Bidirectional locking mechanism of axle and highway-railway transport vehicle

A technology for locking mechanisms and transport vehicles, applied in the directions of axles, transportation and packaging, wheels, etc., can solve problems such as the unstable state of highway axles, and achieve the effect of improving the convenience of operation and driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

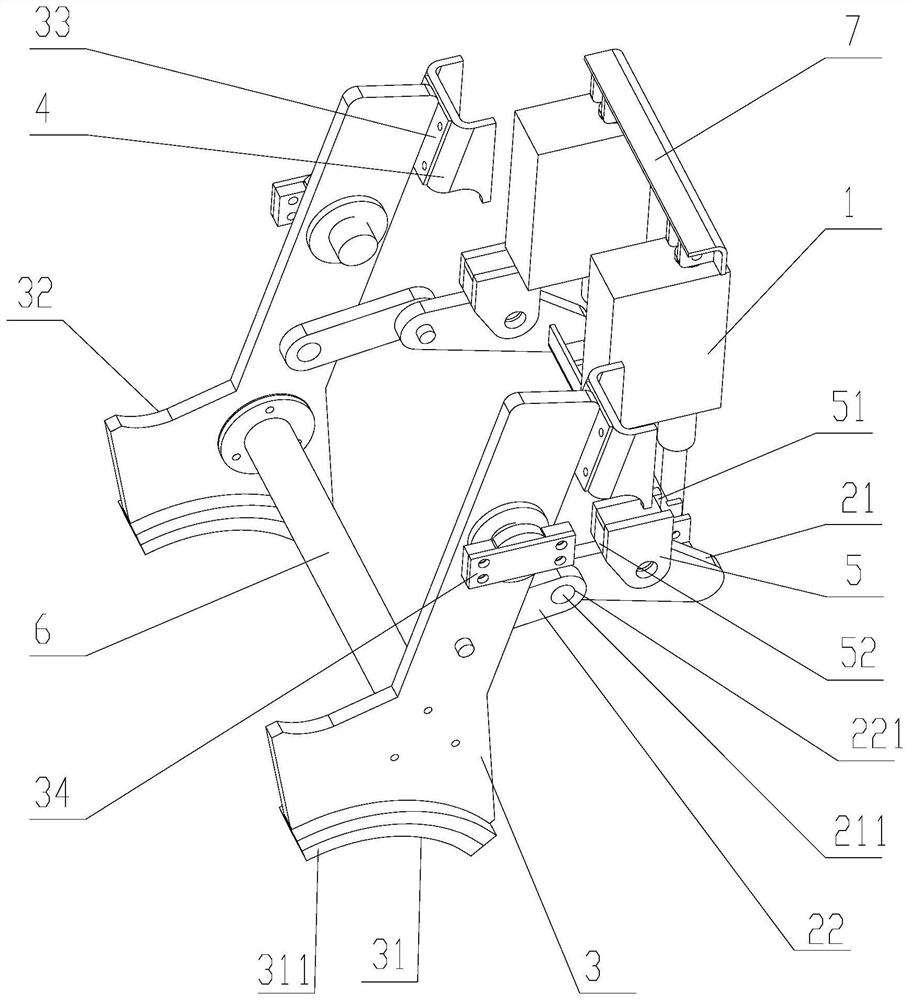

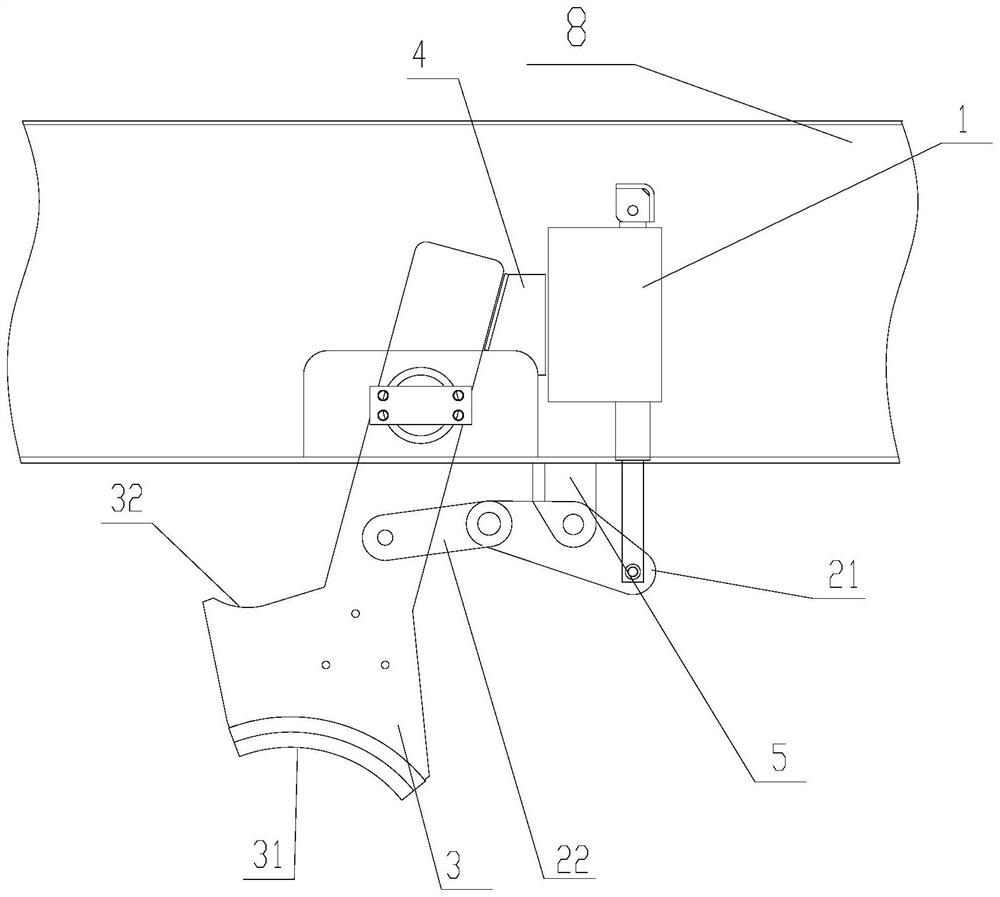

[0033] Such as Figure 1-5 As shown, a two-way locking mechanism for an axle includes a first executing part 1 , a locking part 3 , a stop seat 4 and a support 5 . in:

[0034] The first execution block 21 is hinged on the output end of the first execution part 1, and is used to drive the end of the first execution block 21 to rise and fall. Driven by the first execution part 1, the end of the first execution block 21 Follow up or down.

[0035] The first actuator 1 is a linear drive, which can use an electric push rod, and is an electric drive device that converts the rotational motion of the motor into the linear reciprocating motion of the push rod. It can be used as an executive machine in various simple or complex processes to realize remote control, centralized control or automatic control. It is a new type of linear actuator, which can be considered as an extension of the structure of the rotary motor.

