Fluid heat transferring device

A fluid and heat source technology, applied in the direction of indirect heat exchangers, pipeline heating/cooling, lighting and heating equipment, etc., can solve problems such as unseen solutions or solutions, limited natural gas reserves, unfavorable energy saving and emission reduction, etc., to achieve Facilitate safety management, save resources, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention is illustrated by examples below, but the protection scope of the present invention is not limited thereto.

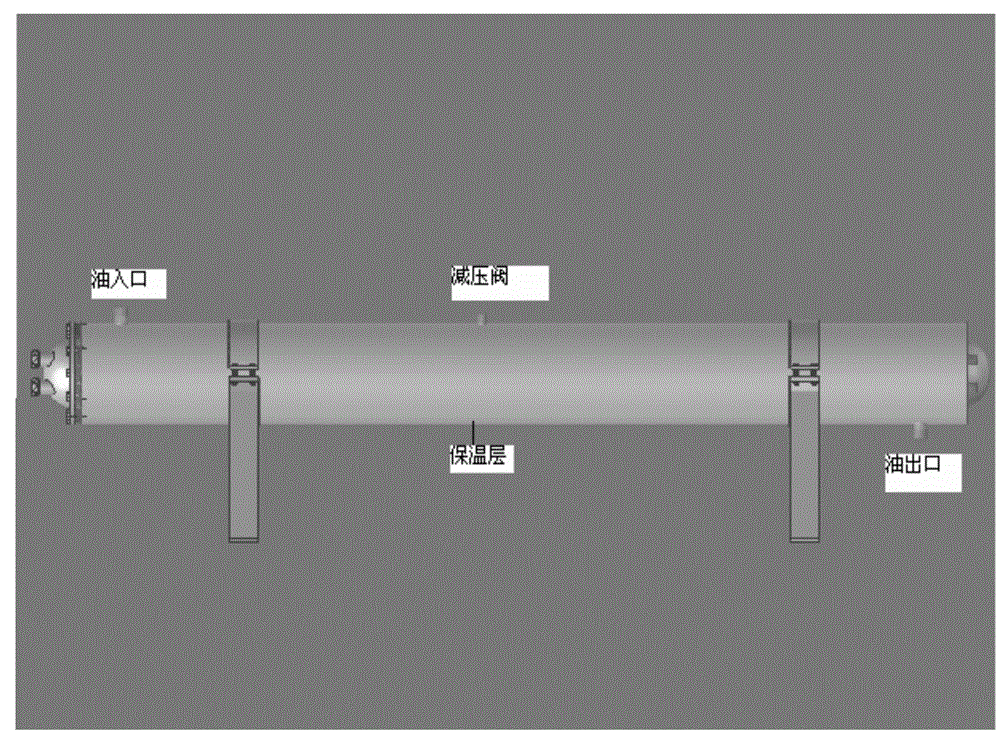

[0070] In some embodiments of the present invention, the pipeline that can be uniformly heated inside includes a cavity (3), the cavity wall (4) of the pipeline is pasted with an insulating layer (5), and the cavity (3) of the pipeline is ) is equipped with a pipeline fluid heat transfer device. Inlets and outlets (6) are opened on the cavity wall (4) of the pipeline and on the insulation layer (5) at the corresponding position for fluid substances to flow in and out. The long 3 meters of described pipeline of single joint, internal diameter 200 millimeters, external diameter 215 millimeters, insulation layer (5) thick 50 millimeters. According to actual needs, a single-section pipeline or a combination of multi-section pipelines can be used for transportation. The thermal insulation layer (5) can be thermal insulation materials such as r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com