Coal underground gasification method

An underground gasification and coal technology, applied in coal gasification, underground mining, construction, etc., can solve the problem of not taking into account the minimization of thermal energy loss, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

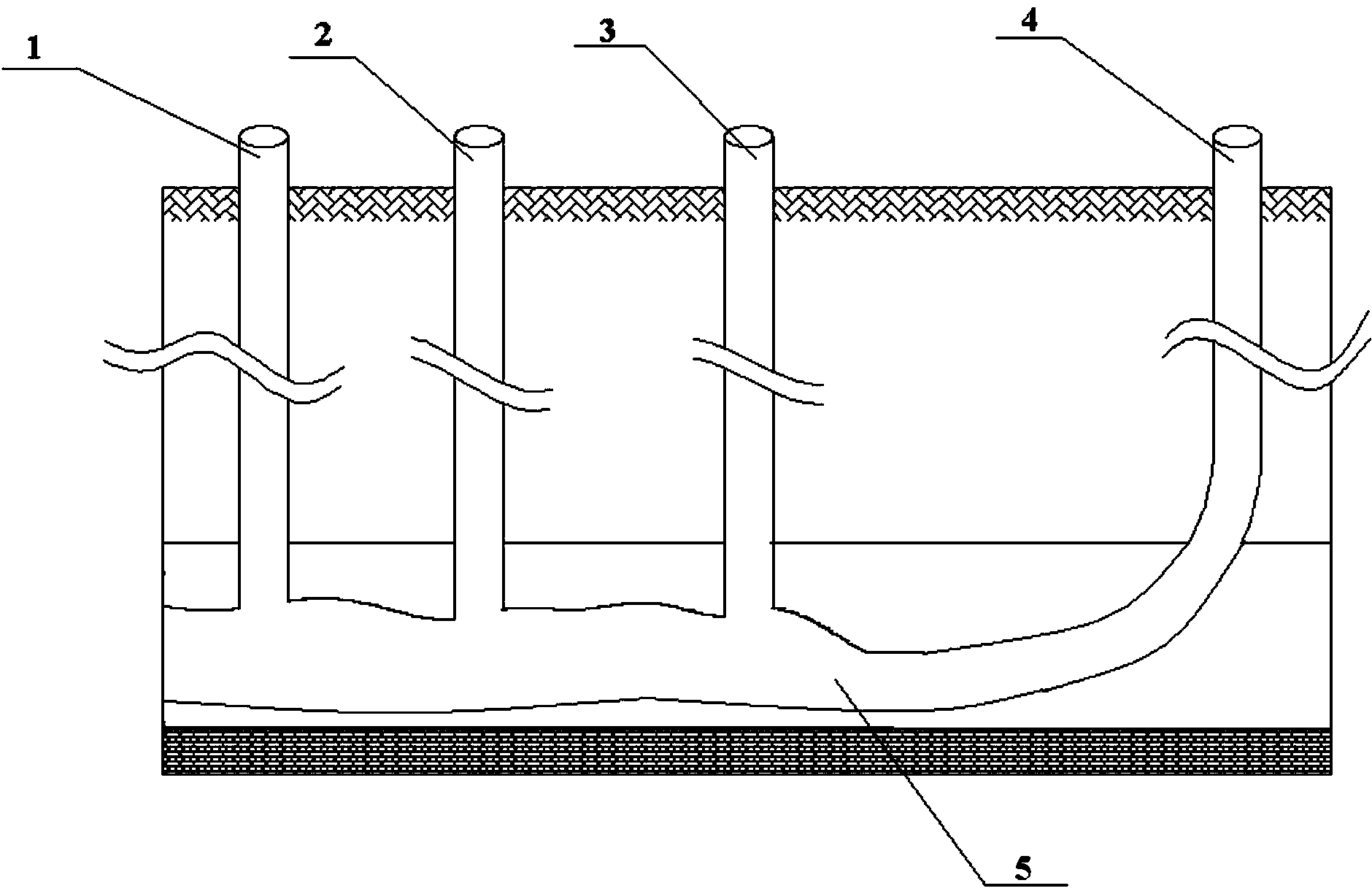

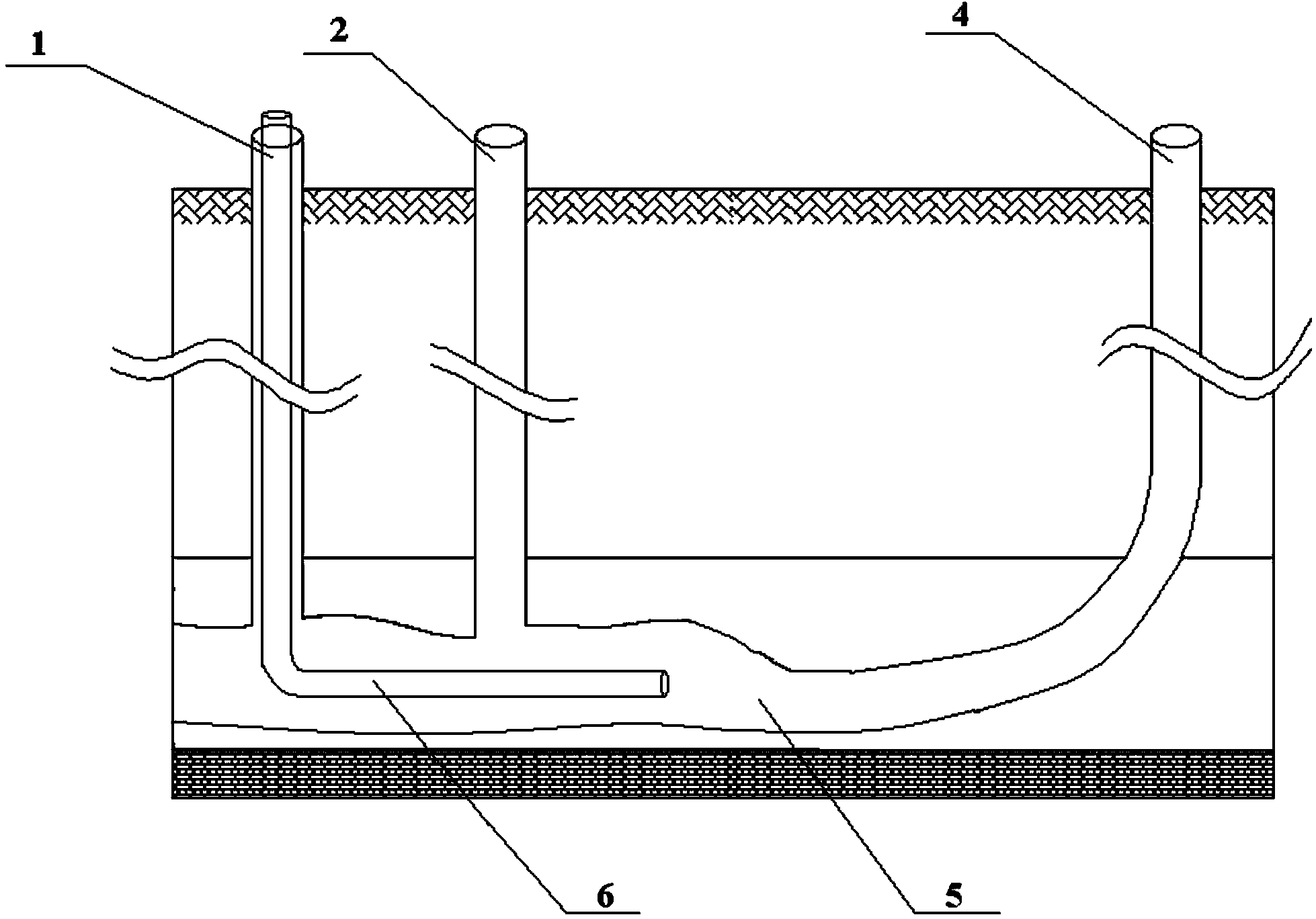

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0026] refer to figure 1 , the underground coal gasification method of the present invention comprises the following steps in sequence:

[0027] (1) Establish an inlet channel, an outlet channel, and a gasification channel connecting the inlet channel and the outlet channel; (2) inject a gasification agent through the inlet channel, wherein the gasification agent includes water vapor and oxygen-enriched gas, water The initial volume ratio of steam and oxygen-enriched gas is in the range of 0.5:1 to 4:1; (3) ignite the coal seam; (4) adjust the ratio of water vapor and oxygen-enriched gas according to the characteristics of the produced gas to form a new volume ratio. Among them, the initial volume ratio is the volume ratio of water vapor and oxygen-enriched gas in the gasification agent injected before the coal seam is ignited, in other words, the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com