Automatic fluid canning crane pipe system

A crane tube, automatic technology, applied in the direction of liquid distribution, conveying or transfer device, packaging, distribution device, etc., to achieve the effect of simplifying the main structure and vertical tube structure, improving safety performance and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

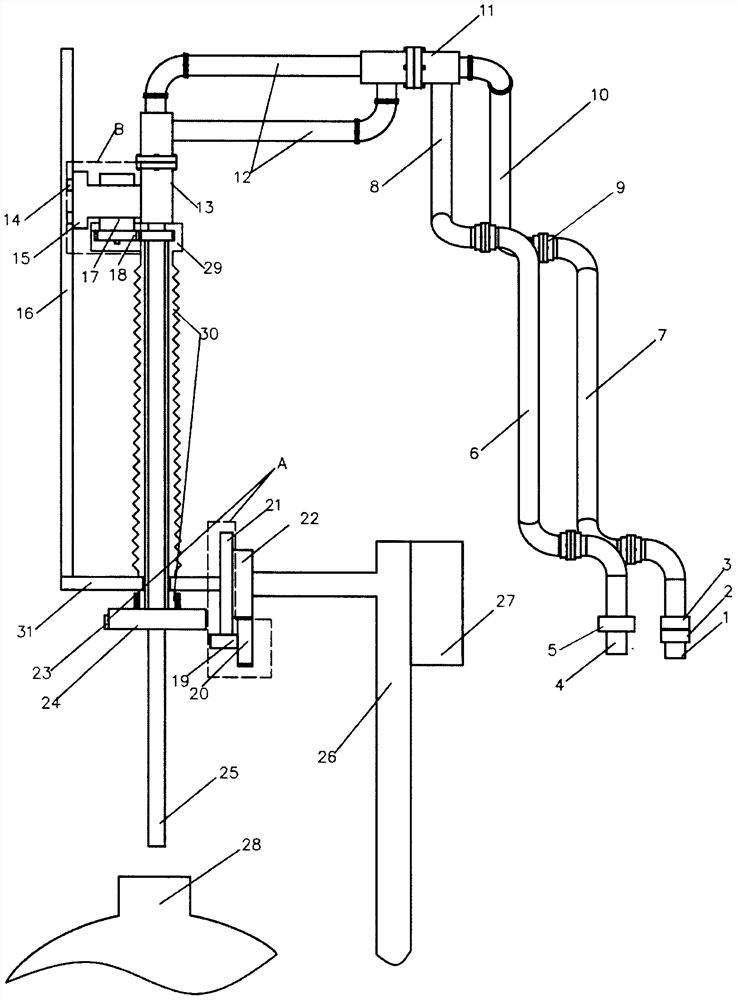

[0011] Below with the accompanying drawings figure 1 The present invention will be further described in detail with specific embodiments, but the examples thereof cannot represent all embodiments of the present invention.

[0012] A crane tube system for automatic filling of fluids, the device mainly consists of a sealing device 24, an alignment system A, a column 26, a control box 27, a vertical drive module B, a transmission system 18, a guide rail 16, a connecting plate 31, a sealing box 29, Sealed telescopic tube 30, crane tube main structure, liquid inlet valve 3, air return valve 5, liquid flow meter 2, etc., wherein alignment system A includes truss truck 21, truss 22, positioning sensor 23, wherein the crane tube main structure includes Vertical pipe 25, second rotating shaft 13, connecting pipe 12, first rotating shaft 11, first liquid inlet crane pipe 10, second liquid inlet crane pipe 7, first air return crane pipe 8, second air return crane pipe 6, Wherein the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com