Electronic product chip detection equipment

A technology for chip detection and electronic products, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of not being able to detect chips and keep picking and placing chips, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

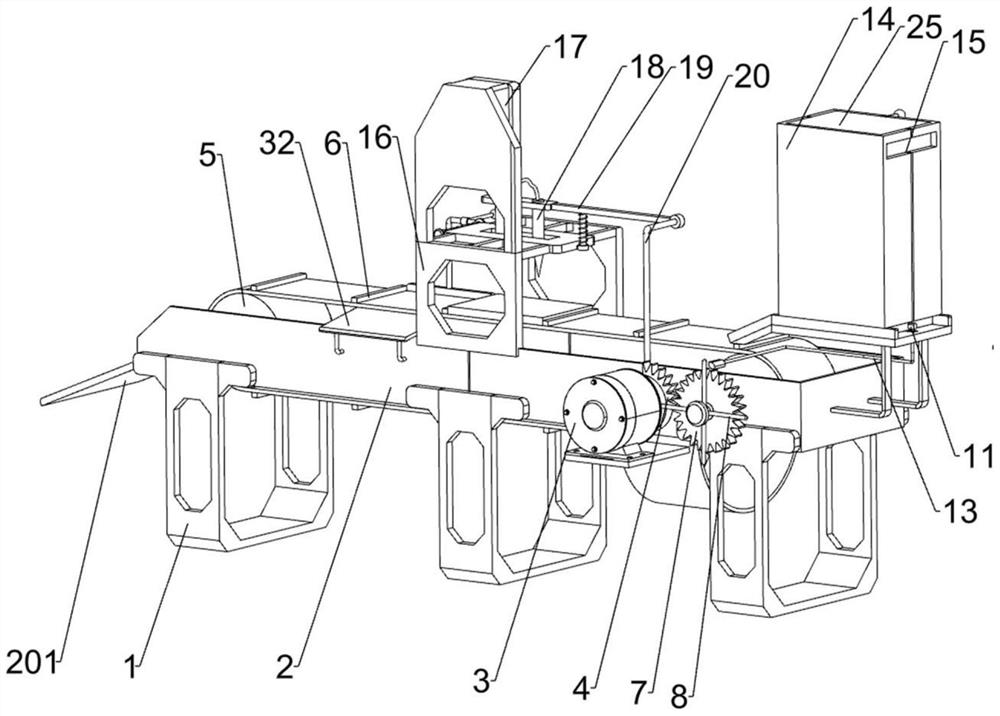

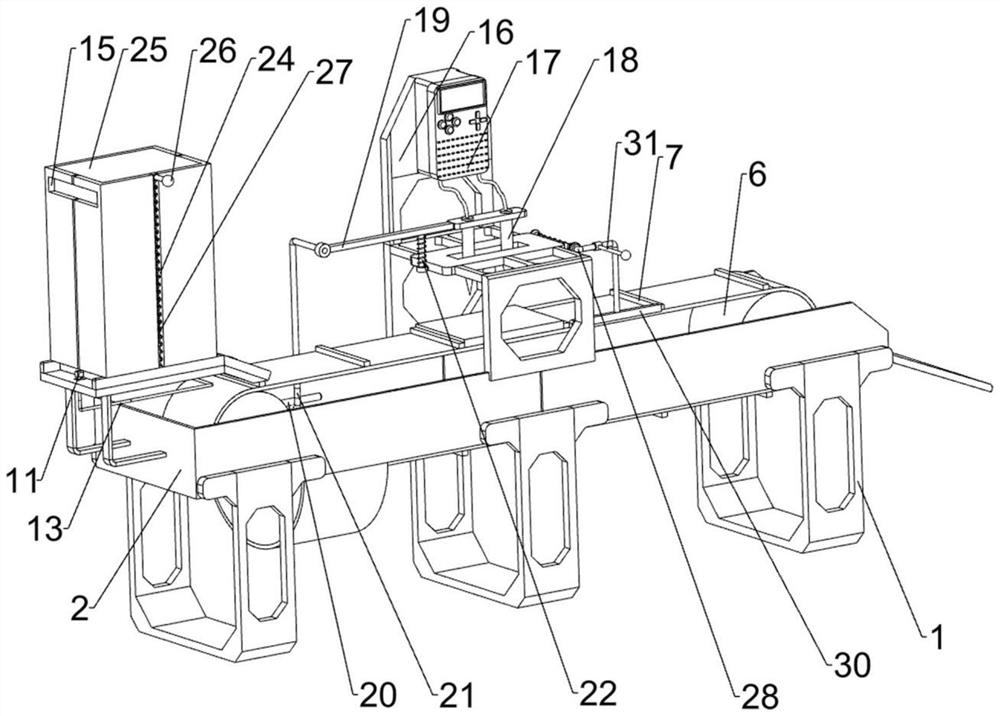

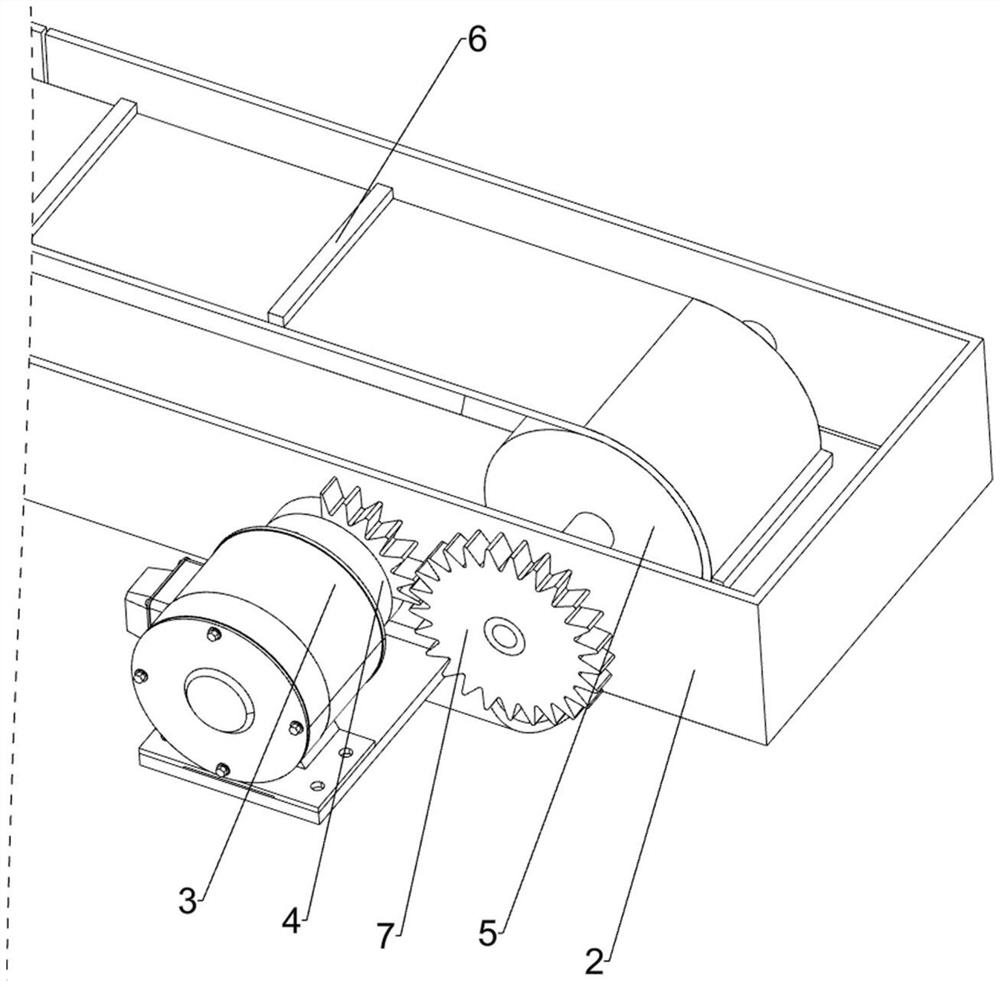

[0023] A chip testing equipment for electronic products, such as Figure 1-Figure 5 As shown, it includes a frame 1, a drive assembly, a blanking assembly and a detection assembly. The frame 1 is used to install the entire device. The top of the frame 1 is provided with a drive assembly that provides power for transmission. The unloading assembly is used for unloading by means of the drive assembly, and the detection assembly for detection by contact is installed in the middle of the drive assembly.

[0024] When it is necessary to perform quality inspection on the chip, the staff will place a certain amount of chips in the blanking assembly, and then start the drive assembly to transfer the chips in the blanking assembly. When the chip is moved to a certain position, the chip stops moving, and at the same time , the testing component performs quality testing on the chip, and after all the chips are tested, the staff can turn off the driving component.

[0025] Such as Figu...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 , figure 2 and Figure 4Shown, also include the first push plate 25, handle 26 and the 3rd spring 27, have the second through hole 24 at the rear portion of the blanking frame 14, the sliding type is provided with the first push plate 25 in the blanking frame 14, the second A handle 26 is welded on the rear side of a push plate 25 , and the handle 26 is slidably connected to the second through hole 24 , and a third spring 27 is connected between the handle 26 and the blanking frame 14 .

[0033] When it is necessary to put chips into the blanking frame 14, pull the handle 26 to slide upwards, and the third spring 27 stretches to drive the first push plate 25 to slide upwards. When a certain amount of chips are put into the blanking frame 14, Unclamp the handle 26, and under the action of the third spring 27, the handle 26 and its upper device are driven to move downwards to push and fix the chips. In this way, chips with po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com