[0036] A second execution block 22 is hinged between the middle...

Embodiment 2

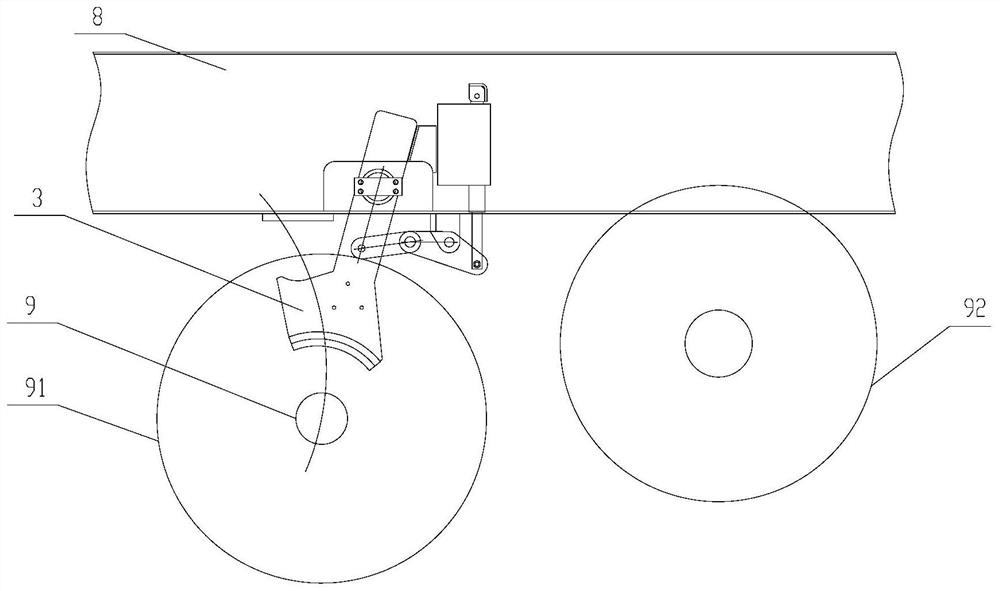

[0056] Such as Figure 1-5 As shown, based on the same inventive concept, the present invention also provides a road-rail transport vehicle, including the two-way locking mechanism of the above-mentioned axle, the vehicle beam 8 and the road axle 9, and the vehicle beam 8 is respectively connected with the locking part 3, the first The execution part 1 is hinged, and the stop seat 4 and the support 5 are respectively fixed on the vehicle beam 8. In addition to the two-way locking mechanism of the above-mentioned axle, the vehicle beam 8 and the road axle 9, the structure of other devices of the transport vehicle, For the connection relationship, installation location, etc., reference may be made to related publications in the prior art, and no further description will be made here.

[0057] Furthermore, when the locking portion 3 and the stopper seat 4 are opposed to each other, a supporting space 10 is formed between the vehicle beam 8 and the supporting position 32 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com