Welding machine laser beam optical mode detection system and method

A detection system and laser beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as wasting time and affecting production, and achieve the effect of improving efficiency, improving production efficiency, and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

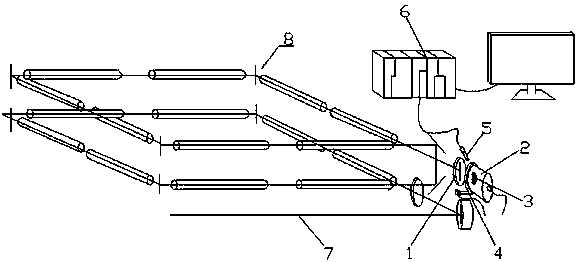

[0023] like figure 1 As shown, a welding machine laser beam optical mode detection system includes a laser power measuring head 2 arranged on the back of the laser output back mirror 1 of the laser output unit, and the photosensitive surface of the laser power measuring head 2 is coated with a layer of photosensitive A developing coating 3, an ultraviolet projection lamp 4 and a camera 5 are arranged near the laser power measuring head 2, the irradiation direction of the ultraviolet projection lamp 4 points to the photosensitive surface, and the shooting direction of the camera 5 points to the photosensitive surface, and the camera 5 passes data The picture on the photosensitive surface is transmitted to the external device through the line;

[0024] When testing the quality of the online optical mode, first start the laser output unit, at this time the laser output back mirror 1 in the laser output unit 8 will reflect 99.97% of the laser rays, and the remaining 0.03% of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com