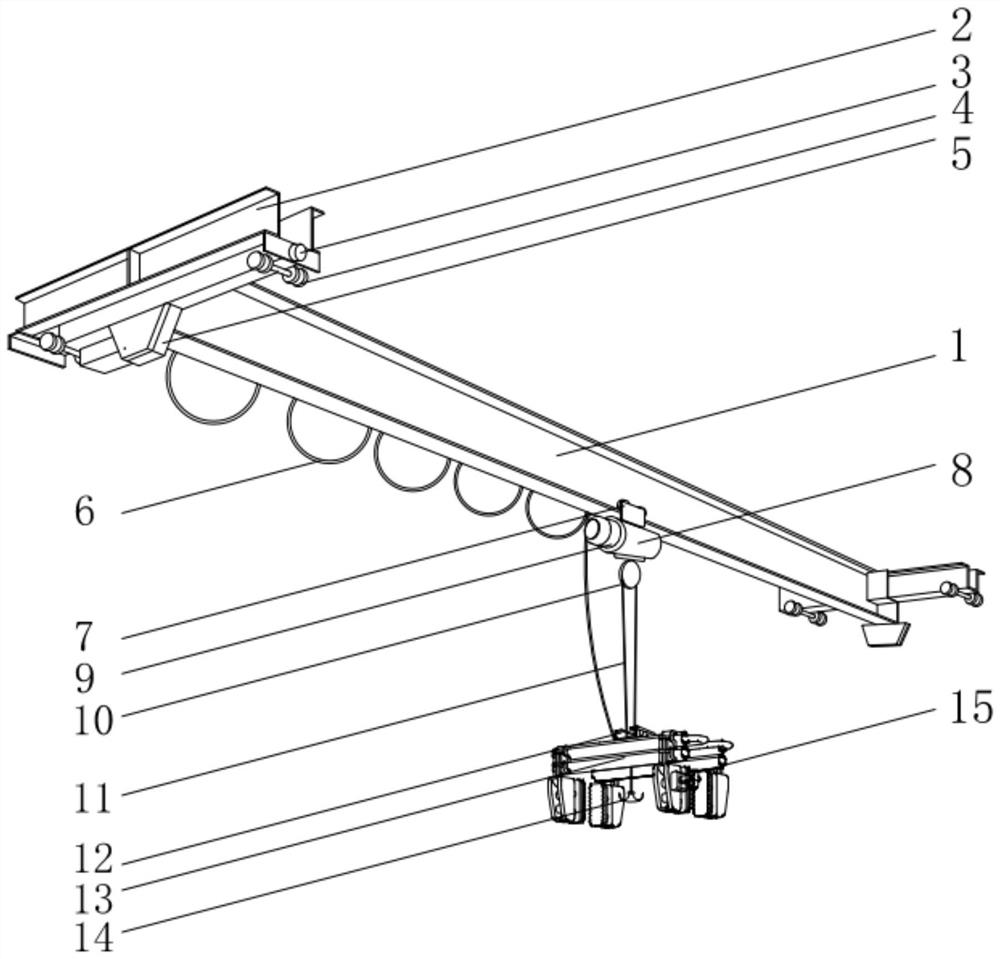

Electric single-beam crane

A crane and single-girder technology, applied in the direction of load block, load suspension components, transportation and packaging, etc., can solve the problems of large-scale equipment damage, violent shaking, large-scale equipment shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

