Method for reusing decommissioned lithium ion power battery

A power battery and lithium-ion technology, which is applied in the field of reuse of retired lithium-ion power batteries, can solve the problems of differences in polarization degree, difficulty in selecting self-discharge batteries, large polarization differences, etc., and achieve the effect of improving consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

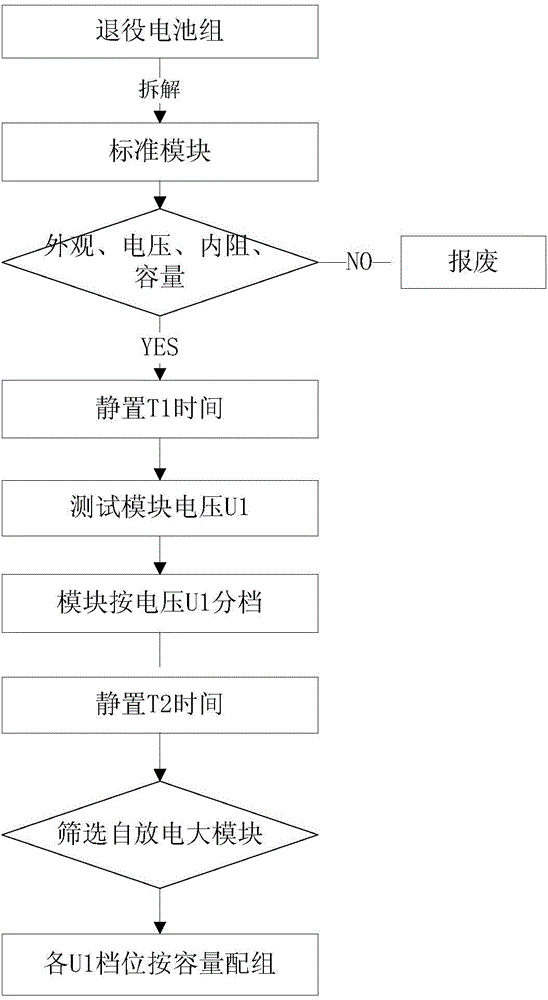

[0019] Such as figure 1 As shown, take the reuse of 10 sets of decommissioned battery packs after use as an example. The specific steps are as follows: (1) Disassemble 10 sets of 168 parallel electric bus decommissioned battery packs into standard modules, a total of 1680 sets of standard modules; (2) Check the appearance, voltage, internal resistance, and capacity of the standard modules, and eliminate unqualified modules. A total of 10 groups of unqualified modules were eliminated; (3) Charge the qualified modules to 100% SOC, and after standing for 12 hours at room temperature, test the module polarization voltage U1; (4) Divide the modules into 5 gears according to U1, U1-1, U1-2, ... U1-5, U1-1: ≥3.35V, 167 pieces, U1-2: >3.338, ≤3.35V, 418 pieces, U1-3: >3.330, ≤3.338, 751 pcs, U1-4: >3.325, ≤3.330, 251 pcs, U1-5: <3.325V, 83 pcs; (5) After the module continues to stand at room temperature for 10 days, test the module voltage U2, and eliminate the module with large self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com