Corrugated paperboard production equipment and processing technology

A technology of corrugated cardboard and production equipment, which is applied in the direction of mechanical processing/deformation, sending objects, and stacking receiving devices, etc., which can solve the problems of high labor intensity for staff, and achieve the effect of reducing work intensity and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-6 The application is described in further detail.

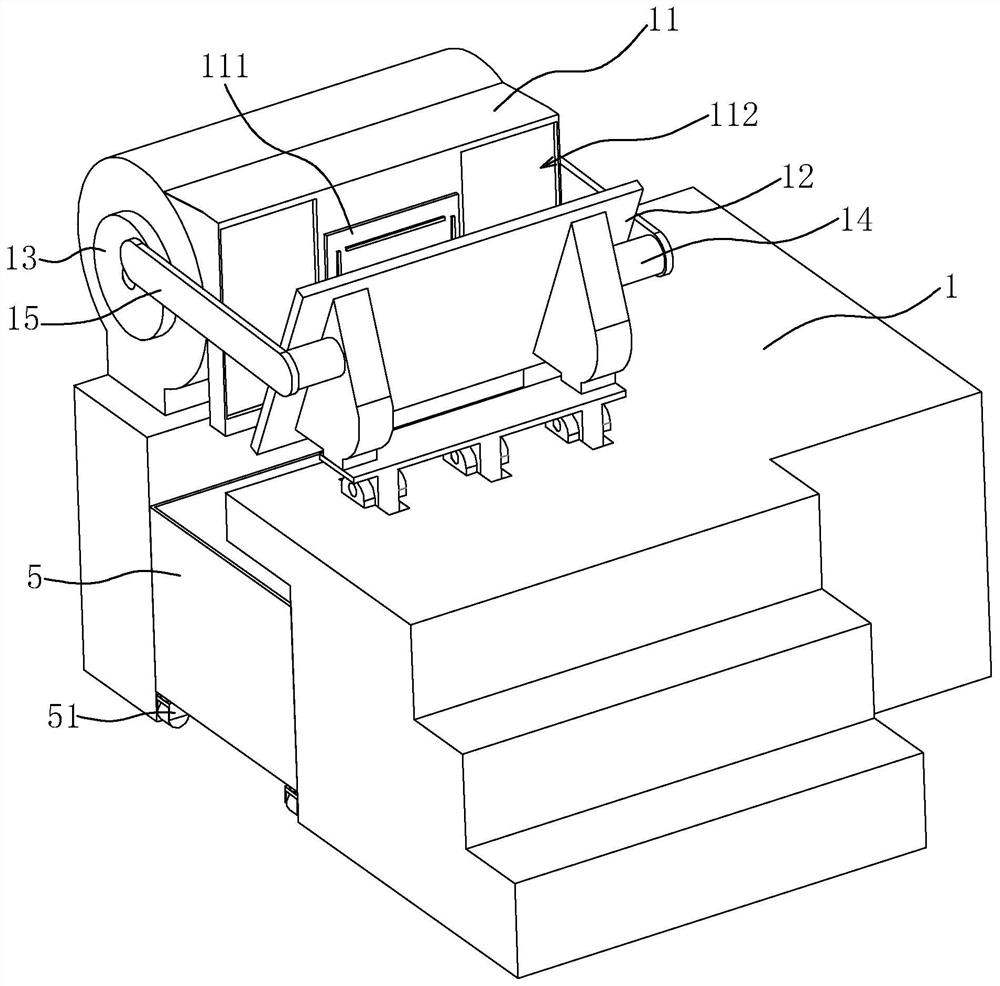

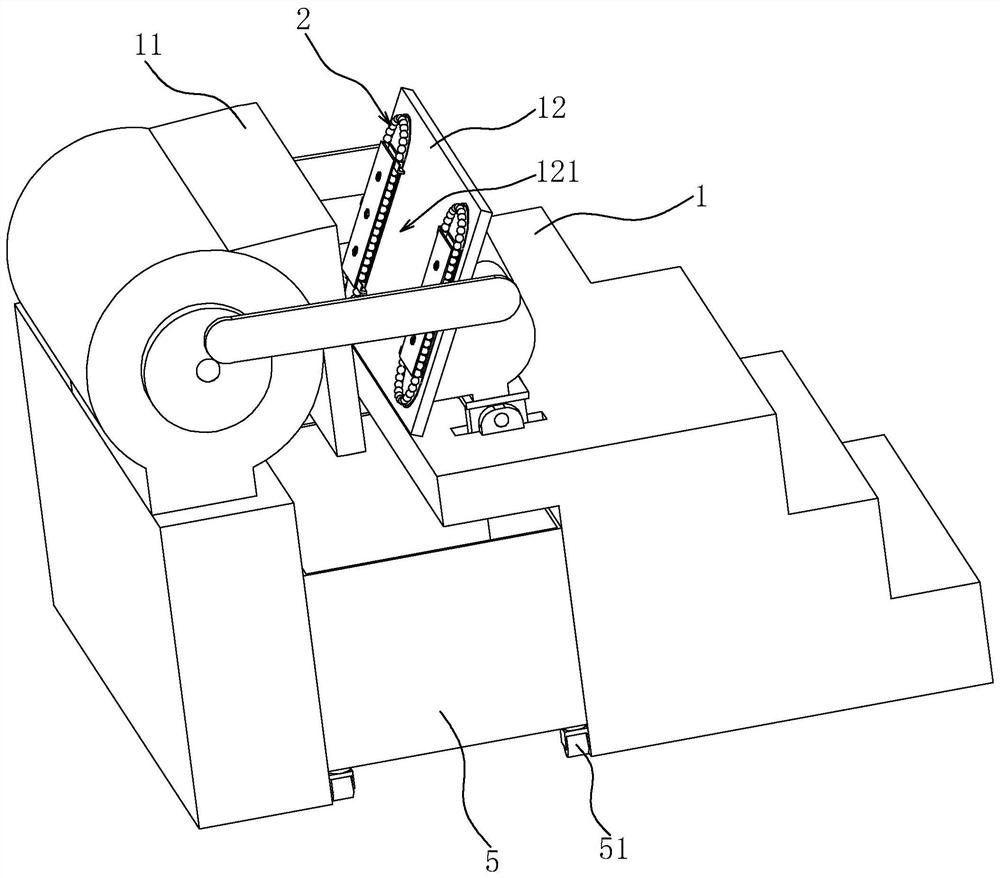

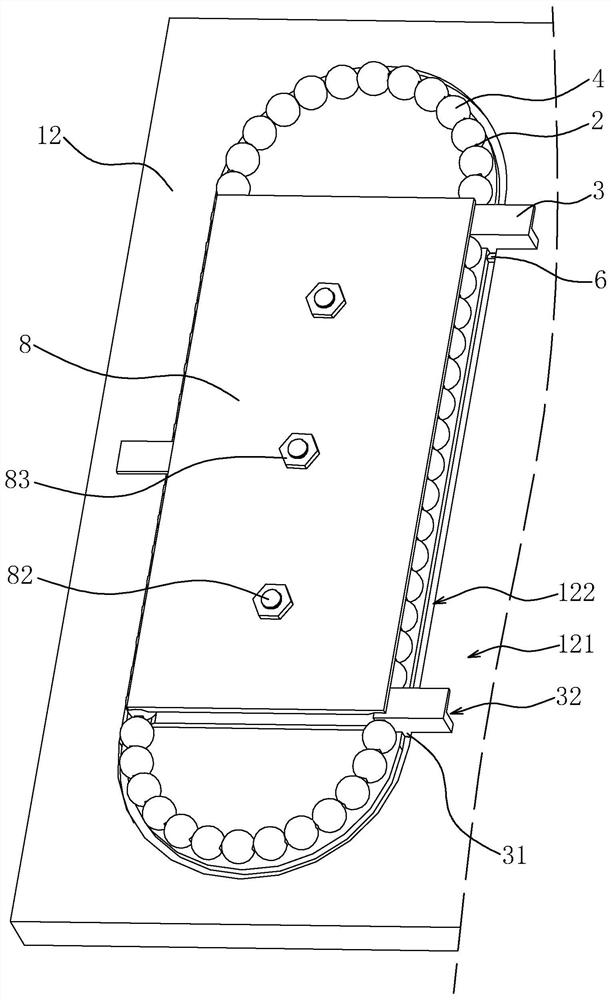

[0042] The embodiment of the present application discloses a corrugated cardboard production equipment. refer to figure 1 The production equipment includes a workbench 1 and a fixed platen 11 and a movable platen 12 installed on the workbench 1, the fixed platen 11 is fixedly installed on the workbench 1, and the bottom of the movable platen 11 is hinged with the workbench 1. Both opposite sides of the fixed platen 11 are rotatably connected with driving wheels 13, the driving wheels 13 are driven by servo motors, and the movable platen 12 is symmetrically provided with two bearing seats 14, between each driving wheel 13 and the corresponding bearing seats 14 Transmission rods 15 are provided, and one end of each transmission rod 15 is hinged on the corresponding driving wheel 13 using a pin shaft. Hinged on the corresponding bearing seat 14. When the driving wheel 13 rotates, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com