Concave edging machining hard alloy chopper convenient to replace

A technology that is easy to replace and hard alloy, used in the field of concave rolling processing carbide rivets, can solve the problems of affecting the efficiency of tool replacement, cumbersome replacement, time-consuming and laborious tool searching, etc., and achieve fast and accurate adjustment of the installation height. , Improve the processing efficiency, the effect of convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

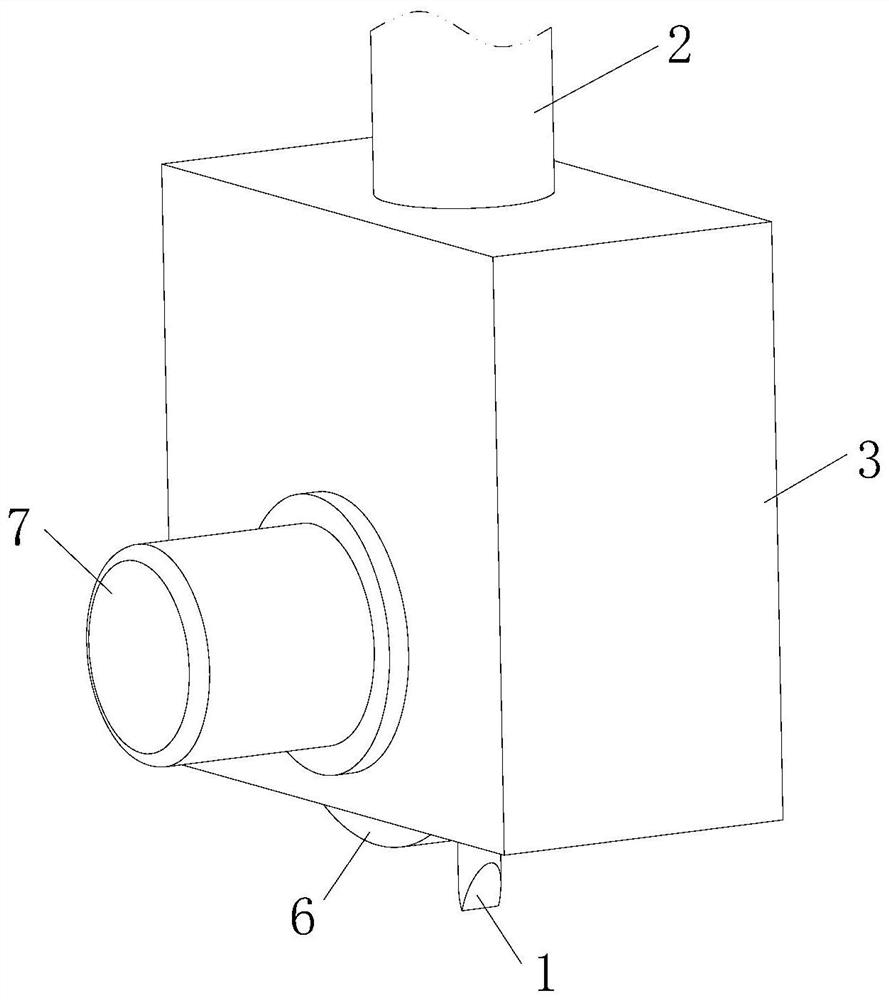

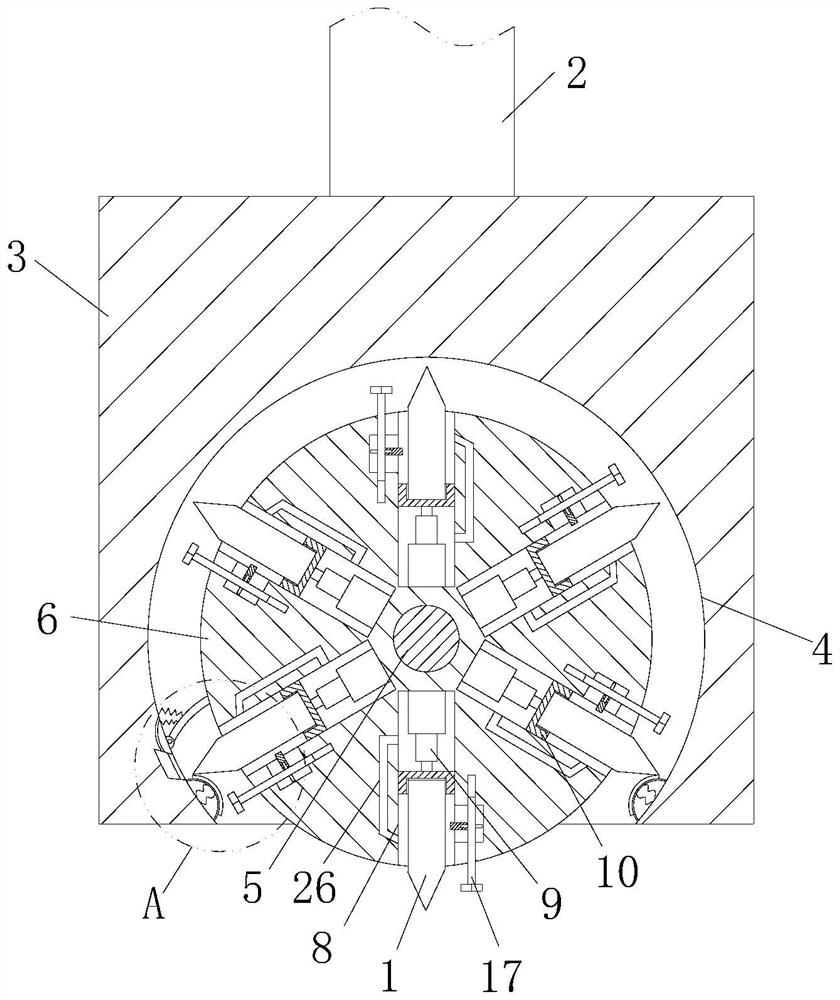

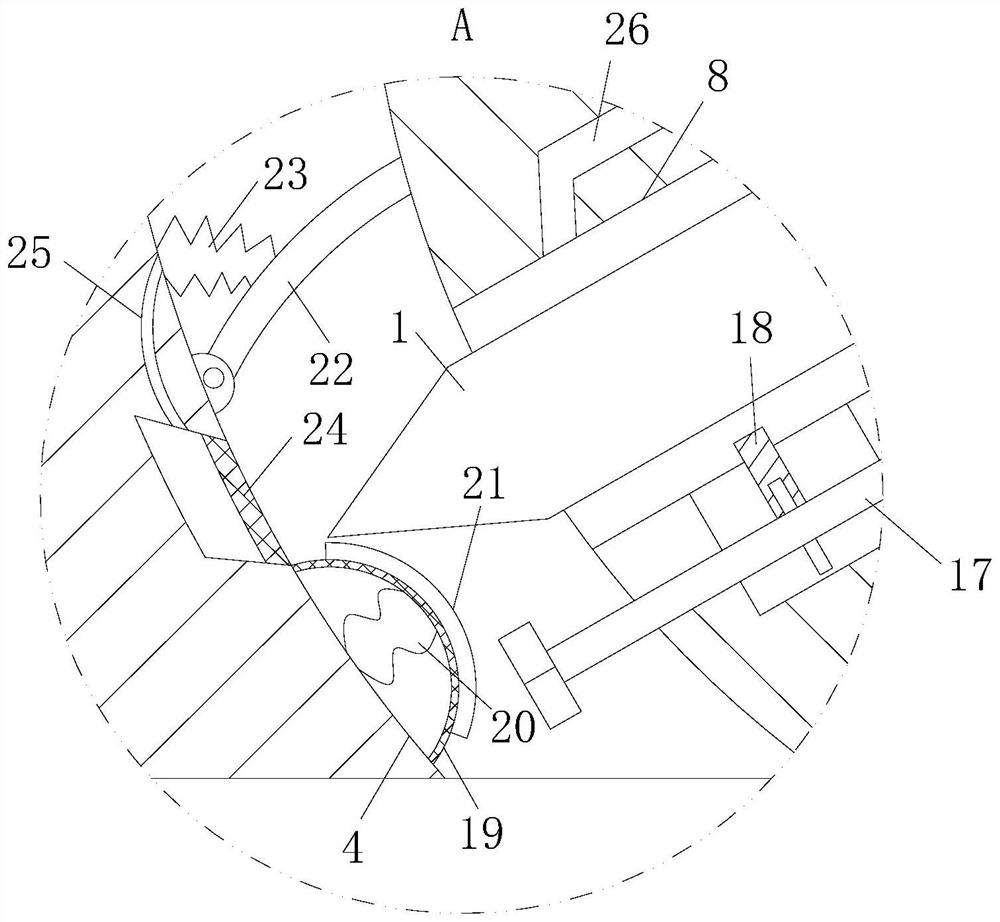

[0033] see Figure 1-Figure 2 As shown, a conveniently replaceable concave-shaped milling carbide riving knife described in the embodiment of the present invention includes a body 1; it also includes a working column 2 on the machine tool, and the bottom end of the working column 2 is connected with a switch block 3, an arc-shaped switching cavity 4 is provided on the bottom surface of the switching block 3, and a cylindrical rotating column 6 is connected to the inside of the switching cavity 4 through a rotating rod 5, and the side wall of the switching block 3 is installed with A motor 7 connected to one end of the rotating rod 5, the other end of the rotating rod 5 is provided with a fixed assembly capable of positioning it, and a set of storage chambers 8 are provided on the side wall of the rotating rod 6, and the storage chamber 8 A No. 1 push rod 9 is installed inside the No. 1 push rod 9, and the end of the No. 1 push rod 9 is connected with a slide plate 10, and the ...

Embodiment 2

[0040] Such as Figure 6-Figure 7 As shown in Comparative Example 1, another embodiment of the present invention is: the inside of the storage cavity 8 is connected with a ring-shaped slip ring 27 through a bracket, and the slip ring 27 is slidably connected with a slider 28, so The inside of the slider 28 is provided with an airflow channel 29, and a hose 30 is connected between one end of the airflow channel 29 and the end of the cleaning groove 26 at the outer end of the storage chamber 8, and the slider 28 is installed on one side facing the body 1. There is No. 1 nozzle 31 communicated with the air passage 29, and No. 2 nozzle 32 is installed on the side wall of the slide block 28 away from the support. The side wall of the cleaning tank 26 is tangent to the side wall; the gas extruded from the cleaning tank 26 can be sprayed from the two nozzles through the hose 30, so that the airflow tangential to the slip ring 27 sprayed from the second nozzle 32 can drive the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com