Glue feeding device with stirring function for LED lamp production

A technology of LED light and glue feeding, which is applied to mixers with rotating mixing devices, mixer accessories, and dissolving directions, can solve the problems of different glue quality, poor glue mixing effect, affecting the production quality of glue feeding devices, etc. The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

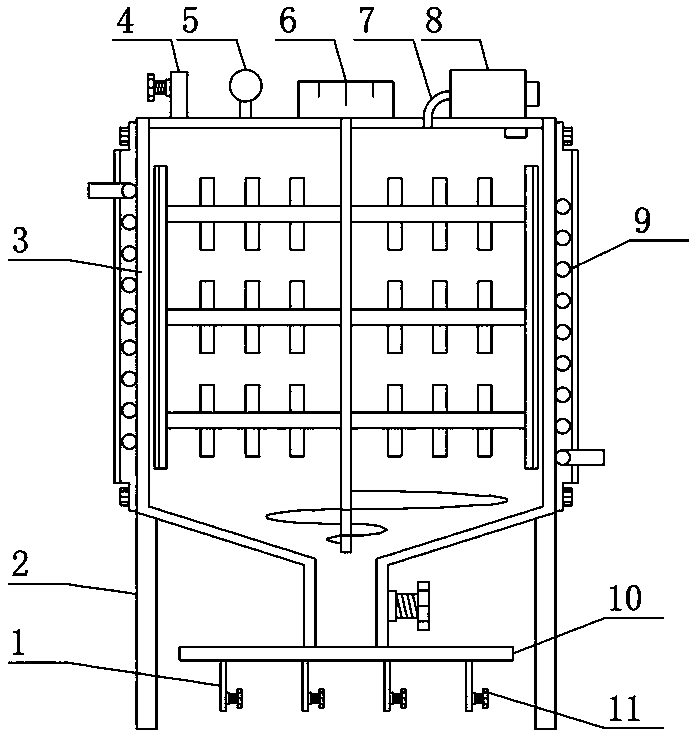

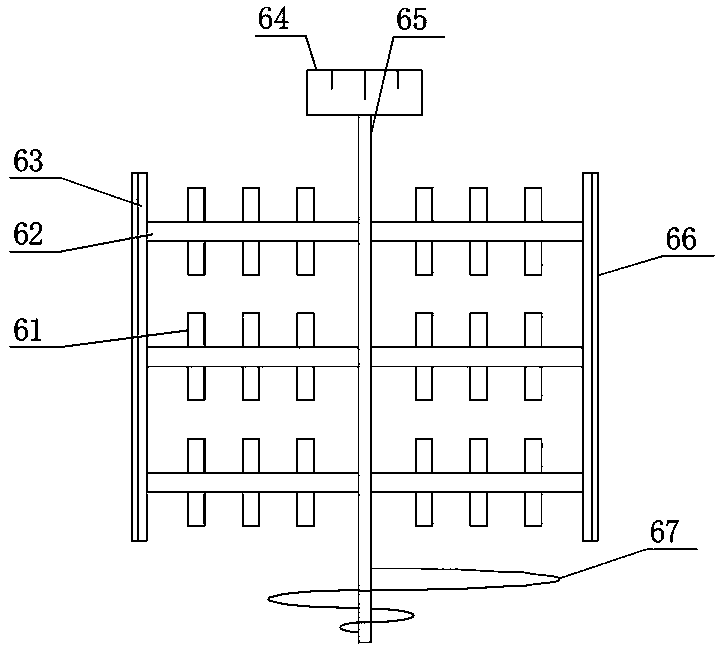

[0022] see Figure 1-Figure 4 , the present invention provides a kind of: a kind of glue feeding device for LED lamp production with stirring function, comprising a storage tank 3, a pressure gauge 5 is arranged on one end of the upper surface of the storage tank 3, and a rubber inlet pipe 4 is arranged on one side of the pressure gauge 5 The other end of the upper surface of the storage tank 3 is provided with an air pump 8, the connection between the storage tank 3 and the air pump 8 is provided with a first connecting pipe 7, and the dispensing device is also provided with a pressure sensor and a controller corresponding to the air pump 8, The use of pressure sensor, controller and air pump 8 is all prior art, and the bottom end of storage tank 3 is provided with main glue supply pipeline 10, and the lower surface of main glue supply pipeline 10 is provided with branch pipeline 1, and on branch pipeline 1 One end away from the main glue supply pipeline 10 is provided with a...

Embodiment 2

[0026] see Figure 1-Figure 4 , on the basis of Embodiment 1, in order to make the function of the glue feeding device more abundant, in this embodiment, preferably, the top of the storage tank 3 is provided with a temperature adjustment mechanism 9, and the temperature adjustment mechanism 9 includes a heat conduction base 91, and the heat conduction base 91 is provided with a heat pipe 92 at the junction of the storage tank 3, the top of the heat pipe 92 is provided with a water outlet pipe 93, and the bottom end of the heat pipe 92 is provided with a water inlet pipe 96, when the user needs to increase the temperature of the glue in the storage tank 3 , inject water with a temperature higher than the temperature of the glue from the water inlet pipe 96. At this time, the water heats the heat-conducting base 91 through the heat-conducting pipe 92, thereby heating the storage tank 3 through the heat-conducting base 91, thereby increasing the temperature of the glue in the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com