Deep mucky riverbed pipe gallery river crossing dual-steel-plate pile cofferdam structure and construction method

A double-steel, silt-based technology, applied in the direction of foundation structure engineering, sheet pile walls, protection devices, etc., can solve the problems of insufficient stability and anti-seepage ability, high engineering cost, slow construction speed, etc., and achieve good environmental protection effect, Good anti-seepage effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

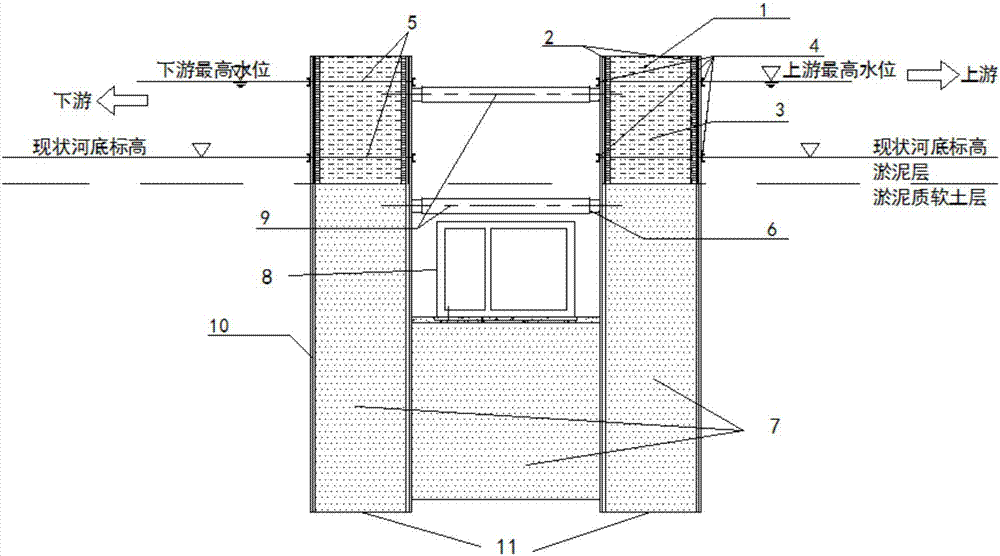

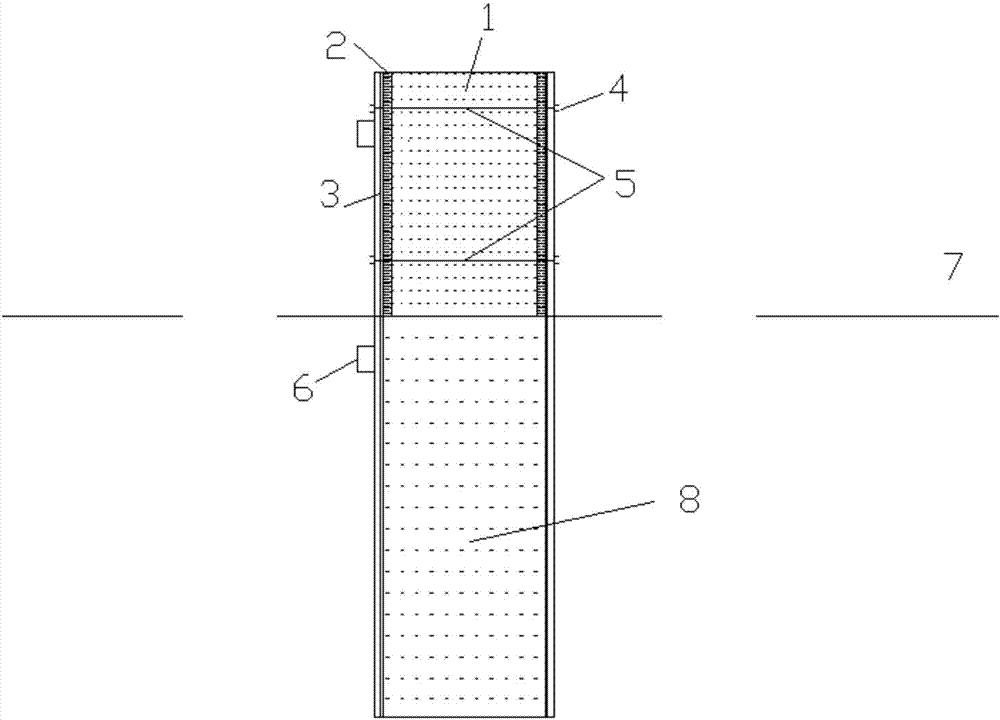

[0035] Such as figure 1 The shown double steel sheet pile cofferdam structure of the deep muddy river bed pipe gallery crossing the river is composed of two rows of double steel sheet piles 11 upstream and downstream. The depth of the cofferdam foundation pit is 10m. Larsen steel sheet piles 10 are used to make the cofferdam. The Larsen steel sheet piles 10 are 18m long and are inserted into the muddy soft soil layer to a depth of 10m. The distance between the double steel sheet piles 11 is 4m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com