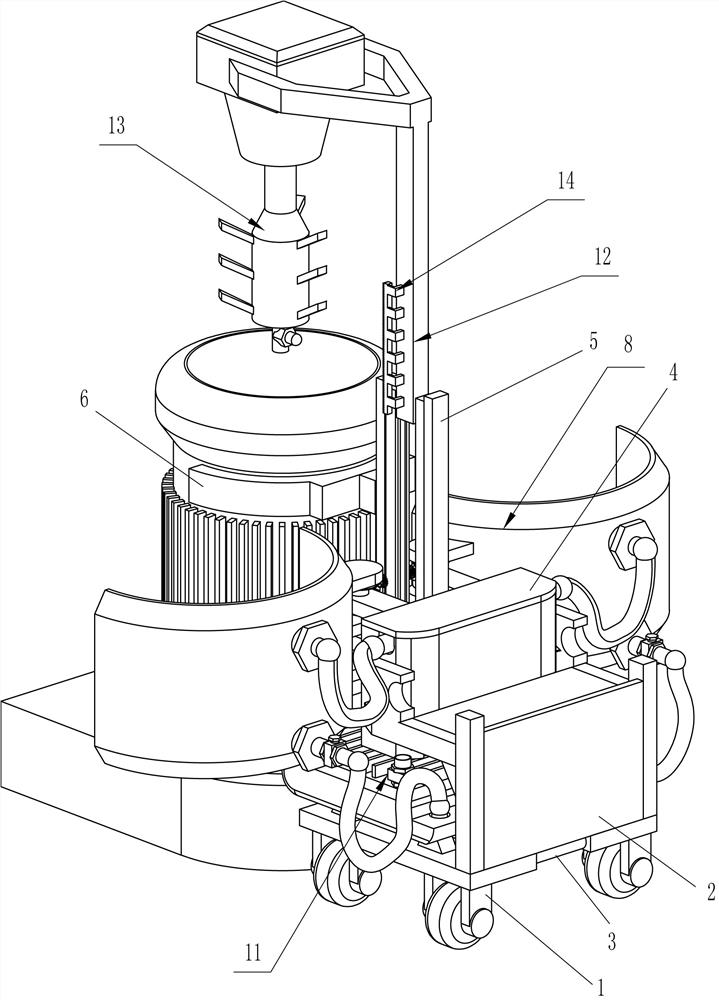

[0042] A temperature intelligent adjustment device for wine brewing and fermentation process, such as Figure 6-16 As shown, the surrounding device 8 includes a fixed seat 81, a surrounding frame 82, a seal 83, a water inlet pipe 84, a cooling solenoid valve 85 and a heat discharging solenoid valve 86, specifically:

[0043] Both sides of the rear side of the mounting plate 4 are provided with fixed seats 81, and the fixed seats 81 are rotatably connected with a surrounding frame 82, and the lower part of the rear side of the surrounding frame 82 is provided with a seal 83, and the upper side of the surrounding frame 82 is provided with a water inlet pipe. 84, the left side water inlet pipe 84 is connected with the refrigeration device 10, the right side water inlet pipe 84 is connected with the heating device 9, and the cooling solenoid valve 85 is arranged under the left surrounding frame 82, and the cooling solenoid valve 85 is connected with the liquid supply device 11 for ...

Embodiment 3

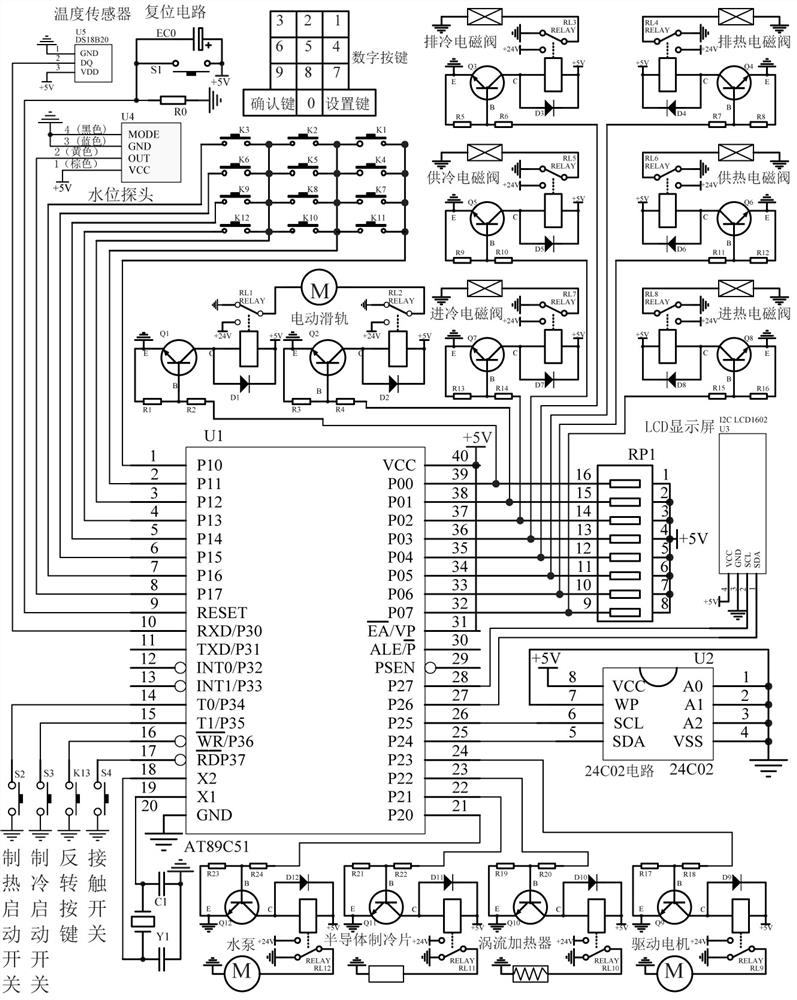

[0064] A temperature intelligent adjustment device for wine brewing and fermentation process, such as Figure 17-18 As shown, the control box 3 includes a switching power supply, a DC-DC power supply module and a microcontroller MCU. The switching power supply supplies power to the temperature intelligent adjustment equipment. It is electrically connected with the DC-DC power supply module. The control box 3 is equipped with a number button, a reverse button, a cooling start switch and a heating start switch, and a number button, a reverse button, a cooling start switch and a heating start switch Both are electrically connected to the microcontroller MCU, the contact switch 61 and the water level probe 7 are electrically connected to the microcontroller MCU, the temperature sensor 123 is electrically connected to the microcontroller MCU, and the microcontroller MCU is connected to There are 24C02 circuits, electric slide rail 121, cooling solenoid valve 85, heat discharging so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com