Thimble supporting plate adjustment tool structure and leveling method

A technology for adjusting work and thimbles, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the inability to directly adjust the level of thimble support plates, and achieve the effects of avoiding bumps, stabilizing positions, and improving speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

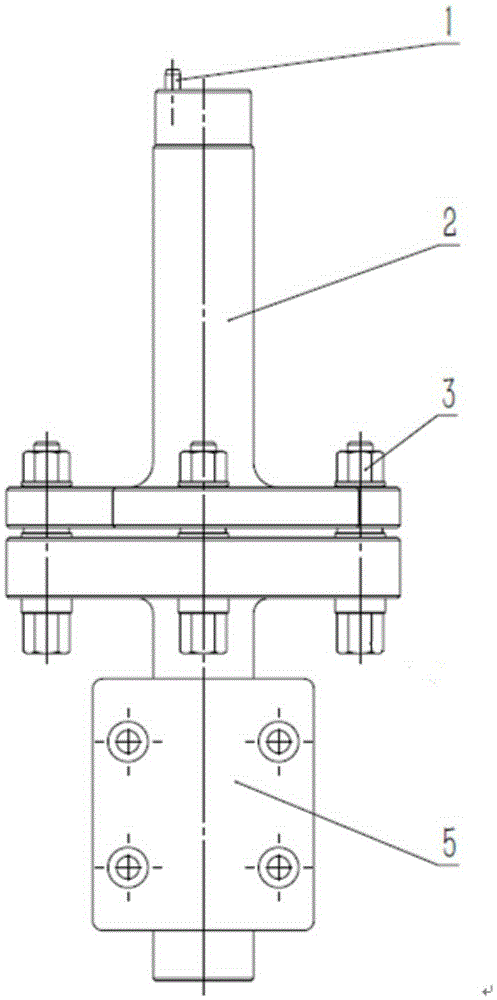

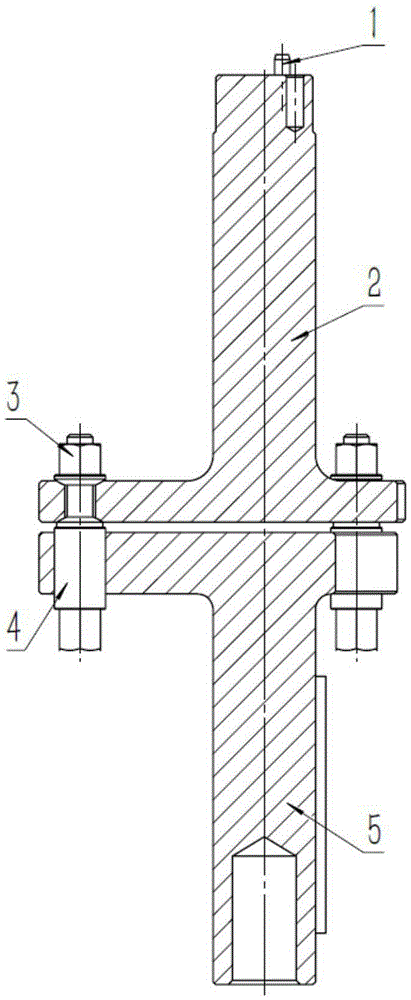

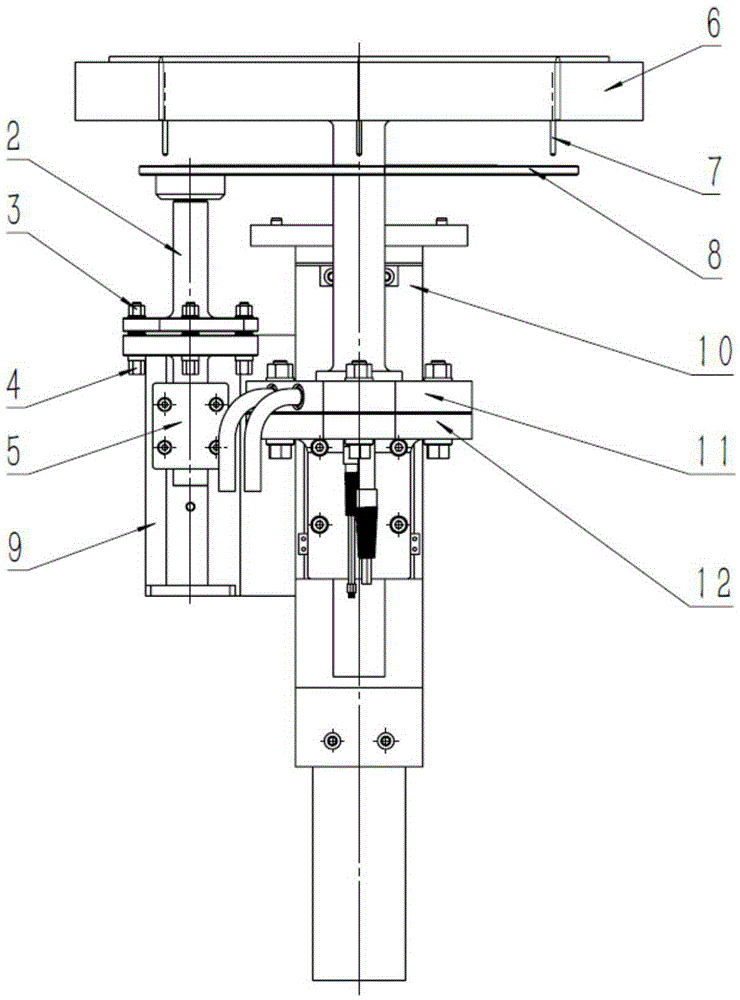

[0017] Reference Figure 1-3 , The thimble support plate adjustment tooling structure, including: positioning pin 1, support rod 2, adjustment nut 3, adjustment bolt 4 and support 5. The support 5 is fixed on the sliding block and drives the thimble support plate adjustment tool to slide on the base 9. The support 5 is provided with three threaded holes uniformly distributed at 120° for adjusting the level of the thimble support plate 8 in cooperation with adjusting bolts. The adjusting bolt 4 adopts fine thread. The rotating bolt 4 adjusts the relative height of the support rod 2 and the support 5, adjusts the level of the upper surface of the thimble support plate 8, and rotates the adjusting bolt 4 once to adjust the height of a pitch. A gasket is installed at the position where the support rod 2 and the support 5 are connected, and an adjustment nut 3 is installed above the gasket. The adjustment nut 3 can ensure that the thimble support plate 8 is always kept horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com