Method for calculating chamfering of tooth tip of spiral bevel gear based on discretization of curved surface

A discretization technology for spiral bevel gears, which is applied in the field of calculation and processing of spiral bevel gear tooth top chamfering, which can solve the problems of low production efficiency and machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

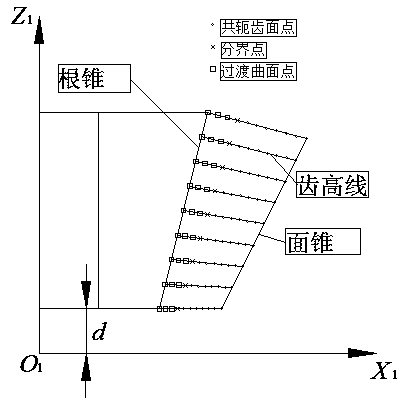

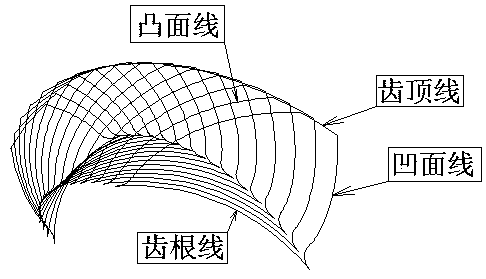

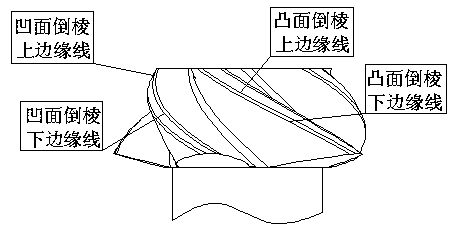

[0085] The chamfer calculation method first creates a gear solid model according to the tooth surface mathematical model, and then creates the tooth tip chamfer feature on the gear solid model. Extract the discrete point coordinates of the upper and lower edge lines of the tooth top chamfer, take the distance between the ball center of the ball end mill and the chamfer edge line as the constraint condition, and use the numerical algorithm to solve the chamfer ball end mill path . According to the relationship between the axis direction of the ball end mill and the contact position of the surface of the ball end mill, the direction angle of the cutter axis can be changed uniformly within the feasible range, so that the contact position between the ball end mill and the tooth top can be evenly distributed on the ball end end mill surface. Install the non-chamfered gear on the four-axis machine tool, complete the axial and circumferential tool setting of the gear through the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com