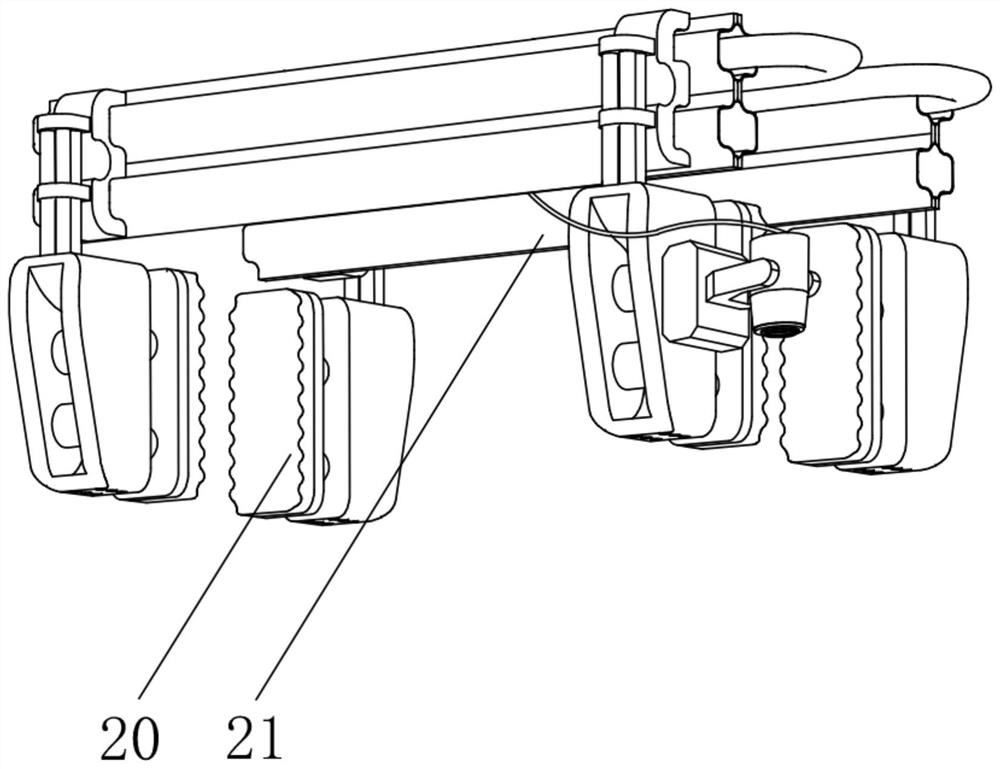

Embodiment approach

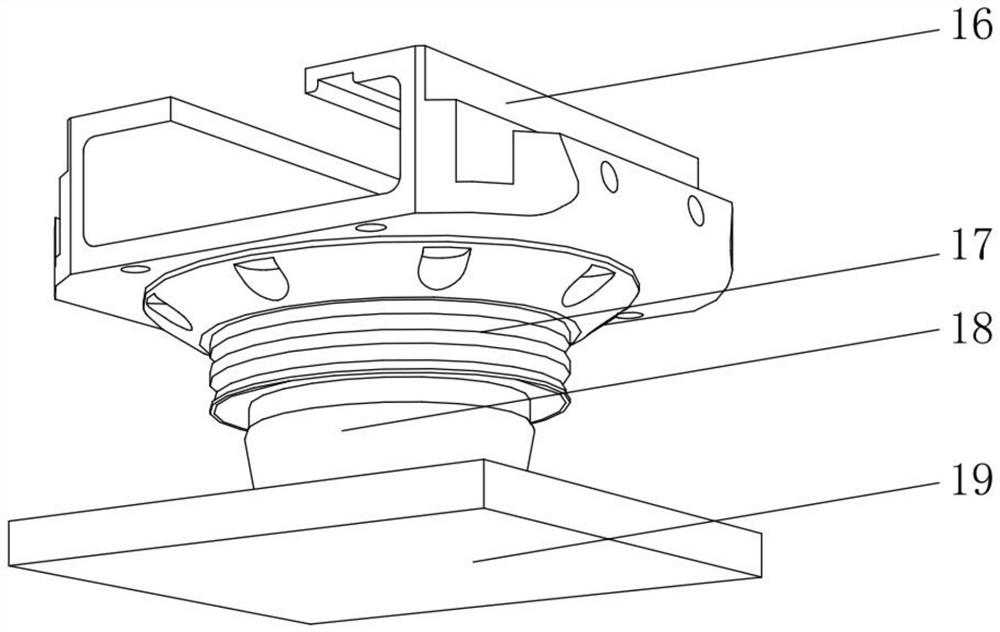

[0038] As an embodiment of the present invention, the electric single girder crane is characterized in that: the rubber air spring 9 includes a cover plate 91, an aluminum alloy flange 93, an air bag 94, a fixing plate 95 and a waist ring 92 The outer surface of the lower end of the cover plate 91 is fixedly equipped with an aluminum alloy flange 93, the outer surface of the lower end of the aluminum alloy flange 93 is fixedly installed with an airbag 94, and the outer surface of the lower end of the airbag 94 is fixedly connected with a fixed The middle position between the plate 95 and the airbags 94 is fixedly connected with a waist ring 92, wherein the core component of the rubber air spring 9 is the airbag 94, and the airbag 94 is filled with compressed air in a flexible rubber capsule, and the air can be compressed The elastic effect is realized by the cover plate 91, the stress point where the airbag 94 contacts with the cushioning air cushion 5, the aluminum alloy flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com